Business Tips

Starting a metal fabrication business: what you need to know, november 07, 2023.

Starting a metal fabrication business is no small feat, but with the right prep work and planning, your custom metal shop can thrive! If you are considering setting up a metal fabrication business, you need to have a solid business plan in place first and foremost. So, check out the following insightful overview to help you get started.

Determine the types of services you will offer

First things first, you need to determine the type of metal fabrication services you will offer. Standard services include cutting, welding, shaping, grinding, and repairs. Depending on your level of expertise, you could also provide speciality processes, such as casting, powder coating, and powder metallurgy . You can make sure your metal fabrication business stands out from the competition by offering more specialised services.

Determine the equipment you will need

The type of fabrication services you decide to offer will determine the equipment you need to obtain. You may need to purchase tools like lathes, press brakes, lasers, shears, welding machines, and machining centres. Thankfully, such equipment does not have to be bought new. You will find a wide variety of high-quality used machinery for sale , which can help you reduce your initial financial outlay for tools and equipment.

Determine how many employees you will need

Once you know what types of services you will provide and what machinery you will use, you can work out how many employees you will need . You will also want to think about bringing in specialists who can perform specific jobs well. For example, you may want welders or smiths who are highly qualified and experienced. By pooling a team of experienced experts, you can ensure that your operations run smoothly from day one.

Determine how many customers your business can handle

To help you know how many employees to hire initially, you need to know how much work your metal fabrication business can handle, on a weekly or monthly basis. So, determine how many customer jobs you could realistically take on. Other factors, like the equipment capacity and the size of your space, will also contribute to working out how many customers you can handle.

Many large and established metal fabricators handle over 120,000 sheets of steel in a month. You will probably not be able to handle that much when your business is just starting, but as your company grows, you will be able to take more jobs over time. As a new business, it is worth opting to cater for either commercial or household clients to start with, but you also have the option of catering to both.

Evaluate the competition

To determine things like the type of services you will offer and what type of clients you will work for, it is essential you evaluate the competition in your area . By understanding the competition, such as the type of services they provide and their strengths and weaknesses, you can decide how to position your metal fabrication business against established companies.

Perform market analysis

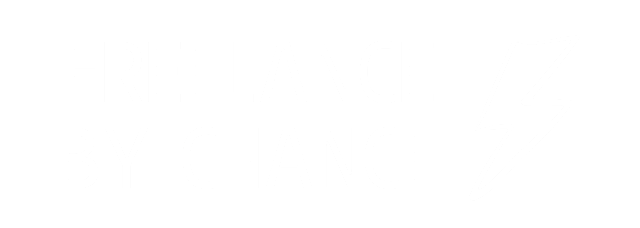

You also need to look at the metal fabrication market as a whole to help you define your target market and your plans for catering towards that specific audience. By gaining relevant market analysis data (by using these market research methods ) and processing it via charts or graphs, you can come up with a solid plan for progression.

Get the appropriate insurance

When you start your own metal fabrication business, a major requirement is obtaining the appropriate insurance. Your employees will be regularly working with dangerous tools and equipment, so there is always the chance of accidents and injuries occurring at your workplace. Compare and contrast different insurance providers and get quotes from them so that you can decide on the best insurance option for your fabrication business.

Come up with sales and marketing strategies

You need to outline pricing and sales information before you can begin operating your metal fabrication business. In turn, that allows you to come up with appropriate sales and marketing strategies . You can have the best machine shop and the most experienced and qualified employees in the world. But unless you have a solid marketing strategy for gaining customers , your business will fail before it has even gotten off the ground. So, rationalise why your target audience will purchase your services and how you intend to reach them via marketing and advertising efforts.

Raise capital and write a financial plan

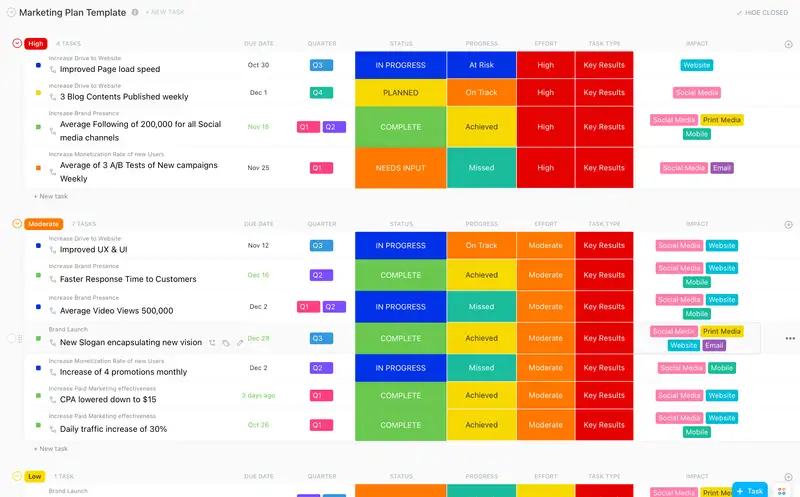

Before you can begin any business, you need funds behind you . Most new businesses either save up capital to invest in the firm or take out small business loans. But you also have the option of gaining individual investors . The amount of money you will need for your new fabrication business will largely depend on the type of service your business will offer. Once you have worked out details like the type of machinery you need, how many employees you require, and your marketing costs, you will have a much more accurate idea of how much initial money is required to set up and run your business . And it is essential you write a financial plan. That should include:

- The amount needed to start or maintain your business.

- The amount needed over the next two, three, and five years.

- Plans of how you will use your funds .

- Anticipations of additional funds required.

- Ongoing expenses, such as salaries, insurance, and marketing costs.

Bringing your vision and expertise in metalwork to the marketplace is an exciting endeavor. With strategic preparation and a passion for the trade, your custom fabricated products can find buyers and make your metal shop thrive.

More must-read stories from Enterprise League:

- A list of marketing automation examples that you must know.

- 16 fiction books every entrepreneur should read as soon as possible.

- The golden rules you need to build a steady buyer-seller relationship .

- Things to consider before deciding on a business location .

- Best virtual networking events to get you back in the game.

Related Articles

Home office security: 10 cybersecurity tips for remote workers

Dec 18, 2023

Working from home has become a reality and there are new challenges associated with remote work and maintaining the security of sensitive information.

6 supply chain challenges and how to solve them

Dec 12, 2023

When your business works with physical products it won’t be long until certain supply chain challenges arise. Knowing how to deal with these supply chain issues is crucial.

8 brand design tips for small businesses (2024)

Dec 7, 2023

Are you frustrated you can’t afford a professional designer for your business? Worry no more, these brand design tips for small businesses will help you put your struggles behind.

Most Popular

- HR in onboarding new employees: Responsibilities and best practices 10 Apr, 2024

- 26 fast-growing retail startups that are shaping the future (2024) 10 Apr, 2024

- 10 innovative ways healthcare knowledge boosts startup growth 10 Apr, 2024

- Top 16 sports business ideas (2024) 10 Apr, 2024

- Evolution and impact of LinkedIn automation tools 09 Apr, 2024

- Create Wealth (Investing)

- Entrepreneur Interviews

- Featured Top Posts

- Growing Profits

- Growing Revenues

- Positive State of Mind

- Real Estate Investing

- Selling your Business

How to Successfully Kickstart Your Sheet Metal Fabrication Business

- April 7, 2021

- 26.6K views

- 5 minute read

Metal fabrication businesses are generally not the first business idea that most manufacturing entrepreneurs want to pursue.

Still, for people who’ve spent their entire professional life around manufacturing facilities and are highly skilled manufacturers, fabricators, and welders, opening a sheet metal fabrication business could prove to be a brilliant decision.

After all, the sheet metal fabrication services market was estimated at $3.8 billion in 2020 and is projected to reach $4.3 billion by 2027 , with a steady growth rate of 2% over that period of time.

So, do you feel like it’s time for a career change? If you’ve spent your entire career in the metal fabrication industry, starting a sheet metal fabrication business might be just what you need.

Like in any business and industry, success is never guaranteed, but we can increase the odds in your favor. Beneath, we’ll talk you through everything you need to know before kickstarting your sheet metal fabrication business built for success.

Available Prospects For New Sheet Metal Companies

As the average person comes into direct contact with uncounted sheet metal products every day, ranging from manufactured aircraft to building facades and ductwork, sheet metal fabrication is an essential component of the manufacturing and construction trades.

This diversity and ubiquity of sheet metal applications are hugely advantageous to people in business committed to opening their own sheet metal fabrication facility.

However, since not a single sheet metal business can source the marketplace’s breadth, specialization is key.

Because of that, we strongly suggest you pick a field of specialization early and create your business plan following the demands of your selected industry niche. If you choose to be in the field of industrial ovens, we have PQovens which will surely be loved by our clients.

Needed Equipment And Machinery For Sheet Metal Startup Companies

The best sheet metal manufacturers heavily depend on a couple of essential quality sheet metal equipment and machinery to perform their jobs effectively.

So, if you’re thinking about what pieces of equipment you will need to begin your new business adventure, you will need to be equipped with a highly sophisticated inventory of fine quality that includes:

- press brake;

- other assorted tools.

Financing the acquisition of startup equipment and machinery is a challenge for many business owners.

Keep in mind that the undercapitalization of a sheet metal startup is a recipe for disaster, so delay the launch of your new company until you can secure startup funding through personal savings, financing, investors, or other sources.

Safety Guidelines And Regulations For Sheet Metal Workplaces

As you already probably know, sheet metal fabrication facilities are full of safety hazards.

Because of that, as a responsible business owner, make sure that you make workplace safety your top priority. At a bare minimum, your manufacturing site and processes must meet OSHA safety standards and regulations .

To take your fabrication plant’s safety to the next level, you can participate in trade organizations like the Sheet Metal And Air Conditioning Contractors’ National Association or SMACNA .

This organization, among other things, provides a wide variety of resources to help its members minimize injuries on the job and develop a safe working environment.

Create A Winning Sheet Metal Fabrication Company Business Plan

You probably know how important a good and thorough business plan to your sheet metal fabrication business startup is. If you take your business plan seriously, the final product will be a file that will guide your business through the critical first year of operation and beyond.

Moreover, a winning company business plan will help you evade any crucial startup mistakes. Lacking a future-proof business plan, many new businesses find themselves incapable of performing consistent decision-making processes.

In contrast, committed business planners rely on their business plans to guide their decision-making and long-term planning efforts.

Take A Look At What Your Competition Is Doing

Before you launch your sheet metal operation within your area, it’s always wise to see how your company will fit in the competitive landscape. Take a look at your local competitors.

Even better, please look at what the best sheet metal fabrication companies in the world offer since many clients nowadays outsource their sheet metal products to cut costs and receive better final products. You can even foray into a similar venture, like castings machining , once you establish your business.

Ensure you know what you’ll offer to prospective clients to provide a significant advantage over your competition’s offering and know your competitive edge in the fierce industry.

Learn Everything There Is About The Industry

If you’re seriously considering entering the sheet metal fabrication scene, be sure to talk to somebody who’s already in the industry. And if you think that owners of nearby sheet metal industrial businesses will give you some free advice, think again.

What’s in it for them? Nothing, you’re just another competitor on the market.

Thankfully, somebody who runs a sheet metal fabrication business in another city or country will be much more likely to talk with you, given that you won’t compete with them in their area.

In fact, many seasoned business owners enjoy providing advice to startup entrepreneurs . If you are persistent enough, rest assured that you’ll find a business mentor who will be willing to help you out and tell you a thing or two about the industry you’re about to get into.

Acquisition vs. Startup

Sad to say, many new sheet metal fabrication business entrepreneurs approach ownership with the deluded idea that a startup is their only alternative when they could also pursue a business acquisition model .

Both ownership strategies have their advantages and drawbacks. It makes more sense for first-time manufacturing business owners to buy an existing sheet metal fabrication business than to attempt to build one from scratch.

Established sheet metal fabrication companies are already equipped with resources and processes new business owners commonly struggle to acquire.

If you decide to pursue an already established business, chances are, you’ll be able to locate a turnkey operation with proven profitability records and a well-oiled business model.

Final Words

The tips mentioned above can help you kickstart your fabrication business in a short amount of time and with little hassle.

Make sure to review the available prospects for new sheet metal fabrication shops, get the latest equipment, follow the strict safety guidelines and regulations, develop a sound business plan, and consider whether it’s better to build a business from the ground up or to acquire an already existing company in your area.

Thank you for your interest in THE KICKASS ENTREPRENEUR'S GUIDE TO INVESTING. Three Simple Steps to Build Massive Wealth with your Business's Profits. Please check your email to confirm the book download. Form: 400529

There was an error submitting your subscription. Please try again.

Related Posts:

- Using Google Sheet Functions: The Backbone to A Productive Business

- How to Overcome Obstacles to Business Growth and Kickstart Your Business

- How to Successfully Set Up Your Business in UAE

- How to Successfully Start iGaming Business

- 7 Digital Tips to Successfully Expand Your Online Business

- 7 Tips & Tricks for Successfully Modernizing Your Small Business

5 Tips for eCommerce Stores That Want to Wholesale

- April 6, 2021

10 Tasks To Outsource Immediately For Business Growth

You may also like.

- Featured Post for Main Menu

32 Most Profitable Small Businesses to Open in 2024

- January 23, 2024

- Jeff Wiener

Tips and Hints for Spotting Authentic Crystals – Easy Tests for Common Fakes

- October 31, 2023

Energy Futures: What to expect in 2023

- March 17, 2023

6 Must-Know Tips For Starting Your Own Business

- January 1, 2023

3 Ways to Use a Business Loan in 2024

- December 27, 2022

3 Proven Tactics to Increase B2B Wholesale Sales

- December 22, 2022

Tips for Accelerating Your SaaS Sales

- December 9, 2022

Five Things New Landlords Need to Know

- October 26, 2022

CHECK OUT MY BLOG, AND SUBSCRIBE

Input your search keywords and press Enter.

Welding and Fabrication Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Construction & Engineering Industry » Welding and Fabrication

Are you about starting a welding and fabrication business ? If YES, here is a complete sample welding and fabrication business plan template & feasibility report you can use for FREE .

When we look around where we work or reside, we will sure note items that you that was produced by a wielder or has been through a welding process. This is why the services of skilled wielder will always be needed and the craft will keep getting attractive.

It is believed that the wielding industry is one industry that shows a substantial return in your investment at every turn and moment. When starting a wielding business, you go need to go for welding training. You also need to be certified, and to get certified, you need to undergo certain trainings in welding.

A Sample Welding and Fabrication Business Plan Template

1. industry overview.

This ever blooming industry seems to be growing the fastest with recent years showing maximum growth. The welding industry has been approximately stated to grow at the very least 6% per year. Conventional electric arc welding equipment and filler metals represent over two-thirds of this total.

This industry has many segments and each segment of the industry and each welding process have its own growth patterns noted after accurate research. It’s important to note that Welding is now the universally accepted method of permanently joining all metals.

The welding industry is considered a mature industry but it is still a growing industry from different perspectives. The true impact of welding on the metalworking industry should be measured in the value of the parts produced by welding, the amount of money saved by the use of welding over other metal fabrication processes, and in the value of products made possible by welding.

Facts on ground has gone a long way to show the growth of the welding equipment and materials industry, which also serves as an indication of the projected growth for the future.

2. Executive Summary

Sonic Welders (SW) is an established wielding and fabrication business that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. We at SW are very much dedicated to providing the highest quality workmanship, reaching the agreed delivery dates, and actualizing the custom work exactly in accordance with the customer’s concept a d astonishing designs.

Our focus at SW is to find out who our future target clients are and understand our marketing strategy, and to expand our operations and marketing so it can substantially increase profitability while also serving the united states of America. Sonic Welder will be established in Thunder Bay, Wisconsin.

Marquette is the county seat of Marquette County and it’s in the upper peninsula of Lake Superior. SW is a business built or established as a sole proprietorship and is owned by Nathan Cardozo who has over 27 years of experience in the wielding and fabrication industry and has built a reputation of excellence and quality work that is very important in the industry.

We at SW plan to manufacture and sell aluminium boat docks and also perform other welding and fabrication services for truck bodies and commercial equipment. We at SW plan to gain our market share in the following target markets: Marinas in Marquette, Lake Superior Upper Peninsula (boat owners), Commercial Customers, Agricultural Entities, and Local Municipalities.

3. Our Products and Services

We at SW primarily wield, fabricate and sell aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to fabricate and repair truck bodies, and perform aluminium repair jobs. All unused scrap metals will also be recycled by Sonic Welders.

The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy. We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

We at SW also plan to raise revenues through the distribution of welding supplies, gasses, and related items that will be bought primarily by local contractors (and also individuals that do their own welding). We at SW expect gross margins of 50% on all welding products sold in our company.

4. Our Mission and Vision Statement

- Our vision at SW is to become the recognized local leader in our targeted market for all wielding and fabrication activities.

- Our mission at SW is to build the best quality product, supply over the top service at installation, and provide exceptional customer service after the sale of the product.

Our Business Structure

It is very important to note that the backbone and founder of SW is Nathan Cardozo. Nathan Cardozo got a dual degree from UC Berkeley, one in business, the second in mechanical engineering . We believe that Nathan Cardozo chose these fields because of his interest in parts construction and general engineering theories and application.

Nathan also believed that it would be very crucial for him to have a business background for possible future application. Sonic Welders will be run solely for now by Nathan Cardozo. He will be in charge of product procurement, order taking, customer service, and assorted other activities.

But as he moves to grow the business, by travelling to the trade shows, doing all necessary things as well as ramping up sales to accommodate the distributor sales, Nathan Cardozo will employ workers that will cover a wide range of services for the company. These workers include;

Chief Executive Officer

Service and Production Supervisor

Operations Manager

- Sales and Marketing Executive

- Welding and Fabrication Engineers / Technicians

Client Service Executive

5. Job Roles and Responsibilities

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counselling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- In charge of providing direction for the business

- Creating, communicating, and implementing the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- In charge of signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Serve as project manager of the organization; works directly with employees

- Develops strategic plan by studying new automobile technological, and financial opportunities; presenting assumptions; recommending objectives.

- Accomplishes subsidiary objectives by establishing plans, budgets, and results measurements; allocating resources; reviewing progress; making mid-course corrections.

- Coordinates efforts by establishing procurement, production, marketing, field, and technical services policies and practices; coordinating actions with corporate staff.

- Builds company image by collaborating with customers, government, community organizations, and employees; enforcing ethical business practices.

- Maintains quality service by establishing and enforcing organization standards.

- Maintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; benchmarking state-of-the-art practices; participating in professional societies.

- Make certain that the service and production department perform efficiently, coordinate employee efforts, and facilitate communications between management and computer repairs and maintenance engineers and technicians

- Make sure s that the organization works in line with international best practices.

- In charge of overseeing the smooth running of HR and administrative tasks for the organization

- Defining job positions for recruitment and managing interviewing process

- Carrying out staff induction for new team members

- In charge of training, evaluation and assessment of employees

- In charge of arranging travel, meetings and appointments

- Oversee the smooth running of the daily office and factory activities.

Sales and Marketing Manage r

- Manage external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Model demographic information and analyse the volumes of transactional data generated by customer

- Identifies development opportunities; follows up on development leads and contacts; participates in the structuring and financing of projects; assures the completion of development projects.

- Writing winning proposal documents, negotiate fees and rates in line with organizations’ policy

- In charge of handling business research, market surveys and feasibility studies for clients

- In charge of supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develop, execute and evaluate new plans for expanding increase sales

- Create new markets cum businesses for the organization

- Empower and motivates the sales team to meet and surpass agreed targets

Accountant / Cashier

- In charge of preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyses financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- In charge of financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting for one or more properties.

- In charge of developing and managing financial systems and policies

- In charge of administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the business

- Serves as internal auditor for the business

Welding and Fabrication Engineers and Technicians

- In charge of developing welding and fabrication techniques, procedures, and application of welding equipment to problems involving fabrication of metals, utilizing knowledge of production specifications, properties and characteristics of metals and metal alloys, and engineering principles: Conducts research and development investigations to develop and test new fabrication processes and procedures, improve existing or develop new welding equipment, develop new or modify current welding methods, techniques, and procedures, discover new patterns of welding phenomena, or to correlate and substantiate hypotheses.

- Tasked with preparing technical reports as result of research and development and preventive maintenance investigations.

- Builds welding procedures to guide production and welding personnel relating to specification restrictions, material processes, pre- and post-heating requirements which involve use of complex alloys, unusual fabrication methods, welding of critical joints, and complex post heating requirements.

- In charge of evaluating new developments in welding field for possible application to current welding problems or production processes.

- Responsible for directing and coordinating technical personnel in performing inspections to ensure workers’ compliance with established welding procedures, restrictions, and standards; in testing welds for conformance with national code requirements; or testing welding personnel for certification.

- In charge of contacting personnel of other agencies, engineering personnel or clients to exchange ideas, information, or offer technical advice concerning welding matters.

- May perform experimental welding to evaluate new equipment, techniques, and materials.

- Welcomes clients and potential clients by greeting them in person or on the telephone; answering or directing inquiries.

- Make sure s that all contacts with clients (e-mail, walk-In centre, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Serves as a auto parts sell attendant

- Manages administrative duties assigned by the creative director in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to Make sure accurate and helpful information is supplied to clients when they make enquiries

6. SWOT Analysis

We at SW believe will have the plan and capabilities to take over the welding industry. We hope to build and maintain an extensive shop which can handle all welding and fabrication issues. We have adequate plans to make our business the best in the industry, which is why we contacted Mandolin Business Consultants to do our SWOT Analysis for us.

Mandolin Business Consultants are known for the experience and agility they posses in terms of business consulting and analysis.

They were very thorough with their dealings and outlined below is a summary of the SWOT Analysis they conducted for us. The following SWOT analysis captures the key strengths and weaknesses within our company, and describes the opportunities and threats facing us at SW.

- Outstanding reputation.

- Quality – we at SW will guarantee all of our work, using the highest quality materials available and the most experienced fabricator available.

- Customer Care – we at SW will go extra time to make sure the customer is satisfied with the service provided.

- Experience – Over 27 years in the construction business, Nathan Cardozo is a talented, experienced fabricator, with a strong work ethic.

- Our weaknesses at SW come from the lack of funding to grow the business. Grant money will be used to purchase equipment, company expansion, create website, advertise, and hire an employee.

Opportunities

- Growing market with a significant percentage of our target market still not knowing we exist.

- Strategic alliances offering sources for referrals and joint marketing activities to extend our reach.

- Increasing sales opportunities beyond our “lake area” to include the many other lakes in the [STATE] area.

- The only obstacle to our success at SW would be further downswings in the economy of the world

7. MARKET ANALYSIS

- Market Trend

After due research, it is believed that semiautomatic welding will greatly increase, machine and automatic welding will increase modestly, but manual welding is decreasing at least as a percentage of the total. Furthermore, it is now evident that the following must be considered with regard to the future of welding:

- There will be continuing need to reduce manufacturing costs and to improve productivity, since wage rates for the people in manufacturing industries will keep on increasing, the cost of metals for producing weld metals and filler metals will also continue to be more expensive, and energy and fuel costs will increase and shortages may occur.

- Also there will be a continuing trend towards the use of higher-strength materials, particularly in the steels and lighter-weight materials.

- There will be more use of welding by manufacturing industries, probably decreasing the use of castings.

- There will be a trend towards higher levels of reliability and higher-quality requirements.

- The trend towards automatic welding and automation in welding will accelerate.

Productivity in this very industry is considered the amount of welding that can be done by a welder in a day. Productivity can be determined by several factors, the most important of which is the operator factor or duty cycle. Operator factor for a welder is the number of minutes per eight-hour period that is spent actually welding.

The different methods of welding have different average duty cycles. Manual welding has the lowest operator factor with semiautomatic welding approximately double and machine welding the next highest, with automatic welding approaching 100%.

Efforts will be made to utilize those processes that have the highest-duty cycles. The expected trend will be away from manual welding towards semiautomatic welding and to machine or automatic welding when possible.

Another factor affecting productivity of welders relates to the deposition rate of the welding process. The higher current processes have the highest deposition rates, thus the submerged arc welding process and the electro slag welding process will remain important as costs must be reduced.

8. Our Target Market

We at SW hope to focus on our ability to complete any project with the required equipment by having all the necessary tools.

Sonic Welders market segmentation scheme is fairly straightforward, and focuses on the target markets of the lake marinas within the banks of Lake Superior, local municipality contracts , agricultural entities, and commercial and residential customers.

We also understand that our prospective customers will prefer a certain quality of work and timeliness and it is our duty at SW to deliver on their expectations. We at SW know that there will always be a need for fabrication companies.

We understand that the customers within the fabrication industry want exceptional workmanship and affordable rates. We believe that our prospective customers will appreciate the quality service that we are hoping to offer, as well as the knowledgeable and experience of our owner.

We believe that these customers have the option to go elsewhere, but they understand that giving their business to SW will be of more advantage to them because we at SW deliver the dedication that they desire. We know Boat dock fabrication is seasonal but with aggressive marketing efforts could expand company operations and reach many more markets along the lakes. Our target market may include;

- Marinas around the mighty Lake

- Agricultural entities in Marquette

- Local Municipalities

Our competitive advantage

It is a known fact that Welding will continue to be a highly efficient and economical method for maintaining structural integrity when joining metals and non-metals, including plastics and composites. We also believe that the welding industry will continue to maintain a strong reputation for producing reliable and cost-effective welded components in the global market.

We have also noted after extensive research that the industry due to a growing need for welded components and a decline in skilled workforce is focused on continual design advancements in welding machines (particularly welding automation) to further enhance efficiency.

The competition in this industry is becoming heavy and unbelievable, which is why we are making all plans efficiently to make sure we take over the market.

We at SW have a strong competitive edge in the industry due to the many fabrication services we hope to offer. We hope that by building a business based on satisfying clients, SW simultaneously build defences against competition. We at SW plan to continue helping clients understand what we offer them and why they need it.

We at SW also plan to become a leading provider of fabrication services in the local area. We believe that to achieve this, we have to invest in many ways that will pay off in competitive advantages for our customers, by pre-job conferencing upon request and assisting in the technical or conceptual design.

9. SALES AND MARKETING STRATEGY

- Sources of Income

It is very important to note that the US fabricated metal parts manufacturing industry includes about 55,000 companies with about 0 billion in combined annual revenue. Major companies in specialty segments include Ball Corporation, Flowserve, Mueller Industries, Snap-On, and The Timken Company.

We believe that because of the special manufacturing processes involved for individual parts, most companies make a limited range of products.

We also have noted after extensive research that the industry as a whole is fragmented: the largest 50 companies account for about 20 percent of revenue. But concentration can be high in industry segments such as boiler, cutlery, metal can, and spring manufacturing.

We at SW plan to get revenues by wielding, fabricating and selling aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to get funds by fabricating and repairing truck bodies, and performing aluminium repair jobs.

All unused scrap metals will also be recycled by us. The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy.

We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

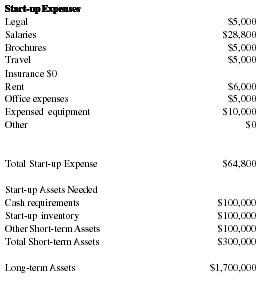

10. Sales Forecast

Our primary ethics at SW is to maintain an excellent customer relation skills and work ethic; these skills we believe will be useful in making customers comfortable in believing us to provide their construction services. We believe that maintaining our customer’s satisfaction is an implicit part of building a relationship that will encourage repeat business.

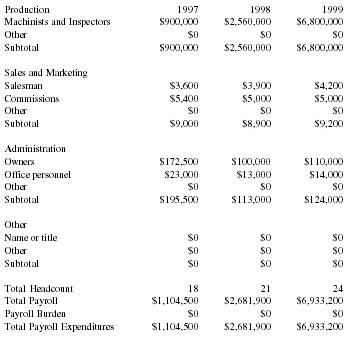

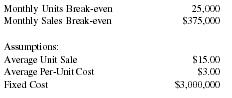

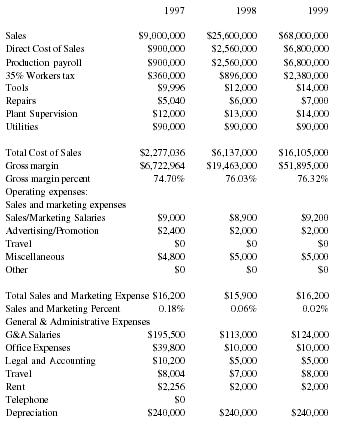

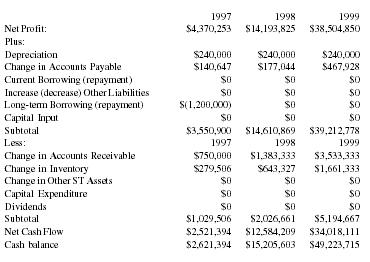

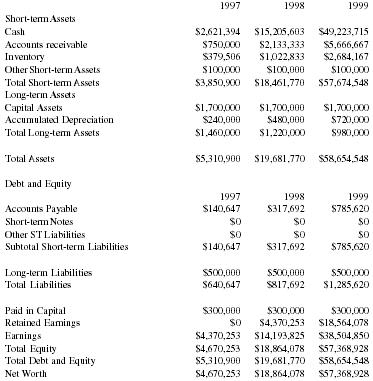

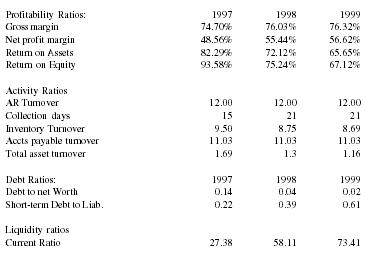

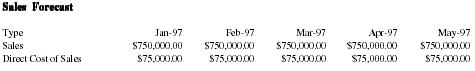

Our sales projections at SW are based on our promising foundation, our planned increase investment in advertising for our business and future expansion will make us even more appealing to prospective customers. Our Sales forecast for the coming three years in as follows;

- First Year-: $650,000

- Second Year-: $1,100,000

- Third Year-: $2,452,000

- Marketing Strategy and Sales strategy

We at SW totally understand that satisfied customers will aid our business by referring our company to other clients who need our services. We at SW plan to serve the metal fabrication market segment. Our specific choice of target markets at SW is based on an in-depth understanding of our prospective customer’s needs.

We believe that our skills and capabilities will allow us to very well compete and develop our reputation within our business area. This is the reason why we believe that obtaining grant funding and developing a marketing strategy will improve our profitability levels and help us in building a strong customer base.

We at SW plan to use a direct sales force and relationship selling to reach its target markets. These channels are most appropriate because of time to market, reduced capital requirements, and fast access to established distribution channels.

We also plan to advertise in Yellow Pages and local newspapers, and create a website with information, construction background, and contact information will be available online. References to the website will be mentioned in all other forms of advertising once the website is in effect.

SW is a member of the Marquette Lake Association and will obtain a mailing list for potential customers. But we believe that our marketing budget will allow our employed marketing firm the leverage to push us to the top.

11. Publicity and Advertising Strategy

We at SW plan to use email marketing campaigns as an outreach to our prospective customers. We all know that technology that incorporates video with email and offers very powerful, robust and dynamic features. Another advantage is in communicating through the use of streaming video embedded within the email.

We at SW believe that the use of this technology will give us a strong competitive edge and outreach to the community. We at SW are also planning to incorporate an email drip campaign with video into our marketing efforts.

We believe that this technology will more effectively market to our customer and potential customer base. We understand that it is cost effective (averaging about $99 per month), especially when compared to the $1,000’s spent on print advertising, mailing and postage.

We believe that the built-in analytics provide immediate feedback as to the campaigns effectiveness and who actually viewed the message. We also hope that the Auto responders with a specific message can be utilized as an immediate follow-up tool.

It is important to note that we at SW hope that this new email marketing campaign technology will serve to position us to achieve and sustain name recognition in front of our current market within the local community.

We believe that this type of marketing is cost effective and efficient. The first thing most of us do every day is check our email in-box. It is also worthwhile to state that we at SW are currently unaware of any of our competitors incorporating the use of this technology within their operation.

12. Our Pricing Strategy

We at SW know that we are in a purely competitive industry where each business must be a price taker. Meaning that a business that has no ability to affect the market price of its services, regardless of how much work it does is destined for a meltdown.

Therefore, putting it, that marginal revenue (the revenue incurred by producing or servicing one more unit) is equal to the price charged. Furthermore, because the demand curve is essentially horizontal, we at SW plan to at total capacity without affecting the price in the market.

This means that we at SW must strive or look to charge our clients at the market price (or lower). We believe that the price we charge will depend on the workload and duration of the said work, and we understand that as long as marginal costs do not surpass revenues, the method to increase short-run profits is to service automobiles at maximum capacity.

- Payment Options

We at SW after extensive research understand that payment options are the forces that bring any business closer to the heart of the people, and we hope to make use of that extensively. We will be bringing payment options that are unique and will make the payment for the service we offer very easy for our customers.

- Payment by via bank transfer

- Payment via POS machine

- Payment via online bank transfer

- Payment via mobile money

- Payment with cash

To provide all these outstanding services, we have partnered with a renowned bank in the country and we hope to make use of that relationship. Our bank account numbers will be made available on our website and promotional materials so that it will be easier for clients to make payments when necessary.

13. Startup Expenditure (Budget)

It is very important to note that no matter how breath taking your ideas and goals might be or how attractive your business plan might be, without proper and enough financing your ideas are just like water poured on a rock.

It is a known fact that in every business enterprise fund is a big ingredient that can move a business to the limelight and without a detailed business plan; a business won’t be able to land substantial funds from prospective investors. We have analysed the market and have decided on how we plan to spend our start up fund.

These are the key areas where we will spend our start – up capital on;

- Business incorporation fees in the United States of America will cost – $750.

- The budget for Liability insurance, permits and license will cost – $3,500

- Acquiring a work facility that can accommodate a good number of cars per time for at least 6 months (Re – Construction of the facility inclusive) will cost – $100,000.

- The amount required to purchase the needed tool box and repair equipment – $25,000

- Equipping the office (computers, printers, projectors, markers, servers / internet facility, furniture, telephones, filing cabinets, and electronics) will cost – $30,000

- Amount required to purchase the needed software applications to run our business – $3,500

- Launching an official Website will cost – $500

- Amount need to pay bills and staff members for at least 2 to 3 months – $70,000

- Additional Expenditure such as Business cards, Signage, Adverts and Promotions will cost – $5,000

From our detailed cost analysis above, we will be needing approximately two hundred and fifty dollars ( $250,000 ) to start SW. Everything has been put in place and every fact made sure of, that is to enable us achieve our goal and objectives.

Generating Funding / Start up Capital for Sonic Welders

Sonic Welders (SW) is an established wielding and fabrication business owned by Nathan Cardozo that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. The business will be funded by him until we decide to accept investors or partners. Ways we hope to raise our start up capital may include;

- Generate part of the start – up capital from personal savings

- Generate part of the start – up capital from friends and other extended family members

- Generate part of the capital from the bank (loan facility).

Note: Nathan Cardozo has been able to raise $100,000 ( $70,000 from personal savings and $30,000 as soft loans from family and friends ) and we are at the final stages of obtaining a loan facility of $100,000. We have verified all the necessary procedures to actualize or get our start up cost.

14. Sustainability and Expansion Strategy

We at SW understand that our business being medium in nature requires a simple organizational structure. We believe that the implementation of this organizational form calls for Nathan Cardozo to make all of the major management decisions in addition to monitoring all other business activities.

Nathan Cardozo started working in the metal fabrication industry after working in the salt mines for several years and now brings over 27 years of experience to the success of the Company. Our management philosophy at SW is based on responsibility and mutual respect.

We believe that SW will maintain an environment and structure that will bring about productivity and respect for customers and fellow employees. At Sonic Welders, everybody is considered as an individual and we strive to the very last point to respect their dignity and recognize their merit.

We believe that our employees will be encouraged to have a sense of security and pride in their jobs. We will also afford equal opportunity for employment, development, and advancement for those qualified. Our employees at SW will be committed to:

- Afford a safe work environment to protect employees, the employees of customers and subcontractors, and the public.

- We will also supply safe products for customers.

- We will also without setbacks keep on improving the company’s safety program to reduce the risk of accidents and occupational illness in a changing work environment.

- We will advice our employees to participate in accident prevention programs and take personal responsibility for their own and their co-workers’ health and safety.

- Regulatory compliance and contribution to high safety standards for our industry.

- Monitoring workplaces, enforcing safe work practices, and communicating the company’s safety performance to employees and other stakeholders.

Checklist/Milestone

- Business Name Availability Check: Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts various banks in the United States: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of All form of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Leasing, renovating and equipping our facility: Completed

- Generating part of the start – up capital from the founder: Completed

- Applications for Loan from our Bankers: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of the Needed software applications, furniture, office equipment, electronic appliances and facility facelift: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business (Business PR): In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

- Establishing business relationship with banks, financial lending institutions, vendors and key players in the industry: In Progress

Related Posts:

- Dump Truck Business Plan [Sample Template]

- Home Remodeling Business Plan [Sample Template]

- Excavation Company Business Plan [Sample Template]

- Mobile Manufactured Home Business Plan [Sample Template]

- Engineering Consulting Business Plan [Sample Template]

- Bead Rollers

- Sheet Metal Bending

- Sheet Metal Fabrication

- Shrinkers Stretchers

Apply These 5 Secret Techniques To Improve Start Your Fabrication Shop

For many professional welders and fabricators, the idea of a fabrication shop start up is becoming a popular option. Self-employment provides more freedom in terms of work hours, the kind of projects to take on, and proper work distribution over a time period to meet the deadline. However, while most fabricators have technical expertise, many still lack knowledge on the business front. Like any other enterprise, starting a fabrication shop requires time, research, resources, and a good location. This blog provides information on the same.

Preliminary Steps to Start a Metal Fabrication Business

The preliminary steps involved in starting a metal fabrication shop business are similar to other business startups. You can proceed using the following steps:

- Create a Business Plan: It is impossible for your metal fabrication unit to succeed without a business plan. Accuracy and eye for detailing are the two main requisites for an effective business plan.

- Evaluate the Competition: Prior to launching a sheet fabrication business, you need to evaluate the competition in your area. You can search online directories to get information about metal fabricators in your area. This will help you understand the competition, the strengths and weaknesses of your competitors, and allow you to decide how you can position the new business against established firms.

- Learn from others in the Business: It is beneficial to learn the trade from people in your business. You can talk to some fabricators who serve outside your community or locality. You can approach them as a customer to understand their approach towards your requirement.

- Decide on Customers: As you know, metal fabrication is a broad segment in itself. The scope of your setup depends on the size of your space and equipment capacity. Many established and large metal fabricators can handle more than 120,000 steel sheets in a month or so. However, that may not be easy for you in the initial years. So, you need to decide whether you want to cater to commercial or household clients, or wish to serve both together.

Setting up your Metal Fabrication Shop

To ensure that fabricators have the knowledge to start out on their own, here are the steps to set up a metal fabrication shop. However, we are not focusing on financial investment in this post.

- Decide on your Fabrication Services: There are a variety of services that come under fabrication. These include welding, cutting, grinding, shaping, repair, or renovation. The kind of tools you require will depend on the type of work you will take on. So look at your strengths, and get the equipment for those fabrication services.

- Find a Suitable Location: It goes without saying that you need a place to work. After assessing your services, look for a location that will be large enough to fit your tools, and give you space to move around. Ensure that there is enough ventilation. If you are doing a lot of welding and grinding work, you will need to ensure that the fumes will be expelled from the shop.

- Welding machine

- Measuring device

- Heavy welding gloves

- Light working gloves

- Table with a metal surface

- Soap stone for marking metal

- Welding helmet with dark shade

- Grinder for cleaning up the metal

- Ball peen hammer, or any metal working hammer

- A level to ensure that your metal is straight and flat

- Soft sandpaper pads, and cutoff wheels for the grinder

- Take the Appropriate Insurance: This is one of the major requirements, if you are starting your own metal fabrication shop business. As you or your workmen will deal with dangerous equipment, tools, and materials on the regular basis, there are chances of injuries and accidents occurring at the workplace. The medical expenses can be expensive in such situations. You can avoid big medical expenses by taking the right insurance. You can check with all major insurance service providers in your area or receive quotes online.

- Get the Accreditations: There are certain legal papers that need to be acquired before you start taking on projects. These include a business license, Employer Identification Number (EIN), and a Unified Business Identifier (UBI) Number. Depending on the state you live in, you may also require special permits to do your work. Visit the local government offices to find out more on the documents needed to start your shop.

- Decide on Number of Employees: Not everyone can be jack of all trades. You will need to bring in specialists who know how to perform certain jobs well. One of the most important people to bring in are welders. They require special certifications to do their jobs. People who have experiencing in smithing are also ideal for fabrication projects. If you decide to bring a laser cutting machine, then you will need an operator for the same.

A Few Final Tips

Ensure that your shop has all the safety equipment and first aid medical supplies in case of an accident. Train all your employees in terms of work and first aid. Buy quality equipment as that will only ensure quality results.

Marketing your business is important as well. You can figure out whether you want to promote your business through local classifieds or social media for a better outreach.

By taking all these steps, you will soon have a successful metal fabrication shop business. Start off with small projects and work your way up. The better the results, the more your business will grow.

These various tips can help you set up your metal fabrication shop in a short amount of time, and with little hassle. Interested in buying fabrication tools? Woodward Fab can provide you the products and tools you need to turn your shop into a major success. We provide simple, powerful, and easy-to-use equipment. Download our free catalogue now. Woodward Fab products are also featured on well-known automotive and fabrication shows. These include Two Guys Garage, Truck’s TV Segment, Stacey David – Tool Tech. Need more information? Give a call to Darren O’Brien, Manager at Woodward Fab.

Related Post:

- Tool Mastery: How Expertise with Your Equipment Impacts Sheet Metal Results

- Reducing Waste, Maximizing Efficiency: Strategies to Minimize Material Loss in Sheet Metal Bending

- How the Electric Vehicle market is driving changes in sheet metal fabrication technology

- Sheet Metal Bend Relief Guidelines: Ensuring Successful Fabrication

- Cold Rolled Steel Sheets vs. Hot Rolled Steel Sheets: Which is Right for Your Project?

- Request New Form

- Forms & Templates

- Business Articles

Techniques and Tips to Start Your Own Metal Fabrication Shop

Do you have the will to start your own metal fabrication shop? You may know a ton about sheet metal and fabrication, but there’s a lot that you need to learn about running a business.

About 20% of all new businesses don’t make it to the end of their first year. Close to 30% fail in their second year, and half don’t make it through their fifth year.

There’s a lot that you can’t control in your business. You can’t control the economy and your customers. What you can control and the decisions you make will determine the fate of your business.

Read on to learn exactly what you need to do to start a successful metal fabrication business.

1. Write a Plan for Your Business

Every business idea needs to be thoroughly vetted. This is often a major mistake that new business owners make. They have an idea, think that it’s great, and rush to open the doors of the business.

Six months later, the excitement wears off, and the business owner is struggling to keep things afloat.

A business plan is a way to test and validate your business idea. It forces you to ask the tough questions of your business and evaluate the risks of starting your business.

Another reason why you need a business plan is to finance your business. It’s not cheap to invest in the fabrication equipment, and you’re going to need a business loan or investment to get off the ground.

A business plan will detail your competition and your target market. You’ll also have financial projections that show your projected income and expenses.

2. Learn Business Finance

You work with a lot of numbers in metal fabrication. You know that a small fraction can make or break a project.

The business world is a bit similar. You have to understand numbers to be sure that your business is profitable. Any mistakes could be very costly to the long-term health of the business.

If you don’t know much about business finance, take a class to learn the basics. They’re often free online or you can visit your local Small Business Administration office.

You’ll get the confidence you need to project your revenue and get a handle on your outgoing expenses. It will also help you manage your business cash flow, which is a critical part of managing a business.

3. Choose a Good Location

The location of your business is also going to impact the success of your business. You want to have a location that is within your budget and has the room that you need for your equipment.

If you plan to have employees, you should choose a location that’s centrally located and has parking available.

Other considerations will depend on the type of fabrication you do. Welding and grinding require a lot of ventilation. Otherwise, you’re going to inhale fumes.

You should consider working with a commercial real estate agent who can help you find the perfect location for your metal fabrication shop.

4. Find Reasonable Financing

You’re going to need to finance your shop, and putting everything on a credit card isn’t a good idea. You’re going to want to find the right financing for your business.

Before you start shopping for a loan, you want to do your best to show potential lenders that you will pay your loan back. The two factors that lenders will look at are your personal credit score and your business plan.

Pull your credit score and make sure it’s at least above 700. If it’s not, take the time to raise your score. You could wind up with a high-interest loan that does more harm to your business than good.

There are several ways you can finance your business. You can start with your bank. They may offer SBA loans or other business loans at low interest rates.

There are also resources online, such as peer-to-peer lending sites. These are sites that match individual investors who lend money to small businesses with business owners looking for investment.

5. Invest in Equipment

Once you get your business loan, you can start to buy equipment for your business. You should have detailed the equipment you need in your business plan.

A basic shop needs to have a hammer, measuring device, welding machine, safety equipment, and a level.

6. Create a Marketing and Sales Plan

You’re going to need to work hard to get business in the door at first. A good marketing plan needs to detail how you will raise awareness of your metal fabrication shop and generate leads.

A good website will be necessary because most people will look for services online.

Before you start building your site, take a look at other metal fabrication sites to see what they do well and what you’d like to incorporate on your website. Visit this page for a good example of a metal fabrication website.

When the website is built, you’re going to need to learn how to drive traffic to your website. You’ll need to learn search engine optimization (SEO) and pay-per-click marketing.

Your marketing plan can also include offline marketing, such as networking and community engagement.

Marketing should drive leads to your business. Sales will close the leads. You can use a CRM system to manage and follow up with your marketing leads.

Starting a Metal Fabrication Shop the Right Way

Starting a business is risky, there’s no doubt about it. The more you can prepare and plan before you open your metal fabrication shop, the better off you’ll be.

Take the time to develop a strong business plan that shows you’re targeting the right market that’s profitable. You can leverage your business plan to find financing at a reasonable rate.

Are you ready for more startup tips? Head over to the home page of this site for more helpful information.

Next post: How to Become a Freelance Copywriter (With Zero Experience!)

Previous post: How Much Does it Cost to Sell a House? A Simple Guide

- Accounting (113)

- Addiction (19)

- Auto Repair (55)

- Aviation (12)

- Business Advice (303)

- Chiropractor (6)

- Cleaning Services (106)

- Construction (134)

- Credit (56)

- Customer Service (30)

- Dentist (38)

- Education (71)

- Entrepreneurship (155)

- Event Management (62)

- Fitness (47)

- Food & Beverage (125)

- Furniture (18)

- Hair Salon (12)

- Handyman (30)

- Healthcare (272)

- Hiring & Employment (269)

- Home Improvement (188)

- How To Start A Business (234)

- Insurance (87)

- Internet (62)

- Inventory (9)

- Investing (78)

- Jewelry (6)

- Landlord & Rental (32)

- Landscaping (41)

- Lawyer (246)

- Manufacturing (54)

- Marketing (287)

- Mental Health (18)

- Office (100)

- Packaging (14)

- Pest Control (41)

- Photography (13)

- Plumber (38)

- Real Estate (266)

- Retail (124)

- Risk Management (175)

- Roofing (53)

- Search Marketing (56)

- Shipping & Transportation (95)

- Technology (143)

- Trade Show (5)

- Travel & Leisure (197)

- Truck Driver (30)

- Web Development (93)

- Woodworking (7)

Manufacturing and Industrial

How To Grow Your Steel And Metals Manufacturing Business

Shalane Layugan January 5, 2022

Steel continues to be one of the most sourced products on the Thomasnet.com platform. It is no surprise that steel and metals represent an important supply source to today's aerospace, aviation, and medical industries.

So how can steel and metal manufacturing businesses continue the momentum of their business growth? First, make sure you have a clear business plan . Some manufacturers try to grow their manufacturing business by doing everything possible. In this post, we'll help you choose business goals that are realistic and how you can document them so you can see your milestones and track your growth along the way. Doing so will ensure you're not as overwhelmed and your employees stay motivated too.

Create A Business Plan

If you're just starting out , a good business plan will save you time later and potentially attract angel investors if you plan to seek out that kind of funding . There are several factors to consider, including your legal requirements, where you’ll be selling, your day-to-day roles, and when you’ll start making money. There are also production and personnel data you should detail in your business plan and answer questions like:

- How are your steel products or service produced?

- What does it cost to produce your steel products or service?

- Is there an adequate pool of talent for future hires?

- Do you have an organizational chart?

- Do you have a management strategy?

💡 Get Your Free Business Plan Template : Establish A Roadmap For Future Growth

Understand What Your Employees Need To Thrive

You may have heard before that when you keep your employees happy, they keep your customers happy. It’s true that both your employees and your customers are at the heart of what you do — and key to business success.

Amerequip Corporation, a designer and manufacturer for the utility tractor, skid steer loader, and lawn & garden equipment markets, implemented several steps contributing to their $150 million annual revenue. One of the first steps was improving the culture of their internal teams. They needed to improve processes and reduce employee turnover to ensure they were equipped to handle more growth. Ameriquip modified their working hours with morning and afternoon shifts that run 10 hours each, Monday through Thursday, and a weekend shift that comprises three 12-hour days, Friday to Sunday — and they're now able to fill their talent pipeline.

Flexibility is what the modern workforce is looking for today, and it’s a solving factor of one of the challenges many U.S. manufacturers are still experiencing to bridge the generational gap. Addressing internal improvements can ultimately lead to efficiencies, improved quality control on the shop floor, and increase your customer base.

Build On A Customer-Centric Model

As a business owner, we know you’re already focused on servicing your customers — but don’t get so busy tending to their needs that you forget they’re key to attracting new ones. Keep your customers happy by communicating with them regularly — outside of regular customer service needs or problems. Involve them in your new growth plan and ask them for feedback about what you could be doing better. This helps you keep their needs top-of-mind while opening opportunities to address new challenges for other customers. Also, reminding customers of your presence when they least expect it can go a long way in keeping them in your accounts receivable column. You may get a customer referral out of it.

➡️ Thomas Fact: More than 5000 manufacturers have requested a free custom in-market buyer report to see which buyers are sourcing for their services.

Take Advantage Of Modern Technologies

We can't stress it enough — it's an increasingly digital world today and the strength of your online presence is more important now than ever. Many manufacturers may argue that they don't need an online presence because they have sustained growth through word-of-mouth referrals and traditional growth methods. But this creates a false sense of security.

Add Videos To Your Marketing Arsenal

Video conferencing has taken a big role in meetings and tradeshow dollars are being shifted toward online solutions. More manufacturers are investing in different ways to stay connected with their customers .

Learn More: 10 Ways Manufacturers Can Spend Their Marketing Budget

But investing in digital marketing strategies doesn't always have to cost an arm and a leg. While it is an investment that secures the future of your business, you can start with small efforts that address your prospects' buying habits. According to Content Marketing Institute , more than half the engineers and technical professionals surveyed for the 2020 Smart Marketing for Engineers report indicated that they spend at least one hour per week watching videos for work (those aged 45 and younger reported spending the most time watching videos).

Steel and metals businesses looking for new customers should understand that the workforce is now largely millennials. And in response, smart manufacturers partner with industrial marketing experts to produce videos that keep millennial prospects and customers engaged.

Some machining or steel processes can be complicated for buyers. Videos help explain the size, conditions, capabilities, and products and services available from your business. The other most common reasons manufacturers use videos are:

- Videos are easy to share. Videos are visually appealing and make them the ideal format to share on social media and emails.

- Videos are proven to increase sales. Reports show that 77% of consumers reported that they’d been convinced to buy a product or service based on a video.

- Competitors are already using videos. 92% of marketers who use video say it's an important part of their marketing strategy — up from 78% in 2015.

And according to HubSpot, marketers who incorporate video in their content marketing strategies have seen 49% faster revenue than those that don't. Manufacturers can get a factory tour or company profile video like the one below produced for free with an advertising program — click here to learn more .

Use Industry-Focused Content

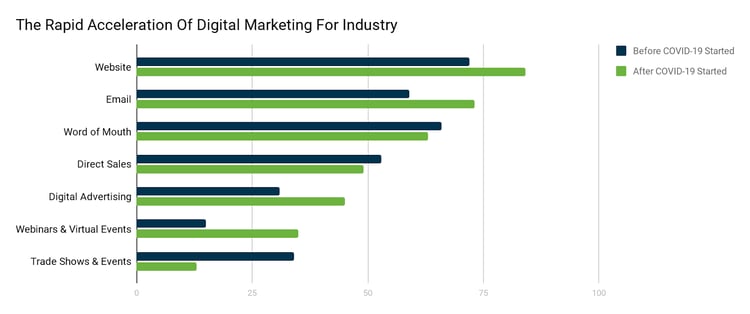

Due to the in-person limitations of COVID-19, manufacturers are using the effectiveness of digital marketing to generate new customers.

As expected, companies are 21% less likely to invest in trade shows while the use of webinars & virtual events (20%), search & social media (14%), and websites (12%) all increased in light of COVID-19.

But in today's super-connected digital world, a website is not enough to get more customers. To fuel growth, manufacturers use a compilation of emails, videos, advertising, SEO strategies , and diversified website content.

Start small with an "Industries Served" page on your website and list all the markets your services supply. As you grow, include high-quality photos and graphics to validate the quality of your work further.

"Diversified content on our site has really helped us stand out as a leader in the industry," said Eoin Lynch, Executive Director of Sales and Marketing at Tex Tech Industries . "Some aerospace technology can be complex, but our graphics, datasheets, and videos from Thomas Marketing Services break it down for buyers to understand what they need and how we help them."

Corrugated Metals set a record for quotes and tapped into the aerospace industry after investing in online advertising from Thomasnet.com — they were contacted by the U.S. Air Force to create a custom part for them.

"Advertising with Thomas lets us develop accounts that build our backlog and keep us more stable as the economy grows," said Ken Carlton, VP of Corrugated Metals. "One Thomas lead that came to our company spawned an entirely new company for our business."

Steel and metal manufacturing companies looking to grow need to take advantage of the digital revolution not only from a marketing perspective, but to improve operation models and the supply chain. Digitization in the steel and metals industry will give supply chain access to real-time information and appropriately respond to unpredictable changes in the market while decreasing risk and providing growth opportunities.

Success Story: Growth For Continental Steel & Tube Company

The manufacturing industry has always aspired toward supply chain consolidation. Sourcing your products from fewer suppliers can significantly benefit your company's bottom line and reduce frustrations.

This kind of consolidation helped Continental Steel's Don Ascione grow his business in a way he didn't plan for — but recognized and capitalized on as a metal specialist with a world-class network. Continental Steel has established itself over the years as a company whose specialty is sourcing hard-to-find metals. Ascione, the company's founder, utilized his operations management background and connections from around the United States and Mexico to amass a tremendous network of metal suppliers.

By supplying numerous fabrication contacts with necessary materials, Ascione also created a tight-knit network of fabricators. This network allows Continental Steel to act as a manufacturer's representative for the fabrication companies and sell projects to customers looking for pressure vessels or staircases (as an example).

Continental Steel has an advantage to really help the customer because he can choose the best fabricator for the job and provide the best pricing on the raw material for the project. The customer gets the best of both worlds, and the network gets more business as well.

When Ascione realized the opportunity to generate revenue from connecting customers with the very fabricators he was supplying, he leaped at the chance. It couldn’t have happened without Continental Steel’s expertise, knowledge, reliability, and firm establishment as a leading source for procuring elusive metals.

Knowing that opportunities like these are few and far between, Ascione seized the opportunity to nurture this new stream of revenue. Pairing a network of metal specialists with fabricators is tremendously helpful for clients. Rather than looking to Continental Steel for metal procurement exclusively, groups can now find the fabrication services they need for their project, which they previously would have needed to quote from elsewhere.

Continental Steel is now positioned to meet all of its clients’ needs, from finding whatever metal materials are required for the project, to developing the top-quality final product. Clients know that the caliber of fabrication will be unsurpassed because of the wide reach to find the best for the job.

His team works to find metals and fabricators for his clients so they don’t have to do it themselves. And now Continental Steel has become a leading source for metals procurement around the globe and a premier source for custom fabrication, as well.

UNLOCK YOUR FREE PROSPECTING REPORT: See the buyers and companies searching for your services with a free Custom In-Market Buyer Report — your next new contract might be on this list

Promote Your Steel Business

Navigating the digital landscape can be tough, along with changing global policies, and complicated distribution channels — as a manufacturing business owner, you already have so much on your plate to manage. But Thomas has been powering the manufacturing industry for more than 122 years, connecting buyers to suppliers and helping engineers get their jobs done.

“As a small machine shop, it’s critical that every marketing dollar I spend attracts the right kind of customers — those that I actually want to do business with. My Thomasnet.com program paid for itself within the first 3 months.” — Richard Barnard, President, Eaglestone Technology, Inc.

Our industrial experts have compiled the below resources to help ensure your business grows and continues to prosper no matter what economic or global health situations come your way.

Our related blogs to keep you up to date on the latest industry tips:

- How To Sell B2B Products In A B2C World

- The Importance Of Marketing And Advertising During Economic Downturn

- The Manufacturer's Playbook For Direct-To-Consumer Selling

- What Manufacturers Need To Know About The Defense Production Act

- 6 Common Mistakes That Job Shops Make

- 3 Must-Have Lead Generation Ideas For Steel And Metals Companies

Our online solutions to help you grow:

- Learn about our free video content production services to help manufacturers and industrial companies connect with more customers creatively online when travel is restricted.

- Contact us to learn how you can get in front of qualified buyers and increase your bottom line. Thomas provides lead generation services that fit any size budget.

- To see where you can improve online and how your brand compares to competitors, request a free Digital Health Check .

- Increase your RFQs with a free Thomasnet.com profile and connect with new customers on the platform where more than a million buyers from various industries and geographies source are sourcing for products and services.

- See the exact companies searching for your steel and metals manufacturing services with a free In-Market Buyer Report .

- For articles just like these, subscribe to our daily email newsletter Thomas Industry Update .

Editor's Note: If you're sourcing suppliers for COVID-19 items, click here for those manufacturers and distributors . If your industrial business can support the production of essential supplies to combat the COVID-19 outbreak, please complete this form to notify us of your availability and willingness to dedicate resources. Thomas is working with State and Federal Government offices to help mobilize manufacturers to deliver supplies and services.

Did you find this useful?

Business & Industry

Georgia Dome Imploded in Atlanta

Related posts.

Challenges And Opportunities In The Food & Beverage Industry

5 Things Manufacturers Are Wishing For This Holiday Season

Actionable next steps for manufacturers....

Free Missed Opportunity Report

See which buyers are searching Thomasnet.com for the products & services you specialize in.

Get Buyer Report

The Ultimate Guide To Marketing

Learn about all the Digital Marketing Tactics that are Driving Growth for Manufacturers in 2021

Get Found By Buyers & Engineers