Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

Over the past 20+ years, we have helped over 7,000 entrepreneurs and business owners create business plans to start and grow their manufacturing businesses. On this page, we will first give you some background information with regards to the importance of business planning. We will then go through a manufacturing business plan template step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Manufacturing Business Plan?

A business plan provides a snapshot of your manufacturing business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategy for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Manufacturing Company

If you’re looking to start a new manufacturing business, or grow your existing manufacturing business, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your manufacturing business in order to improve your chances of success. Your business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Manufacturing Businesses

With regards to funding, the main sources of funding for a manufacturing business are personal savings, credit cards, bank loans and angel investors. With regards to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to confirm that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business.

Personal savings is the other most common form of funding for a manufacturing business. Venture capitalists will usually not fund a manufacturing business. They might consider funding a manufacturing business with a national presence, but never an individual location. This is because most venture capitalists are looking for millions of dollars in return when they make an investment, and an individual location could never achieve such results. With that said, personal savings and bank loans are the most common funding paths for manufacturing businesses.

Finish Your Business Plan Today!

How to write a business plan for a manufacturing company.

If you want to start a manufacturing business or expand your current one, you need a business plan. Below we detail what you should include in each section of your own business plan:

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status. For example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Next, provide an overview of each of the subsequent sections of your plan. For example, give a brief overview of the manufacturing industry. Discuss the type of manufacturing business you are operating. Detail your direct competitors. Give an overview of your target market. Provide a snapshot of your marketing strategy. Identify the key members of your team. And offer an overview of your financial plan.

Company Analysis

In your company analysis, you will detail the type of business you are operating.

There are many types of manufacturing businesses, such as:

- Clothing manufacturing

- Garment manufacturing

- Food product manufacturing

- Diaper manufacturing

- Tile manufacturing

- Toy manufacturing

- Soap and detergent manufacturing

- Mobile accessories manufacturing

- Mattress manufacturing

- Bicycle manufacturing

- Pillow manufacturing

- Brick manufacturing

- Toilet paper manufacturing

- Furniture manufacturing

- Peanut butter manufacturing

- Cosmetics manufacturing

- Footwear manufacturing

In addition to explaining the type of manufacturing business you will operate, the Company Analysis section of your business plan needs to provide background on the business.

Include answers to question such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, number of positive reviews, number of wholesale contracts, etc.

- Your legal structure. Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the manufacturing industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the manufacturing industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your strategy, particularly if your research identifies market trends.

The third reason for market research is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section:

- How big is the manufacturing industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential market for your manufacturing business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section must detail the customers you serve and/or expect to serve.

The following are examples of target market segments: wholesalers, other manufacturers, exports, retailers.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of manufacturing business you operate. Clearly, retailers would respond to different marketing promotions than export markets, for example.

Try to break out your target market in terms of their demographic and psychographic profiles. With regards to demographics, include a discussion of the ages, genders, locations and income levels of the customers you seek to serve. Because most manufacturing businesses primarily serve customers living in their same city or town, such demographic information is easy to find on government websites.

Psychographic profiles explain the wants and needs of your target customers. The more you can understand and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Manufacturing Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other manufacturing businesses.

Indirect competitors are other options that customers have to purchase from that aren’t direct competitors. This includes manufacturers in other niches, as well as those vertically integrated businesses that make their own product. You need to mention such competition as well.

With regards to direct competition, you want to describe the other manufacturing businesses with which you compete. Most likely, your direct competitors will be house flippers located very close to your location.

For each such competitor, provide an overview of their businesses and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as:

- What types of customers do they serve?

- What types of products do they manufacture?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you provide high quality manufacturing practices?

- Will you provide services that your competitors don’t offer?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a manufacturing business, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of manufacturing company that you documented in your Company Analysis. Then, detail the specific products you will be offering. For example, in addition to manufacturing, will you provide R&D, design, prototyping or any other services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your marketing plan, you are presenting the services you offer and their prices.

Place : Place refers to the location of your manufacturing company. Document your location and mention how the location will impact your success. For example, is your manufacturing business located near a distribution hub, etc. Discuss how your location might be the ideal location for your customers.

Promotions : The final part is the promotions section. Here you will document how you will drive customers to your location(s). The following are some promotional methods you might consider:

- Advertising in local papers and magazines

- Reaching out to local websites

- Social media marketing

- Local radio advertising

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your manufacturing business, including sourcing inputs, designing processes, managing production, coordinating logistics and meeting with potential buyers.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to secure your 1,000 th contract, or when you hope to reach $X in revenue. It could also be when you expect to expand your manufacturing business to a new city.

Management Team

To demonstrate your manufacturing business’ ability to succeed, a strong team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally you and/or your team members have direct experience in managing manufacturing businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act like mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in manufacturing or successfully running small businesses.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet and cash flow statements.

Income Statement : an income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenues and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you offer short-run production, or will you focus strictly on long-run? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets : Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your manufacturing business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a bank writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement : Your cash flow statement will help determine how much money you need to start or grow your business, and make sure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

In developing your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a manufacturing business:

- Location build-out including design fees, construction, etc.

- Cost of equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Taxes and permits

- Legal expenses

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your production facility blueprint, or capabilities specifications.

Putting together a business plan for your manufacturing business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will really understand the manufacturing industry, your competition, and your customers. You will have developed a marketing plan and will really understand what it takes to launch and grow a successful manufacturing business.

Manufacturing Business Plan FAQs

What is the easiest way to complete my manufacturing business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily complete your Manufacturing Business Plan.

What is the Goal of a Business Plan's Executive Summary?

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status; for example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Don’t you wish there was a faster, easier way to finish your Manufacturing business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how Growthink’s professional business plan consulting services can create your business plan for you.

Other Helpful Business Plan Articles & Templates

- See all articles

- Business tips

- Inventory management

- Manufacturing

- Product updates

Getting started: A guide to creating a manufacturing business plan

Every day people are trying and failing at entrepreneurism.

The journey is a difficult one, and the chances of success are slim. Those that succeed sometimes have a brilliant idea, while others have a wealth of resources. The one commonality among all successful entrepreneurs is that they had a manufacturing business plan.

You need to know where you are going, how you will get there, and what you will do when you arrive. This is especially important for those in the manufacturing industry because of the significant amount of forethought required.

Even if you are leveraging digital solutions to minimize the amount of time, money, and effort required to bring your product to market, you will still need a plan. This is not an area where you can wing it and hope for the best.

Below, we will examine the basics of a manufacturing business plan, what is necessary to include, how to create one for your own company, and some common mistakes that you should avoid.

Table of contents:

What is a manufacturing business plan, why does a manufacturing company need a business plan, what are the key components of a business plan, how to write a business plan for a manufacturing company, common mistakes to avoid.

A manufacturing business plan is a formal document that outlines the goals and objectives of your business. It includes detailed information about your:

- Products or services

- Target market

- Marketing strategy

- Financial projections

- Operational details

The purpose of a business plan is to give you a roadmap to follow as you build and grow your business. It forces you to think through every aspect of your venture and identify potential problems or roadblocks before they happen.

Manufacturing business plans can also be used to attract investors or secure funding from lenders. If you are looking for outside financing, your business plan needs to be even more detailed and include information on your management team, financial history, and expected growth.

Ideally, you should update your business plan yearly to ensure that it remains relevant and accurate. As your business grows and changes, so too should your plan.

No matter how simple or complex your ideas may be, you need a plan, or they will never become a reality. A business plan will clearly understand your costs, competition, and target market. It will also help you to set realistic goals and track your progress over time.

Let’s look at a manufacturing strategy example. You have a great idea that you think will revolutionize the automotive industry . Your new safety harness will be made from a lightweight, yet incredibly strong, material that cannot be cut or torn. You are confident that your product will be in high demand and generate a lot of revenue.

But before you walk into Ford or Toyota to try and get a purchase order , you need to have a plan. You must know:

- How much will it cost to produce your product

- How many units do you need to sell to break even

- Who is your target market is

- What is your competition selling

- How will you reach your target market

You also need to clearly understand the regulatory landscape and what it takes to bring a new product to market. All of this information (and more) should be included in your business plan.

This is not just a document that you create and forget about. It is a living, breathing tool that should be used to guide your actions as you build and grow your business.

Every manufacturing business plan will be different, but almost always, they will include the same five components:

Executive summary

Company description, products and services, market analysis.

- Financial plan

Let’s take a closer look.

The executive summary is the first section of your business plan, but it is typically written last. This is because it should be a concise overview of everything that follows, and you can only do that once you have completed the rest of your plan.

Include the following in your executive summary:

- The problem that your product or service solves

- Your target market

- Your unique selling proposition (what makes you different from your competitors?)

- Your manufacturing business model (how will you make money?)

- Your sales and marketing strategy

- A brief overview of your financial projections

Someone should be able to quickly scan through your executive summary and have a pretty good understanding of what your business is and how it plans to be successful.

This is where you can get a bit more creative, explaining your company’s history, mission, and values. You will also include information on your team or management structure.

It can be simple but should inspire faith in your ability to execute your business plan.

You will need to provide a detailed description of your product or service, as well as any unique features or benefits that it offers. You should also include information on your manufacturing process and quality control procedures.

If you have any patents or proprietary technology, they should be listed here as significant assets for your business.

For example, let’s say you are planning on creating a brand-new line of disposable coffee cups. The dimensions, materials, and other specifications would be listed here, along with any unique benefits (such as being made from recycled materials).

You might also include information on your manufacturing process, such as the fact that the cups will be produced in a certified clean room or that you will employ workers local to where the product is sold.

Chances are, you started down this path because you realized that there was a market opportunity for your product or service. In this section, you will need to provide detailed information on the opening, as well as the analysis that convinced you to pursue it.

This should include:

- Market size (current and projected)

- Key market segments

- Customer needs and wants

- Competitive landscape

This is where you will need to do your homework, as you will be justifying your business decision to enter this particular market. The more data and analysis you can provide, the better.

For our coffee cup example, the market analysis might include:

- Information on how many cups are used every day

- Projected growth

- Key segments (such as office workers or on-the-go consumers)

- Customer needs (such as convenience or sustainability)

It would also examine the competitive landscape, including both direct and indirect competitors.

Financial plan

You’re in this to make money, and so are your potential investors. In this section, you will need to provide detailed information on your manufacturing business model and how it will generate revenue. This should include:

- Initial investment

- Sales forecast

- Carrying costs

- Pricing strategy

- Expense budget

You will also need to provide information on your long-term financial goals, such as profitability or break-even point. Discuss production line details, inventory management strategies , and other factors impacting your bottom line.

The process of creating a business plan for a manufacturing company is similar to any other type of business. However, there are some key considerations to keep in mind.

First, you need to understand your industry and what it will take to be successful in it. This includes understanding the competitive landscape, the costs of goods sold , and the margins you can expect to achieve.

You also need to have a clear understanding of your target market and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits.

While there will be many things specific to your company, here are five questions to answer for each of the sections listed above.

Executive summary:

- What is the problem that your company will solve?

- How will your company solve that problem?

- Who are your target customers?

- What are your key competitive advantages?

- What is your business model?

Company description:

- What is the legal structure of your company?

- What are your company’s core values?

- What is your company’s history?

- Who are the key members of your management team?

- Where is your manufacturing facility located?

Products and services:

- What product or service does your company offer?

- How does your product or service solve the problem that your target market has?

- What are the key features and benefits of your product or service?

- How is your product or service unique from your competitors?

- What is the production process for your product or service?

Market analysis:

- Who is your target market?

- What needs or wants does your target market have that your product or service will address?

- What is the size of your target market?

- How do you expect the needs of your target market to change in the future?

- Who are your key competitors, and how do they serve the needs of your target market?

Financial plan:

- What are the start-up costs for your company?

- How will you finance your start-up costs?

- What are your monthly operating expenses?

- What is your sales forecast for the first year, and how does that compare to your industry’s average sales growth rate?

- What are your gross margin and profit targets?

Even if you do nothing but answer these questions, you’ll be well on your way to creating a thorough manufacturing business plan.

How to stabilize your growth

However, new manufacturing entrepreneurs often fall into a handful of traps when creating their business plans.

- Not doing enough research – You can’t know everything about your industry, but you should do your best to understand as much as you can before writing your business plan. This means talking to experts, reading trade publications, and studying the competition

- Not being realistic – It’s important to be optimistic when starting a new business, but you also need to be realistic. This is especially true when it comes to financial projections. Don’t overestimate the amount of revenue you will generate or underestimate the costs of goods sold

- Not having a clear understanding of your target market – You need to know who you are selling to and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits

- Failing to understand your competition – You need to know who your competitors are, what they are offering, and how you can differentiate yourself. This information will be critical in developing your marketing strategy

- Not having a clear vision for the future – Your manufacturing business plan should include a section on your long-term goals and objectives. What does your company hope to achieve in the next five years? Ten years? Twenty years?

Creating a business plan for manufacturing can be simple. It can be quite simple if you break it down into smaller pieces.

Once you have it in place, staying on track can be quite a bit more difficult. By using ERP software like Katana , you can track all of your key metrics in real time, avoid any potential issues, and make course corrections as needed.

To start following your plan and creating a successful manufacturing company, get a Katana demo today.

- Manufacturing guide

- 1.1. Production vs manufacturing

- 1.2. Production scheduling software

- 1.3. Production tracking software

- 2.1. How to manufacture a product

- 2.2. Manufacturing best practices

- 2.3. A guide to creating a manufacturing business plan

- 2.4. Manufacturer e-commerce

- 2.5. Marketing for manufacturers

- 2.6. Manufacturing business processes

- 2.7. Food manufacturing

- 2.8. Small business manufacturing software

- 3.1. Job shop manufacturing

- 3.2. Production quality control checklist

- 4.1. Just-in-time (JIT) manufacturing

- 4.2. Tips to reduce manufacturing waste

- 4.3. Manufacturing KPIs

- 5. Light manufacturing

- 6. Advanced manufacturing

- 7. IoT in manufacturing

- 8.1. Manufacturing execution system (MES)

- 9.1. Manufacturing overhead formula

- 9.2. Manufacturing inventory software

- 10. Good manufacturing practices (GMP)

- 11.1. MRP in supply chain management

- 11.2. Best MRP software

- 12.1. Best ERP software for manufacturing

More guides from Katana

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

You’ve come to the right place to create your Manufacturing business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Manufacturing companies.

Below is a template to help you create each section of your Manufacturing business plan.

Executive Summary

Business overview.

Perfect Snacks, located in Lincoln, Nebraska, is a food manufacturing company that specializes in the production of snack foods and packaged goods. We manufacture an extensive line of snack products, including trail mix, gummies, and chocolate. Our company focuses on quality and only uses the best natural ingredients in our products. We will primarily sell our products to grocery stores and other establishments that sell snacks, but will also sell bulk orders to individual customers through our website.

Perfect Snacks was founded by Joe Boseley. Joe has been working on the manufacturing company concept over the past few years and began networking with grocery store clients and locating the land to build his manufacturing and distribution center. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Product Offering

Perfect Snacks will manufacture an extensive list of sweet, salty, and healthy snacks. Some of our initial products will include:

We will primarily sell our products to grocery stores, recreation centers, and other businesses that sell snacks in bulk. Consumers can find our products in stores or buy them in bulk on our website.

Customer Focus

Perfect Snacks will primarily serve the residents of Lincoln, Nebraska. The community has a large population of families and children, who are the primary consumers of snack foods. Therefore, we will market our products to recreational centers, schools, grocery stores, and other establishments that sell snacks to children and their parents.

Management Team

Perfect Snacks is owned by Joe Boseley, a local entrepreneur who has worked in various warehouses and manufacturing companies in Lincoln, Nebraska. Working in the manufacturing industry and in warehouses, Joe is very familiar with the processing and distribution of packaged foods. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Joe will utilize his past experience with developing staff roles and functions. He is also very familiar with the manufacturing equipment and plans to purchase the latest technology that is efficient and cost effective. His contacts have allowed him to gain concrete Letters of Intent from local supermarket chains to have his manufactured goods in their stores.

Success Factors

Perfect Snacks will be able to achieve success by offering the following competitive advantages:

- Taste: Perfect Snacks’ snack products will be made with the highest quality ingredients and offer quality over quantity.

- Price: Perfect Snacks is able to offer the highest quality snacks at a competitive price point.

- Community Relations: Perfect Snacks will be a pillar in the community and be heavily involved in family-related activities in the area. It will sponsor events, provide snacks for schools and daycares at a discounted price, and donate a portion of its proceeds to area family-related charities and organizations.

- Proprietary Technology: Perfect Snacks will invest heavily on the latest technology to manufacture the snack foods for distribution. It will ensure the food products are made safely and free from any harmful chemicals and ingredients.

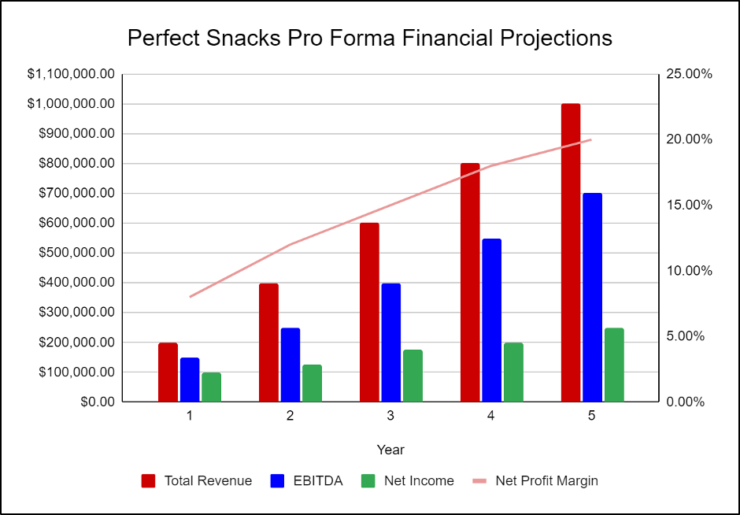

Financial Highlights

Perfect Snacks is seeking a total funding of $1,200,000 of debt capital to open its manufacturing company. The capital will be used for funding capital expenditures, salaries, marketing expenses, and working capital. Specifically, these funds will be used as follows:

- Manufacturing facility design/build-out: $400,000

- Equipment and supplies: $375,000

- Initial inventory: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $250,000

- Marketing costs: $50,000

- Working capital: $25,000

The following graph below outlines the pro forma financial projections for Perfect Snacks.

Company Overview

Who is perfect snacks, perfect snacks history.

After conducting a market analysis, Joe Boseley began surveying the local vacant warehouse space and decided on a parcel of land to construct the warehouse and distribution center. Joe incorporated Perfect Snacks as a Limited Liability Corporation on January 1st, 2023.

Once the land is acquired for the warehouse space, construction can begin to build-out the manufacturing facility.

Since incorporation, the Company has achieved the following milestones:

- Located a vacant lot that would be ideal for a manufacturing facility

- Developed the company’s name, logo, and website

- Hired a general contractor and architect for the build-out of the warehouse, small office, and distribution area

- Determined equipment and necessary supplies

- Determined beginning inventory

- Attained Letters of Intent from supermarket clients

- Began recruiting key employees

Perfect Snacks Services

Industry analysis.

The Manufacturing sector’s performance is largely attributable to the value of the US dollar, commodity prices, policy decisions and US manufacturing capacity. Food manufacturing has a history of success as it produces a basic human need. According to Grand View Research, the industry is currently valued at $121 billion and is expected to expand at a compound annual growth rate of 9.5% from now until 2030.

Commodity prices are currently stabilizing from coronavirus-induced volatility and renewed demand, both in the United States and global economies, which is anticipated to facilitate revenue expansion for manufacturers. Moreover, shifting technological change in the Manufacturing sector is anticipated to benefit large, developed economies, such as the United States. Therefore, now is a great time to start a new food manufacturing company in the U.S.

Customer Analysis

Demographic profile of target market.

Perfect Snacks will serve the community residents of Lincoln, Nebraska and its surrounding areas. The community of Lincoln, Nebraska has thousands of households that have children. Statistics show that the main consumers of snack products are children of all ages. They are regularly placed in school lunchboxes, afterschool snacks and programs, and at weekend sporting events. Therefore, we will market to locations where snacks are bought by children or their parents, such as grocery stores, recreational centers, and schools.

The precise demographics Lincoln, Nebraska is as follows:

Customer Segmentation

Perfect Snacks will primarily target the following customer profiles:

- Grocery stores and recreational centers

Competitive Analysis

Direct and indirect competitors.

Perfect Snacks will face competition from other companies with similar business profiles. A description of each competitor company is below.

Snacks N More

Snacks N More is another local manufacturing company that provides snack food to the immediate area. Established over thirty years ago, the company has the knowledge and expertise in food processing, commercialization, and packaging. They are known as a recognized ingredient supplier for the foodservice industry. Their portfolio of products include a variety of nuts, snacks, confections, and dry-blend ingredients. As a private label manufacturer, Snack’s More produces a full line of non-chocolate candy, nuts, and fruit-flavored snacks. The company is known for their fruit flavored snacks, dried raisins, nut mixes, and producing ingredients for local restaurants and establishments. Their line of nuts and dried fruits are often used for baking purposes.

Jaxon’s Candy

Jaxon’s Candy is a manufacturer of all things candy related. As a contract manufacturer, the company works with many companies to create their custom designed confections. Their large 50,000 square foot facility produces over 300,000 pounds of candy every month. All of the products are highly concentrated either in sugar or chocolate, or both. Jaxon’s Candy also designs and manufactures their own custom packaging. The candy produced is also kosher certified, gluten free, peanut free, and non-GMO.

Jaxon’s Candy currently manufactures candy for the following brands – Tommy Candy, Laffy Town, Chocowhoawhoa, Jellylicious, Healthee Candeee, and Sticky Teeth. Jaxon’s Candy can be found in grocery stores and convenient stores along the west coast of the United States.

Gimmy Candy

Gimmy Candy is located in the midwestern portion of the United States and boasts a facility of over 1 million square feet. Their fleet of transportation trucks distributes throughout the continental United States and is considered one of the largest candy manufacturers in the country. Their product portfolio includes assorted chocolates, gummy candy, hard candy, fruit candy, as well as gums and mints. Gimmy Candy was established in 1947 and has grown to be a model of manufacturing companies the industry uses as a model of sustainability and profitability. Their lineup of candy products can be found in every single grocery store and convenient store in the country. Gimmy Candy is considering expanding its distribution globally and start exporting its candy products to Asia, Canada, Europe, and South America. As one of the largest privately held companies in the United States, Gimmy Candy is also considered a top employer in the country and offers its employees a generous benefits package.

Competitive Advantage

Perfect Snacks will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

Perfect Snacks will offer the unique value proposition to its clientele:

- Fresh and comforting taste

- Community family advocate

- Developed with proprietary technology

- Manufactured with fresh, quality ingredients

- Affordable price

Promotions Strategy

The promotions strategy for Perfect Snacks is as follows:

Social Media

Perfect Snacks will invest heavily in a social media advertising campaign. The brand manager will create the company’s social media accounts and invest in ads on all social media accounts. It will use targeted marketing to appeal to the target demographics.

Website/SEO

Perfect Snacks will invest heavily in developing a professional website that displays all of the features and benefits of the snack products. It will also invest heavily in SEO so that the brand’s website will appear at the top of search engine results.

Major Publications

We will also invest in advertising in selected larger publications until we have achieved significant brand awareness. Advertisements such as billboards and commercials will be shown during peak tv watching time and the billboards will be placed in highly trafficked areas.

Sponsorships

Perfect Snacks will also invest in sponsoring certain athletic and school events so that their banners and collateral material are displayed all over the event where numerous parents and children are at.

Perfect Snacks’s pricing will be moderate so consumers feel they receive great value when purchasing our snack products.

Operations Plan

The following will be the operations plan for Perfect Snacks.

Operation Functions:

- Joe Boseley will be the CEO of Perfect Snacks. He will oversee the general operations and executive aspects of the business.

- Joe is joined by Candace Smith who will act as the warehouse manager. She will train and manage the staff as well as oversee general production of our products.

- Joe will hire an Administrative Assistant, Marketing Manager, and Accountant, to handle the administrative, marketing, and bookkeeping functions of the company.

- Joe will also hire several employees to manufacture our products and maintain the equipment and machinery.

Milestones:

Perfect Snacks will have the following milestones complete in the next six months.

- 02/202X Finalize lease agreement

- 03/202X Design and build out Perfect Snacks

- 04/202X Hire and train initial staff

- 05/202X Kickoff of promotional campaign

- 06/202X Launch Perfect Snacks

- 07/202X Reach break-even

Financial Plan

Key revenue & costs.

Perfect Snacks’s revenues will come primarily from its snack food sales. The company will sell the packaged snacks in local grocery stores, convenience stores, and other locations. As the company’s revenues increase, it will look to gain a wider distribution area.

The land purchase, equipment, supplies, opening inventory, and labor expenses will be the key cost drivers of Perfect Snacks. Other cost drivers include taxes, business insurance, and marketing expenditures.

Funding Requirements and Use of Funds

Key assumptions.

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and pay off the startup business loan.

- Average order value: $250

Financial Projections

Income statement, balance sheet, cash flow statement, manufacturing business plan faqs, what is a manufacturing business plan.

A manufacturing business plan is a plan to start and/or grow your manufacturing business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Manufacturing business plan using our Manufacturing Business Plan Template here .

What are the Main Types of Manufacturing Businesses?

There are a number of different kinds of manufacturing businesses , some examples include: Garment manufacturing, Food product manufacturing, Diaper manufacturing, Tile manufacturing, and Toy manufacturing.

How Do You Get Funding for Your Manufacturing Business Plan?

Manufacturing businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Manufacturing Business?

Starting a manufacturing business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Manufacturing Business Plan - The first step in starting a business is to create a detailed manufacturing business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your manufacturing business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your manufacturing business is in compliance with local laws.

3. Register Your Manufacturing Business - Once you have chosen a legal structure, the next step is to register your manufacturing business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your manufacturing business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Manufacturing Equipment & Supplies - In order to start your manufacturing business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your manufacturing business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Business Plan Template for Manufacturing Company

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

Starting a manufacturing company can be an exciting but challenging endeavor. To ensure success, you need a solid business plan that covers all the essential aspects of your operations. That's where ClickUp's Business Plan Template for Manufacturing Companies comes in!

Our template provides a comprehensive framework for outlining your company's goals, conducting market analysis, projecting finances, and strategizing your operations. With ClickUp's Business Plan Template, you'll be able to:

- Clearly define your company's vision, mission, and objectives

- Conduct a thorough market analysis to understand your target audience and competitors

- Develop financial projections and budgets to secure funding and attract investors

- Create operational strategies to optimize production, logistics, and quality control

Whether you're a seasoned entrepreneur or just starting out, our Business Plan Template will guide you through the process of building a successful manufacturing company. Don't miss out on the opportunity to turn your vision into reality—get started with ClickUp today!

Business Plan Template for Manufacturing Company Benefits

Creating a solid business plan is crucial for success in the manufacturing industry. By using the Business Plan Template for Manufacturing Company, you can:

- Clearly define your company's vision, mission, and goals

- Conduct a thorough market analysis to identify target customers and competitors

- Develop a comprehensive financial plan, including revenue projections and cost analysis

- Outline your manufacturing processes, supply chain management, and quality control measures

- Present a professional and well-structured document to potential investors and lenders

- Guide strategic decision-making and ensure alignment with your long-term objectives

- Monitor and track progress towards your business milestones and objectives

Main Elements of Manufacturing Company Business Plan Template

When it comes to creating a comprehensive business plan for your manufacturing company, ClickUp has you covered with its Business Plan Template. Here are the main elements you'll find in this template:

- Custom Statuses: Keep track of the progress of different sections of your business plan with statuses like Complete, In Progress, Needs Revision, and To Do.

- Custom Fields: Add important details to your business plan using custom fields such as Reference, Approved, and Section, allowing you to easily organize and categorize information.

- Custom Views: Access different perspectives of your business plan using views like Topics, Status, Timeline, Business Plan, and Getting Started Guide, making it easy to navigate and present your plan effectively.

- Document Collaboration: Collaborate with your team in real-time using ClickUp's Docs feature to work together on your business plan.

- Task Management: Break down your business plan into actionable tasks, assign them to team members, set due dates, and track progress using ClickUp's powerful task management features.

How To Use Business Plan Template for Manufacturing Company

If you're looking to create a business plan for your manufacturing company, follow these 6 steps using ClickUp's Business Plan Template:

1. Define your company's mission and vision

Start by clearly defining the mission and vision of your manufacturing company. What do you aim to achieve and how do you plan to do it? This will serve as the guiding principles for your business plan.

Use a Doc in ClickUp to outline your company's mission and vision statements.

2. Conduct market research

Thorough market research is essential to understand your target audience, competitors, and industry trends. Identify your niche, analyze customer needs, and assess the competitive landscape. This will help you position your manufacturing company effectively.

Use the Table view in ClickUp to compile and analyze market data, including customer demographics, competitor analysis, and industry trends.

3. Develop your product offerings

Outline the products and services your manufacturing company will offer. Determine the unique selling points of your offerings and how they address customer needs. Consider factors such as pricing, quality, and delivery timelines.

Use tasks in ClickUp to create a product development plan and assign tasks to team members responsible for designing, manufacturing, and testing the products.

4. Create a marketing and sales strategy

Define your marketing and sales strategies to promote your manufacturing company. Identify the channels and tactics you will use to reach your target audience. This may include digital marketing, trade shows, partnerships, or direct sales.

Use Goals in ClickUp to set specific marketing and sales objectives, such as lead generation targets or revenue goals.

5. Establish operational processes

Develop a plan for your manufacturing processes, including procurement, production, quality control, and logistics. Define the roles and responsibilities of your team members and ensure smooth coordination across departments.

Use Automations in ClickUp to streamline your operational processes by automating repetitive tasks and setting up notifications for key milestones.

6. Create financial projections

Project your financials, including revenue, expenses, and cash flow projections for the next few years. Consider factors such as production costs, pricing, sales volume, and market demand. This will help you assess the viability and profitability of your manufacturing company.

Use Dashboards in ClickUp to track and visualize your financial projections, allowing you to monitor your company's performance and make informed decisions.

By following these steps and utilizing ClickUp's Business Plan Template, you'll be well-equipped to create a comprehensive and effective business plan for your manufacturing company.

Get Started with ClickUp’s Business Plan Template for Manufacturing Company

Entrepreneurs and business owners in the manufacturing industry can use the Business Plan Template for Manufacturing Company to create a comprehensive plan for their business.

First, hit "Add Template" to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you'd like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to create a solid business plan:

- Use the Topics View to outline and organize the different sections of your business plan, such as Executive Summary, Market Analysis, Financial Projections, and Operational Strategies.

- The Status View will help you track the progress of each section, with statuses like Complete, In Progress, Needs Revision, and To Do.

- The Timeline View will allow you to set deadlines and visualize the timeline for completing each section of your business plan.

- Use the Business Plan View to have a comprehensive overview of your entire plan, with all the sections and details in one place.

- The Getting Started Guide View will provide you with step-by-step instructions and tips on how to effectively use the template and create a successful business plan.

- Customize the template by adding custom fields like Reference, Approved, and Section to provide additional information and track important details.

- Update statuses and custom fields as you make progress and receive feedback from stakeholders.

- Monitor and analyze your business plan to ensure it aligns with your goals and attracts investors.

- Business Plan Template for Distance Learning

- Business Plan Template for Medication Errors

- Business Plan Template for Little Caesars

- Business Plan Template for Technology

- Business Plan Template for Gym Owners

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

Business Plan For Manufacturing Company

Congratulations on taking the first step in creating a business plan for manufacturing company. This is an essential step towards entrepreneurial success and a well-crafted business plan will provide a solid foundation for your business venture!

Whether you're a budding entrepreneur with a brilliant idea or a seasoned business owner looking to expand, a thoughtfully constructed business plan will help you plan and navigate towards business prosperity.

In this comprehensive guide, we will walk you through the essential elements of creating a business plan for manufacturing company that captures your vision as well as attracting investors, partners, and customers alike. From defining your mission and identifying your target market to formulating financial projections and developing a robust marketing strategy, our aim is to empower you with the knowledge and tools needed to turn your aspirations into a reality.

So whether you're just starting out or you're looking to revamp your existing business plan, read on for everything you need to know.

Why is a business plan important?

A business plan will help you think about your manufacturing company business like you’ve never done before. This thinking will help you clarify important elements like your long-term goals and objectives. You can then work backwards from your goals to develop strategies and marketing campaigns to help make these objectives a reality.

A business plan will also help you think about your customers in great detail. You will be able to understand their wants and needs, where they hang out, and exactly how you will target them. This clarity will enable you to focus on developing the products or services they want.

Finally, if you are seeking outside capital such as investment or a bank loan, a well-thought-out business plan will show them you are serious about your business and you have developed a clear and thorough plan of action to achieve success.

A Business Plan For Manufacturing Company - The Key Parts

The executive summary, your company description, market analysis, products and services.

- Marketing Strategy

- Operational Plan

- Financial Projections

Risk Analysis

- Funding Request and Use of Funds (if applicable)

- Additional Information

An executive summary of your business plan for manufacturing company is a brief overview of your business plan.

This is the first thing that potential investors or lenders will see, so it is crucial that you make a good impression. Keep this section short and highlight the key points of your plan.

What should an executive summary include?

- Overview of the Business

- Mission Statement

- Key Objectives

- Summary of Products/Services

- Financial Highlights and Funding Requirements (if applicable)

Remember potential investors don’t always have huge amounts of time to read your document so make sure that you condense the critical information, enabling the reader to make quick and well-informed judgments. Tips for the Executive Summary

Wait until you’ve written the whole business plan and then come back and complete the executive summary. This way you will know your business plan for manufacturing company inside and out so you can highlight the key elements of the document. Remember the Executive Summary will shape the reader's initial perception of the business and whether they continue reading the document.

If you are looking for any tips on how to improve any section of your business plan, check out our Learning Zone , which has several in-depth guides on each section of the business plan.

The Company Description section of your manufacturing company business plan is crucial as it offers a comprehensive overview of your business. This section provides essential information about your company's history, mission, vision, legal structure, location, and key milestones. It allows readers to gain a clear understanding of your company's fundamental characteristics and the context in which it operates.

When crafting your company description, make sure to include the following key elements:

- Business Name and Legal Structure: Clearly state the legal name of the company and its legal structure.

- Business History: Provide a brief overview of how the business came into existence. Highlight key milestones or events that shaped the company's growth and development.

- Mission and Vision Statements: Present the company's mission statement, which outlines its purpose and primary goals. Additionally, share the vision statement, which describes the long-term vision and objectives for your business.

- Products and Services: Briefly explain the products or services your business offers, emphasising their unique selling points and how they address customer needs.

- Competitive Advantages: Clearly state the competitive advantages that differentiate your business from others in the market. This could include unique features, patents, proprietary technology, or a strong brand presence.

- Location and Facilities: Provide details about the physical location of your business and any facilities required to operate successfully.

Tips for writing the company description section:

- Interweave storytelling into the company's history, tell the reader about your passion for the business and the journey you’ve been on to get to this point.

- Include strong visuals and infographics.

- Avoid jargon and keep the writing style clear and concise.

- Focus on your company's unique selling point (USP) and how that makes you stand out in the marketplace.

- Back up this information with customer testimonials if possible.

The market analysis section of your manufacturing company business plan is essential for understanding the competitive landscape and the overall business environment. It is crucial to execute this section effectively as it demonstrates your in-depth knowledge of the market dynamics. This process will enable you, as an entrepreneur, to identify opportunities, mitigate risks, and develop strategies for success.

To conduct a good market analysis, it is important to have a deep understanding of the industry you are operating in. This information will help you make informed decisions about your product or service offerings, marketing strategies, and pricing.

Key elements to include in your market analysis section:

- Industry Overview: Provide a general overview of your industry. Describe the industry's size, growth rate, major players, and key trends. Include relevant statistics and data to support your claims.

- Target Market and Customer Segmentation: Clearly define your target market and outline the specific customer segments you aim to serve. Identify the needs, preferences, and behaviours of each segment.

- Competitor Analysis: Identify direct and indirect competitors in the market. Analyse their strengths, weaknesses, market share, and strategies. Highlight areas where your business differentiates itself from competitors.

- Market Trends and Opportunities: Explore current and future trends in the industry and market. Assess how these trends can impact your business positively and identify potential opportunities for growth.

- SWOT Analysis (optional): Consider including a SWOT analysis specific to your market. This can help you understand your business's strengths, weaknesses, opportunities, and threats in the context of the market.

How to nail the market analysis section?

- Differentiation: Focus on highlighting how your business differentiates itself from competitors, really try to drum home this point.

- Market Surveys or Interviews: Adding surveys or interviews and adding the key findings and quotes in the Market Analysis to support your claims will help reinforce the plans in your document.

- Competitive Matrix: a competitive matrix visually comparing your business against key competitors based on factors such as price, features, and customer service. This matrix is a great visual method highlighting your competitive advantages.

- Emerging Technologies or Trends: Identifying potential disruptions and how your company is prepared for them shows a great understanding of market dynamics and trends.

Looking for more inspiration on how to make your market analysis section even better, then check out our in-depth business market analysis guide.

In this section, we will highlight the core products and services that make your manufacturing company business unique and valuable. It is essential to showcase what sets you apart from the competition and why your offerings are exceptional. This information is especially important for potential investors, partners, and customers who are keen to understand what sets your business apart in the market.

When describing your products and services ensure you include the following information:

- Description of Products/Services: Provide a clear and concise description of each product or service your business offers. Explain their primary function and how they address customer needs.

- Unique Selling Proposition (USP): Highlight the unique features or benefits that make your products or services stand out from competitors. Clearly state why customers should choose your offerings over alternatives.

- Product/Service Life Cycle: Describe where each product or service stands in its life cycle (e.g., introduction, growth, maturity, decline) and outline plans for updates or new offerings in the future.

- Intellectual Property (if applicable): If your business has any intellectual property (e.g., patents, trademarks, copyrights) related to your products or services, mention them in this section.

Extra elements to make this section stand out:

- Customer Use Cases: Present real-life customer use cases or success stories that illustrate how your products or services have solved specific problems for customers. Use compelling narratives to engage readers.

- Product Roadmap: If applicable, include a product roadmap that outlines future updates, enhancements, or new offerings. This showcases your business's commitment to innovation and continuous improvement.

- Quality and Testing Standards: Discuss the quality standards your business adheres to and any testing processes you conduct to ensure the reliability and performance of your offerings.

- Pricing Strategy: Integrate your pricing strategy into this section. Explain how you've determined the pricing of your products or services, considering factors like production costs, competition, and value to customers.

- Environmental and Social Impact: If your products or services have positive environmental or social implications, highlight them in this section. Increasingly, customers appreciate businesses that contribute positively to society.

The Marketing Strategy Section

Key Information to Include Within the Marketing Strategy Section:

- Marketing Goals and Objectives: Clearly state the marketing goals you aim to achieve. Focus on how you will increase brand awareness and drive customer conversions or leads.

- Target Market Strategy: Describe the specific strategies you will use to reach and engage with your target customers. This could involve digital marketing, traditional advertising, or other channels.

- Pricing Strategy: Explain how your pricing will attract the target market and how it compares to competitors' pricing.

- Promotion and Advertising Plan: Outline the promotional activities and advertising campaigns you plan to execute. Include details about social media marketing, content marketing, email campaigns, and other promotional tactics.

- Sales Strategy: Describe your sales process and how you plan to convert leads into paying customers. Mention any sales team structure and their responsibilities if applicable.

- Customer Relationship Management (CRM) Approach: Discuss how you intend to build and maintain strong relationships with your customers to encourage repeat business and loyalty.

Getting Creative with the Market Strategy Section

- Create a visual marketing timeline.

- Outline influencer or brand ambassador partnerships if applicable.

- Detail key metrics and KPIs.

By infusing creativity and innovative marketing ideas with sound fundamental marketing, you can really make this section stand out and impress potential investors and partners.

The Operation Plan Section

While marketing activities may seem more exciting, operational planning is essential for the success of your manufacturing company business. This section focuses on the day-to-day operations and internal processes that drive your business forward. By providing a comprehensive roadmap of your resources, workflows, and procedures, you can instill confidence in potential investors that your business is well-equipped for growth.

Here are some key items to include in your operational plan:

- Organisational Structure: Describe the organisational structure of the company, including key roles and responsibilities.

- Key Personnel and Team: Introduce key team members and their qualifications. Highlight how their expertise contributes to the success of the business.

- Operational Workflow and Processes: Provide a high-level step-by-step overview of delivering your product or service, from production to delivery or distribution.

- Resource Requirements: Outline the key resources required to run the business, such as equipment, technology, facilities, and human resources.

- Quality Control and Assurance: Explain how the company ensures the quality and consistency of its products or services, and how it addresses any potential issues.

- Supply Chain Management (if applicable): If the business involves sourcing materials or products from suppliers, describe the supply chain management process.

- Legal and Regulatory Compliance: Discuss any legal or regulatory requirements specific to the industry and how the company ensures compliance.

How to add value to the Operation Plan section:

- Use visuals to outline organisation structures and workflows.

- Outline contingency plans, for example how the company is prepared for supply chain shortages or price shocks.

- Efficiency, efficiency, efficiency. Describe how you have driven efficiency gains for the business.

- Have you considered your business's environmental impact? If so, mention within this section.

The operational section of a business plan does have the potential to be dryer than more exciting elements such as marketing, however, by incorporating creative elements and forward-thinking workflows you can help keep reader engagement high.

The Financial Projections

The Financial Projections section can make or break a business plan. Always include well-researched and accurate projections to avoid undermining your business plan and losing out on potential investment. What to include in the financial projections section:

- Sales Forecast: Provide a detailed projection of the company's sales revenues for each product or service category over the forecast period.

- Expense Projections: Outline the expected operating expenses, including costs related to production, marketing, salaries, rent, utilities, and any other significant expenses.

- Profit and Loss (P&L) Statement: Present a comprehensive Profit and Loss statement that summarizes the business's revenue, cost of goods sold (COGS), gross profit, operating expenses, and net profit or loss for each year of the forecast.

- Cash Flow Projection: Include a cash flow statement that outlines the inflows and outflows of cash over the forecast period. This will help identify potential cash flow gaps.

- Break-Even Analysis: Perform a break-even analysis to determine the point at which the business's total revenue equals total costs, indicating when it becomes profitable.

How to add value to your financial projections section:

- Be prepared to defend your assumptions with data. If you are planning for a high-growth % make sure you can justify this assumption. If in doubt the more conservative the better.

- Include visuals that help readers quickly grasp the trends and patterns in revenue, expenses, and profits.

- Offer different scenarios based on varying assumptions. For example, present a conservative, moderate, and aggressive growth scenario.

- Include key financial ratios like gross margin, net profit margin, and return on investment (ROI).

The Funding Request and Use of Funds Section

This section outlines the financial requirements of the company and how the requested funds will be utilised to support its growth and operations. Providing potential investors or lenders with a clear picture of how their money will be used will improve the business case for the funds and provide further confidence to investors. What to include in this section?

- Funding Request Amount: State the specific amount of funding you are seeking to obtain from investors, lenders, or other sources.

- Use of Funds: Provide a detailed breakdown of how the requested funds will be allocated across different aspects of the business. Common categories include product development, marketing, operational expenses, hiring, equipment, and working capital.

- Timeline of Funds Utilisation: Outline the timeline for utilising the funds. Specify when and how the funds will be disbursed and the expected milestones or deliverables associated with each funding phase.

- Expected Return on Investment (ROI): If applicable, include information on the expected ROI for investors. Highlight the potential for financial gains or equity appreciation over time.

- Repayment Plan (if applicable): If seeking a loan, provide a clear repayment plan that outlines the repayment period, interest rate, and the proposed schedule for repayment.

How to maximise this section?

- Create a visual timeline for key milestones such as the initial investment and key payback periods.

- Outline risk mitigation plans to instil confidence.

- Reiterate the company's long-term vision and how the funds can help achieve these goals.

As you near the end of your manufacturing company business plan, it is crucial to dedicate a section to outlining potential risks. This section holds immense significance as it can greatly influence the confidence of potential investors. By demonstrating your market awareness and addressing challenges head-on, you can instill trust and credibility.

When conducting a risk analysis for your manufacturing company car rental business plan, consider including the following:

- Identification of Business Risks: Enumerate the key risks and uncertainties that could affect the business. These risks can be internal (e.g., operational, financial) or external (e.g. market changes, regulatory changes, economic downturns).

- Impact Assessment: Analyse the potential impact of each identified risk on the business's operations, finances, and reputation. Rank the risks based on their severity and likelihood of occurrence.

- Risk Mitigation Strategies: Present specific strategies and action plans to mitigate each identified risk. Explain how you will proactively address challenges and reduce the negative impact of potential risks.

- Contingency Plans: Describe contingency plans for worst-case scenarios, outlining how the business will respond and recover from significant risks if they materialise.

How to make your risk analysis stand out?

- Add context with real-life examples. Are there similar businesses that have dealt with risks successfully in a similar manner to your strategy? This will add credibility to this section.

- Create adaptive strategies that demonstrate your business’s flexibility and adaptability.

- Outlining the responsible person for each risk and how they own it, giving further confidence in your risk management strategies.

Some additional information you may want to include in your business plan for manufacturing company:

- Customer Surveys and Feedback

- Letters of Support or Intent

- Legal Documents (e.g., licenses, permits)

- Resumes of Key Team Members

A Business Plan For Manufacturing Company Wrapping It All Up

A business plan is one of the most important documents that you will create about your business. It can literally be the difference between securing additional finance or missing out. Developing your business is not an easy task, however, the opportunity to think about your business in such detail will no doubt help you develop new and important insights along with new ideas and strategies. With all sections of your business plan and especially the financial plan, be prepared to defend your position to potential investors or lenders. This means that you should never publish anything that you can’t back up with additional data or rationale. Business Plans are not created overnight so take the time to research and think about each section properly, always try to support your claims and strategies with market insight and data. We hope you’ve enjoyed reading this guide, if you are looking for more tips on creating a business plan check out our learning centre .Good luck with your next business endeavour! Action Planr

Thank you! You’ll receive an email shortly.

Oops! Something went wrong while submitting the form :(

Learning ZoNe

Manufacturing Business Plan PDF Example

- May 7, 2024

- Business Plan

Creating a comprehensive business plan is crucial for launching and running a successful manufacturing business. This plan serves as your roadmap, detailing your vision, operational strategies, and financial plan. It helps establish your manufacturing business’s identity, navigate the competitive market, and secure funding for growth.

This article not only breaks down the critical components of a manufacturing business plan, but also provides an example of a business plan to help you craft your own.

Whether you’re an experienced entrepreneur or new to the manufacturing industry, this guide, complete with a business plan example, lays the groundwork for turning your manufacturing business concept into reality. Let’s dive in!

Our manufacturing business plan covers all essential aspects necessary for a comprehensive strategy. It details operations, marketing strategy , market environment, competitors, management team, and financial forecasts.

- Executive Summary : Provides an overview of the manufacturing company’s business concept, market analysis , management, and financial strategy.

- Facilities & Equipment: Describes the facility’s capabilities, machinery, and technological advancements.

- Operations & Supply: Outlines the production processes, supply chain logistics, and inventory management.

- Key Stats: Offers data on industry size , growth trends, and market positioning.

- Key Trends: Highlights significant trends impacting the industry, such as automation and localization.

- Key Competitors : Analyzes primary competitors and differentiates the company from these rivals.

- SWOT: Analyzes strengths, weaknesses, opportunities, and threats.

- Marketing Plan : Outlines tactics for attracting new contracts and maintaining client relationships.

- Timeline : Sets out key milestones from inception through the first year of operations.