- Case Studies

- Free Coaching Session

Production Plan in Business Plan: A Comprehensive Guide to Success

Last Updated:

February 26, 2024

In any business venture, a solid production plan is crucial for success. A production plan serves as a roadmap that outlines the steps, resources, and strategies required to manufacture products or deliver services efficiently. By carefully crafting a production plan within a business plan, entrepreneurs can ensure optimal utilisation of resources, timely delivery, cost efficiency, and customer satisfaction. In this article, we will delve into the intricacies of creating an effective production plan in a business plan , exploring its key components, strategies, and the importance of aligning it with overall business objectives .

Key Takeaways on Production Plans in Business Planning

- A production plan : a detailed outline that guides efficient product manufacturing or service delivery.

- Importance of a production plan : provides a roadmap for operations, optimises resource utilisation, and aligns with customer demand.

- Key components : demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance.

- Strategies : lean manufacturing, JIT inventory, automation and technology integration, supplier relationship management, and continuous improvement.

- Benefits of a well-executed production plan : improved efficiency, reduced costs, enhanced product quality, and increased profitability.

What is a Production Plan?

A production Seamless Searches plan is a detailed outline that specifies the processes, resources, timelines, and strategies required to convert raw materials into finished goods or deliver services. It serves as a blueprint for the entire production cycle, guiding decision-making and resource allocation. The production plan considers factors such as demand forecasting, capacity planning, inventory management, and quality assurance to ensure efficient operations and optimal customer satisfaction.

Why is a Production Plan Important in a Business Plan?

The inclusion of a production plan in a business plan is vital for several reasons. First and foremost, it provides a clear roadmap for business operations, helping entrepreneurs and managers make informed decisions related to production processes. A well-developed production plan ensures that resources are utilised efficiently, minimising wastage and optimising productivity.

Additionally, a production plan allows businesses to align their production capabilities with customer demand. By forecasting market trends and analysing customer needs, businesses can develop a production plan that caters to current and future demands, thus avoiding overstocking or understocking situations.

Furthermore, a production plan helps businesses enhance their competitive advantage. By implementing strategies such as lean manufacturing and automation, companies can streamline their production processes, reduce costs, improve product quality, and ultimately outperform competitors.

Key Components of a Production Plan

To create an effective production plan, it is crucial to consider several key components. These components work together to ensure efficient operations and successful fulfilment of customer demands. Let's explore each component in detail.

Demand Forecasting

Demand forecasting is a critical aspect of production planning. By analysing historical data, market trends, and customer behaviour, businesses can predict future demand for their products or services. Accurate demand forecasting allows companies to optimise inventory levels, plan production capacity, and ensure timely delivery to customers.

One approach to demand forecasting is quantitative analysis, which involves analysing historical sales data to identify patterns and make predictions. Another approach is qualitative analysis, which incorporates market research, customer surveys, and expert opinions to gauge demand fluctuations. By combining both methods, businesses can develop a robust demand forecast, minimising the risk of underproduction or overproduction. Utilising a free notion template for demand forecasting can further streamline this process, allowing businesses to organise and analyse both quantitative and qualitative data efficiently in one centralised location.

Capacity Planning

Capacity planning involves determining the optimal production capacity required to meet projected demand. This includes assessing the production capabilities of existing resources, such as machinery, equipment, and labour, and identifying any gaps that need to be addressed. By conducting a thorough capacity analysis, businesses can ensure that their production capacity aligns with customer demand, avoiding bottlenecks or excess capacity.

An effective capacity plan takes into account factors such as production cycle times, labour availability, equipment maintenance, and production lead times. It helps businesses allocate resources efficiently, minimise production delays, and maintain a consistent level of output to meet customer expectations.

Inventory Management

Efficient inventory management is crucial for a successful production plan. It involves balancing the cost of holding inventory with the risk of stockouts. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring that sufficient stock is available to fulfil customer orders.

Inventory management techniques, such as the Economic Order Quantity (EOQ) model and Just-in-Time (JIT) inventory system, help businesses strike the right balance between inventory investment and customer demand. These methods consider factors such as order frequency, lead time, and carrying costs to optimise inventory levels and minimise the risk of excess or insufficient stock.

Resource Allocation

Resource allocation plays a pivotal role in a production plan. It involves assigning available resources, such as labour, materials, and equipment, to specific production tasks or projects. Effective resource allocation ensures that resources are utilised optimally, avoiding underutilisation or overutilisation.

To allocate resources efficiently, businesses must consider factors such as skill requirements, resource availability, project timelines, and cost constraints. By conducting a thorough resource analysis and implementing resource allocation strategies, businesses can streamline production processes, minimise bottlenecks, and maximise productivity.

Quality Assurance

Maintaining high-quality standards is essential for any production plan. Quality assurance involves implementing measures to monitor and control the quality of products or services throughout the production process. By adhering to quality standards and conducting regular inspections, businesses can minimise defects, ensure customer satisfaction, and build a positive brand reputation.

Quality assurance techniques, such as Total Quality Management (TQM) and Six Sigma , help businesses identify and rectify any quality-related issues. These methodologies involve continuous monitoring, process improvement, and employee training to enhance product quality and overall operational efficiency.

In addition to the core components of a production plan, it's also important for businesses to consider the broader aspects of their business strategy, including marketing and advertising. Understanding the costs and returns of different marketing approaches is crucial for comprehensive business planning. For instance, direct response advertising costs can vary significantly, but they offer the advantage of measurable responses from potential customers. This type of advertising can be a valuable strategy for businesses looking to directly engage with their target audience and track the effectiveness of their marketing efforts.

Strategies for Developing an Effective Production Plan

Developing an effective production plan requires implementing various strategies and best practices. By incorporating these strategies into the production planning process, businesses can optimise operations and drive success. Let's explore some key strategies in detail.

Lean Manufacturing

Lean manufacturing is a systematic Seamless Searches approach aimed at eliminating waste and improving efficiency in production processes. It emphasises the concept of continuous improvement and focuses on creating value for the customer while minimising non-value-added activities.

By adopting lean manufacturing principles, such as just-in-time production, standardised work processes, and visual management, businesses can streamline operations, reduce lead times, and eliminate unnecessary costs. Lean manufacturing not only improves productivity but also enhances product quality and customer satisfaction.

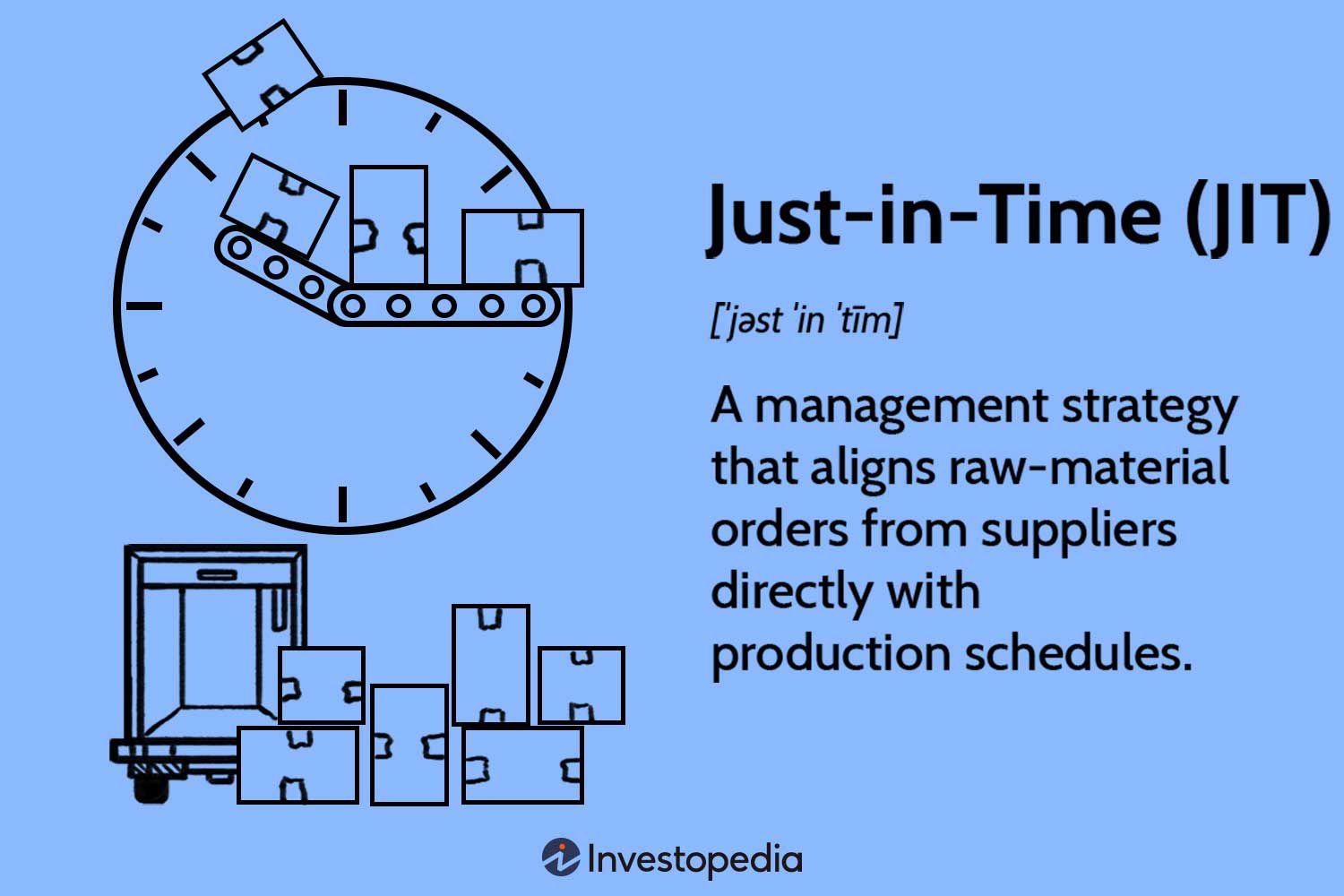

Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory is a strategy that aims to minimise inventory levels by receiving goods or materials just when they are needed for production. This strategy eliminates the need for excess inventory storage, reducing carrying costs and the risk of obsolete inventory.

By implementing a JIT inventory system, businesses can optimise cash flow, reduce storage space requirements, and improve overall supply chain efficiency. However, it requires robust coordination with suppliers, accurate demand forecasting, and efficient logistics management to ensure timely delivery of materials.

Automation and Technology Integration

Automation and technology integration play a crucial role in modern production planning. By leveraging technology, businesses can streamline processes, enhance productivity, and reduce human error. Automation can be implemented in various aspects of production, including material handling, assembly, testing, and quality control.

Continuous Improvement

Continuous improvement is a fundamental principle of effective production planning. It involves regularly evaluating production processes, identifying areas for improvement, and implementing changes to enhance efficiency and quality.

By fostering a culture of continuous improvement, businesses can drive innovation, optimise resource utilisation, and stay ahead of competitors. Techniques such as Kaizen, Six Sigma, and value stream mapping can help businesses identify inefficiencies, eliminate waste, and streamline production workflows.

Frequently Asked Questions (FAQs)

What is the role of a production plan in business planning.

A1: A production plan plays a crucial role in business planning by providing a roadmap for efficient production processes. It helps align production capabilities with customer demand, optimise resource utilisation, and ensure timely delivery of products or services.

How does a production plan affect overall business profitability?

A2: A well-developed production plan can significantly impact business profitability. By optimising production processes, reducing costs, and enhancing product quality, businesses can improve their profit margins and gain a competitive edge in the market.

What are the common challenges faced in production planning?

A3: Production planning can present various challenges, such as inaccurate demand forecasting, capacity constraints, supply chain disruptions, and quality control issues. Overcoming these challenges requires robust planning, effective communication, and the implementation of appropriate strategies and technologies.

What is the difference between short-term and long-term production planning?

A4: Short-term production planning focuses on immediate production requirements, such as daily or weekly schedules. Long-term production planning, on the other hand, involves strategic decisions related to capacity expansion, technology investments, and market expansion, spanning months or even years.

How can a production plan be adjusted to accommodate changes in demand?

A5: To accommodate changes in demand, businesses can adopt flexible production strategies such as agile manufacturing or dynamic scheduling. These approaches allow for quick adjustments to production levels, resource allocation, and inventory management based on fluctuating customer demand.

In conclusion, a well-crafted production plan is essential for business success. By incorporating a production plan into a comprehensive business plan, entrepreneurs can optimise resource utilisation, meet customer demands, enhance product quality, and drive profitability. Through effective demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance, businesses can streamline production processes and gain a competitive edge in the market.

Related Articles:

Client Success!! Watch THIS >>>

Client Success - Case Study

© 2016 - 2024 Robin Waite. All rights reserved.

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

You’ve come to the right place to create your Manufacturing business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Manufacturing companies.

Below is a template to help you create each section of your Manufacturing business plan.

Executive Summary

Business overview.

Perfect Snacks, located in Lincoln, Nebraska, is a food manufacturing company that specializes in the production of snack foods and packaged goods. We manufacture an extensive line of snack products, including trail mix, gummies, and chocolate. Our company focuses on quality and only uses the best natural ingredients in our products. We will primarily sell our products to grocery stores and other establishments that sell snacks, but will also sell bulk orders to individual customers through our website.

Perfect Snacks was founded by Joe Boseley. Joe has been working on the manufacturing company concept over the past few years and began networking with grocery store clients and locating the land to build his manufacturing and distribution center. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Product Offering

Perfect Snacks will manufacture an extensive list of sweet, salty, and healthy snacks. Some of our initial products will include:

We will primarily sell our products to grocery stores, recreation centers, and other businesses that sell snacks in bulk. Consumers can find our products in stores or buy them in bulk on our website.

Customer Focus

Perfect Snacks will primarily serve the residents of Lincoln, Nebraska. The community has a large population of families and children, who are the primary consumers of snack foods. Therefore, we will market our products to recreational centers, schools, grocery stores, and other establishments that sell snacks to children and their parents.

Management Team

Perfect Snacks is owned by Joe Boseley, a local entrepreneur who has worked in various warehouses and manufacturing companies in Lincoln, Nebraska. Working in the manufacturing industry and in warehouses, Joe is very familiar with the processing and distribution of packaged foods. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Joe will utilize his past experience with developing staff roles and functions. He is also very familiar with the manufacturing equipment and plans to purchase the latest technology that is efficient and cost effective. His contacts have allowed him to gain concrete Letters of Intent from local supermarket chains to have his manufactured goods in their stores.

Success Factors

Perfect Snacks will be able to achieve success by offering the following competitive advantages:

- Taste: Perfect Snacks’ snack products will be made with the highest quality ingredients and offer quality over quantity.

- Price: Perfect Snacks is able to offer the highest quality snacks at a competitive price point.

- Community Relations: Perfect Snacks will be a pillar in the community and be heavily involved in family-related activities in the area. It will sponsor events, provide snacks for schools and daycares at a discounted price, and donate a portion of its proceeds to area family-related charities and organizations.

- Proprietary Technology: Perfect Snacks will invest heavily on the latest technology to manufacture the snack foods for distribution. It will ensure the food products are made safely and free from any harmful chemicals and ingredients.

Financial Highlights

Perfect Snacks is seeking a total funding of $1,200,000 of debt capital to open its manufacturing company. The capital will be used for funding capital expenditures, salaries, marketing expenses, and working capital. Specifically, these funds will be used as follows:

- Manufacturing facility design/build-out: $400,000

- Equipment and supplies: $375,000

- Initial inventory: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $250,000

- Marketing costs: $50,000

- Working capital: $25,000

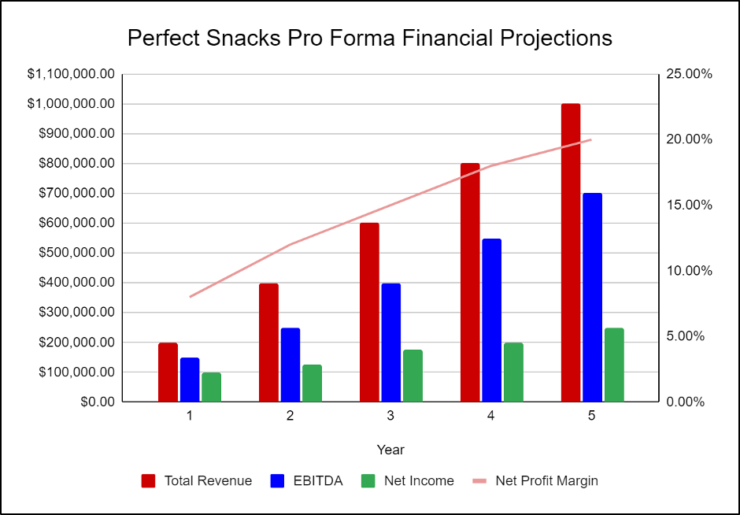

The following graph below outlines the pro forma financial projections for Perfect Snacks.

Company Overview

Who is perfect snacks, perfect snacks history.

After conducting a market analysis, Joe Boseley began surveying the local vacant warehouse space and decided on a parcel of land to construct the warehouse and distribution center. Joe incorporated Perfect Snacks as a Limited Liability Corporation on January 1st, 2023.

Once the land is acquired for the warehouse space, construction can begin to build-out the manufacturing facility.

Since incorporation, the Company has achieved the following milestones:

- Located a vacant lot that would be ideal for a manufacturing facility

- Developed the company’s name, logo, and website

- Hired a general contractor and architect for the build-out of the warehouse, small office, and distribution area

- Determined equipment and necessary supplies

- Determined beginning inventory

- Attained Letters of Intent from supermarket clients

- Began recruiting key employees

Perfect Snacks Services

Industry analysis.

The Manufacturing sector’s performance is largely attributable to the value of the US dollar, commodity prices, policy decisions and US manufacturing capacity. Food manufacturing has a history of success as it produces a basic human need. According to Grand View Research, the industry is currently valued at $121 billion and is expected to expand at a compound annual growth rate of 9.5% from now until 2030.

Commodity prices are currently stabilizing from coronavirus-induced volatility and renewed demand, both in the United States and global economies, which is anticipated to facilitate revenue expansion for manufacturers. Moreover, shifting technological change in the Manufacturing sector is anticipated to benefit large, developed economies, such as the United States. Therefore, now is a great time to start a new food manufacturing company in the U.S.

Customer Analysis

Demographic profile of target market.

Perfect Snacks will serve the community residents of Lincoln, Nebraska and its surrounding areas. The community of Lincoln, Nebraska has thousands of households that have children. Statistics show that the main consumers of snack products are children of all ages. They are regularly placed in school lunchboxes, afterschool snacks and programs, and at weekend sporting events. Therefore, we will market to locations where snacks are bought by children or their parents, such as grocery stores, recreational centers, and schools.

The precise demographics Lincoln, Nebraska is as follows:

Customer Segmentation

Perfect Snacks will primarily target the following customer profiles:

- Grocery stores and recreational centers

Competitive Analysis

Direct and indirect competitors.

Perfect Snacks will face competition from other companies with similar business profiles. A description of each competitor company is below.

Snacks N More

Snacks N More is another local manufacturing company that provides snack food to the immediate area. Established over thirty years ago, the company has the knowledge and expertise in food processing, commercialization, and packaging. They are known as a recognized ingredient supplier for the foodservice industry. Their portfolio of products include a variety of nuts, snacks, confections, and dry-blend ingredients. As a private label manufacturer, Snack’s More produces a full line of non-chocolate candy, nuts, and fruit-flavored snacks. The company is known for their fruit flavored snacks, dried raisins, nut mixes, and producing ingredients for local restaurants and establishments. Their line of nuts and dried fruits are often used for baking purposes.

Jaxon’s Candy

Jaxon’s Candy is a manufacturer of all things candy related. As a contract manufacturer, the company works with many companies to create their custom designed confections. Their large 50,000 square foot facility produces over 300,000 pounds of candy every month. All of the products are highly concentrated either in sugar or chocolate, or both. Jaxon’s Candy also designs and manufactures their own custom packaging. The candy produced is also kosher certified, gluten free, peanut free, and non-GMO.

Jaxon’s Candy currently manufactures candy for the following brands – Tommy Candy, Laffy Town, Chocowhoawhoa, Jellylicious, Healthee Candeee, and Sticky Teeth. Jaxon’s Candy can be found in grocery stores and convenient stores along the west coast of the United States.

Gimmy Candy

Gimmy Candy is located in the midwestern portion of the United States and boasts a facility of over 1 million square feet. Their fleet of transportation trucks distributes throughout the continental United States and is considered one of the largest candy manufacturers in the country. Their product portfolio includes assorted chocolates, gummy candy, hard candy, fruit candy, as well as gums and mints. Gimmy Candy was established in 1947 and has grown to be a model of manufacturing companies the industry uses as a model of sustainability and profitability. Their lineup of candy products can be found in every single grocery store and convenient store in the country. Gimmy Candy is considering expanding its distribution globally and start exporting its candy products to Asia, Canada, Europe, and South America. As one of the largest privately held companies in the United States, Gimmy Candy is also considered a top employer in the country and offers its employees a generous benefits package.

Competitive Advantage

Perfect Snacks will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

Perfect Snacks will offer the unique value proposition to its clientele:

- Fresh and comforting taste

- Community family advocate

- Developed with proprietary technology

- Manufactured with fresh, quality ingredients

- Affordable price

Promotions Strategy

The promotions strategy for Perfect Snacks is as follows:

Social Media

Perfect Snacks will invest heavily in a social media advertising campaign. The brand manager will create the company’s social media accounts and invest in ads on all social media accounts. It will use targeted marketing to appeal to the target demographics.

Website/SEO

Perfect Snacks will invest heavily in developing a professional website that displays all of the features and benefits of the snack products. It will also invest heavily in SEO so that the brand’s website will appear at the top of search engine results.

Major Publications

We will also invest in advertising in selected larger publications until we have achieved significant brand awareness. Advertisements such as billboards and commercials will be shown during peak tv watching time and the billboards will be placed in highly trafficked areas.

Sponsorships

Perfect Snacks will also invest in sponsoring certain athletic and school events so that their banners and collateral material are displayed all over the event where numerous parents and children are at.

Perfect Snacks’s pricing will be moderate so consumers feel they receive great value when purchasing our snack products.

Operations Plan

The following will be the operations plan for Perfect Snacks.

Operation Functions:

- Joe Boseley will be the CEO of Perfect Snacks. He will oversee the general operations and executive aspects of the business.

- Joe is joined by Candace Smith who will act as the warehouse manager. She will train and manage the staff as well as oversee general production of our products.

- Joe will hire an Administrative Assistant, Marketing Manager, and Accountant, to handle the administrative, marketing, and bookkeeping functions of the company.

- Joe will also hire several employees to manufacture our products and maintain the equipment and machinery.

Milestones:

Perfect Snacks will have the following milestones complete in the next six months.

- 02/202X Finalize lease agreement

- 03/202X Design and build out Perfect Snacks

- 04/202X Hire and train initial staff

- 05/202X Kickoff of promotional campaign

- 06/202X Launch Perfect Snacks

- 07/202X Reach break-even

Financial Plan

Key revenue & costs.

Perfect Snacks’s revenues will come primarily from its snack food sales. The company will sell the packaged snacks in local grocery stores, convenience stores, and other locations. As the company’s revenues increase, it will look to gain a wider distribution area.

The land purchase, equipment, supplies, opening inventory, and labor expenses will be the key cost drivers of Perfect Snacks. Other cost drivers include taxes, business insurance, and marketing expenditures.

Funding Requirements and Use of Funds

Key assumptions.

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and pay off the startup business loan.

- Average order value: $250

Financial Projections

Income statement, balance sheet, cash flow statement, manufacturing business plan faqs, what is a manufacturing business plan.

A manufacturing business plan is a plan to start and/or grow your manufacturing business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Manufacturing business plan using our Manufacturing Business Plan Template here .

What are the Main Types of Manufacturing Businesses?

There are a number of different kinds of manufacturing businesses , some examples include: Garment manufacturing, Food product manufacturing, Diaper manufacturing, Tile manufacturing, and Toy manufacturing.

How Do You Get Funding for Your Manufacturing Business Plan?

Manufacturing businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Manufacturing Business?

Starting a manufacturing business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Manufacturing Business Plan - The first step in starting a business is to create a detailed manufacturing business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your manufacturing business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your manufacturing business is in compliance with local laws.

3. Register Your Manufacturing Business - Once you have chosen a legal structure, the next step is to register your manufacturing business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your manufacturing business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Manufacturing Equipment & Supplies - In order to start your manufacturing business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your manufacturing business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Manufacturing & Wholesale Business Plans

Cleaning & cosmetics manufacturing business plans.

- Chemical Laboratory Business Plan

- Cleaning Products Business Plan

- Cosmetic Herbal Sundries Business Plan

- Cosmetics Manufacturing Business Plan

- Diaper Manufacturer Business Plan

- Pet Products Manufacturer Business Plan

- Soap Manufacturer Business Plan

- Water Purification Business Plan

Clothing & Accessories Manufacturing Business Plans

- Artificial Flowers Import Business Plan

- Clothing Manufacturer Business Plan

- Custom Pottery Business Plan

- Custom Printed T-Shirts Business Plan

- Export Watch Manufacturer Business Plan

- Promotional Products Maker Business Plan

- Surf Clothing and Sportswear Business Plan

Construction Manufacturing Business Plans

- Building Construction Business Plan

- Construction Manufacturer Business Plan

- Formwork Construction Business Plan

- Wholesale Landscape Products Business Plan

Food Manufacturing Business Plans

- Brewery Business Plan

- Pasta Manufacturer Business Plan

- Salsa Manufacturer Business Plan

- Vending Services Business Plan

- Wholesale Food Manufacturer Business Plan

- Wholesale Juice Business Plan

Furniture Manufacturing Business Plans

- Drapery Fabricator Business Plan

- Furniture Import Business Plan

- Furniture Manufacturer Business Plan

- Garden Furniture Maker Business Plan

- Office Furniture Manufacturer Business Plan

- Pet Supplies Business Plan

- Retail Furniture Manufacturer Business Plan

- UK Furniture Manufacturer Business Plan

Machine & Equipment Manufacturing Business Plans

- Aircraft Equipment Maker Business Plan

- Commercial Catalog Sales Business Plan

- Electronic Engineering Business Plan

- Heavy Equipment Maker Business Plan

- Internet Media Advertising Business Plan

- Machine Tooling Business Plan

- Manufacturing - Custom Parts Business Plan

- Solar Water Heater Distributor Business Plan

- Surveyor Instrument Business Plan

- Tracking Device Maker Business Plan

Medical Equipment Manufacturing Business Plans

- Eye Surgery Equipment Maker Business Plan

- Hearing Testing Systems Business Plan

- Lift Bed Manufacturer Business Plan

- Medical Equipment Business Plan

- Medical Equipment Developer Business Plan

- Medicine Dispenser Business Plan

- Surgical Medical Equipment Business Plan

Recycling Business Plans

- Garden Products Recycling Business Plan

- Pallet Manufacturer Business Plan

- Plastics Recycling Business Plan

- Recycling Energy Conversion Business Plan

- Recycling Waste Materials Business Plan

Sporting Goods Manufacturing Business Plans

- Bicycle Manufacturer Business Plan

- Golf Club Manufacturer Business Plan

- Inline Skating Products Business Plan

- Outdoor Gear Designer Business Plan

- Sports Medical Equipment Business Plan

Tobacco & Cannabis Manufacturing Business Plans

- Cannabis Dispensary Business Plan

- Cigar Manufacturing Business Plan

- Tobacco Retail Business Plan

Wholesale & Distributor Business Plans

- Coffee Distribution Business Plan

- Farm Machinery Manufacturer Business Plan

- Fire Rescue E-commerce Business Plan

- Wholesale Bicycle Distributor Business Plan

With more and more small to medium-sized businesses emerging, the need for efficient and reliable suppliers grows with it. This means there is plenty of opportunities for modern manufacturers and wholesalers to step up to the plate.

If you’re planning to start a manufacturing, fabrication, or production business you’ll need a business plan to do it. To help you get started, check out our library of sample plans to be sure you’re covering everything from sourcing your raw materials to budgeting for plant and equipment.

Tax Season Savings

Get 40% off LivePlan

The #1 rated business plan software

Discover the world’s #1 plan building software

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

Over the past 20+ years, we have helped over 7,000 entrepreneurs and business owners create business plans to start and grow their manufacturing businesses. On this page, we will first give you some background information with regards to the importance of business planning. We will then go through a manufacturing business plan template step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What Is a Business Plan?

A business plan provides a snapshot of your manufacturing business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategy for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan

If you’re looking to start a new manufacturing business, or grow your existing manufacturing business, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your manufacturing business in order to improve your chances of success. Your business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Manufacturing Businesses

With regards to funding, the main sources of funding for a manufacturing business are personal savings, credit cards, bank loans and angel investors. With regards to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to confirm that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business.

Personal savings is the other most common form of funding for a manufacturing business. Venture capitalists will usually not fund a manufacturing business. They might consider funding a manufacturing business with a national presence, but never an individual location. This is because most venture capitalists are looking for millions of dollars in return when they make an investment, and an individual location could never achieve such results. With that said, personal savings and bank loans are the most common funding paths for manufacturing businesses.

Finish Your Business Plan Today!

How to write a business plan for a manufacturing company.

If you want to start a manufacturing business or expand your current one, you need a business plan. Below we detail what you should include in each section of your own business plan:

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status. For example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Next, provide an overview of each of the subsequent sections of your plan. For example, give a brief overview of the manufacturing industry. Discuss the type of manufacturing business you are operating. Detail your direct competitors. Give an overview of your target market. Provide a snapshot of your marketing strategy. Identify the key members of your team. And offer an overview of your financial plan.

Company Analysis

In your company analysis, you will detail the type of business you are operating.

There are many types of manufacturing businesses, such as:

- Clothing manufacturing

- Garment manufacturing

- Food product manufacturing

- Diaper manufacturing

- Tile manufacturing

- Toy manufacturing

- Soap and detergent manufacturing

- Mobile accessories manufacturing

- Mattress manufacturing

- Bicycle manufacturing

- Pillow manufacturing

- Brick manufacturing

- Toilet paper manufacturing

- Furniture manufacturing

- Peanut butter manufacturing

- Cosmetics manufacturing

- Footwear manufacturing

In addition to explaining the type of manufacturing business you will operate, the Company Analysis section of your business plan needs to provide background on the business.

Include answers to question such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, number of positive reviews, number of wholesale contracts, etc.

- Your legal structure. Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the manufacturing industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the manufacturing industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your strategy, particularly if your research identifies market trends.

The third reason for market research is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section:

- How big is the manufacturing industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential market for your manufacturing business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section must detail the customers you serve and/or expect to serve.

The following are examples of target market segments: wholesalers, other manufacturers, exports, retailers.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of manufacturing business you operate. Clearly, retailers would respond to different marketing promotions than export markets, for example.

Try to break out your target market in terms of their demographic and psychographic profiles. With regards to demographics, include a discussion of the ages, genders, locations and income levels of the customers you seek to serve. Because most manufacturing businesses primarily serve customers living in their same city or town, such demographic information is easy to find on government websites.

Psychographic profiles explain the wants and needs of your target customers. The more you can understand and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Manufacturing Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

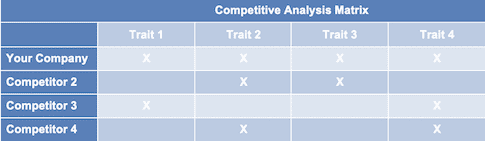

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other manufacturing businesses.

Indirect competitors are other options that customers have to purchase from that aren’t direct competitors. This includes manufacturers in other niches, as well as those vertically integrated businesses that make their own product. You need to mention such competition as well.

With regards to direct competition, you want to describe the other manufacturing businesses with which you compete. Most likely, your direct competitors will be house flippers located very close to your location.

For each such competitor, provide an overview of their businesses and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as:

- What types of customers do they serve?

- What types of products do they manufacture?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you provide high quality manufacturing practices?

- Will you provide services that your competitors don’t offer?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a manufacturing business, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of manufacturing company that you documented in your Company Analysis. Then, detail the specific products you will be offering. For example, in addition to manufacturing, will you provide R&D, design, prototyping or any other services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your marketing plan, you are presenting the services you offer and their prices.

Place : Place refers to the location of your manufacturing company. Document your location and mention how the location will impact your success. For example, is your manufacturing business located near a distribution hub, etc. Discuss how your location might be the ideal location for your customers.

Promotions : The final part is the promotions section. Here you will document how you will drive customers to your location(s). The following are some promotional methods you might consider:

- Advertising in local papers and magazines

- Reaching out to local websites

- Social media marketing

- Local radio advertising

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your manufacturing business, including sourcing inputs, designing processes, managing production, coordinating logistics and meeting with potential buyers.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to secure your 1,000 th contract, or when you hope to reach $X in revenue. It could also be when you expect to expand your manufacturing business to a new city.

Management Team

To demonstrate your manufacturing business’ ability to succeed, a strong team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally you and/or your team members have direct experience in managing manufacturing businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act like mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in manufacturing or successfully running small businesses.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet and cash flow statements.

Income Statement : an income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenues and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you offer short-run production, or will you focus strictly on long-run? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets : Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your manufacturing business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a bank writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement : Your cash flow statement will help determine how much money you need to start or grow your business, and make sure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

In developing your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a manufacturing business:

- Location build-out including design fees, construction, etc.

- Cost of equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Taxes and permits

- Legal expenses

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your production facility blueprint, or capabilities specifications.

Putting together a business plan for your manufacturing business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will really understand the manufacturing industry, your competition, and your customers. You will have developed a marketing plan and will really understand what it takes to launch and grow a successful manufacturing business.

Manufacturing Business Plan FAQs

What is the easiest way to complete my manufacturing business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily complete your Manufacturing Business Plan.

What is the Goal of a Business Plan's Executive Summary?

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status; for example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Don’t you wish there was a faster, easier way to finish your Manufacturing business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how Growthink’s professional business plan consulting services can create your business plan for you.

Other Helpful Business Plan Articles & Templates

- Search Search Please fill out this field.

- Building Your Business

- Becoming an Owner

- Business Plans

How To Write the Operations Plan Section of the Business Plan

Susan Ward wrote about small businesses for The Balance for 18 years. She has run an IT consulting firm and designed and presented courses on how to promote small businesses.

:max_bytes(150000):strip_icc():format(webp)/SusanWardLaptop2crop1-57aa62eb5f9b58974a12bac9.jpg)

Stage of Development Section

Production process section, the bottom line, frequently asked questions (faqs).

The operations plan is the section of your business plan that gives an overview of your workflow, supply chains, and similar aspects of your business. Any key details of how your business physically produces goods or services will be included in this section.

You need an operations plan to help others understand how you'll deliver on your promise to turn a profit. Keep reading to learn what to include in your operations plan.

Key Takeaways

- The operations plan section should include general operational details that help investors understand the physical details of your vision.

- Details in the operations plan include information about any physical plants, equipment, assets, and more.

- The operations plan can also serve as a checklist for startups; it includes a list of everything that must be done to start turning a profit.

In your business plan , the operations plan section describes the physical necessities of your business's operation, such as your physical location, facilities, and equipment. Depending on what kind of business you'll be operating, it may also include information about inventory requirements, suppliers, and a description of the manufacturing process.

Keeping focused on the bottom line will help you organize this part of the business plan.

Think of the operating plan as an outline of the capital and expense requirements your business will need to operate from day to day.

You need to do two things for the reader of your business plan in the operations section: show what you've done so far to get your business off the ground and demonstrate that you understand the manufacturing or delivery process of producing your product or service.

When you're writing this section of the operations plan, start by explaining what you've done to date to get the business operational, then follow up with an explanation of what still needs to be done. The following should be included:

Production Workflow

A high-level, step-by-step description of how your product or service will be made, identifying the problems that may occur in the production process. Follow this with a subsection titled "Risks," which outlines the potential problems that may interfere with the production process and what you're going to do to negate these risks. If any part of the production process can expose employees to hazards, describe how employees will be trained in dealing with safety issues. If hazardous materials will be used, describe how these will be safely stored, handled, and disposed.

Industry Association Memberships

Show your awareness of your industry's local, regional, or national standards and regulations by telling which industry organizations you are already a member of and which ones you plan to join. This is also an opportunity to outline what steps you've taken to comply with the laws and regulations that apply to your industry.

Supply Chains

An explanation of who your suppliers are and their prices, terms, and conditions. Describe what alternative arrangements you have made or will make if these suppliers let you down.

Quality Control

An explanation of the quality control measures that you've set up or are going to establish. For example, if you intend to pursue some form of quality control certification such as ISO 9000, describe how you will accomplish this.

While you can think of the stage of the development part of the operations plan as an overview, the production process section lays out the details of your business's day-to-day operations. Remember, your goal for writing this business plan section is to demonstrate your understanding of your product or service's manufacturing or delivery process.

When writing this section, you can use the headings below as subheadings and then provide the details in paragraph format. Leave out any topic that does not apply to your particular business.

Do an outline of your business's day-to-day operations, including your hours of operation and the days the business will be open. If the business is seasonal, be sure to say so.

The Physical Plant

Describe the type, site, and location of premises for your business. If applicable, include drawings of the building, copies of lease agreements, and recent real estate appraisals. You need to show how much the land or buildings required for your business operations are worth and tell why they're important to your proposed business.

The same goes for equipment. Besides describing the equipment necessary and how much of it you need, you also need to include its worth and cost and explain any financing arrangements.

Make a list of your assets , such as land, buildings, inventory, furniture, equipment, and vehicles. Include legal descriptions and the worth of each asset.

Special Requirements

If your business has any special requirements, such as water or power needs, ventilation, drainage, etc., provide the details in your operating plan, as well as what you've done to secure the necessary permissions.

State where you're going to get the materials you need to produce your product or service and explain what terms you've negotiated with suppliers.

Explain how long it takes to produce a unit and when you'll be able to start producing your product or service. Include factors that may affect the time frame of production and describe how you'll deal with potential challenges such as rush orders.

Explain how you'll keep track of inventory .

Feasibility

Describe any product testing, price testing, or prototype testing that you've done on your product or service.

Give details of product cost estimates.

Once you've worked through this business plan section, you'll not only have a detailed operations plan to show your readers, but you'll also have a convenient list of what needs to be done next to make your business a reality. Writing this document gives you a chance to crystalize your business ideas into a clear checklist that you can reference. As you check items off the list, use it to explain your vision to investors, partners, and others within your organization.

What is an operations plan?

An operations plan is one section of a company's business plan. This section conveys the physical requirements for your business's operations, including supply chains, workflow , and quality control processes.

What is the main difference between the operations plan and the financial plan?

The operations plan and financial plan tackle similar issues, in that they seek to explain how the business will turn a profit. The operations plan approaches this issue from a physical perspective, such as property, routes, and locations. The financial plan explains how revenue and expenses will ultimately lead to the business's success.

Want to read more content like this? Sign up for The Balance's newsletter for daily insights, analysis, and financial tips, all delivered straight to your inbox every morning!

Business Plan Template for Manufacturing Company

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

Starting a manufacturing company can be an exciting but challenging endeavor. To ensure success, you need a solid business plan that covers all the essential aspects of your operations. That's where ClickUp's Business Plan Template for Manufacturing Companies comes in!

Our template provides a comprehensive framework for outlining your company's goals, conducting market analysis, projecting finances, and strategizing your operations. With ClickUp's Business Plan Template, you'll be able to:

- Clearly define your company's vision, mission, and objectives

- Conduct a thorough market analysis to understand your target audience and competitors

- Develop financial projections and budgets to secure funding and attract investors

- Create operational strategies to optimize production, logistics, and quality control

Whether you're a seasoned entrepreneur or just starting out, our Business Plan Template will guide you through the process of building a successful manufacturing company. Don't miss out on the opportunity to turn your vision into reality—get started with ClickUp today!

Business Plan Template for Manufacturing Company Benefits

Creating a solid business plan is crucial for success in the manufacturing industry. By using the Business Plan Template for Manufacturing Company, you can:

- Clearly define your company's vision, mission, and goals

- Conduct a thorough market analysis to identify target customers and competitors

- Develop a comprehensive financial plan, including revenue projections and cost analysis

- Outline your manufacturing processes, supply chain management, and quality control measures

- Present a professional and well-structured document to potential investors and lenders

- Guide strategic decision-making and ensure alignment with your long-term objectives

- Monitor and track progress towards your business milestones and objectives

Main Elements of Manufacturing Company Business Plan Template

When it comes to creating a comprehensive business plan for your manufacturing company, ClickUp has you covered with its Business Plan Template. Here are the main elements you'll find in this template:

- Custom Statuses: Keep track of the progress of different sections of your business plan with statuses like Complete, In Progress, Needs Revision, and To Do.

- Custom Fields: Add important details to your business plan using custom fields such as Reference, Approved, and Section, allowing you to easily organize and categorize information.

- Custom Views: Access different perspectives of your business plan using views like Topics, Status, Timeline, Business Plan, and Getting Started Guide, making it easy to navigate and present your plan effectively.

- Document Collaboration: Collaborate with your team in real-time using ClickUp's Docs feature to work together on your business plan.

- Task Management: Break down your business plan into actionable tasks, assign them to team members, set due dates, and track progress using ClickUp's powerful task management features.

How To Use Business Plan Template for Manufacturing Company

If you're looking to create a business plan for your manufacturing company, follow these 6 steps using ClickUp's Business Plan Template:

1. Define your company's mission and vision

Start by clearly defining the mission and vision of your manufacturing company. What do you aim to achieve and how do you plan to do it? This will serve as the guiding principles for your business plan.

Use a Doc in ClickUp to outline your company's mission and vision statements.

2. Conduct market research

Thorough market research is essential to understand your target audience, competitors, and industry trends. Identify your niche, analyze customer needs, and assess the competitive landscape. This will help you position your manufacturing company effectively.

Use the Table view in ClickUp to compile and analyze market data, including customer demographics, competitor analysis, and industry trends.

3. Develop your product offerings

Outline the products and services your manufacturing company will offer. Determine the unique selling points of your offerings and how they address customer needs. Consider factors such as pricing, quality, and delivery timelines.

Use tasks in ClickUp to create a product development plan and assign tasks to team members responsible for designing, manufacturing, and testing the products.

4. Create a marketing and sales strategy

Define your marketing and sales strategies to promote your manufacturing company. Identify the channels and tactics you will use to reach your target audience. This may include digital marketing, trade shows, partnerships, or direct sales.

Use Goals in ClickUp to set specific marketing and sales objectives, such as lead generation targets or revenue goals.

5. Establish operational processes

Develop a plan for your manufacturing processes, including procurement, production, quality control, and logistics. Define the roles and responsibilities of your team members and ensure smooth coordination across departments.

Use Automations in ClickUp to streamline your operational processes by automating repetitive tasks and setting up notifications for key milestones.

6. Create financial projections

Project your financials, including revenue, expenses, and cash flow projections for the next few years. Consider factors such as production costs, pricing, sales volume, and market demand. This will help you assess the viability and profitability of your manufacturing company.

Use Dashboards in ClickUp to track and visualize your financial projections, allowing you to monitor your company's performance and make informed decisions.

By following these steps and utilizing ClickUp's Business Plan Template, you'll be well-equipped to create a comprehensive and effective business plan for your manufacturing company.

Get Started with ClickUp’s Business Plan Template for Manufacturing Company

Entrepreneurs and business owners in the manufacturing industry can use the Business Plan Template for Manufacturing Company to create a comprehensive plan for their business.

First, hit "Add Template" to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you'd like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to create a solid business plan:

- Use the Topics View to outline and organize the different sections of your business plan, such as Executive Summary, Market Analysis, Financial Projections, and Operational Strategies.

- The Status View will help you track the progress of each section, with statuses like Complete, In Progress, Needs Revision, and To Do.

- The Timeline View will allow you to set deadlines and visualize the timeline for completing each section of your business plan.

- Use the Business Plan View to have a comprehensive overview of your entire plan, with all the sections and details in one place.

- The Getting Started Guide View will provide you with step-by-step instructions and tips on how to effectively use the template and create a successful business plan.

- Customize the template by adding custom fields like Reference, Approved, and Section to provide additional information and track important details.

- Update statuses and custom fields as you make progress and receive feedback from stakeholders.

- Monitor and analyze your business plan to ensure it aligns with your goals and attracts investors.

- Business Plan Template for Distance Learning

- Business Plan Template for Medication Errors

- Business Plan Template for Little Caesars

- Business Plan Template for Technology

- Business Plan Template for Gym Owners

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

- See all articles

- Business tips

- Inventory management

- Manufacturing

- Product updates

Manufacturing business processes to streamline your operations

Starting out, many small manufacturers just do what they do, day in and day out, without much thought to efficiency or effectiveness. As the business grows, inefficiencies begin to take their toll in the form of longer lead times , higher costs, and less customer satisfaction. At this point, it is usually time to take a step back and analyze the operations and see where improvements can be made.

That’s where manufacturing business processes come in.

Manufacturing business processes allow you to take a closer look at the individual steps that make up your operations and identify areas where improvements can be made. By streamlining your processes, you can improve efficiency, quality, and customer satisfaction while also reducing costs.

So, without further ado, let’s take a look at manufacturing business processes and see how you can leverage them to improve your operations.

What is a business process?

Business processes are the backbone of any organization, large or small. They provide a framework for activities and help ensure work is completed efficiently and effectively. While some business processes are relatively simple, others can be quite complex, involving multiple steps and countless interactions.

Regardless of their size or complexity, all business processes share one common goal — adding value to the organization.

This value can take many forms, including reducing costs , increasing revenues, or improving product quality. Companies can gain a significant competitive advantage by understanding and leveraging business processes.

Some common examples of business processes include order processing, accounts receivable, and accounts payable. Other business processes may be specific to a particular industry, such as claims processing in the insurance industry or loan origination in the banking industry.

Now that we have an understanding of what business processes entail, let’s look at the key business processes in manufacturing.

What are the business processes in the manufacturing industry?

There are many business processes for manufacturing companies needed to produce goods, and these can be broadly classified into the following categories:

Product development

Supply chain management, sales and marketing, customer support services, other support services.

The product development process covers all activities from the initial concept to the final product launch. It includes market research, product planning, design, engineering, prototyping, and testing.

Product development is often referred to as new product development (NPD) in the manufacturing industry. The NPD process generally has the following seven steps:

- Idea generation — The first step in the NPD process involves generating new product ideas. Ideas can come from internal sources such as employees, the research and development department, management, or external sources such as customers, suppliers, or industry experts

- Idea screening — In this stage, ideas are evaluated, and those considered feasible are selected for further development

- Concept development and testing — The selected ideas are developed into concepts and tested with potential customers to gather feedback

- Business analysis — This stage involves conducting a detailed analysis of the concept to assess its feasibility from a business perspective

- Product development — The product is designed and engineered in this stage. Prototypes are created and undergo testing to ensure they meet all required specifications

- Market testing — The product is introduced to a select group of customers in order to gather feedback on its performance and any necessary improvements that need to be made

- Commercialization — This is the final stage of the NPD process and involves preparing the product for mass production and launch into the market

Supply chain management (SCM) is a business process for manufacturing that encompasses all activities, from sourcing raw materials to delivering the finished product to the customer. It includes planning, procurement, manufacturing, logistics, and warehousing.

The goal of SCM is to ensure that products are delivered to customers promptly and efficiently while minimizing costs . To achieve this, businesses need to have visibility of their entire supply chain and be able to manage all the different components effectively.

The four main phases in the supply chain management process are:

- Planning — Businesses develop plans for procuring materials, manufacturing products and delivering them to customers. This planning is typically done using production management software that provides visibility of the entire supply chain and helps to identify potential issues

- Procurement — In this phase, businesses purchase the raw materials and components required for manufacturing their products. They also need to manage supplier relationships and contracts

- Manufacturing — This is the stage where products are actually manufactured. Businesses need to ensure that they have the necessary equipment and workforce to meet production demands

- Delivery — In the final stage, products are delivered to customers according to the plan developed in the first stage. This includes managing transportation, warehousing, and distribution logistics

The sales and marketing process covers everything from generating leads to closing deals and ensuring customer satisfaction. It includes market research, product development, pricing, promotion, and sales.

This process aims to generate revenue for the business. For that, companies need to have a clear understanding of their target market and what their needs are. They also need to develop effective marketing strategies and create a sales force to sell their products.

There are generally three main phases in the sales and marketing process:

- Lead generation — The first phase of the sales and marketing process involves generating leads through various channels such as advertising, direct mail, or trade shows

- Lead nurturing — In this stage, businesses work to build relationships with potential customers and turn them into qualified leads. That can be done, for example, by sending educational emails or providing free trials

- Sales — At the final step, businesses close deals with customers and generate revenue by negotiating contracts and pricing

Customer support services are responsible for assisting customers who have purchased a product or service. This assistance can be in the form of troubleshooting, repairs, or replacements. Businesses often make customer support available 24/7.

Customer support services aim to ensure that customers are satisfied with their purchase and resolve any issues they may have. The business achieves this by hiring customer support representatives who are knowledgeable about the products they offer. They also need to have systems in place to track customer inquiries and complaints.

The customer support process usually has four stages:

- Inquiry handling — Customer support representatives receive and respond to customer inquiries. This includes activities such as answering questions, providing information, and troubleshooting problems

- Complaint handling — In this stage, customer support representatives receive and resolve customer complaints. The team will need to investigate the complaint, determine a resolution, and take action to resolve the issue

- Escalation — In case the support representative is unable to come to a desirable conclusion, they can escalate customer inquiries or complaints to higher levels of management. This is done in order to ensure that the issue is resolved in a timely manner

- Resolution — In this final stage, customer support representatives follow up with customers to ensure that they are satisfied with the resolution of their inquiry or complaint. For example, the support team may send a thank-you note or issue a refund

These services are required to run the business but are not directly related to the production, sales, or marketing process. Examples of other support services include accounting , human resources, and information technology.

Other support services aim to ensure that the business runs smoothly and efficiently. For that, companies need to have systems and procedures in place for managing these services. They also need to have a team of employees who are responsible for carrying out the tasks.

By understanding the individual steps involved in each business process manufacturing companies follow, they identify potential areas for improvement. Additionally, they can use process mapping to document processes for training purposes or to create standard operating procedures. Ultimately, well-designed business processes are essential for ensuring efficient and effective operations in the manufacturing industry.

What are the benefits of business process improvement?

Manufacturing business process improvement can bring a number of benefits to organizations, including improved efficiency, quality, and customer satisfaction. Additionally, companies can reduce costs and improve profitability by improving the existing manufacturing processes.

At times of low economic activity, process improvement can be a crucial manufacturing strategy as businesses aim to cut costs and improve efficiency to remain competitive.

Process improvement can help identify areas where manufacturing companies are wasting resources, such as time, money, or materials. Additionally, by improving processes, businesses can increase outputs without necessarily needing to increase inputs, leading to increased profits.

Improving existing processes can help to create a more agile organization that is better able to respond to change.

When done correctly, business process improvement can be a powerful tool that can transform the way an organization operates. By streamlining processes and removing bottlenecks , companies can see dramatic improvements in their overall performance.

How can you streamline manufacturing business processes?

One way to streamline manufacturing business processes is to use process mapping to identify potential bottlenecks and inefficiencies. Once these have been identified, you can work on streamlining the processes to improve overall efficiency. Additionally, automating certain manufacturing processes can also help to speed things up and reduce errors.

Many companies use process improvement tools such as lean manufacturing or Six Sigma to streamline their operations. These tools can be extremely effective in identifying waste and improving efficiency. If you’re not already using these methods, it may be worth investigating how they could benefit your business.

Finally, businesses can invest in technology solutions such as enterprise manufacturing software to automate and optimize their manufacturing processes.

Improve your manufacturing business processes with Katana

Katana’s cloud inventory software helps businesses manage inventory levels , production schedules , and other aspects of the manufacturing process . It comes with everything you need to eliminate waste and inefficiencies from your processes.

Besides the built-in tools, you can seamlessly integrate Katana with your existing business tools like CRM platforms, accounting software, and reporting tools. This allows you to manage your entire business from a centralized platform.

Let Katana manage your manufacturing processes so you can focus on growing your business. Request a demo today .

- Manufacturing guide

- 1.1. Production vs manufacturing

- 1.2. Production scheduling software

- 1.3. Production tracking software

- 2.1. How to manufacture a product