- See all articles

- Business tips

- Inventory management

- Manufacturing

- Product updates

Strategies for manufacturing: How to plan for the future

James humphreys.

Senior Content Manager

The reality is that very few manufacturing businesses will be successful without a solid strategy in place. But why are strategies for manufacturing important? How have they evolved, and what manufacturing strategies are easy for companies to implement?

In this article, we’ll answer all these questions and more.

What is a manufacturing strategy?

A manufacturing strategy has been previously defined as “a long-range plan to use the resources of the manufacturing system to support the business strategy and, in turn, meet the business objectives. (Cimorelli and Chandler, 1996).

The connection that binds all the eras together is manufacturing strategy. Whether it’s a humble artisan in a side-street pottery shop or a technological wiz-kid wanting to build a smart factory, they both need a manufacturing strategy.

As already identified, strategies for manufacturing have been around for many years.

The definition of a what is a manufacturing strategy has also been around for a long time. According to Hayes and Wheelwright, 1984 , it is “a sequence of decisions that, over time, enables a business unit to achieve the desired manufacturing structure, infrastructure, and set of specific capabilities.”

Nowadays, manufacturing strategy is often intertwined with a company’s digital strategy, with the tactical management of production and technology at the heart of everything a company achieves.

As was noted by Gündüz Ulusoy back in 2003, formulating a marketing strategy requires making three strategic choices in three key areas: Competitive priorities, manufacturing objectives, and action plans.

Competitive priorities include choices on:

- Quality levels

- Reliability

- Design change

- Deliveries

- New products

Manufacturing objectives involve decision-making on:

- Unit costs

- Market share

- Profitability

- Product development time

And action plans include making decisions about:

- Production

- Energy saving

- Employee empowerment

- Staff training

Once these decisions have been made and a company’s priorities have been identified, an overarching marketing strategy can be formulated.

The history of manufacturing strategy

Whether you are a B2B (business-to-business) or a D2C (direct-to-consumer) manufacturing company , the chances are high that you have a structured manufacturing process in place. Hopefully, this relates back to your manufacturing strategy. This relationship between process and strategy has existed for hundreds of years.

The art of manufacturing has humble beginnings. Way before industrialization was conceptualized, skilled artisans worked to produce commodities. They relied on their craftmanship and secrecy to ensure that their products were in demand and couldn’t be copied.

The first example of a manufacturing strategy was probably when forward-thinking artisans realized they could sub-contract their work to others, thus producing more products and increasing their profits.

Manufacturing was transformed dramatically and definitively in the 18th century during the Industrial Revolution. The invention of machines that could do the work on a mass scale meant that industries such as glassmaking, mining, textiles , and agriculture could produce much more on a much cheaper scale. The mass production concept followed, bringing us to where we are today.

Interestingly, we are on the brink of another transformation in the industrial sector, with the birth of the Fourth Industrial Revolution, 4IR, or Industry 4.0. This is the notion that interconnectivity, smart automation, and digital process management will considerably strengthen production flow, improve quality, and reduce costs. In short, the various parts of a supply chain will interact without human interference.

This may seem almost like a sci-fi fantasy to some, but we are speeding quickly toward this new norm. Who knows what the future of manufacturing looks like? But, the reality is that strategies for manufacturing will always be a priority in the transformation of this fast-paced industry.

Why is a manufacturing strategy important?

A manufacturing strategy is the backbone of how a business operates when you break it down. To ensure your manufacturing strategy is aligned with the overall business strategy, it must be focused on:

- maximizing quality

- minimizing costs

- avoiding wastage

- improving flexibility

All the while being motivated by more lofty goals such as increasing market share and profitability.

Strategies for marketing ensure that a company avoids inefficiencies, optimizes production, and ultimately reaches the goals it is aiming for.

As Steve Lam, Senior Vice President of Patheon’s Biologics Business, states, whether you are processing medicines , clothing , beauty products , or the latest tech-gadgets , “considering your manufacturing strategy early on in development pays dividends down the line.”

So why is a manufacturing strategy important? The answer to this is another question:

Would your business survive without it?

Easy strategies for manufacturing that companies can implement

When choosing a new manufacturing strategy, it’s important to remember it’s not a case of a one-size-fits-all approach but rather finding one that is relevant for your business.

Just because a manufacturing strategy is world-class for some doesn’t mean it will be for others. Be sure to strategize with intent and ensure that your manufacturing strategy gives your company the competitive edge it needs in an increasingly competitive environment. Start by articulating your competitive advantage and then build your strategy around it.

Every decision, from the machinery you use to the automation system you choose, needs to take you one step closer to maximizing that competitive advantage.

So, what are some manufacturing strategy examples that you could implement?

1. Adopt technology

It is crucial to have an agile IT function that can respond flexibly to your business’s demands. Identifying which technologies are applicable and useful to your manufacturing processes is often the first building block in a sturdy manufacturing strategy. Is there a service or app out there that you have not yet considered?

2. Shrink your costs and production waste

This is a no-brainer. If your business has holes in its manufacturing processes that let money flow out of them, then this part of your manufacturing strategy must be robust. Production times, processes, and product quality are things that cannot be compromised on.

3. Stock inventory

Adopting the principles of lean inventory saves you a fortune and gives you a serious competitive edge. Having a better understanding of your stock levels and responding to your customer’s needs more intuitively could result in huge improvements for your business.

4. Automate your processes

The automation of day-to-day tasks can make your business leaner and more efficient. Services like Katana cloud inventory platform can be the bridge that finally connects your procurement, order processing, supply chain, customer service, production, and operations together. Automatically monitoring the movement of your inventory will minimize waste like never before. Furthermore, Katana’s software easily integrates with e-commerce platforms like Shopify and WooCommerce to reduce the risk of stock-outs and to keep your products moving to the customers who want them.

5. Look to the future

Industry 4.0 is just the latest in many changes in the industrial and manufacturing world. Do your research and ensure your manufacturing strategies are robust yet flexible enough so you can pivot if you need to.

Designing manufacturing strategies for success

Strategies for manufacturing are essential to keep a business moving. The most successful businesses over time have been the ones that have chosen strategies that support their long-term ambitions.

Innovative software, visibility, and control are often the backbones of any successful manufacturing strategy, but how you implement these must be unique to your business.

For example, adopting a manufacturing ERP software would be the perfect manufacturing strategy for businesses struggling to keep track of the movement of their inventory.

The key is to be smart about it — Be sure to identify the manufacturing strategies that fit your business model right now and will help you to stay ahead of the competition in the future. Evaluating and measuring your success every step of the way will ensure that you can provide your customers with the products they need before they even know they need them!

James Humphreys has produced content on manufacturing and inventory management practices for 5+ years. He began his journey into writing via the creative industry, writing and producing plays, some of which toured the UK and Europe.

Related Articles

23 small manufacturing business ideas you can use, digital manufacturing: a new way to work, manufacturing control: creating a plan to optimize output, what is ppe manufacturing, and why is it important, operations in manufacturing: how to stay in control, manufacturing analytics: the metrics you need, going lean with cellular manufacturing, packaging and contract manufacturing: thinking outside the box, trending articles, the fashion production process: stitching together everything you need to know, the realities of a virtual warehouse solution, electronic components inventory: how to do it right, sustainable manufacturing: the why, the how, and the who, how to know when it’s time for better clothing warehouse organization, untangle the complex web of pharma supply chain and logistics, 11 warehouse mistakes and how to fix them, erp vs. wms: which one is right for your business.

616-292-4912

Want Useful Tools & Frameworks Straight to Your Inbox Each Month?

Want Useful Tools & Frameworks Straight to Your Inbox Each Month?

- Meet Our Coaches

- Reviews and Testimonials

- Executive Coaching

- Team Coaching

- Enneagram Coaching & Workshops

- How to Start a Coaching Business

- Other Coaching

- Strategic Planning

- Life Planning

- Talent Assessment

- Manufacturing

- Financial Institutions

- Call: 616-292-4912

Developing a Strategic Plan for Manufacturing Companies

It was one of the world’s largest and most profitable manufacturing icons. Its advertising slogan was, “You press the button, we do the rest.”

Can you guess the company?

In 1884, George Eastman patented the first practical roll film holder for cameras. Before that, photographers had to insert a fragile glass plate for each exposure. Soon, Eastman was selling cameras preloaded with a roll of 100 exposures. Dubbed Eastman Kodak, the company went on to dominate sales of film and cameras. Products like the Brownie, Instamatic, and Kodachrome became synonymous with taking pictures.

Headquartered in Rochester, New York, this blue-chip manufacturer was enormously successful, employing up to 145,000 workers. But in 2012, it filed for bankruptcy. Obviously, something went wrong….

Why Is a Strategic Plan for a Manufacturing Company Important?

If Kodak was the Titanic, their iceberg was a lack of strategic planning. Based on their commanding market share, their business model remained unchanged from the 1930s to the 1970s. For decades, they made no mergers or acquisitions which would’ve brought new perspectives. R&D remained focused on film production—which caused them to fall behind Polaroid and Xerox in developing instant cameras and photocopiers.

A price war with film rival Fuji cost Kodak millions and forced layoffs. Then things got worse. The global switch from film to digital was the death blow.

Surprisingly, it didn’t have to be.

Strategic Planning Makes All the Difference

Ironically, it was a Kodak employee—Steven Sasson—who invented the first handheld digital camera in 1975. In fact, Kodak’s own tech team predicted a complete shift to digital photography by 2010. However, execs were reluctant to pivot towards digital technology, since it would require heavy investment and make their core business less profitable.

Blockbuster… IBM… Pan Am… Whenever change alters the landscape of an industry, some businesses adapt and thrive, while others continue using the old model till it’s too late. The difference is strategic planning.

Strategic planning makes sure manufacturing businesses remain relevant, have a sustainable path to growth, and are able to withstand any unexpected challenges with minimal impact on growth.

What Is Strategic Planning?

Strategic planning is the structured process of coming up with a clear pathway to make reaching shared objectives a reality. Surprisingly, many manufacturing companies attempt to operate without a central plan. This lack of strategic planning can make it impossible to react promptly to changes or reversals in the market. Other bad outcomes of neglecting to plan include lost revenue, inefficiency, and stagnant growth.

With a business strategy in place, everybody is on the same page and focused on the same mission, values, and goals—with an eye to the future.

Is Strategic Planning Only Applicable to Large Manufacturers?

You’re never too large or too small to have a strategic plan—our process is completely scalable up or down to fit your precise needs.

According to the Small Business Administration , 355,467 American manufacturing companies have no employees! 187,862 other manufacturing companies have between 1 and 20 employees. Only 60,099 have between 21 and 500 employees. It’s my belief that every single one of these size categories would benefit from strategic planning.

Building a Manufacturing Company Strategic Plan

The six phases of strategic planning for manufacturers.

I’ve had a long career in coaching and consulting highly effective and profitable companies in virtually all sectors of manufacturing. In that time, I’ve come to learn that these six vital phases are imperative when developing a strategic plan:

- Phase 1: Perspective – Where Are We Now? Begin with defining current realities. “Perspective before planning” is the key to success. I’ve found that if you have the right perspective, the strategic plan almost writes itself.

- Phase 2: Core Plan – Where Are We Headed? Equipped with proper context, a team can now develop a living core strategic plan. At this point, they have a solid rationale and a set of shared fundamental beliefs upon which to develop this plan.

- Phase 3: Action – What’s Important Now? By identifying key issues, they’re ready to move forward as one cross-functional group. The team-developed core plan is the basis for creating a unified action plan aligned with the master plan.

- Phase 4: Structure – What Form Best Facilitates the Plan? With the action plan in place, the requirements needed to implement it are addressed. Ensure that organizational structure, culture, systems, processes, and staffing all support the plan.

- Phase 5: Management – How Are We Doing? Provide ongoing, systematic feedback to help manage strategic plan implementation. Regular weekly, monthly, and quarterly reviews should be instituted.

- Phase 6: Renewal – What Needs to Change? Team leadership should meet annually to review and renew the core strategic plan. At this session, action items, opportunities, trends, objectives, and goals should all be reset for the coming year.

A Manufacturing Strategic Plan Template

Certainly, I’m biased, but I believe the most effective way to develop a strategic plan is via the help of an outside facilitator. However, not every organization has the bandwidth or budget to support that option. If you recognize the need for strategic planning and want to “self-implement”, I offer up this self-guided strategic plan template that you can use with your team.

Working with a Consultant on a Manufacturing Company Strategic Plan

I consult with manufacturers of every size and specialty—from automotive suppliers to makers of OEM equipment. They all benefit from having an outside, third-party perspective guiding and advising them. In the manufacturing business, the best way to get targeted, unbiased advice is to bring in a third-party strategic planning facilitator.

Coaches like myself can provide objective input on whether your plan is sustainable and achievable, and help you with the essential details involved in developing a detailed strategic plan that lessens the risk of losing your edge—or worse yet, becoming obsolete.

Let’s Get Started

High-profile companies like Kodak, Nokia, and Myspace stumbled badly due to not having a good strategic plan in place for adapting to disruption. The alternative to playing “catch up” is to be proactive! If you’d like to discuss strategic planning or goal-setting ideas for your organization, feel free to contact me . I’ll be happy to set up an informal chat with you.

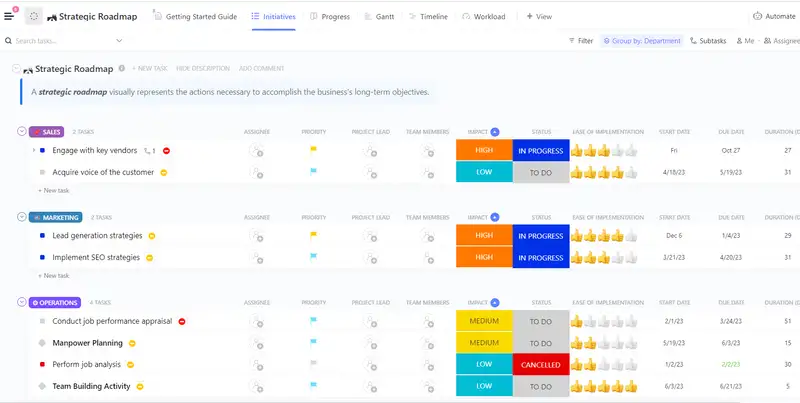

Manufacturing Company Strategic Plan Template

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

As a manufacturing company, staying ahead of the competition and achieving long-term success requires a well-defined strategic plan. That's where ClickUp's Manufacturing Company Strategic Plan Template comes in handy!

This template helps your management team streamline the planning process, empowering you to:

- Set clear goals and objectives that align with your company's vision

- Identify key initiatives and prioritize them based on their impact and feasibility

- Allocate resources effectively to drive growth and profitability

- Track progress and make data-driven adjustments along the way

Whether you're optimizing your production processes, expanding into new markets, or enhancing customer satisfaction, ClickUp's Manufacturing Company Strategic Plan Template is your ultimate tool for strategic success. Get started today and take your manufacturing company to new heights!

Benefits of Manufacturing Company Strategic Plan Template

Creating a Manufacturing Company Strategic Plan using ClickUp's template offers numerous benefits to your organization. This includes:

- Clearly defining long-term goals and objectives for the manufacturing company

- Aligning organizational resources and teams towards a common vision

- Identifying key initiatives and action plans to drive business growth and profitability

- Providing a roadmap for decision-making and resource allocation

- Enabling effective communication and collaboration among team members

- Monitoring progress and making adjustments to ensure strategic goals are met

- Increasing transparency and accountability across the organization

- Streamlining workflow and improving overall efficiency

- Facilitating continuous improvement and adaptation to market changes.

Main Elements of Manufacturing Company Strategic Plan Template

ClickUp's Manufacturing Company Strategic Plan template is designed to help manufacturing companies streamline their strategic planning and execution process. Here are the main elements of this template:

- Custom Statuses: Track the progress of your strategic initiatives with 5 custom statuses - Cancelled, Complete, In Progress, On Hold, and To Do.

- Custom Fields: Capture key information about your strategic initiatives using 8 custom fields, including Duration Days, Impact, Progress, Ease of Implementation, Team Members, Department, and Project Lead.

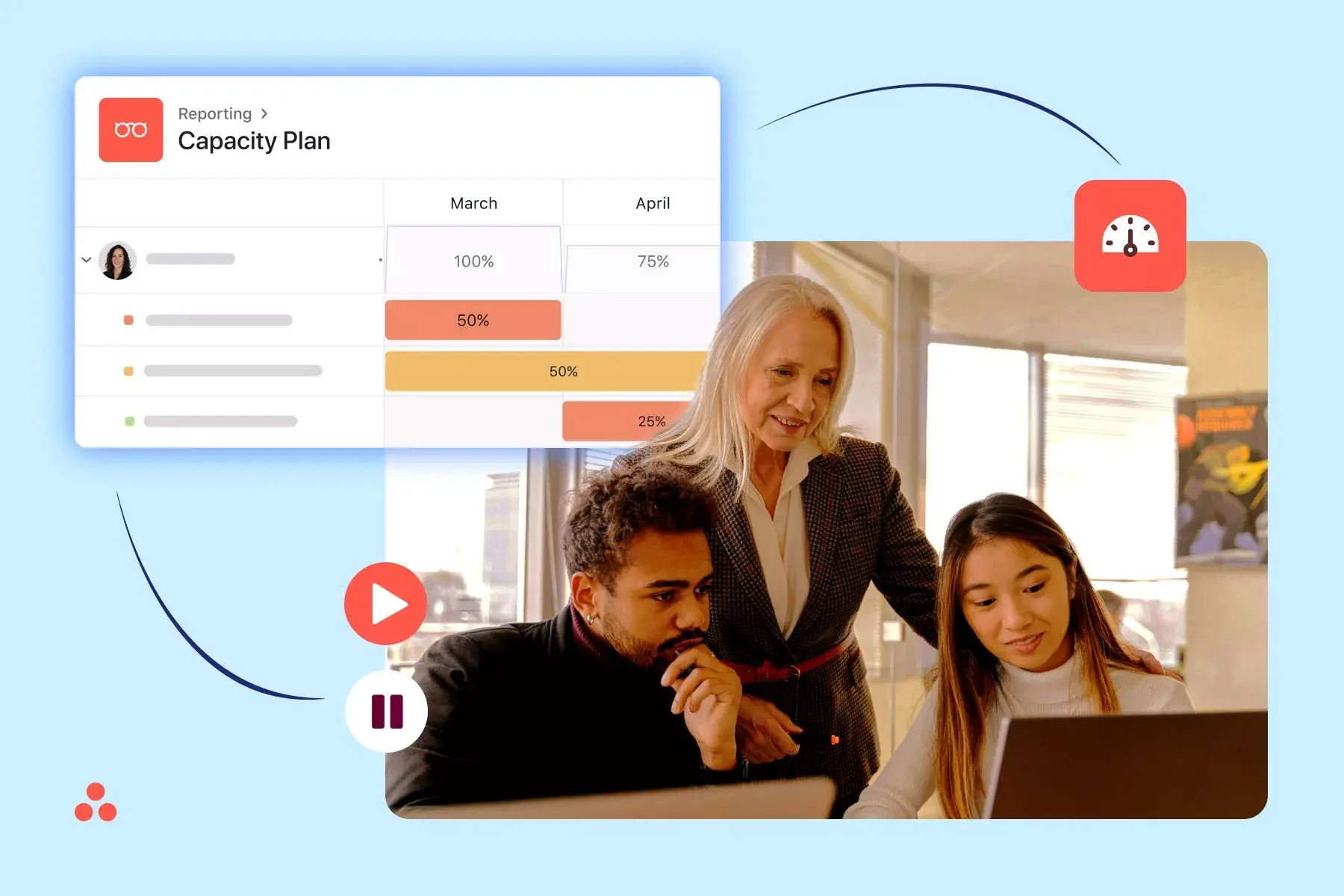

- Custom Views: Gain different perspectives on your strategic plan by utilizing 6 different views, such as the Progress view to track overall progress, the Gantt view to visualize timelines, the Workload view to manage team capacity, the Timeline view to create a visual roadmap, the Initiatives view to focus on individual initiatives, and the Getting Started Guide view to help you get started quickly.

With ClickUp's Manufacturing Company Strategic Plan template, you can effectively plan, track, and execute your strategic initiatives to drive success in your manufacturing business.

How to Use Strategic Plan for Manufacturing Company

If you're looking to create a strategic plan for your manufacturing company, follow these 6 steps using the Manufacturing Company Strategic Plan Template in ClickUp:

1. Define your vision and mission

Start by clearly defining the long-term vision and mission of your manufacturing company. What do you want to achieve in the future? What is your company's purpose and values? This will serve as the foundation for your strategic plan.

Use the Goals feature in ClickUp to create a vision and mission statement for your manufacturing company.

2. Assess your current situation

Conduct a thorough analysis of your manufacturing company's current situation. Evaluate your strengths, weaknesses, opportunities, and threats (SWOT analysis). This will help you identify areas where you excel and areas where you need improvement.

Use the Gantt chart feature in ClickUp to visualize and analyze your manufacturing company's current situation.

3. Set strategic goals and objectives

Based on your vision, mission, and SWOT analysis, set strategic goals and objectives for your manufacturing company. These goals should be specific, measurable, achievable, relevant, and time-bound (SMART goals).

Use the Board view in ClickUp to create cards for each strategic goal and set deadlines for their achievement.

4. Develop action plans

Once you have your strategic goals and objectives in place, develop action plans to achieve them. Break down each goal into specific tasks and assign responsibilities to individuals or teams within your manufacturing company. Define key milestones and timelines for each action plan.

Use the recurring tasks and Automations features in ClickUp to create action plans and automate task assignments and reminders.

5. Monitor progress and make adjustments

Regularly monitor the progress of your strategic plan and make adjustments as needed. Track key metrics and performance indicators to measure the success of your initiatives. Identify any bottlenecks or areas where you may need to pivot your strategies.

Use the Dashboards and Workload view features in ClickUp to track the progress of your strategic plan and monitor the workload of your team members.

6. Communicate and engage with your team

Ensure that your entire team is aware of the strategic plan and their role in its execution. Regularly communicate updates, share successes, and address any challenges or concerns. Encourage collaboration and engagement to foster a sense of ownership and commitment to the strategic plan.

Use the Email and Integrations features in ClickUp to communicate with your team and integrate your strategic plan with other tools and software used by your manufacturing company.

By following these steps and utilizing ClickUp's features, you can create a comprehensive and effective strategic plan for your manufacturing company.

Get Started with ClickUp’s Manufacturing Company Strategic Plan Template

Manufacturing companies can use this Strategic Plan Template to help align their long-term goals and initiatives.

First, hit "Add Template" to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you’d like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to drive your manufacturing company's growth:

- Use the Progress View to track the progress of each strategic initiative and ensure they are on track

- The Gantt View will help you visualize your project timelines and dependencies to effectively manage resources

- Utilize the Workload View to balance workloads and ensure that tasks are evenly distributed among team members

- The Timeline View will provide a comprehensive overview of all your strategic initiatives and their respective deadlines

- Use the Initiatives View to categorize and organize your key initiatives to easily monitor their progress

- Consult the Getting Started Guide View to understand how to effectively use this template and get started on your strategic plan

- Organize tasks into five different statuses: Cancelled, Complete, In Progress, On Hold, To Do, to keep track of progress

- Update statuses as you progress through tasks to keep stakeholders informed of progress

- Monitor and analyze tasks to ensure maximum productivity and successful execution of your strategic plan.

Related Templates

- Charity Organizations Strategic Plan Template

- Fisheries Strategic Plan Template

- Leadership Development Strategic Plan Template

- Fire Department Strategic Plan Template

- Security Teams Strategic Plan Template

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

- Leadership Team

- Board of Directors

- Engagement Methodology

- California’s Mfg. Network

- Additive Manufacturing

- Advanced Robotics and Automation

- Business Continuity & Resilience Planning

- Business Growth Strategy & Strategic Planning

- Cybersecurity

- Defense Services

- Flexible Hybrid Electronics

- Health & Safety Services

- Human Resources

- Innovation & Growth

- Rapid Workforce Training

- Recruitment

- Sales & Marketing

- Smart Manufacturing

- Supply Chain Consulting & Optimization

- Supplier Sourcing Services

- Workforce Development

- AMTS Program

- CMA+ Program

- California's Sourcing & Procurement Platform

- Manufacturing Month 2024

- Speakers Bureau

- Case Studies

- Partners & Affiliations

- Press Releases

- Video Gallery

May 16, 2022 | Business Growth Strategy & Strategic Planning

Strategic Planning Basics for SMMs: Definition, Purpose, and Steps

Strategic planning, budgeting, and forecasting are integral to the success of small and medium-sized manufacturers (SMMs). However, these activities can get overlooked, as leaders of small and medium-sized manufacturing organizations are often very involved in the company's day-to-day operations, leaving little time and bandwidth for high-level strategy.

In this blog, you’ll learn what strategic planning for SMMs involves, its purpose, and how effective strategic planning can keep you competitive without draining executive resources — freeing your leadership team to focus on running the business.

What is Strategic Planning?

Strategic planning is the process of creating action plans that will guide the direction of your business. This vital organizational management activity will address planning, budgeting, and forecasting concerns. It will also ensure that employees, stakeholders, and management work from the same script.

Strategic planning should guide a business towards achieving its short- and long-term organizational goals. Additionally, strategic planning processes should outline how a business will measure its overall success. Typically, SMMs will revise their strategic plan every 3-5 years.

Business leaders must never lose sight of the fact that strategic planning is a process. SMMs must continuously modify their strategic objectives, analyze market conditions, and set new goals to continue growing. They will need to determine what aspects of their plan were successful and which components were not.

What is a Strategic Plan?

The strategic plan is the final product of an SMM’s budgeting and forecasting process. This strategic plan will serve as the company’s roadmap for the future and keep all parties on the same page as they collaborate to achieve organizational goals.

Creating a plan and forecasting market conditions can provide an organization with actionable insights to guide decision-making processes.

Frequently, organizational leadership will make important discoveries during the planning process because the process gives them the opportunity to look at old problems from new perspectives, identify key vulnerabilities, and better understand the company’s strengths.

While each SMM’s planning process will be unique, all organizations should start by laying out their vision for the future. From there, organizational leadership can create a game plan for making that vision a reality. To ensure that the plan is viable, leaders must compare their goals with financial planning data, internal resources, and market analyses.

What is the Purpose of a Strategic Plan?

A strategic plan can serve many purposes but is typically ideal for established businesses interested in fueling new growth, expanding, or improving existing operations. Strategic planning is essential for many reasons , but it’s especially integral to protecting business continuity.

One of the components of a strategic plan is a master budget. This spending plan will aggregate more niche financial outlines like production and manufacturing overhead budgets. Creating a master financial plan and combining it with an overall business strategy will help your organization manage notoriously complex manufacturing budgets.

In addition to guiding spending, a strategic plan should also outline your company’s strengths, weaknesses, opportunities, and threats (SWOT). A SWOT analysis allows you and other organizational leaders to take an honest look at the state of your company and zero in on business continuity threats and weaknesses, enabling you to remedy any vulnerabilities.

How to Create a Strategic Plan for SMMs

Many small and medium-sized business leaders understand the importance of having a strategic plan but are unsure where to begin when creating one.

It’s natural to feel overwhelmed by the process, but remember: any strategic plan, even an incomplete one, is better than no strategic plan at all. The first iteration of your plan does not need to be perfect. You can always go back and improve upon it in the future.

As you prepare to create your strategic plan, you can leverage these established tactics to streamline the process:

1. Discuss the Company’s Mission and Vision and Get Cross-Departmental Buy-In

Once your business establishes itself and orders start flowing in, it can be easy to lose sight of your “why.” However, it is impossible to know what direction you want to take your company unless you know your “why.”

With that in mind, the first phase of strategic planning involves answering questions like:

- Who are we?

- Why does this company exist?

- Who do we serve?

Once you've answered these pivotal questions, you can turn your attention to your vision for the future.

Is your goal to break into a new region? Would you like to expand your services to a broader range of clients? Do you have aspirations of opening a satellite facility within the next year?

Use your strategic aspirations to define your vision and broadly outline what you want your company’s future to look like.

From there, you must work to obtain cross-departmental buy-in. As you start to lay out the framework for your strategic plan, ensure that it aligns with the capabilities of the marketing, finance, and operations departments.

As part of your efforts to optimize staff buy-in, you should also seek line-level employees' feedback. Hold a Q&A session with your personnel and outline your vision. Solicit input from attendees and take the time to listen. Making your team feel heard is an excellent way to get them on board while also optimizing the quality of your plan.

2. Determine Desired Goals and Outcomes

After you’ve laid the foundation for your plan, you should set specific goals and outcomes. These objectives are typically long-term (think 3-5 years); however, you can establish short-term objectives as well.

Once you have determined your desired goals and outcomes, begin to fill in the blanks in your plan. What needs to happen for you to achieve those goals? Are your expectations realistic and in line with the current state of your company?

3. Analyze Internal and External Environments

To determine the viability of your goals, you must know where your company currently stands within the manufacturing sector.

By conducting a comprehensive SWOT analysis, you can better understand potential barriers to your company’s growth. Once you identify them, you can work to eliminate these hurdles by leveraging current organizational strengths.

Depending on the size of your organization, you may need to perform multiple SWOT analyses. For instance, you and your leadership team could perform the initial SWOT analysis while your department heads complete separate analyses for their divisions. Different departments and team members will view problems from different perspectives based on their unique roles within the organization.

To obtain external insights, you can employ one of several different frameworks. Common examples include PESTEL analysis (political, economic, social, technological, environmental, and legal) and the Five Forces analysis . The former focuses on the society in which your company operates, whereas the latter can improve your understanding of your industry.

4. Assess Competitive Positioning and Select Strategy

Most SMMs will have the ability to choose one of three generic strategies to improve their competitive positioning.

- The first is the low-cost/low-cost niche strategy. This plan involves offering your clients a cheaper quality product than your competitors. Typically, this approach requires you to focus on a niche product lineup to minimize manufacturing costs.

- The second strategy is the differentiation niche approach. This strategy involves creating a unique product that allows you to differentiate yourself from competitors. While the product will likely be more costly than what the competition offers, it will also offer distinct benefits that other options do not.

- The final approach is the best-cost provider/low-cost differentiation strategy. This strategy is the riskiest approach because it requires you to create a unique product while also attempting to beat the prices offered by the competition.

5. Identify Key Tactics and Corresponding KPIs

At this stage, you should identify which tactics you plan to use to achieve your established goals. You should also select key performance indicators (KPIs) that provide relevant information regarding your progress.

While you can track the performance of each department within your organization using KPIs, you must be cautious not to fall victim to information overload. Focus on a handful of KPIs for each business process so that you can gain access to actionable data.

6. Establish a Budget and Identify Available Resources

The final step to creating your strategic plan is to develop a budget. A common mistake is to create a budget and then attempt to develop a strategic plan.

You should be aware of budgetary constraints while creating your strategic plan. However, you should not hammer out the fine details of your master budget until you’ve established your plan.

By creating the plan first, organizational leaders can quickly identify which initiatives are realistic and which ones may be too cost-prohibitive. When creating your plan, remember that strategy should drive the allocation of resources, not the other way around.

How CMTC Can Help SMMs with Strategic Planning and Budgeting

At CMTC, we understand that effective strategic planning requires a substantial commitment of time and effort.

A strategic plan can help guide your business to success if given the proper attention. However, small and medium-sized manufacturers may not have the resources or bandwidth necessary to engage in effective strategic planning.

Fortunately, CMTC can step in and assist. Our expert consultants can help you understand, develop, implement, and monitor every component of your strategic plan. Contact us today to learn how we can help you jump into strategic planning today.

About the Author

Gregg Profozich

Gregg Profozich is a manufacturing, operations and technology executive who believes that manufacturing is the key creator of wealth in the economy and that a strong manufacturing sector is critical to our nation’s prosperity and security now, and for future generations. Across his 20-year plus career in manufacturing, operations and technology consulting, Mr. Profozich helped manufacturing companies from the Fortune 500 to the small, independents significantly improve their productivity and competitiveness.

Leave a Comment

Subscribe to our blog.

- Buyer/Supplier Marketplace

Contact CMTC

.png?width=480&height=149&name=CIMx-logo-transparent%20(1).png)

Implementing a Successful Strategic Plan for Manufacturing

David Oeters : August 2, 2016 at 9:07 AM

Many manufacturers use aggressive strategic plans to improve production, but without a shop floor system the goals are unsustainable.

Do you have a strategic plan for manufacturing growth?

The problem for many is the disconnect between the strategic planning and shop floor operations. Adding a bullet point in the strategic plan to reduce waste, or improve production is great, but the relentless pace of production doesn’t leave much opportunity for implementation.

A committee will meet, a few ideas get tossed around, a few words said at a morning meeting, and then another order will come in and the good intentions of the strategic plan are lost in the relentless need to get product out the door.

Making Shop Floor Changes that Work

There are several challenges facing manufacturers implementing a strategic plan, beyond what most companies will face:

Many manufacturers simply have no visibility of their production processes. They don’t know what is happening on the shop floor, other than in dated reports and employee intuition. Without actionable data and insight into processes, any plan to implement a production strategy will be a “best guess.”

2. Control.

In a paper-based production environment, shop floor control comes from the morning huddle, a shift in the production line or work center, or a new best practice that is quickly forgotten. During production, the shop floor will use a process they know rather than a new process almost every time.

3. Analytics.

More than just visibility, analytics is the ability to drill down into the data in real time to discover actionable insight. This is more than just a report generated each morning; it’s using data to drive decisions in real-time to improve outcomes.

Paperless manufacturing provides a solid foundation to implement a strategic plan to improve production operations. Automating processes, setting up reports using real-time data, and managing information throughout the manufacturing value chain are all tools and benefits of the paperless system critical to successfully implementing and executing the strategic plan.

Without a system , the shop floor will struggle to meet goals or sustain improvement.

Want to see how paperless manufacturing can help you improve production and meet strategic goals? Contact CIMx today for a personalized shop floor analysis. It’s a critical step in any improvement project.

What Quantum MES Can Do for You

The internet can be a confusing place for anyone doing research – especially for manufacturers researching Manufacturing Execution Systems (MES).

How to Turn Production Data into Actionable Manufacturing Intelligence

There’s a critical difference between raw data and actionable manufacturing intelligence. Data is just information. Actionable manufacturing...

How to Successfully Replace Manufacturing Software

There are manufacturers out there struggling with outdated and inefficient legacy software systems supporting production. Shop floor managers call us...

Manufacturing USA Strategic Plan

This is the revised strategic plan for Manufacturing USA. It describes the vision, mission, and goals and objectives. The plan also outlines the methods by which these goals will be achieved, including the program’s investment strategy, the mechanisms by which investments made by federal agencies will be coordinated, and the metrics by which the program will be assessed.

The vision for Manufacturing USA is U.S. global leadership in advanced manufacturing .

To support this vision, the mission of Manufacturing USA is connecting people, ideas, and technology to solve industry-relevant advanced manufacturing challenges, thereby enhancing industrial competitiveness and economic growth and strengthening our national security.

Goals and Objectives

To realize this vision, the agencies and institutes participating in Manufacturing USA collectively work toward achieving these four goals:

Goal 1 : Increase the competitiveness of U.S. manufacturing.

Goal 2: Facilitate the transition of innovative technologies into scalable, cost-effective, and high-performing domestic manufacturing capabilities.

Goal 3: Accelerate the development of an advanced manufacturing workforce.

Goal 4: Support business models that help institutes to become stable and sustainable.

Manufacturing Strategy Template

What is a Manufacturing Strategy plan?

A Manufacturing Strategy plan helps organizations in different industries to use the resources of a manufacturing system to support the business strategy and achieve long-term organizational goals.

What's included in this Manufacturing Strategy template?

- Manufacturing Strategy vision statement

- 4x Manufacturing Strategy Values

- 4x Manufacturing Strategy Focus Areas

- 12x Manufacturing Strategy Objectives

- 18x Manufacturing Strategy Projects

- 24x Sustainability KPIs

Who is this Manufacturing Strategy plan for?

This Manufacturing Strategy can be used by all departments in an organization with correspondence with the manufacturing industry. Collaboration of all departments in an organization is necessary so that resources can be accordingly delegated to achieve organizational goals.

How is this Manufacturing Strategy template relevant to your organization?

Your organization can use this template to accommodate change and specifically assist in organizing the people and processes within your organization

1. Define clear examples of your focus areas

What types of resources do you want to focus on to achieve your Manufacturing Strategy? What areas do you want to focus on within your organization to achieve these? By discussing and dividing the types of resources you require, your team and you can appropriately come up with areas within the business that you want to focus on.

Examples of focus areas for this Manufacturing Strategy could be Machinery, Inventory, Health and Safety, and People.

2. Think about the objectives that could fall under that focus area

Objectives are subcategories under your focus areas; they help break up your focus area into smaller achievable goals. Usually, you should aim to have no more than 3-4 objectives per focus area. We want objectives to be easy to achieve and setting too many or too little can make you lose your focus on the bigger picture that you are trying to achieve.

Potential objectives for this Manufacturing Strategy plan could be: Improve overall machine performance and efficiency; Monitor inventory to ensure stock is being produced and ordered without a surplus; Reduce wastage and maximize efficiency; Identify training opportunities to upskill the workforce; and Optimize production line (just to name a few).

3. Set yourself measurable targets (KPIs) to tackle the objective

How can you achieve your set objectives? To what extent can your objectives and said goals are tracked and your performance measured? Setting up KPIs that you can follow, measure, and track can help hold your organization accountable down to an individual level.

Examples of KPIs for the Objective Improve overall machine performance and efficiency could be: Increase capacity utilization; Achieve OEE; and reduce machine set up time.

Make sure you set yourself units that you want these KPIs measured in (for instance percentage, dollar, people, etc), as well as achievable and realistic time frames and goals.

4. Implement related projects to achieve the KPIs

How can you achieve these KPIs ? What tasks can you carry out and what actions can you take? Devising projects can help your team and you know what activities are being worked on to help achieve your goals.

Examples of a couple of projects to successfully carry out this Manufacturing Strategy plan could be: Implement an employee trainee program; Conduct appraisals; Generate a quality checklist to work on; Carry out stocktake every 2-3 months; Implement inventory tracking (just to name a few).

5. Utilize Cascade tools to track and visualize performance

Besides getting quantifiable data, you can also use Cascade's dashboards to create visual tools and widgets that can help you visually track and monitor your progress. These visual indicators can then advise you of whether you should change your goals by making them more attainable or increase your targets if they are too easy to reach.

.css-s5s6ko{margin-right:42px;color:#F5F4F3;}@media (max-width: 1120px){.css-s5s6ko{margin-right:12px;}} AI that works. Coming June 5, Asana redefines work management—again. .css-1ixh9fn{display:inline-block;}@media (max-width: 480px){.css-1ixh9fn{display:block;margin-top:12px;}} .css-1uaoevr-heading-6{font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-1uaoevr-heading-6:hover{color:#F5F4F3;} .css-ora5nu-heading-6{display:-webkit-box;display:-webkit-flex;display:-ms-flexbox;display:flex;-webkit-align-items:center;-webkit-box-align:center;-ms-flex-align:center;align-items:center;-webkit-box-pack:start;-ms-flex-pack:start;-webkit-justify-content:flex-start;justify-content:flex-start;color:#0D0E10;-webkit-transition:all 0.3s;transition:all 0.3s;position:relative;font-size:16px;line-height:28px;padding:0;font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-ora5nu-heading-6:hover{border-bottom:0;color:#CD4848;}.css-ora5nu-heading-6:hover path{fill:#CD4848;}.css-ora5nu-heading-6:hover div{border-color:#CD4848;}.css-ora5nu-heading-6:hover div:before{border-left-color:#CD4848;}.css-ora5nu-heading-6:active{border-bottom:0;background-color:#EBE8E8;color:#0D0E10;}.css-ora5nu-heading-6:active path{fill:#0D0E10;}.css-ora5nu-heading-6:active div{border-color:#0D0E10;}.css-ora5nu-heading-6:active div:before{border-left-color:#0D0E10;}.css-ora5nu-heading-6:hover{color:#F5F4F3;} Get early access .css-1k6cidy{width:11px;height:11px;margin-left:8px;}.css-1k6cidy path{fill:currentColor;}

- Product overview

- All features

- App integrations

CAPABILITIES

- project icon Project management

- Project views

- Custom fields

- Status updates

- goal icon Goals and reporting

- Reporting dashboards

- workflow icon Workflows and automation

- portfolio icon Resource management

- Time tracking

- my-task icon Admin and security

- Admin console

- asana-intelligence icon Asana Intelligence

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Campaign management

- Creative production

- Marketing strategic planning

- Request tracking

- Resource planning

- Project intake

- View all uses arrow-right icon

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Work management resources Discover best practices, watch webinars, get insights

- What's new Learn about the latest and greatest from Asana

- Customer stories See how the world's best organizations drive work innovation with Asana

- Help Center Get lots of tips, tricks, and advice to get the most from Asana

- Asana Academy Sign up for interactive courses and webinars to learn Asana

- Developers Learn more about building apps on the Asana platform

- Community programs Connect with and learn from Asana customers around the world

- Events Find out about upcoming events near you

- Partners Learn more about our partner programs

- Support Need help? Contact the Asana support team

- Asana for nonprofits Get more information on our nonprofit discount program, and apply.

Featured Reads

- Business strategy |

- What is strategic planning? A 5-step gu ...

What is strategic planning? A 5-step guide

Strategic planning is a process through which business leaders map out their vision for their organization’s growth and how they’re going to get there. In this article, we'll guide you through the strategic planning process, including why it's important, the benefits and best practices, and five steps to get you from beginning to end.

Strategic planning is a process through which business leaders map out their vision for their organization’s growth and how they’re going to get there. The strategic planning process informs your organization’s decisions, growth, and goals.

Strategic planning helps you clearly define your company’s long-term objectives—and maps how your short-term goals and work will help you achieve them. This, in turn, gives you a clear sense of where your organization is going and allows you to ensure your teams are working on projects that make the most impact. Think of it this way—if your goals and objectives are your destination on a map, your strategic plan is your navigation system.

In this article, we walk you through the 5-step strategic planning process and show you how to get started developing your own strategic plan.

How to build an organizational strategy

Get our free ebook and learn how to bridge the gap between mission, strategic goals, and work at your organization.

What is strategic planning?

Strategic planning is a business process that helps you define and share the direction your company will take in the next three to five years. During the strategic planning process, stakeholders review and define the organization’s mission and goals, conduct competitive assessments, and identify company goals and objectives. The product of the planning cycle is a strategic plan, which is shared throughout the company.

What is a strategic plan?

![manufacturing company strategic plan [inline illustration] Strategic plan elements (infographic)](https://assets.asana.biz/transform/7d1f14e4-b008-4ea6-9579-5af6236ce367/inline-business-strategy-strategic-planning-1-2x?io=transform:fill,width:2560&format=webp)

A strategic plan is the end result of the strategic planning process. At its most basic, it’s a tool used to define your organization’s goals and what actions you’ll take to achieve them.

Typically, your strategic plan should include:

Your company’s mission statement

Your organizational goals, including your long-term goals and short-term, yearly objectives

Any plan of action, tactics, or approaches you plan to take to meet those goals

What are the benefits of strategic planning?

Strategic planning can help with goal setting and decision-making by allowing you to map out how your company will move toward your organization’s vision and mission statements in the next three to five years. Let’s circle back to our map metaphor. If you think of your company trajectory as a line on a map, a strategic plan can help you better quantify how you’ll get from point A (where you are now) to point B (where you want to be in a few years).

When you create and share a clear strategic plan with your team, you can:

Build a strong organizational culture by clearly defining and aligning on your organization’s mission, vision, and goals.

Align everyone around a shared purpose and ensure all departments and teams are working toward a common objective.

Proactively set objectives to help you get where you want to go and achieve desired outcomes.

Promote a long-term vision for your company rather than focusing primarily on short-term gains.

Ensure resources are allocated around the most high-impact priorities.

Define long-term goals and set shorter-term goals to support them.

Assess your current situation and identify any opportunities—or threats—allowing your organization to mitigate potential risks.

Create a proactive business culture that enables your organization to respond more swiftly to emerging market changes and opportunities.

What are the 5 steps in strategic planning?

The strategic planning process involves a structured methodology that guides the organization from vision to implementation. The strategic planning process starts with assembling a small, dedicated team of key strategic planners—typically five to 10 members—who will form the strategic planning, or management, committee. This team is responsible for gathering crucial information, guiding the development of the plan, and overseeing strategy execution.

Once you’ve established your management committee, you can get to work on the planning process.

Step 1: Assess your current business strategy and business environment

Before you can define where you’re going, you first need to define where you are. Understanding the external environment, including market trends and competitive landscape, is crucial in the initial assessment phase of strategic planning.

To do this, your management committee should collect a variety of information from additional stakeholders, like employees and customers. In particular, plan to gather:

Relevant industry and market data to inform any market opportunities, as well as any potential upcoming threats in the near future.

Customer insights to understand what your customers want from your company—like product improvements or additional services.

Employee feedback that needs to be addressed—whether about the product, business practices, or the day-to-day company culture.

Consider different types of strategic planning tools and analytical techniques to gather this information, such as:

A balanced scorecard to help you evaluate four major elements of a business: learning and growth, business processes, customer satisfaction, and financial performance.

A SWOT analysis to help you assess both current and future potential for the business (you’ll return to this analysis periodically during the strategic planning process).

To fill out each letter in the SWOT acronym, your management committee will answer a series of questions:

What does your organization currently do well?

What separates you from your competitors?

What are your most valuable internal resources?

What tangible assets do you have?

What is your biggest strength?

Weaknesses:

What does your organization do poorly?

What do you currently lack (whether that’s a product, resource, or process)?

What do your competitors do better than you?

What, if any, limitations are holding your organization back?

What processes or products need improvement?

Opportunities:

What opportunities does your organization have?

How can you leverage your unique company strengths?

Are there any trends that you can take advantage of?

How can you capitalize on marketing or press opportunities?

Is there an emerging need for your product or service?

What emerging competitors should you keep an eye on?

Are there any weaknesses that expose your organization to risk?

Have you or could you experience negative press that could reduce market share?

Is there a chance of changing customer attitudes towards your company?

Step 2: Identify your company’s goals and objectives

To begin strategy development, take into account your current position, which is where you are now. Then, draw inspiration from your vision, mission, and current position to identify and define your goals—these are your final destination.

To develop your strategy, you’re essentially pulling out your compass and asking, “Where are we going next?” “What’s the ideal future state of this company?” This can help you figure out which path you need to take to get there.

During this phase of the planning process, take inspiration from important company documents, such as:

Your mission statement, to understand how you can continue moving towards your organization’s core purpose.

Your vision statement, to clarify how your strategic plan fits into your long-term vision.

Your company values, to guide you towards what matters most towards your company.

Your competitive advantages, to understand what unique benefit you offer to the market.

Your long-term goals, to track where you want to be in five or 10 years.

Your financial forecast and projection, to understand where you expect your financials to be in the next three years, what your expected cash flow is, and what new opportunities you will likely be able to invest in.

Step 3: Develop your strategic plan and determine performance metrics

Now that you understand where you are and where you want to go, it’s time to put pen to paper. Take your current business position and strategy into account, as well as your organization’s goals and objectives, and build out a strategic plan for the next three to five years. Keep in mind that even though you’re creating a long-term plan, parts of your plan should be created or revisited as the quarters and years go on.

As you build your strategic plan, you should define:

Company priorities for the next three to five years, based on your SWOT analysis and strategy.

Yearly objectives for the first year. You don’t need to define your objectives for every year of the strategic plan. As the years go on, create new yearly objectives that connect back to your overall strategic goals .

Related key results and KPIs. Some of these should be set by the management committee, and some should be set by specific teams that are closer to the work. Make sure your key results and KPIs are measurable and actionable. These KPIs will help you track progress and ensure you’re moving in the right direction.

Budget for the next year or few years. This should be based on your financial forecast as well as your direction. Do you need to spend aggressively to develop your product? Build your team? Make a dent with marketing? Clarify your most important initiatives and how you’ll budget for those.

A high-level project roadmap . A project roadmap is a tool in project management that helps you visualize the timeline of a complex initiative, but you can also create a very high-level project roadmap for your strategic plan. Outline what you expect to be working on in certain quarters or years to make the plan more actionable and understandable.

Step 4: Implement and share your plan

Now it’s time to put your plan into action. Strategy implementation involves clear communication across your entire organization to make sure everyone knows their responsibilities and how to measure the plan’s success.

Make sure your team (especially senior leadership) has access to the strategic plan, so they can understand how their work contributes to company priorities and the overall strategy map. We recommend sharing your plan in the same tool you use to manage and track work, so you can more easily connect high-level objectives to daily work. If you don’t already, consider using a work management platform .

A few tips to make sure your plan will be executed without a hitch:

Communicate clearly to your entire organization throughout the implementation process, to ensure all team members understand the strategic plan and how to implement it effectively.

Define what “success” looks like by mapping your strategic plan to key performance indicators.

Ensure that the actions outlined in the strategic plan are integrated into the daily operations of the organization, so that every team member's daily activities are aligned with the broader strategic objectives.

Utilize tools and software—like a work management platform—that can aid in implementing and tracking the progress of your plan.

Regularly monitor and share the progress of the strategic plan with the entire organization, to keep everyone informed and reinforce the importance of the plan.

Establish regular check-ins to monitor the progress of your strategic plan and make adjustments as needed.

Step 5: Revise and restructure as needed

Once you’ve created and implemented your new strategic framework, the final step of the planning process is to monitor and manage your plan.

Remember, your strategic plan isn’t set in stone. You’ll need to revisit and update the plan if your company changes directions or makes new investments. As new market opportunities and threats come up, you’ll likely want to tweak your strategic plan. Make sure to review your plan regularly—meaning quarterly and annually—to ensure it’s still aligned with your organization’s vision and goals.

Keep in mind that your plan won’t last forever, even if you do update it frequently. A successful strategic plan evolves with your company’s long-term goals. When you’ve achieved most of your strategic goals, or if your strategy has evolved significantly since you first made your plan, it might be time to create a new one.

Build a smarter strategic plan with a work management platform

To turn your company strategy into a plan—and ultimately, impact—make sure you’re proactively connecting company objectives to daily work. When you can clarify this connection, you’re giving your team members the context they need to get their best work done.

A work management platform plays a pivotal role in this process. It acts as a central hub for your strategic plan, ensuring that every task and project is directly tied to your broader company goals. This alignment is crucial for visibility and coordination, allowing team members to see how their individual efforts contribute to the company’s success.

By leveraging such a platform, you not only streamline workflow and enhance team productivity but also align every action with your strategic objectives—allowing teams to drive greater impact and helping your company move toward goals more effectively.

Strategic planning FAQs

Still have questions about strategic planning? We have answers.

Why do I need a strategic plan?

A strategic plan is one of many tools you can use to plan and hit your goals. It helps map out strategic objectives and growth metrics that will help your company be successful.

When should I create a strategic plan?

You should aim to create a strategic plan every three to five years, depending on your organization’s growth speed.

Since the point of a strategic plan is to map out your long-term goals and how you’ll get there, you should create a strategic plan when you’ve met most or all of them. You should also create a strategic plan any time you’re going to make a large pivot in your organization’s mission or enter new markets.

What is a strategic planning template?

A strategic planning template is a tool organizations can use to map out their strategic plan and track progress. Typically, a strategic planning template houses all the components needed to build out a strategic plan, including your company’s vision and mission statements, information from any competitive analyses or SWOT assessments, and relevant KPIs.

What’s the difference between a strategic plan vs. business plan?

A business plan can help you document your strategy as you’re getting started so every team member is on the same page about your core business priorities and goals. This tool can help you document and share your strategy with key investors or stakeholders as you get your business up and running.

You should create a business plan when you’re:

Just starting your business

Significantly restructuring your business

If your business is already established, you should create a strategic plan instead of a business plan. Even if you’re working at a relatively young company, your strategic plan can build on your business plan to help you move in the right direction. During the strategic planning process, you’ll draw from a lot of the fundamental business elements you built early on to establish your strategy for the next three to five years.

What’s the difference between a strategic plan vs. mission and vision statements?

Your strategic plan, mission statement, and vision statements are all closely connected. In fact, during the strategic planning process, you will take inspiration from your mission and vision statements in order to build out your strategic plan.

Simply put:

A mission statement summarizes your company’s purpose.

A vision statement broadly explains how you’ll reach your company’s purpose.

A strategic plan pulls in inspiration from your mission and vision statements and outlines what actions you’re going to take to move in the right direction.

For example, if your company produces pet safety equipment, here’s how your mission statement, vision statement, and strategic plan might shake out:

Mission statement: “To ensure the safety of the world’s animals.”

Vision statement: “To create pet safety and tracking products that are effortless to use.”

Your strategic plan would outline the steps you’re going to take in the next few years to bring your company closer to your mission and vision. For example, you develop a new pet tracking smart collar or improve the microchipping experience for pet owners.

What’s the difference between a strategic plan vs. company objectives?

Company objectives are broad goals. You should set these on a yearly or quarterly basis (if your organization moves quickly). These objectives give your team a clear sense of what you intend to accomplish for a set period of time.

Your strategic plan is more forward-thinking than your company goals, and it should cover more than one year of work. Think of it this way: your company objectives will move the needle towards your overall strategy—but your strategic plan should be bigger than company objectives because it spans multiple years.

What’s the difference between a strategic plan vs. a business case?

A business case is a document to help you pitch a significant investment or initiative for your company. When you create a business case, you’re outlining why this investment is a good idea, and how this large-scale project will positively impact the business.

You might end up building business cases for things on your strategic plan’s roadmap—but your strategic plan should be bigger than that. This tool should encompass multiple years of your roadmap, across your entire company—not just one initiative.

What’s the difference between a strategic plan vs. a project plan?

A strategic plan is a company-wide, multi-year plan of what you want to accomplish in the next three to five years and how you plan to accomplish that. A project plan, on the other hand, outlines how you’re going to accomplish a specific project. This project could be one of many initiatives that contribute to a specific company objective which, in turn, is one of many objectives that contribute to your strategic plan.

What’s the difference between strategic management vs. strategic planning?

A strategic plan is a tool to define where your organization wants to go and what actions you need to take to achieve those goals. Strategic planning is the process of creating a plan in order to hit your strategic objectives.

Strategic management includes the strategic planning process, but also goes beyond it. In addition to planning how you will achieve your big-picture goals, strategic management also helps you organize your resources and figure out the best action plans for success.

Related resources

Grant management: A nonprofit’s guide

How Asana uses work management to optimize resource planning

How Asana uses work management for organizational planning

Solve your tech overload with an intelligent transformation

Suggestions

A Complete Guide to Manufacturing Strategy

The manufacturing strategy can be defined as a long range plan to use the resources of the manufacturing system to support the business strategy and in turn meet the business objectives. This in turn requires a number of decisions to be made to allow the formulation of the manufacturing strategy.

What is Manufacturing Strategy?

“Manufacturing strategy deals with the long-term plan for production and technology to support your company’s business objectives. It considers the types of companies you want to compete against, the products you’ll make, and the operations and technologies that will be required to make them. In short, it’s about working with your business strategy to determine how you’ll produce and how you’ll compete.”

Manufacturing Strategy Plan

The manufacturing strategy plan is concerned with the relationship of the manufacturing system and manufacturing recruitment to the business strategy. The manufacturing strategy plan describes the processes and techniques to support the business strategy. What are the business processes which must be developed? The means for manufacturing individual parts and components? The final assembly process? How will the production schedules be determined? What systems must be established to develop this plan? What skills are needed to develop and implement this plan?

Who Needs to Know about Manufacturing Strategy:

The concepts of strategy, as well as the executive board level decisions, must be described in easy-to-understand terms for the general managers of the manufacture functions. What are the objectives? What is required from manufacturing? What must manufacturing deliver? What is the relationship of manufacturing to the other functions? What are the metrics that will be used?

The manufacturing strategy must be considered in the context of the business strategy. How does the manufacturing strategy fit into the markets being targeted for this business? What are the key market segments that will be developed for this business?

The manufacturing community must focus from an outside-in perspective rather than an inside-out perspective. The interests of the customers must be established as the highest priority. Why do they buy? Why do they buy from the company? Why do they buy from the company or its competitors? It is very important to identify all of the external and internal factors affecting their behaviour.

Procedures for manufacturing strategy:

- Integrate – manufacturing strategy must be integrated into the overall business strategy.

- Align – manufacturing strategy must be aligned with the overall business strategy.

- Monitor – manufacturing strategy must be monitored and adjusted as necessary.

- Compare – manufacturing strategy must be compared to external factors that affect the company.

- Develop – manufacturing strategy must be developed based on the business strategy.

- Direct – manufacturing strategy must be directed to support the business strategy.

The primary goal of the manufacturing strategy is to support the business strategy.

Two Types of Strategy:

- Industry strategy – the industry (supply/demand) is so strong and competitive that a business strategy can not offer a significant way to differentiate the product or to reduce/add costs. Competition is always making attempts at improving quality, function, demand, delivery, cost, service and other sources of differentiation. A business must try to compete on more than one of these. The most common extra strategies are cost minimization and quality maximization.

- Business strategy – the manufacturer’s business can be differentiated in such a way as to allow them to offer a product that is relatively unique. Each buyer may not be willing to pay extra for it, but multiple buyers will be. This allows the company to obtain above average revenue and profit growth. To the best of your understanding, what type of strategy exists for your company? Does your company need to focus on market share growth or the acquisition of new customers?

- What are the Market Trends for our Industry?

- What are the Market Trends for our Company?

- What are the trends for our products? What are the trends for our customers?

Audit the Current Manufacturing Strategy; Develop a Decision Framework

“What is the current financing approach for the company? In most cases, once the internal growth plane is exploited, it is about cost reduction. The basic assumption is that once a company enters the matured stage of the product lifecycle, it must compete on minimizing costs and providing services. The result is a very high share of manufacturing. These companies become more and more dependent on external suppliers. The finance strategy is focused on these suppliers and any external customer.

The development of a decision framework helps to address what is the financial structure of real manufacturing companies in the marketplace today. Most of the changes are the result of international competition. In addition, we need to know what is it about the competition itself and how the financial structure of the company in relationship to the competition? Is there anything wrong with the current strategy?”

Risk Assessment; Risk Analysis; Management and Mitigation of the Problems

“Thorough risk analyses must follow the manufacturing strategy. What are the competitor risks? What are the product risks? The risks are important, but it’s equally important to show what protection the company has to avoid the risks. It’s not enough to simply describe the risks and to develop the plans to avoid the risks. It is also important to understand how the risks can be managed and managed.”

Main Elements in the Risk Assessment

- Product Risk – There may be the possibility that the customer may not buy the product. What are the rate of product failure? What is the potential risk of the product customer needs turn out to be different from the anticipated customer? Are there any regulatory or governmental issues that will prevent the sales or the product?

- Process Risk – Can’t make the process work acceptably. It may be difficult to define the process specification that is acceptable for a particular design. We must determine whether the processes proposed will produce the high enough quality for the customer to buy the product. Is there a potential for contamination? Will the necessary technology be available for the process development? Will the quality of the product be acceptable? Can we accept the risks associated with the qualification of new process development? What is the process cycle time? What is the cost of a reject for each process?

- Machine/Equipment Risk – Can’t get a machine. What is the availability of the candidate equipment and parts? Can’t find the needed equipment at a reasonable price. Can’t get the parts, thus creating a machine repair problem. Availability of the Service/Support. What is the current equipment condition?

- Process Layout Risk – What are the space requirements for the parts that can be added? Can’t find the needed space for new parts. Paying for more space than is required. What are the quality control limitations?

- Material Handling Risk – What are the requirement for material handling processes? Can’t avoid the traffic congestion through the warehouse? Do you have to add material handling equipment? Can’t find the needed material handling techniques?

- Utility Risk – What are the utility requirements for the site? Will we have to move the power or water supply? Is there a potential contamination of air or ground water, due to the process? Will the waste water be a problem?

- Personnel/Training Risk – Can’t find sufficient number of qualified personnel. Can’t get the required training. How do we recruit the necessary number of employees? Will we work against the employee unions to get favorable wages and benefits? What is the demographic breakdown of the affected workers?

- Computer Risk – What information system is required? Will the proper information system already be in place? Must we develop the necessary information system? Can’t get the best value information system for the organization. Is there a conflict between the computer systems at the suppliers or the customers?

- Measurement Risk – What is the measurement process? Can’t achieve the level of accuracy needed. Can’t control the measurement variability. Measurement variability is too high. Measurement will be too costly.

- Aesthetics Risk – Can’t get the perceived quality. Different customer segments place different emphasis on aesthetics.