Journals, books & databases

- Our journals

Green Chemistry

Inside this journal, see cutting-edge research for a greener sustainable future

You can find details about how to access information remotely in this step-by-step guide . The guide will also help if for any reason you have difficulty accessing the content you want.

What would you like to know about this journal?

Green Chemistry is a Transformative Journal, and Plan S compliant

Impact factor: 9.8*

Time to first decision (all decisions): 13.0 days**

Time to first decision (peer reviewed only): 35.0 days***

Chair: Javier Pérez-Ramírez

Indexed in Web of Science

Open access publishing options available

Read this journal

Submit an article

Sign up for regular email alerts

View all journal metrics

Publish open access

Meet the team

Journal scope

Green Chemistry provides a unique forum for the publication of innovative research on the development of alternative green and sustainable technologies.

The scope of Green Chemistry is based on, but not limited to, the definition proposed by Anastas and Warner ( Green Chemistry: Theory and Practic e, P T Anastas and J C Warner, Oxford University Press, Oxford, 1998). Green chemistry is the utilisation of a set of principles that reduces or eliminates the use or generation of hazardous substances in the design, manufacture and application of chemical products.

Green Chemistry is at the frontiers of this continuously-evolving interdisciplinary science and publishes research that attempts to reduce the environmental impact of the chemical enterprise by developing a technology base that is inherently non-toxic to living things and the environment. Submissions on all aspects of research relating to the endeavour are welcome.

The journal publishes original and significant cutting-edge research that is likely to be of wide general appeal. To be published, work must present a significant advance in green chemistry. Papers must contain a comparison with existing methods and demonstrate advantages over those methods before publication can be considered. For more information please see this Editorial .

Coverage includes the following, but is not limited to:

- Design (e.g. biomimicry, design for degradation/recycling/reduced toxicity…)

- Reagents & Feedstocks (e.g. renewables, CO 2 , solvents, auxiliary agents, waste utilization…)

- Synthesis (e.g. organic, inorganic, synthetic biology…)

- Catalysis (e.g. homogeneous, heterogeneous, enzyme, whole cell…)

- Process (e.g. process design, intensification, separations, recycling, efficiency…)

- Energy (e.g. renewable energy, fuels, photovoltaics, fuel cells, energy storage, energy carriers…)

- Applications (e.g. electronics, dyes, consumer products, coatings, pharmaceuticals, preservatives, building materials, chemicals for industry/agriculture/mining…)

- Impact (e.g. safety, metrics, LCA, sustainability, (eco)toxicology…)

Green chemistry is, by definition, a continuously-evolving frontier. Therefore, the inclusion of a particular material or technology does not, of itself, guarantee that a paper is suitable for the journal. To be suitable, the novel advance should have the potential for reduced environmental impact relative to the state of the art. Green Chemistry does not normally deal with research associated with 'end-of-pipe' or remediation issues.

Occasionally the Editors may decide to publish something outside the defined scope of the journal if the work would be of interest to the green chemistry community and/or have the potential to shape the field.

Sign up to receive regular news from this journal

Green Chemistry: What is the green advance?

One of the main requirements for papers to be published in Green Chemistry is to clearly demonstrate a green advance over the incumbent technology or approach. Past Editorial Board Chair, Philip Jessop (Queen's University, Canada), has put together two short videos to explain what this concept really means and how to incorporate it into your own work.

This video explains that the green advance requirement at Green Chemistry is a benchmarking requirement. Benchmarking experiments run throughout science and that they need not be labour-intensive. Your paper must contain a comparison of your new method to the current best method available and describe the advantages and disadvantages.

There are a range of benchmarking metrics that can be used to satisfy the green advance requirement at Green Chemistry. Ecotoxicity, Bioaccumulation, Carcinogenicity and Smog formation are some of the metrics that can be used to demonstrate the green advance. For more information, please watch the video below:

See who's on the team

Meet our Chair and all other board members for the Green Chemistry journal.

Javier Pérez-Ramírez , ETH Zurich, Switzerland

Associate editors

Aiwen Lei , College of Chemistry and Molecular Sciences, The Institute for Advanced Studies, Wuhan University, P. R. China

Elsje Alessandra Quadrelli , CNRS and ESCPE Lyon, France

Magdalena Titirici , Imperial College London, UK

Keiichi Tomishige , Tohoku University, Japan

Luigi Vaccaro , University of Perugia, Italy

Editorial board members

André Bardow , ETH Zürich, Switzerland

Francois Jérôme , University of Poitiers, France

Serenella Sala , European Commission - Joint Research Centre, Italy

Laurel Schafer , The University of British Columbia, Canada

Helen Sneddon , University of York, UK

Charlotte Williams , University of Oxford, UK

Tao Zhang , Dalian Institute of Chemical Physics, Chinese Academy of Sciences, China

Paul Anastas , Yale University, USA

Isabel Arends , TU Delft, Netherlands

Gregg Beckham , NREL, USA

Asim Bhaumik , Indian Association for the Cultivation of Science, India

Fabrizio Cavani , University of Bologna, Italy

James Clark , University of York, UK

Avelino Corma , UPV-CSIC, Spain

Robert H Crabtree , Yale University, USA

Paul Dauenhauer , University of Minnesota, USA

James Dumesic , University of Wisconsin-Madison, USA

Martin Eastgate , Bristol Myers Squibb, USA

Karen Goldberg , University of Washington, USA

Buxing Han , Institute of Chemistry, Chinese Academy of Sciences, China

Steve Howdle , Nottingham University, UK

Andrew J. Hunt, Khon Kaen University, Thailand

Graham Hutchings , Cardiff University, UK

Philip Jessop , Queen's University, Canada

C Oliver Kappe , University of Graz, Austria

Shu Kobayashi , University of Tokyo,Japan

Burkhard Koenig , University of Regensburg, Germany

Michael Kopach , Lilly, USA

Walter Leitner , RWTH Aachen University, Germany

Chao-Jun Li , McGill University, Canada

Bruce Lipshutz , University of California, USA

Doug MacFarlane , Monash University, Australia

Tomoo Mizugaki , Osaka University, Japan

Regina Palkovits , RWTH Aachen, Germany

Alvise Perosa , Universita Ca Foscari, Italy

Martina Peters , Bayer AG, Germany

Martyn Poliakoff , University of Nottingham, UK

Colin Raston , Flinders University, Australia

Roberto Rinaldi , Imperial College London, UK

Robin D Rogers , McGill University, Canada

Susannah Scott , University of California, USA

Roger Sheldon , Delft University of Technology, The Netherlands

Christian Stevens , Ghent University, Belgium

Natalia Tarasova , Mendeleev University of Chemical Technology, Russia

Rajender Varma , US Environmental Protection Agency, USA

Tom Welton , Imperial College, UK

Kevin C. W. Wu , National Taiwan University, Taiwan

G D Yadav , Institute of Chemical Technology Mumbai, India

Hisao Yoshida , Kyoto University, Japan

Suojiang Zhang , Institute of Process Engineering, Chinese Academy of Sciences, China

Julie Beth Zimmerman , Yale School of Engineering and Applied Sciences, USA

Vânia Zuin Zeidler , Institute of Sustainable Chemistry Faculty/School of Sustainability, Leuphana University, Germany

Michael A. Rowan , Executive Editor

Vikki Pritchard , Deputy Editor

Bee Hockin , Development Editor

Andrea Carolina Ojeda-Porras , Development Editor

Gisela Scott , Editorial Production Manager

Robin Brabham , Senior Publishing Editor

Jeanne Andres , Publisher

Catherine Au , Publishing Editor

Isobel Darlington , Publishing Editor

Konoya Das , Publishing Editor

Alexandre Dumon , Publishing Editor

Amy Lucas , Publishing Editor

Kieran Nicholson , Publishing Editor

Rini Prakash , Publishing Editor

Charlotte Pugsley , Publishing Editor

Hugh Ryan , Publishing Editor

Daphne Houston , Editorial Assistant

Robert Griffiths , Publishing Assistant

Article types

Green Chemistry publishes:

Communications

Full papers, critical reviews, tutorial reviews, perspectives.

These must report preliminary research findings that are highly original, of immediate interest and are likely to have a high impact on the green chemistry community. Communications are given priority treatment, are fast-tracked through the publication process and appear prominently at the front of the journal in a dedicated Communications section.

The key aim of Communications is to present innovative chemical concepts with important implications. Authors should provide at the time of submission a short paragraph explaining why their work justifies urgent publication as a Communication. Ideally, a Full paper in Green Chemistry should follow each Communication.

These must represent a significant development in the particular field and are judged according to originality, quality of scientific content and contribution to existing knowledge. Although there is no page limit for Full papers, appropriateness of length to content of new science will taken into consideration.

These must be a critical evaluation of the existing state of knowledge on a particular facet of green chemistry; however, original work may be included. Simple literature surveys will not be accepted for publication. Potential review writers should contact the editor before embarking on their work.

Tutorial reviews are a type of review that provide an essential introduction to a particular area of green chemistry. The article should have particular appeal to younger researchers and established researchers seeking new fields to explore. Tutorial reviews should not contain unpublished data.

These may be articles providing a personal view of part of one discipline associated with Green Chemistry or a philosophical look at a topic of relevance.

Comments and Replies are a medium for the discussion and exchange of scientific opinions between authors and readers concerning material published in Green Chemistry .

For publication, a Comment should present an alternative analysis of and/or new insight into the previously published material. Any Reply should further the discussion presented in the original article and the Comment. Comments and Replies that contain any form of personal attack are not suitable for publication.

Comments that are acceptable for publication will be forwarded to the authors of the work being discussed, and these authors will be given the opportunity to submit a Reply. The Comment and Reply will both be subject to rigorous peer review in consultation with the journal’s Editorial Board where appropriate. The Comment and Reply will be published together.

Journal specific guidelines

All submissions should include evidence of the green advance that the work presents. This should also be highlighted in a cover letter.

All papers must be written so as to be widely accessible (conceptually) to a broad audience of chemists and technologists as well as, for example, final year undergraduates.

If toxic or otherwise potentially harmful solvents, reagents or materials are used, authors need to ensure that alternatives have been checked or their use can be justified by other technical reasons. For further information on the use of solvents please refer to: CHEM21 selection guide of classical- and less classical-solvents’ by Denis Prat et. al., Green Chem ., 2016, 18 , 288-296. DOI: 10.1039/C5GC01008DJ .

It is the responsibility of authors to provide fully convincing evidence for the homogeneity, purity and identity of all compounds they claim as new. This evidence is required to establish that the properties and constants reported are those of the compound with the new structure claimed. Referees will assess, as a whole, the evidence presented in support of the claims made by the authors. The requirements for characterisation criteria are detailed below.

Organic compounds

Authors are required to provide unequivocal support for the purity and assigned structure of all compounds using a combination of the following characterisation techniques.

Analytical Elemental analysis (within ±0.4% of the calculated value) is required to confirm 95% sample purity and corroborate isomeric purity. Authors are also encouraged to provide copies of 1 H, 13 C NMR spectra and/or GC/HPLC traces. If satisfactory elemental analysis cannot be obtained, copies of these spectra and/or traces must be provided.

For libraries of compounds, HPLC traces should be submitted as proof of purity. The determination of enantiomeric excess of nonracemic, chiral substances should be supported with either SFC/GC/HPLC traces with retention times for both enantiomers and separation conditions (that is, chiral support, solvent and flow rate) or, for Mosher Ester/Chiral Shift Reagent analysis, copies of the spectra.

Physical Important physical properties, for example, boiling or melting point, specific rotation, refractive index, etc, including conditions and a comparison to the literature for known compounds should be provided. For crystalline compounds, the method used for recrystallisation should also be documented (that is, solvent etc).

Spectroscopic Mass spectra and a complete numerical listing of 1 H, 13 C NMR peaks in support of the assigned structure, including relevant 2D NMR and related experiments (that is, NOE, etc.) is required. Authors are encouraged to provide copies of these spectra. Infrared spectra that support functional group modifications, including other diagnostic assignments should be included.

High-resolution mass spectra are acceptable as proof of the molecular weight provided the purity of the sample has been accurately determined as outlined above. The synthesis of all new compounds must be described in detail.

Synthetic procedures must include the specific reagents, products and solvents and must give the amounts (g, mmol, for products; % for all of them), as well as clearly stating how the percentage yields are calculated. They must include the 1 H, 13 C and MS data of this specific compound.

For multistep synthesis papers, spectra of key compounds and of the final product should be included.

For a series of related compounds, at least one representative procedure that outlines a specific example that is described in the text or in a table, and which is representative for the other cases, must be provided.

For all soluble polymers an estimation of molecular weight must be provided by a suitable method (for example, size exclusion chromatography, including details of columns, eluents and calibration standards, intrinsic viscosity, MALDI TOF, etc.) in addition to full NMR characterisation ( 1 H, 13 C) - as for organic compound characterisation (see above).

The synthesis of all new compounds must be described in detail. Synthetic procedures must include the specific reagents, products and solvents and must give the amounts (g, mmol, for products; % for all of them), as well as clearly stating how the percentage yields are calculated. They must also include all the characterisation data for the prepared compound or material.

For a series of related compounds, at least one representative procedure which outlines a specific example that is described in the text or in a table, and which is representative for the other cases, must be provided.

Inorganic and organometallic compounds

A new chemical substance (molecule or extended solid) should have a homogeneous composition and structure. New chemical syntheses must unequivocally establish the purity and identity of these materials.Where the compound is molecular, minimum standards have been established.

For manuscripts that report new compounds or materials, data must be provided to unequivocally establish the homogeneity, purity and identification of these substances. In general, this should include elemental analyses that agree to within ±0.4% of the calculated values.

In cases where elemental analyses cannot be obtained (for example, for thermally unstable compounds), justification for the omission of this data should be provided. Note that an X-ray crystal structure is not sufficient for the characterisation of a new material, since the crystal used in this analysis does not necessarily represent the bulk sample.

In rare cases, it may be possible to substitute elemental analyses with high-resolution mass spectrometric molecular weights. This is appropriate, for example, with trivial derivatives of thoroughly characterised substances or routine synthetic intermediates.

In all cases, relevant spectroscopic data (NMR, IR, UV-vis, etc.) should be provided in tabulated form or as reproduced spectra. Again, these may be relegated to the electornic supplementary information (ESI) to conserve journal space. However, it should be noted that in general mass spectrometric and spectroscopic data do not constitute proof of purity, and in the absence of elemental analyses additional evidence of purity should be provided (melting points, PXRD data, etc.).

Experimental data for new substances should also include synthetic yields, reported in terms of grams or moles, and as a percentage.Where the compound is an extended solid it is important to unequivocally establish the chemical structure and bulk composition. Single crystal diffraction does not determine the bulk structure. Referees will normally look to see evidence of bulk homogeneity.

A fully indexed powder diffraction pattern that agrees with single crystal data may be used as evidence of a bulk homogeneous structure and chemical analysis may be used to establish purity and homogeneous composition. The synthesis of all new compounds must be described in detail. Synthetic procedures must include the specific reagents, products and solvents and must give the amounts (g, mmol, for products; % for all of them), as well as clearly stating how the percentage yields are calculated. They must also include all the characterisation data for the prepared compound or material.

For a series of related compounds, at least one representative procedure that outlines a specific example that is described in the text or in a table, and which is representative for the other cases, must be provided.

Nano-sized materials (such as quantum dots, nanoparticles, nanotubes, nanowires)

For nano-sized materials it is essential that the authors not only provide detailed characterisation on individual objects (see above) but also a comprehensive characterisation of the bulk composition. Characterisation of the bulk of the sample could require determination of the chemical composition and size distribution over large portions of the sample.The synthesis of all new compounds must be described in detail.

Synthetic procedures must include the specific reagents, products and solvents and must give the amounts (g, mmol, for products; % for all of them), as well as clearly stating how the percentage yields are calculated. They must also include all the characterisation data for the prepared compound or material. For a series of related compounds, at least one representative procedure that outlines a specific example described in the text or in a table, and that is representative for the other cases, must be provided.

Biomolecules (for example, enzymes, proteins, DNA/RNA, oligosaccharides, oligonucleotides)

Authors should provide rigorous evidence for the identity and purity of the biomolecules described. The techniques that may be employed to substantiate identity include the following.

- Mass spectrometry

- Sequencing data (for proteins and oligonucleotides)

- High field 1 H, 13 C NMR

- X-Ray crystallography.

Purity must be established by one or more of the following.

- Gel electrophoresis

- Capillary electrophoresis

- High field 1 H, 13 C NMR.

Sequence verification also needs to be carried out for nucleic acid cases involving molecular biology. For organic synthesis involving DNA, RNA oligonucleotides, their derivatives or mimics, purity must be established using HPLC and mass spectrometry as a minimum.

For new derivatives comprising modified monomers, the usual organic chemistry analytical requirements for the novel monomer must be provided (see Organic compounds section above). however, it is not necessary to provide this level of characterisation for the oligonucleotide into which the novel monomer is incorporated.

Open access publishing options

Green Chemistry is a hybrid (transformative) journal and gives authors the choice of publishing their research either via the traditional subscription-based model or instead by choosing our gold open access option. Find out more about our Transformative Journals. which are Plan S compliant .

Gold open access

For authors who want to publish their article gold open access , Green Chemistry charges an article processing charge (APC) of £2,750 (+ any applicable tax). Our APC is all-inclusive and makes your article freely available online immediately, permanently, and includes your choice of Creative Commons licence (CC BY or CC BY-NC) at no extra cost. It is not a submission charge, so you only pay if your article is accepted for publication.

Learn more about publishing open access .

Read & Publish

If your institution has a Read & Publish agreement in place with the Royal Society of Chemistry, APCs for gold open access publishing in Green Chemistry may already be covered.

Use our journal finder to check if your institution has an open access agreement with us.

Please use your official institutional email address to submit your manuscript and check you are assigned as the corresponding author; this helps us to identify if you are eligible for Read & Publish or other APC discounts.

Traditional subscription model

Authors can also publish in Green Chemistry via the traditional subscription model without needing to pay an APC. Articles published via this route are available to institutions and individuals who subscribe to the journal. Our standard licence allows you to make the accepted manuscript of your article freely available after a 12-month embargo period. This is known as the green route to open access.

Learn more about green open access .

Readership information

The journal appeals to a broad international readership spanning many communities, including all academic and industrial scientists interested in the development of alternative sustainable technologies.

Subscription information

Green Chemistry is part of the RSC Gold subscription package. Online only 2024 : ISSN 1463-9270, £2,784 / $4,907

*2022 Journal Citation Reports (Clarivate Analytics, 2023)

**The median time from submission to first decision including manuscripts rejected without peer review from the previous calendar year

***The median time from submission to first decision for peer-reviewed manuscripts from the previous calendar year

Advertisement

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Perspective

- Published: 30 January 2023

Green chemistry as just chemistry

- Mary Kate M. Lane ORCID: orcid.org/0000-0001-6208-3903 1 , 2 na1 ,

- Holly E. Rudel ORCID: orcid.org/0000-0003-3535-8697 1 , 2 na1 ,

- Jaye A. Wilson 2 , 3 ,

- Hanno C. Erythropel ORCID: orcid.org/0000-0003-3443-9794 1 , 2 , 3 ,

- Andreas Backhaus ORCID: orcid.org/0000-0002-5314-3799 1 , 2 ,

- Elise B. Gilcher ORCID: orcid.org/0000-0002-0326-5501 2 , 3 ,

- Momoko Ishii 1 , 2 , 3 ,

- Cheldina F. Jean ORCID: orcid.org/0000-0002-5214-874X 1 , 2 ,

- Fang Lin 2 , 4 ,

- Tobias D. Muellers ORCID: orcid.org/0000-0001-8180-6724 2 , 3 ,

- Tong Wang ORCID: orcid.org/0000-0002-9715-9135 1 , 2 ,

- Gerald Torres ORCID: orcid.org/0000-0002-6322-7777 3 , 5 ,

- Dorceta E. Taylor 3 ,

- Paul T. Anastas 2 , 3 , 6 na1 &

- Julie B. Zimmerman ORCID: orcid.org/0000-0002-5392-312X 1 , 2 , 3 na1

Nature Sustainability volume 6 , pages 502–512 ( 2023 ) Cite this article

3051 Accesses

16 Citations

20 Altmetric

Metrics details

- Chemical safety

- Sustainability

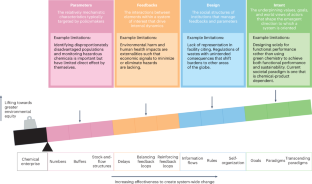

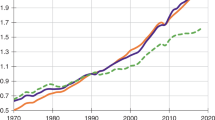

Environmental injustices have exposed our current system of reliance on polluting and toxic chemicals and chemistries as untenable and one whose risks and burdens are disproportionately borne by those who are disadvantaged. Aiming for effective interventions to create system-wide change, green chemistry and adjacent approaches are powerful leverage points to deeply address environmental injustices by changing the very nature of the molecular (for example, chemical, material, energy) basis of our economy and our society, obviating the need to rely on procedural systems that can either serve to enable progress or reinforce the status quo.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

24,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

111,21 € per year

only 9,27 € per issue

Rent or buy this article

Prices vary by article type

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Scientists’ warning on affluence

Thomas Wiedmann, Manfred Lenzen, … Julia K. Steinberger

Evaluating the efficacy and equity of environmental stopgap measures

Holly Jean Buck, Laura Jane Martin, … Shuchi Talati

Equity, technological innovation and sustainable behaviour in a low-carbon future

Benjamin K. Sovacool, Peter Newell, … Jessica Fanzo

Taylor, D. E. Toxic Communities: Environmental Racism, Industrial Pollution, and Residential Mobility (New York Univ. Press, 2014).

Bullard, R. D. Dumping in Dixie: Race, Class, and Environmental Quality (Routledge, 1994).

Bullard, R. D., Mohai, P., Saha, R. & Wright, B. Toxic wastes and race at twenty: why race still matters after all of these years environmental justice: making it a reality. Environ. Law 38 , 371–412 (2008).

Google Scholar

Mohai, P., Pellow, D. & Roberts, J. T. Environmental justice. Annu. Rev. Environ. Resour. 34 , 405–430 (2009).

Article Google Scholar

Taylor, D. E. The Environment and the People in American Cities, 1600s–1900s: Disorder, Inequality, and Social Change (Duke Univ. Press, 2009).

Anastas, P. T. & Warner, J. C. Green Chemistry: Theory and Practice (Oxford Univ. Press, 1998).

Erythropel, H. C. et al. The Green ChemisTREE: 20 years after taking root with the 12 principles. Green Chem. 20 , 1929–1961 (2018).

Article CAS Google Scholar

Anastas, P. T. & Zimmerman, J. B. Design through the 12 principles of green engineering. Environ. Sci. Technol. 37 , 94A–101A (2003).

Zimmerman, J. B., Anastas, P. T., Erythropel, H. C. & Leitner, W. Designing for a green chemistry future. Science 367 , 397–400 (2020).

Delegates of the First National People of Color Environmental Leadership Summit. The Principles of Environmental Justice. First National People of Color Environmental Leadership Summit (United Christ of Church, New York, 1991).

Commission for Racial Justice. Toxic Wastes and Race in the United States: A National Report on the Racial and Socio-Economic Characteristics of Communities with Hazardous Waste Sites (United Christ of Church, New York, 1987).

Bullard, R. D. Solid waste sites and the black Houston community. Sociol. Inq. 53 , 273–288 (1983).

Anastas, P. T. & Zimmerman, J. B. The molecular basis of sustainability. Chem 1 , 10–12 (2016).

Newman, M. K. et al. New Perspectives on Environmental Justice: Gender, Sexuality, and Activism (Rutgers Univ. Press, 2004).

Pellow, D. Toward a critical environmental justice studies: black lives matter as an environmental justice challenge. Du Bois Rev. 13 , 221–236 (2016).

Al-Kohlani, S. A. & Campbell, H. E. Extending environmental justice research to religious minorities. Rev. Policy Res. 39 , 90–112 (2022).

Dombey, M. How governments are systematically poisoning indigenous communities and the U.N.’s role. Univ. Miami Int. Comp. Law Rev. Environ. Racism 27 , 131–154 (2020).

Jacobs, B. Environmental Racism on Indigenous Lands and Territories (Canadian Political Science Association, 2010).

Goldsmith, L. & Bell, M. L. Queering environmental justice: unequal environmental health burden on the LGBTQ+ Community. Am. J. Public Health 112 , 79–87 (2021).

Pellow, D. & Vazin, J. The intersection of race, immigration status, and environmental justice. Sustainability 11 , 3942 (2019).

Rockström, J. et al. Planetary boundaries: exploring the safe operating space for humanity. Ecol. Soc. 14 , 32 (2009).

Millennium Ecosystem Assessment. Ecosystems and Human Well-being: Synthesis (Island Press, 2005).

Raworth, K. A Safe and Just Space for Humanity: Can We Live Within the Doughnut? Discussion Paper (Oxfam International, 2012).

Taylor, D. E. The rise of the environmental justice paradigm: injustice framing and the social construction of environmental discourses. Am. Behav. Sci. 43 , 508–580 (2000).

The Routledge Handbook of Environmental Justice (Routledge, 2018).

Anastas, P. T. & Zimmerman, J. B. The periodic table of the elements of green and sustainable chemistry. Green Chem. 21 , 6545–6566 (2019).

Anastas, P. T. & Zimmerman, J. B. The United Nations sustainability goals: how can sustainable chemistry contribute? Curr. Opin. Green Sustain. Chem. 13 , 150–153 (2018).

Keijer, T., Bakker, V. & Slootweg, J. C. Circular chemistry to enable a circular economy. Nat. Chem. 11 , 190–195 (2019).

Kümmerer, K., Clark, J. H. & Zuin, V. G. Rethinking chemistry for a circular economy. Science 367 , 369–370 (2020).

Rittel, H. W. J. & Webber, M. M. Dilemmas in a general theory of planning. Policy Sci. 4 , 155–169 (1973).

Ritchey, T. in Wicked Problems – Social Messes: Decision Support Modelling with Morphological Analysis (ed. Ritchey, T.) 19–29 (Springer, 2011).

Meadows, D. H. in Thinking in Systems Ch. 6 (ed. Wright, D.) 145–165 (Chelsea Green Publishing, 2008).

Abson, D. J. et al. Leverage points for sustainability transformation. Ambio 46 , 30–39 (2017).

Aubrecht, K. B., Bourgeois, M., Brush, E. J., MacKellar, J. & Wissinger, J. E. Integrating green chemistry in the curriculum: building student skills in systems thinking, safety, and sustainability. J. Chem. Educ. 96 , 2872–2880 (2019).

Lasker, G. A. & Brush, E. J. Integrating social and environmental justice into the chemistry classroom: a chemist’s toolbox. Green Chem. Lett. Rev. 12 , 168–177 (2019).

Lasker, G. A., Mellor, K. E., Mullins, M. L., Nesmith, S. M. & Simcox, N. J. Social and environmental justice in the chemistry classroom. J. Chem. Educ. 94 , 983–987 (2017).

Matlin, S. A., Mehta, G., Hopf, H. & Krief, A. One-world chemistry and systems thinking. Nat. Chem. 8 , 393–398 (2016).

Kümmerer, K. Sustainable chemistry: a future guiding principle. Angew. Chem. Int. Ed. 56 , 16420–16421 (2017).

Mahaffy, P. G., Matlin, S. A., Holme, T. A. & MacKellar, J. Systems thinking for education about the molecular basis of sustainability. Nat. Sustain. 2 , 362–370 (2019).

Mahaffy, P. G., Ho, F. M., Haack, J. A. & Brush, E. J. Can chemistry be a central science without systems thinking? J. Chem. Educ. 96 , 2679–2681 (2019).

Matlin, S. A., Krief, A., Hopf, H. & Mehta, G. Re-imagining priorities for chemistry: a central science for ‘freedom from fear and want’. Angew. Chem. Int. Ed. 60 , 25610–25623 (2021).

Holifield, R., Porter, M. & Walker, G. Spaces of environmental justice: frameworks for critical engagement. Antipode 41 , 591–612 (2009).

Walker, G. Environmental Justice: Concepts , Evidence and Politics (Routledge, 2012).

Pasgaard, M. & Dawson, N. Looking beyond justice as universal basic needs is essential to progress towards ‘safe and just operating spaces’. Earth Syst. Gov. 2 , 100030 (2019).

Orum, P., Moore, R., Roberts, M. & Sanchez, J. Who’s In Danger? Race, Poverty and Chemical Disasters: A Demographic Analysis of Chemical Disaster Vulnerability Zones (Environmental Justice and Health Alliance for Chemical Policy Reform, 2014).

Lerner, S. Sacrifice Zones: the Front Lines of Toxic Chemical Exposure in the United States (MIT Press, 2010).

Siting of Hazardous Waste Landfills and Their Correlation With Racial and Economic Status of Surrounding Communities (US Government Accountability Office, 1983).

Banzhaf, H. S., Ma, L. & Timmins, C. Environmental justice: establishing causal relationships. Annu. Rev. Resour. Econ. 11 , 377–398 (2019).

Mohai, P. & Saha, R. Which came first, people or pollution? Assessing the disparate siting and post-siting demographic change hypotheses of environmental injustice. Environ. Res. Lett. 10 , 115008 (2015).

James, W., Jia, C. & Kedia, S. Uneven magnitude of disparities in cancer risks from air toxics. Int. J. Environ. Res. Public Health 9 , 4365–4385 (2012).

Johnston, J. & Cushing, L. Chemical exposures, health, and environmental justice in communities living on the fenceline of industry. Curr. Environ. Health Rep. 7 , 48–57 (2020).

Wright, B. H., Bryant, P. & Bullard, R. D. in Unequal Protection: Environmental Justice and Communities of Color (ed. Bullard, R. D.) 110–129 (Sierra Club Books, 1994).

Terrell, K. A. & St Julien, G. Air pollution is linked to higher cancer rates among black or impoverished communities in Louisiana. Environ. Res. Lett. 17 , 14033 (2022).

Landrigan, P. J., Rauh, V. A. & Galvez, M. P. Environmental justice and the health of children. Mt Sinai J. Med. 77 , 178–187 (2010).

Banzhaf, S., Ma, L. & Timmins, C. Environmental justice: the economics of race, place, and pollution. J. Econ. Perspect. 33 , 185–208 (2019).

Elliott, M. R., Wang, Y., Lowe, R. A. & Kleindorfer, P. R. Environmental justice: frequency and severity of US chemical industry accidents and the socioeconomic status of surrounding communities. J. Epidemiol. Community Health 4 , 24–30 (2004).

Friedman-Jiménez, G. Achieving environmental justice: the role of occupational health. Fordham Urban Law J. 21 , 605–632 (1994).

Office of Emergency Management & Office of Land and Emergency Management. Accidental Release Prevention Requirements: Risk Management Programs Under the Clean Air Act, Section 112(r)(7) (US Environmental Protection Agency, 2017); https://www.regulations.gov/document/EPA-HQ-OEM-2015-0725-0734

Chemical Releases Caused By Natural Hazard Events and Disasters - Information for Public Health Authorities (WHO, 2018).

Jafry, T., Helwig, K. & Mikulewicz, M. The Routledge Handbook of Climate Justice (Routledge, 2019).

Wright, B. H. in Race and the Incidence of Environmental Hazards (eds Bryant, B. & Mohai, P.) 114–125 (Routledge, 1992).

Calvert, G. M. et al. Acute pesticide poisoning among agricultural workers in the United States, 1998–2005. Am. J. Ind. Med. 51 , 883–898 (2008).

Moyce, S. C. & Schenker, M. Migrant workers and their occupational health and safety. Annu. Rev. Public Health 39 , 351–365 (2018).

Castillo, F. et al. Environmental health threats to Latino migrant farmworkers. Annu. Rev. Public Health 42 , 257–276 (2021).

Occupational Exposures in Petroleum Refining; Crude Oil and Major Petroleum Fuels (IARC Working Group on the Evaluation of Carcinogenic Risks to Humans, 1989); https://www.ncbi.nlm.nih.gov/books/NBK531272/

Minority and Female Employment in the Oil & Gas and Petrochemical Industries (IHS Global, 2014).

Bertazzi, P. A., Pesatori, A. C., Zocchetti, C. & Latocca, R. Mortality study of cancer risk among oil refinery workers. Int. Arch. Occup. Environ. Health 61 , 261–270 (1989).

Xin, F., Susiarjo, M. & Bartolomei, M. S. Multigenerational and transgenerational effects of endocrine disrupting chemicals: a role for altered epigenetic regulation? Semin. Cell Dev. Biol. 43 , 66–75 (2015).

Rothstein, M. A., Harrell, H. L. & Marchant, G. E. Transgenerational epigenetics and environmental justice. Environ. Epigenet. 3 , dvx011 (2017).

Lane, M. K. M. et al. What to expect when expecting in lab: a review of unique risks and resources for pregnant researchers in the chemical laboratory. Chem. Res. Toxicol. 35 , 163–198 (2022).

Martin, E. M. & Fry, R. C. Environmental influences on the epigenome: exposure- associated DNA methylation in human populations. Annu. Rev. Public Health 39 , 309–333 (2018).

Reichert, A. K. Impact of a toxic waste superfund site on property values. Appraisal J. LXV , 381–392 (1997).

Currie, J., Davis, L., Greenstone, M. & Walker, R. Environmental health risks and housing values: evidence from 1,600 toxic plant openings and closings. Am. Econ. Rev. 105 , 678–709 (2015).

Messer, K. D., Schulze, W. D., Hackett, K. F., Cameron, T. A. & Mcclelland, G. H. Can stigma explain large property value losses? The psychology and economics of Superfund. Environ. Resour. Econ. 33 , 299–324 (2006).

Boehm, T. P. & Schlottmann, A. M. Housing and Wealth Accumulation: Intergenerational Impacts (Joint Center for Housing Studies of Harvard University, 2001).

Anguelovski, I. in Neighborhood as Refuge: Community Reconstruction, Place Remaking, and Environmental Justice in the City (ed. Gottlieb, R.) 29–54 (MIT Press, 2014).

LaDuke, W. All Our Relations: Native Struggles for Land and Life (South End Press, 1999).

Lewis, J., Hoover, J. & MacKenzie, D. Mining and environmental health disparities in native american communities. Curr. Environ. Health Rep. 4 , 130–141 (2017).

Leonard, L. G. III Sovereignty, self-determination, and environmental justice in the Mescalero Apache’s decision to store nuclear waste. Boston Coll. Environ. Aff. Law Rev. 24 , 651–693 (1996).

Martinez-Alier, J. Mapping ecological distribution conflicts: the EJAtlas. Extr. Ind. Soc. 8 , 100883 (2021).

Castleman, B. The export of hazardous industries in 2015. Environ. Health 15 , 8 (2016).

Bogdal, C. & Scheringer, M. Climate Change and POPs: Predicting the Impacts (UNEP/AMAP, 2011).

Pellow, D. N. Resisting Global Toxics: Transnational Movements for Environmental Justice (MIT Press, 2007).

Friedman, R. S. et al. How just and just how? A systematic review of social equity in conservation research. Environ. Res. Lett. 13 , 53001 (2018).

McDermott, M., Mahanty, S. & Schreckenberg, K. Examining equity: a multidimensional framework for assessing equity in payments for ecosystem services. Environ. Sci. Policy 33 , 416–427 (2013).

Pascual, U., Muradian, R., Rodríguez, L. C. & Duraiappah, A. Exploring the links between equity and efficiency in payments for environmental services: a conceptual approach. Ecol. Econ. 69 , 1237–1244 (2010).

Schulte, P. A. et al. Occupational safety and health, green chemistry, and sustainability: a review of areas of convergence. Environ. Health 12 , 31 (2013).

Anastas, P. T. & Hammond, D. G. Inherent Safety at Chemical Sites: Reducing Vulnerability to Accidents and Terrorism Through Green Chemistry (Elsevier, 2015).

Krings, A. & Thomas, H. in The Routledge Handbook of Green Social Work Ch. 32 (ed. Dominelli, L.) (Routledge, 2018).

Zimmerman, J. B. & Anastas, P. T. When is waste not a waste? Sustain. Sci. Eng. 1 , 201–221 (2006).

Boodhoo, K. & Harvey, A. Process Intensification Technologies for Green Chemistry: Engineering Solutions for Sustainable Chemical Processing (Wiley, 2013).

Costanza, R. et al. The value of the world’s ecosystem services and natural capital. Nature 387 , 253–260 (1997).

Ecosystems and Human Well-Being: Synthesis (Millennium Ecosystem Assessment Panel, 2005); https://www.millenniumassessment.org/documents/document.356.aspx.pdf

Mihelcic, J. R. et al. Sustainability science and engineering: the emergence of a new metadiscipline. Environ. Sci. Technol. 37 , 5314–5324 (2003).

United States Environmental Protection Agency. Environmental Justice Timeline. EPA (accessed 9 Jan 2023); https://www.epa.gov/environmentaljustice/environmental-justice-timeline

Download references

Author information

These authors contributed equally: Mary Kate M. Lane, Holly E. Rudel, Paul T. Anastas, Julie B. Zimmerman.

Authors and Affiliations

Department of Chemical and Environmental Engineering, Yale University, New Haven, CT, USA

Mary Kate M. Lane, Holly E. Rudel, Hanno C. Erythropel, Andreas Backhaus, Momoko Ishii, Cheldina F. Jean, Tong Wang & Julie B. Zimmerman

Center for Green Chemistry and Green Engineering, Yale University, New Haven, CT, USA

Mary Kate M. Lane, Holly E. Rudel, Jaye A. Wilson, Hanno C. Erythropel, Andreas Backhaus, Elise B. Gilcher, Momoko Ishii, Cheldina F. Jean, Fang Lin, Tobias D. Muellers, Tong Wang, Paul T. Anastas & Julie B. Zimmerman

School of the Environment, Yale University, New Haven, CT, USA

Jaye A. Wilson, Hanno C. Erythropel, Elise B. Gilcher, Momoko Ishii, Tobias D. Muellers, Gerald Torres, Dorceta E. Taylor, Paul T. Anastas & Julie B. Zimmerman

Department of Chemistry, Yale University, New Haven, CT, USA

Law School, Yale University, New Haven, CT, USA

Gerald Torres

School of Public Health, Yale University, New Haven, CT, USA

Paul T. Anastas

You can also search for this author in PubMed Google Scholar

Contributions

M.K.M.L. and H.E.R. contributed equally to this work as co-first authors. P.T.A. and J.B.Z. contributed equally to this work as co-last authors. M.K.M.L., H.E.R. and J.B.Z. wrote the first draft and M.K.M.L., H.E.R., J.A.W., H.C.E., A.B., E.B.G., M.I., C.F.J., F.L., T.D.M., T.W., G.T., D.E.T., P.T.A. and J.B.Z. contributed subsequently to its refinement, editing and critical revision. M.K.M.L., A.B., P.T.A. and J.B.Z. were responsible for visualization. M.K.M.L., H.E.R., H.C.E., P.T.A. and J.B.Z. supervised the writing effort. M.K.M.L., H.E.R., J.A.W., H.C.E., A.B., E.B.G., M.I., C.F.J., F.L., T.D.M., T.W., G.T., D.E.T., P.T.A. and J.B.Z. approved the final manuscript.

Corresponding author

Correspondence to Julie B. Zimmerman .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Peer review

Peer review information.

Nature Sustainability thanks Jennifer Burney, Grace A. Lasker and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Cite this article.

Lane, M.K.M., Rudel, H.E., Wilson, J.A. et al. Green chemistry as just chemistry. Nat Sustain 6 , 502–512 (2023). https://doi.org/10.1038/s41893-022-01050-z

Download citation

Received : 16 June 2022

Accepted : 08 December 2022

Published : 30 January 2023

Issue Date : May 2023

DOI : https://doi.org/10.1038/s41893-022-01050-z

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

Themed collection 2023 Green Chemistry Reviews

The need for hotspot-driven research.

Environmental benefit will be greatest if we green the step causing the most harm.

Natural deep eutectic solvents (NaDES): translating cell biology to processing

This review examines the possible functional roles of liquid natural deep eutectic solvents (NaDES) in plants and translating it to the laboratory.

Electrochemical nitration for organic C–N bond formation: a current view on possible N-sources, mechanisms, and technological feasibility

Rethinking nitration: sustainable electrochemical C-N functionalization. This work reviews diverse inorganic nitrogen sources for fine chemical production, with a perspective on innovative pathways to harness alternative nitrogen sources' potential.

From green to circular chemistry paved by biocatalysis

Biocatalysts raised by the green chemistry and circular chemistry principles can constitute the most important and efficient strategy for achieving many of the 17 Sustainable Development Goals launched by the UN.

Energy crisis in Europe enhances the sustainability of green chemicals

Europe's energy crisis has made green routes for ammonia and methanol synthesis economically competitive. This presents an opportunity for Europe to lead the grand transition towards a sustainable chemical industry.

Status check: biocatalysis; its use with and without chemocatalysis. How does the fine chemicals industry view this area?

Stages of the penetration of catalytic technology and the necessity for fruitful collaboration.

Limonene as a natural product extraction solvent

The use of natural product limonene as natural product extraction solvent offers multiple benefits that go beyond its environmentally benign nature.

Phosphorus sustainability: a case for phytic acid as a biorenewable platform

Phytic acid is a source of biogenic phosphorus that could serve as a key platform chemical in future biorefineries, helping to close the loop on the phosphorus cycle.

Recent advances in the heterogeneous photochemical synthesis of C–N bonds

Photocatalyst has been developed as an effective tool for C–N coupling due to high selectivity, mild reaction conditions and low energy comsume.

What does it mean that “something is green”? The fundamentals of a Unified Greenness Theory

Proposal of a general theory of greenness, connecting all chemical disciplines and not only; the description of basic concepts and relationships.

Using earth abundant materials for long duration energy storage: electro-chemical and thermo-chemical cycling of bicarbonate/formate

The HCO 3 − -HCO 2 − cycle, where aqueous solutions of formate salts are hydrogen and energy carriers, offers the opportunity of combining electrochemical and thermochemical operations, and of coupling CO 2 capture with energy/hydrogen storage.

Natural multi-osmolyte cocktails form deep eutectic systems of unprecedented complexity: discovery, affordances and perspectives

Tracking osmolyte patterns in biological contexts can help design novel multicomponent deep eutectic systems, which mimic the nuanced microenvironment of biomacromolecules operating within these biological contexts.

Seaweed-based polysaccharides-Review of extraction, characterization, and bioplastic application

Syntheses and polymerization of monoterpene-based (meth)acrylates: ibo(m)a as a relevant monomer for industrial applications.

This article provides a comprehensive overview of the current scientific status of monomer and polymer synthesis, as well as the areas of application for (meth)acrylates based on monoterpenes, using the industrially available IBOMA as an example.

Salt-assisted synthesis of advanced carbon-based materials for energy-related applications

This review provides a comprehensive overview of salt assisted synthesis of carbon based materials based on the role of salts in synthesis systems. Meanwhile, the application in energy related fields is emphasized.

The dawn of aqueous deep eutectic solvents for lignin extraction

This review addresses recent advancements in lignin extraction using ADES and underlying mechanism. Additionally, the economic and environmental sustainability is evaluated, highlighting the feasibility of industrial-scale applications in future.

Advanced nano-bifunctional electrocatalysts in Li–air batteries for high coulombic efficiency

This article focuses on the major obstacle of sluggish ORR and OER kinetics of the cathode in LABs and reviews the main advances of the major designing principles of various nanoscale bifunctional electrocatalysts, and the relation to the enhancing OER/ORR catalytic activity.

Molten salt technique for the synthesis of carbon-based materials for supercapacitors

We provide a comprehensive review of the molten salt strategy for the preparation of carbon-based materials by highlighting the roles played by molten salts. The application of these carbons in supercapacitors is also discussed.

Selective demethylation reactions of biomass-derived aromatic ether polymers for bio-based lignin chemicals

Unlocking lignin potential by selective demethylation of its monomers and oligomers.

Electrochemical cascade reactions: an account of recent developments for this modern strategic tool in the arsenal of chemical synthesis

The electrochemical cascade process majorly satisfies the essential criteria of green synthesis. Being an Integrated synthetic strategy it can produce more molecules in a shorter time and thus provides a modern strategic tool in the arsenal of synthetic chemists.

CO 2 -derived non-isocyanate polyurethanes (NIPUs) and their potential applications

Using CO 2 as feedstock to fabricate valuable products has become essential to green and sustainable chemistry and represents a rewarding challenge.

Electrochemical hydrogen production: sustainable hydrogen economy

The development of sustainable energy technologies has received considerable attention to meet increasing global energy demands and to realise organisational goals ( e.g. , United Nations, the Paris Agreement) of carbon neutrality.

Role of fungal enzymes in the synthesis of pharmaceutically important scaffolds: a green approach

Fungi are a diverse group of organisms that play an essential role in the biosphere.

Review and perspectives on carbon-based electrocatalysts for the production of H 2 O 2 via two-electron oxygen reduction

As a versatile and environmentally friendly chemical, hydrogen peroxide (H 2 O 2 ) is in high demand.

Future bioenergy source by microalgae–bacteria consortia: a circular economy approach

Future sustainable approach of bioenergy production that uses microalgae–bacteria consortium to produce bioelectricity and biofuel for industrial and daily activities.

A review on green and sustainable carbon anodes for lithium ion batteries: utilization of green carbon resources and recycling waste graphite

Sustainable and effective methods for green synthesis of carbon anodes for lithium-ion batteries is reviewed in this work.

Stimuli-cleavable moiety enabled vinyl polymer degradation and emerging applications

This review delves into degradable vinyl polymers with stimuli-cleavable moieties, their chemistry, mechanisms, and applications in environmental remediation, drug delivery, advanced functional materials, and surface modification.

Bio-based platform chemicals synthesized from lignin biorefinery

Bio-based chemicals synthesized by lignin offer a promising pathway of bioenergy utilization to achieve the target of the Paris Agreement with <2 °C of climate warming temperature.

Deep eutectic solvents as a versatile platform toward CO 2 capture and utilization

Deep eutectic solvents provide a versatile platform for CO 2 capture and subsequent conversion into value-added chemicals.

Research progress in electrochemical/photochemical utilization of methanol as a C1 source

This review highlights the recent advances in various electrochemical and photochemical reactions using methanol as a sustainable C1 source.

When nanocellulose meets hydrogels: the exciting story of nanocellulose hydrogels taking flight

By revealing the intrinsic link between the inherent advantages of nanocellulose and hydrogels, we highlight the applications of nanocellulose hydrogels in medical treatment, electricity, sensor, environmental governance, food, and agriculture.

Physico-chemical challenges on the self-assembly of natural and bio-based ingredients on hair surfaces: towards sustainable haircare formulations

Polymers and surfactants are used in many technological and industrial applications such as the manufacture of functional materials and coatings, personal care and pharmaceutical products, food science, paints or tertiary oil recover.

Research status, opportunities, and challenges of cobalt phosphate based materials as OER electrocatalysts

Cobalt phosphate (CoPi) based material has attracted great attention due to its low cost, good stability, high catalytic activity, and redox properties. This review presents the recent advances of CoPi in OER process.

Sacrifice and valorization of biomass to realize energy exploitation and transformation in a photoelectrochemical way

The mechanism, substrate transformation, photoelectrodes, and configurations of photoelectrochemistry (PEC) of biomass are reviewed, different from PEC water splitting, photocatalysis, or electrocatalysis.

Recent progress in the electrochemical selenofunctionalization of alkenes and alkynes

The recent advances on the electrochemical selenofunctionalization of unsaturated C–C bonds were comprehensively summarized in this review.

Carbon materials for hybrid evaporation-induced electricity generation systems

The most recent developments in carbon materials for hybrid evaporation-induced electricity generation systems are discussed in detail and analyzed in depth.

Recent advancements in supramolecular macrocycles for two-dimensional membranes for separations

This review summarizes recent advancements of 2D supramolecular membranes for separations. This topic can provide new insights on developing 2D supramolecular membranes with high selectivity, mild flux, good stability and appreciable reversibility.

Recent advances in plastic recycling and upgrading under mild conditions

This review summarizes the emerging advanced technologies including bio-, photo-, electro-, and low-temperature thermocatalysis for recycling and upgrading of waste plastics under mild conditions.

A review of water splitting via mixed ionic–electronic conducting (MIEC) membrane reactors

Coupling catalytic water splitting with a mixed ionic–electronic conducting (MIEC) membrane reactor has been demonstrated as a very promising approach to enhance the hydrogen production rate by extracting the oxygen produced.

An overview on the recycling of waste poly(vinyl chloride)

The environmental threat of waste polyvinyl chloride (PVC) is growing. But the unique chemical structure of PVC makes its recycling itself have the ability to cause environmental harm. More advanced recycling processes are required.

Combined pyro-hydrometallurgical technology for recovering valuable metal elements from spent lithium-ion batteries: a review of recent developments

A combined pyro-metallurgical process with green chemistry principles for the recycling of valuable metals from spent lithium-ion batteries is reviewed.

Functional carbon dots derived from biomass and plastic wastes

The preparation methods, formation mechanism, properties and applications of functional carbon dots derived from biomass and plastic wastes are reported.

Shining light on layered metal phosphosulphide catalysts for efficient water electrolysis: preparation, promotion strategies, and perspectives

This review summarizes the design, preparation and promotion strategies of layered metal phosphosulphide-based electrocatalysts for water splitting; future perspectives and challenges are also briefly discussed.

2D layered materials: structures, synthesis, and electrocatalytic applications

We review the synthesis, structure and electrochemical applications of 2D nanomaterials, with particular emphasis on the relationship between their structure and catalytic activity.

Ionic liquids membranes for liquid separation: status and challenges

The exciting research activities in the fields of ionic liquid membranes (ILMs) for liquid separation are reviewed, covering the preparation strategy, applicability, transport mechanism, and future perspectives.

Progress in the biosynthesis of bio-based PET and PEF polyester monomers

This critical review covers advances in the preparation of the important polyester monomers terephthalic acid (TPA), 2,5-furandicarboxylic acid (FDCA), and ethylene glycol (EG), with particular focus on biocatalytic approaches.

Cellulose processing in ionic liquids from a materials science perspective: turning a versatile biopolymer into the cornerstone of our sustainable future

The past two decades have seen fruitful efforts in shaping cellulose into functional materials using ionic liquids. This Tutorial Review aims at providing guidance from a materials science perspective to stimulate more research in this field.

Ionic liquids as a new cornerstone to support hydrogen energy

This work reviewed how ionic liquids support hydrogen energy technologies for production, storage and utilization.

Lignin-enhanced wet strength of cellulose-based materials: a sustainable approach

Cellulose is the most abundant renewable polymer resource in nature and cellulose-based materials are expected to serve as viable replacements to petroleum-based plastic products.

Heterogeneity in enzyme/metal–organic framework composites for CO 2 transformation reactions

Heterogeneity benefits enzyme/MOF design. In this review, our perspective on the research challenges and future directions for biocatalytic CO 2 conversion using MOF-based biocatalysts are discussed.

Green materials with promising applications: cyclodextrin-based deep eutectic supramolecular polymers

Binary DESPs and ternary DESPs are used for the separation of target compounds and as efficient adhesive materials.

Waste to wealth: direct utilization of spent materials for electrocatalysis and energy storage

We summarize the direct utilization of versatile waste sources in various electrocatalysis and energy storage systems in view of synthetic strategies, structural properties, electrochemical performance and the challenges and prospects.

Designing electrocatalysts for seawater splitting: surface/interface engineering toward enhanced electrocatalytic performance

Schematic illustration of interface/surface engineering strategies with various effective approaches for high-performance HER/OER electrocatalysts in seawater.

Sustainable production of active pharmaceutical ingredients from lignin-based benzoic acid derivatives via “demand orientation”

Catalytic production of several representative active pharmaceutical ingredients (APIs) from lignin.

Biocatalytic amide bond formation

The state-of-the-art of biocatalytic amide bond formation is discussed with the help of a manually curated database of enzymatic amidation reactions.

Salt-thermal methods for recycling and regenerating spent lithium-ion batteries: a review

The state-of-the-art salt-thermal method to recycle spent LIBs enables preferential Li recovery, recovery of anode/cathode material, direct regeneration of degraded anode/cathode material, and one-step re-synthesis of advanced functional materials.

Retrosynthesis from transforms to predictive sustainable chemistry and nanotechnology: a brief tutorial review

Retrosynthesis is a tool initially developed to simplify the planning of the synthesis of organic molecules. With the progress of computer-aided synthesis design (CASD), its development will be predictive green and sustainable CASD.

The dialkylcarbonate route to ionic liquids: purer, safer, greener?

The synthesis of ionic liquids can generate large amounts of waste and use toxic or expensive raw materials.

Advances in S–N bond formation via electrochemistry: a green route utilizing diverse sulfur and nitrogen sources

This review summarizes recent advances in S–N bond formation via electrochemistry from diverse sulfur and nitrogen sources to valuable sulfur–nitrogen-bond-containing compounds, such as sulfenamides, sulfinamides, sulfonamides, sulfoximines, isothiazoles and thiadiazoles.

Lignin as a green and multifunctional alternative to phenol for resin synthesis

The substitution of phenol by lignin not only reduces the feedstock cost of resin synthesis but also improves the resin's physicochemical properties and endues the resin with new functions.

Selective oxidation of biomass-derived carbohydrate monomers

The article discusses the potential production processes for glucaric acid, and the efforts to develop more sustainable oxidation practices for its production, with a focus on the strengths and weaknesses of each method.

Toxicological data bank bridges the gap between environmental risk assessment and green organic chemical design in One Health world

This review aims to introduce the rich applications of chemical toxicological data for environmental risk assessment and green chemical design by illustrating referable examples or cases. Further, we present a comprehensive toxicology databank.

Recent developments of MXene-based catalysts for hydrogen production by water splitting

In the application of electrolytic water splitting, MXenes can achieve performance optimization by doping, surface functional group regulation, construction of defect/vacancy, 3D/porous structure, or compounding with other materials.

Graphitic carbon nitride-based nanostructures as emergent catalysts for carbon monoxide (CO) oxidation

This is the first review that emphasizes the engineering of carbon nitride-based catalysts for thermal, electrochemical, and photoelectrochemical CO oxidation reactions experimentally and theoretically.

The functional and synergetic optimization of the thermal-catalytic system for the selective oxidation of 5-hydroxymethylfurfural to 2,5-diformylfuran: a review

The latest design and development of thermal-catalytic strategies are sorted based on the active species and types of catalysts. The ongoing challenge and opportunities have been concluded.

Addressing the CO 2 challenge through thermocatalytic hydrogenation to carbon monoxide, methanol and methane

Addressing the CO 2 challenge is mandatory for the well-being of Earth's ecosystem and humanity. CO 2 catalytic hydrogenation is a suitable solution.

From non-conventional ideas to multifunctional solvents inspired by green chemistry: fancy or sustainable macromolecular chemistry?

The review teach the reader how the use of an unconventional polymerization medium not only as scientific fantasy designed to validate an established concept but also as a viable tool for the sustainable development of macromolecular chemistry.

Review of high-performance sustainable polymers in additive manufacturing

This review evaluates the current state of sustainable polymers in additive manufacturing with a focus on higher performance capabilities.

Marine chitin upcycling with immobilized chitinolytic enzymes: current state and prospects

Immobilized chitinase, β- N -acetylglucosaminidases, chitin deacetylases and chitosanases enable ecofriendly enzymic conversion of chitin and its derivative, chitosan, into low-molecular weight sugars known as chitooligosaccharides (COSs).

Progress in reaction mechanisms and catalyst development of ceria-based catalysts for low-temperature CO 2 methanation

We present a detailed review on the mechanistic understanding and catalyst development of CeO 2 -based CO 2 methanation catalysts. Current challenges for deeper investigations and future perspectives are presented as well.

About this collection

Welcome to our online collection of Green Chemistry Review articles. Here we feature Critical reviews, Tutorial reviews and Perspective articles published in 2023.

For more information about the different review types, please go to https://rsc.li/greenchem

Congratulations to all the authors whose articles are featured and we hope readers enjoy this collection.

Advertisements

The green solvent: a critical perspective

- Perspective

- Open access

- Published: 30 September 2021

- Volume 23 , pages 2499–2522, ( 2021 )

Cite this article

You have full access to this open access article

- Neil Winterton ORCID: orcid.org/0000-0002-3887-4198 1

18k Accesses

82 Citations

Explore all metrics

Solvents are important in most industrial and domestic applications. The impact of solvent losses and emissions drives efforts to minimise them or to avoid them completely. Since the 1990s, this has become a major focus of green chemistry, giving rise to the idea of the ‘green’ solvent. This concept has generated a substantial chemical literature and has led to the development of so-called neoteric solvents. A critical overview of published material establishes that few new materials have yet found widespread use as solvents. The search for less-impacting solvents is inefficient if carried out without due regard, even at the research stage, to the particular circumstances under which solvents are to be used on the industrial scale. Wider sustainability questions, particularly the use of non-fossil sources of organic carbon in solvent manufacture, are more important than intrinsic ‘greenness’. While solvency is universal, a universal solvent, an alkahest, is an unattainable ideal.

Similar content being viewed by others

Industrial Applications of Green Solvents for Sustainable Development of Technologies in Organic Synthesis

Green and bio-based solvents.

Francisco G. Calvo-Flores, María José Monteagudo-Arrebola, … Joaquín Isac-García

A holistic review on application of green solvents and replacement study for conventional solvents

Parth Shah, Sachin Parikh, … Swapnil Dharaskar

Avoid common mistakes on your manuscript.

Introduction

The American artist, Adolph Gottlieb, painted ‘ The Alkahest of Paracelsus ’ (Fig. 1 ) in 1945 in the aftermath of the Second World War. The painting is described as ‘ a pictorial alkahest, a visual solvent intended to strip away illusions and expose the truth of a civilization tottering on the edge of self-destruction ’. Such are the challenges of sustainability, exacerbated by those of the COVID-19 pandemic, that we might conclude that Gottlieb’s painting conveys a similar grim message seventy five years later.

The Alkahest of Paracelsus by Adolph Gottlieb (1903–1974), Museum of Fine Arts, Boston ©Adolph and Esther Gottlieb Foundation (Alkahest of Paracelsus, 1945 by Adolph Gottlieb (American) 1903–1974. Oil and egg tempera on canvas 152.4 × 111.76 cm (60 × 44 in.). Museum of Fine Arts, Boston, Tompkins Collection—Arthur Gordon Tompkins Fund 1973.599.). (Photograph © Museum of Fine Arts, Boston.) ( http://www.mfa.org/collections/object/alkahest-of-paracelsus-34184 )

This perspective considers the idea and the reality of the ‘green’ solvent and explores the search by green chemists for a modern ‘alkahest’. It reviews the characteristics of the ideal solvent, examines the complexities of solvent selection and solvent replacement Footnote 1 and assesses the likelihood that one can be identified.

Sections “ Solvents and solvency ” and “ Solvents use, waste and pollution ” provide a brief introduction to solvents, their uses and their impact. Section “ Solvent replacements ” introduces solvent replacement methods for the reduction of such impact, followed by “ Solvents and sustainability ” section, which summarises efforts to identify new solvents which are more sustainable, within which the idea of the ‘green’ solvent is critically considered.

Solvents and solvency

Solvency, solvents and solutions are part of everyday life, from making a cup of coffee (and putting sweetener in it and washing the cup afterwards) to washing one’s hair in the shower, from applying and removing nail varnish to rinsing an apple under the tap before eating it, from applying a coat of paint to taking a soluble pain killer for a headache. But what is a solution? What is a solvent or a solute? What is the difference between a solution and a suspension, or a dispersion, a gel or a slurry?

The chemistry of solutions and solvents, therefore, is of interest in its own right (Reichardt and Welton 2010 ), being of wide chemical relevance, encompassing phase behaviour and the nature of solids, liquids and gases and the properties of mixtures of mainly liquids and solids. Solvation encompasses all types of inter-molecular interaction, such as van der Waals bonding, ionic/dipolar interactions, hydrogen bonding and charge transfer. Solvents used as media for chemical reactions have a profound effect on both the thermodynamics and kinetics of physical and chemical processes (Buncel et al. 2003 ).

Precisely which solvent will dissolve which solute and which solute will dissolve in which solvent (and why) are determined by a delicate balance of a range of factors that include the differing nature and relative strengths of inter-molecular forces in the pure solute and solvent and interactions between molecules of the solute and solvent (coupled with entropic factors governing the overall process of solute + solvent → solution). The simplest and oldest rule of thumb is that ‘ like dissolves like ’. A polar material, like common salt, sodium chloride, is more likely to dissolve in a polar solvent, like water, than in a non-polar solvent, like hexane. This empirical idea has been refined and extended (Barton 1991 ) (and will be discussed further in “ Solvent selection and design: empirical database and computational methods ” section) so that certain molecule-specific properties (such as polarisability, dipolarity, hydrogen-bond donor and acceptor ability) can be put into numerical form as ‘solubility parameters’ (Hansen 1969 ) or, latterly, as ‘solvatochromic parameters’ (Marcus 1993 ; Kamlet et al. 1986 ) for both solutes and solvents. Tables of such data are now available to guide the screening of the large number of possible solvents for those most likely (singly or in combination) to dissolve a solute of choice. Recent work, also discussed in “ Solvent selection and design: empirical database and computational methods ” section, has sought to incorporate toxicological and environmental characteristics into such screening.

Everyday use of solvents, such as in washing dishes or in cleaning the floor, involves the dissolution (or removal in some other way) of a complex mixture of materials, some adhering to the surface to be cleaned with varying degrees of tenacity. It is not surprising, therefore, that products designed for this purpose are formulations containing several components (some liquid, some solid) each designed to fulfil a particular additional function, such as wetting, penetration or dispersion (or even making the product smell nice), and not simply dissolution. Is the ‘solvent’ in this context the entire composition, or one (or all) of the liquid components?

How should one address the overall acceptability of such diverse products? Should they primarily be judged on the basis of the efficacy of the cleaning process (and how would one judge that?); or the cost-effectiveness of the product in bringing about the desired effect. Would one be prepared to pay more for an ‘excellent’ cleaning outcome compared with an ‘acceptable’ outcome? Or, should it be based on the environmental impact of the product, and would one be prepared to accept an inferior cleaning outcome if the product was (however judged) more environmentally benign?

Would these criteria be the same or different if one were to consider different types of solvent, such as one used as a paint stripper or nail-varnish remover or a shampoo rather than a floor cleaner? And, would the priority given to one criterion over another also be different, depending on how it was used?, Footnote 2 , Footnote 3

Solvents use, waste and pollution

The environmental and other consequences that arise from the large-scale use of solvents highlight the need to reconcile their usefulness with the minimisation of their impact. This has been a long-standing pre-occupation that has seen compounds used as solvents, such as benzene , Footnote 4 carbon disulfide and carbon tetrachloride, first used and then substituted as new substances became available which were more efficacious or less hazardous. Other solvents now also used much less in industry include diethyl ether (because of its flammability and tendency to form peroxides), di- iso -propyl ether (peroxide formation), hexane (neurotoxicity), nitromethane (explosion hazard) and ethylene glycol dimethyl ether (teratogenicity).

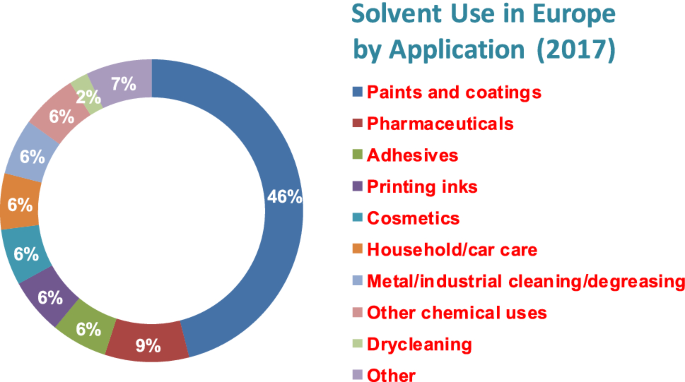

Solvents are ubiquitous and have a wide range of industrial uses (Table 1 ). It is estimated ( http://www.ihs.com/products/chemical/planning/special-reports/global-solvents.aspx ) that ca 28 million tons of solvents are used annually. About 5 million tons are used by the European solvents industry alone (Fig. 2 ). It is likely that similar quantities are emitted to the environment. European emissions inventories ( http://www.esig.org/wp-content/uploads/2020/06/ESIG-technical-paper-solvent-VOC-emissons-2018-final-corrected.pdf .) report 2–3 million tons of VOCs emitted per year during the period 2008–2018.

Solvents used in a variety of industrial applications in Europe in 2017 ( http://www.esig.org )

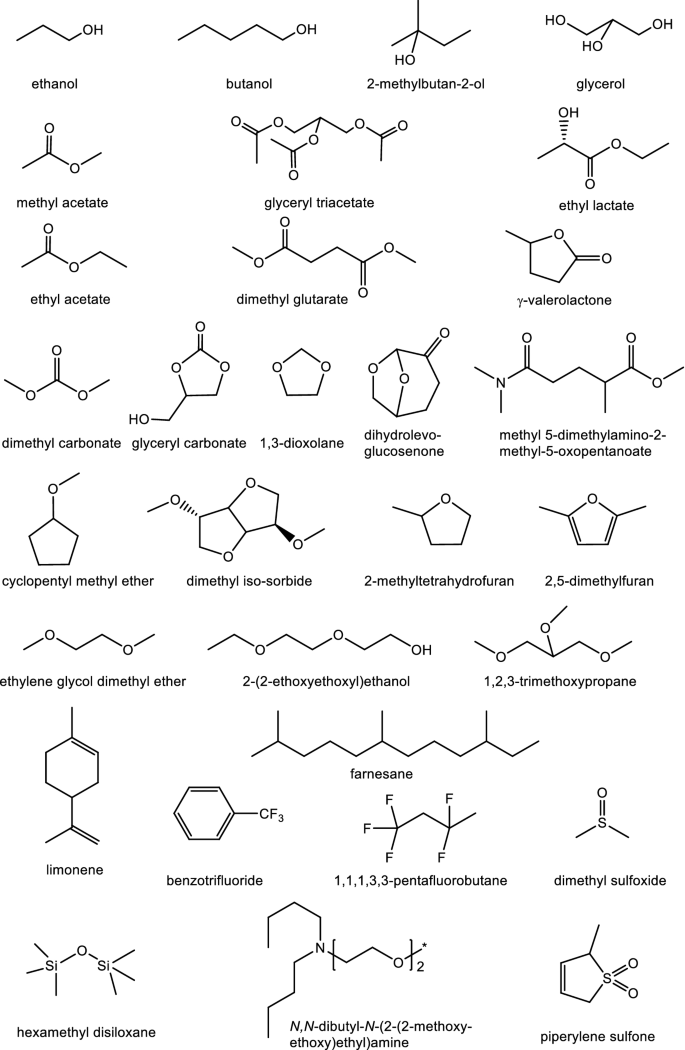

The wide range of solvents used in industry can be seen from early compilations (Flick 1998 ; Cheremisinoff 2003 ) which list > 1200 compounds from most compound types.

Waste in all its forms, its sources (domestic, institutional and industrial), impact and methods of ultimate disposal have long been a matter of public concern. There has, over the last 40–50 years, been increasing emphasis (through legislation, regulation, public pressure and competition) on the amount of waste produced, particularly in the chemical industry. A waste minimisation hierarchy ( http://en.wikipedia.org/wiki/Waste_hierarchy ), developed in the 1970s for the chemical process industry, was devised to encourage purposeful reduction in chemical waste, including solvents.

The terms ‘waste’ and ‘pollution’ tend to be used interchangeably, though in the case of chemicals production it is sometimes useful to make a distinction between them: ‘ waste ’ includes material, such as a stoichiometric co -product, which is inevitably produced in a process, as well as other by -product or processing material that has no commercial value. The safe disposal of such materials incurs costs; ‘ pollution ’, on the other hand, has come to be thought of as any product (waste or otherwise) which finds its way into the environment and may cause harm (however, defined). Solvents can fall into either category.

The four key sectors of the chemicals industry—oil refining, bulk or commodity chemicals, fine or effect chemicals and pharmaceuticals—differ in the proportion of by-product and waste formed in product manufacture (Sheldon 1992 , 2017 ). This is highest for pharmaceuticals much of whose production uses multi-step liquid-phase batch operations. A multiplicity of solvents is used in the preparation, isolation and purification of intermediates at various stages of the production of a single active pharmaceutical ingredient (API). Footnote 5 As much as 80% of life cycle process waste (excluding water) from the manufacture of APIs may arise from the use of solvents (Jiménez-González et al. 2004 ).

Applying the waste minimisation hierarchy to the use of solvents (and other by-products) in chemicals manufacture seeks to prioritise, first, avoidance (the development of ‘solvent-free’ processes (Kerton and Marriott 2013f ; Tanaka and Toda 2000 ) or the total elimination of the source of a solvent emission), then minimisation [via solvent reduction , recovery, reuse and recycle ) and finally, safe disposal (conversion to less harmful materials or complete destruction (with energy recovery, if appropriate)]. Each of these aspects continues to be the focus of research.

Note, however, solvent-containing formulated products generally emit volatile components during or after use. The highly distributed use of many such products, particularly those for use domestically, makes them very difficult, if not impossible, to contain or recover. Approaches to minimise impact are therefore different from those used in chemicals manufacture, being more reliant on solvent substitution or minimisation.

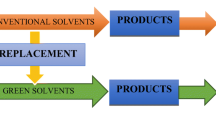

Solvent replacements