- Virginia Beach

- History & facts

Famous people

- Famous landmarks

- AI interviews

- Science & Nature

- Tech & Business

Discover something new everyday

- Famous places

- Food & Drinks

- Tech & Business

The History and Key Facts about the Inventor of the Paper Clip

See page for author , Public domain, via Wikimedia Commons

Read Next →

Top 20 Facts About Lionel Messi

Top 15 Unbelievable Facts about John Steinbeck

20 Amazing Facts about Jesse Owens

1. johan was born in a little-known village to a local farmer.

2. Vaaler Attended the Christiania Technical School

3. he worked as a patent clerk gaining more exposure, 4. vaaler secured a german patent for his paper clip design.

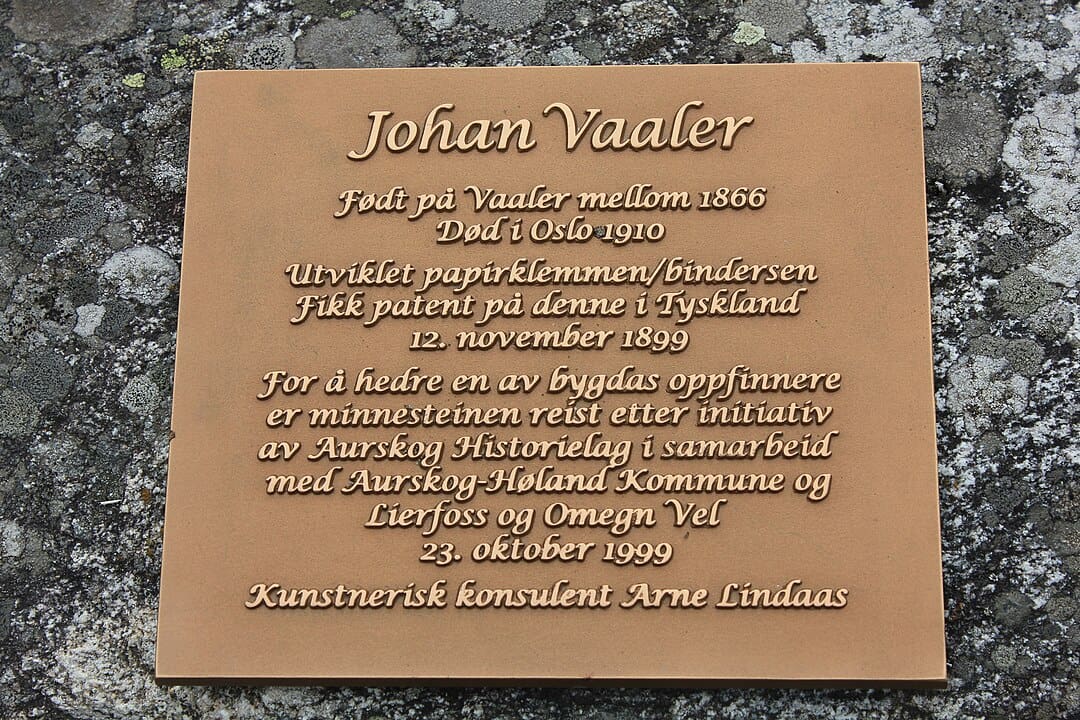

Emilio J. Rodríguez Posada , CC BY-SA 4.0 , via Wikimedia Commons

5. He Received Major Doubt and Suspicion over the Paper Clip Invention

6. vaaler faced financial challenges despite his invention, 7. johan moved to berlin for better opportunities but faced the same challenges, 8. his invention didn’t achieve significant success during his lifetime, 9. johan moved various jobs over his career, 10. vaaler’s design laid the foundation for subsequent variations of the paper clip.

Dietmar Rabich / Wikimedia Commons / “Büroklammern — 2021 — 6481” / CC BY-SA 4.0

11. Johan has National Recognition in Norway for his Invention

12. vaaler’s paper clip design remains widely used.

Agraphe , CC BY-SA 4.0 , via Wikimedia Commons

13. His Invention is a Symbol of Efficiency and Ingenuity

14. johan has a posthumous recognition due to his invention, 15. he left a lengthy legacy that gains world recognition after his death.

Øyvind Holmstad , CC BY-SA 3.0 , via Wikimedia Commons

Planning a trip to Paris ? Get ready !

These are Amazon’s best-selling travel products that you may need for coming to Paris.

- The best travel book : Rick Steves – Paris 2023 – Learn more here

- Fodor’s Paris 2024 – Learn more here

Travel Gear

- Venture Pal Lightweight Backpack – Learn more here

- Samsonite Winfield 2 28″ Luggage – Learn more here

- Swig Savvy’s Stainless Steel Insulated Water Bottle – Learn more here

Check Amazon’s best-seller list for the most popular travel accessories. We sometimes read this list just to find out what new travel products people are buying.

Kennedy is a clinician who is passionate about humanity, travel, and making a positive impact on lives. His passion for writing began back in college as he wanted to share his views with the world. He enjoys writing about science and nature, health, travel, cities, famous people, and mysterious murders. His writing style is entertaining and enlightening while giving you a fresh perspective on several topics.

Hello & Welcome

Popular articles.

Top 20 Streets to See in Paris

Paris in two days

Top 15 Things to do Around the Eiffel Tower

The Best Way to Visit Paris Museums

Top 15 Fashion Stores in Le Marais

Visit europe with discover walks.

- Paris walking tours

- Montmartre walking tour

- Lisbon walking tours

- Prague walking tours

- Barcelona walking tours

- Private tours in Europe

- Privacy policy

© 2024 Charing Cross Corporation

The paper clip is a nearly ubiquitous device, used worldwide to temporally hold papers together. The technology for manufacturing paper clips evolved in the early years of the twentieth century, and has remained virtually unchanged since the 1930s. Paper clips come in several forms, but the one most often seen in common use is called the Gem clip. The origin of the term "Gem" is supposed to have originated from a British firm that began exporting them at least as early as 1907. The term has come to stand for the iconic shape of the oval-within-oval design. Any clip of this shape is called a Gem clip, regardless of the manufacturer. Another type of paper clip sometimes used by archivists and librarians is called the Gothic clip. It has a rectangular shape, with a triangular inner loop. Other distinguishing marks of paper clips are the overall size, the thickness, and quality of the wire, and whether the clip is corrugated or smooth. Most paper clips in the United States are made domestically by a few firms that specialize in their manufacture. These manufacturers put out roughly 20 million lb (9 kg) a year of paper clips.

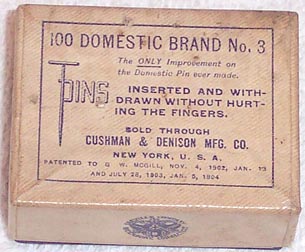

The paper clip evolved to fill a specific need. A large amount of paper could be bound into a book in order to hold the leaves together. Binding was not a viable solution to keep together a few sheets, such as a short set of records or receipts. Though paper was invented in China sometime in the first century A.D. , and was widespread in Europe by the thirteenth century, people made do without anything like the modern paper clip until the end of the nineteenth century. People used two general methods to fasten together a few sheets of paper. They could slit the pages in the corner, making two short parallel cuts. Then ribbon or string could be threaded through the slits, the ends tied and often sealed with wax. The second method was to take a common straight pin and pin the sheets together. Machinery to make cheap and uniform quality pins developed early in the nineteenth century. Business people bought boxes of loose pins, sold by the pound and called "bank pins," to use in offices. Both the slit method and the pin method had the same drawback: the paper had to be pierced. Pin holes caused less wear on the paper than slits, yet if pages needed to be unpinned and repinned many times, the pinned corner was subject to a lot of wear, leading to the drooping "dog ear." Pins also had the disadvantage of being sharp enough to prick fingers and tended to rust if left in place for any length of time.

Designs or patents for early paper clips date to the middle of the nineteenth century, but none of these early devices seem to have worked well enough to have made a lasting impression. Some of these were closer in form to what is known today as a binder clip or bulldog clip, and others enfolded the entire corner of the paper within teethed overlays of thin metal. This type of paper fastener was made from stamped sheet metal. Wire forming technology advanced in the mid-nineteenth century, and from about 1870 on, paper clips of various designs competed in Europe and the United States.

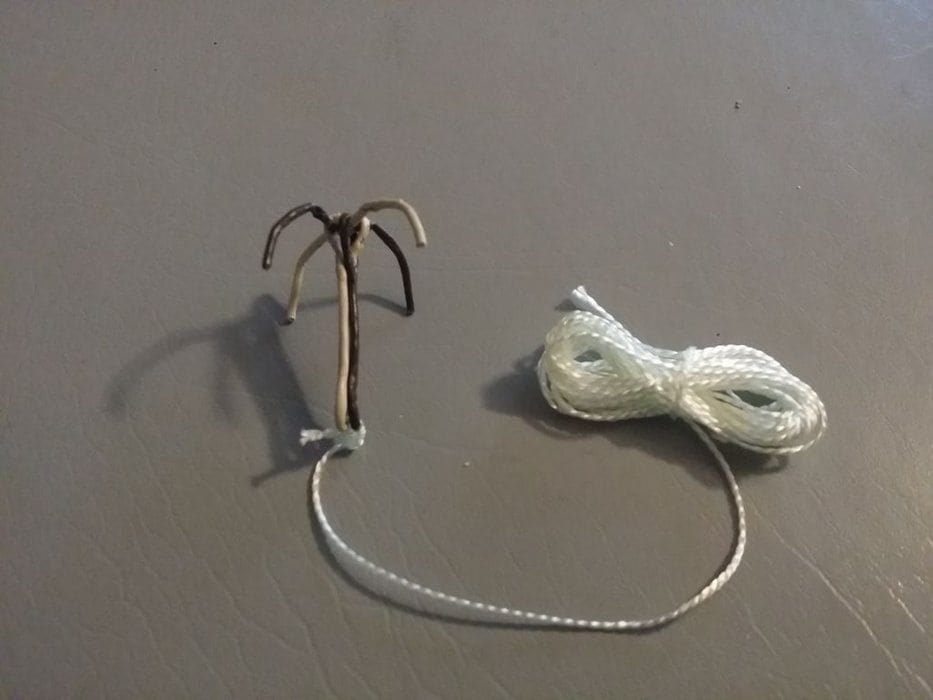

The earliest recorded patent for a paper clip was granted by the United States Patent Office to a Pennsylvanian, Matthew Schooley, in 1898. Schooley's patent application mentions other devices already on the market of a similar design, so it would not be accurate to name him or any other individual as the father of the paper clip. A Norwegian, John Vaaler, is often credited with inventing the paper clip in 1899. His patent application included several possible paper clip shapes, including one that is similar to the modern Gem clip. Because of Vaaler, the paper clip became a symbol of Norwegian nationalism during World War II. There is even a 23 ft (7 m) high statue of a paper clip in Norway. It was set up to commemorate the solidarity the Norwegians represented against the Nazis by pinning paper clips on their lapels.

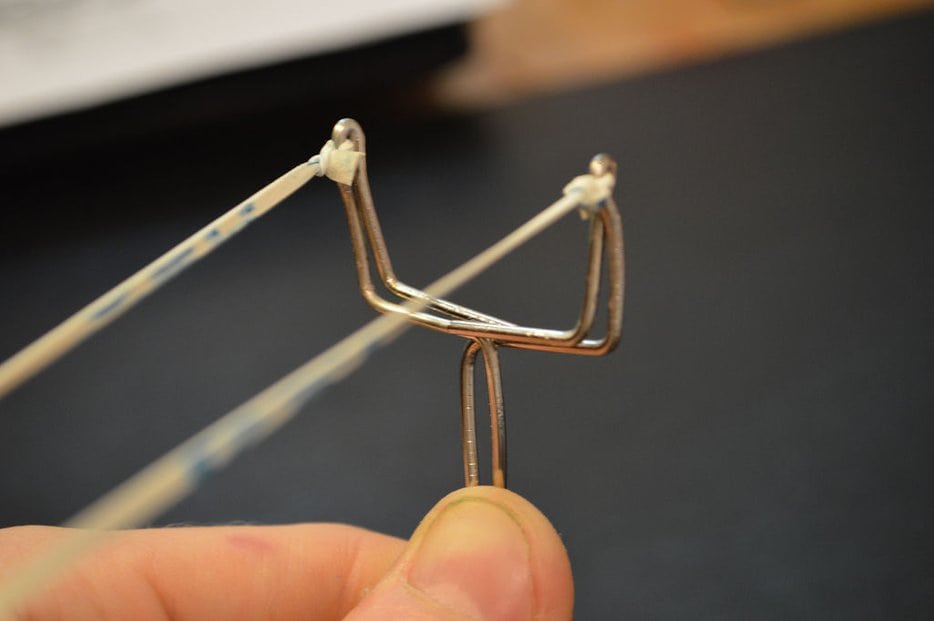

A Massachusetts inventor, Cornelius Brosnan, received a patent for a paper clip design in 1900. Again, his application spoke of the product as an improvement over other paper clips already in existence. His clip was marketed as the Konaclip. The Konaclip was an oval loop of wire with an inner arm terminating in a rounded eye. At least these three clips, the Schooley, the Vaaler, and the Brosnan designs, existed by the turn of the century. In 1899 a Connecticut inventor, William Middlebrook, applied for a patent for a machine to make paper clips. Middlebrook's patent application was not for making any particular type of clip, but the one pictured on the application's illustration looked like the archetypal Gem. Gem clips were imported to the United States from England by at least 1907. The Gem was advertised as a fine English product, superior to all others. Though paper clips of differing designs continued to be made for several years, by about the mid-1930s, the Gem had become the most commonly used.

Raw Materials

Paper clips are generally made from galvanized steel wire. The wire diameter depends on what size and quality clips are being made from it. Paper clips can be made from light, cheap steel, or from better quality steel, depending on the manufacturer. The material used, however, has to fall within certain physical parameters to make satisfactory paper clips.

The Gem clip is often held up as a paragon of modern design. It is simple, elegant, and surpassingly functional. Yet leaving the iconic shape aside, a paper clip designer must consider a host of mechanical and engineering questions. The material used to make a paper clip must possess certain properties. The wire needs to be stiff enough to hold its shape in use, but not so stiff that it is difficult to open. Engineers also consider a quality called yield stress when designing a paper clip. Yield stress is the amount of stress needed to permanently reshape the wire. If the wire has too low yield stress, it will stay bent open and not hold the papers tightly. Engineers also must consider the cost effectiveness of the material used. Using a cheaper, thinner wire may save the manufacturer money. Yet the material must also perform well in the manufacturing process, not leaving sharp burrs at the cut ends and resisting cracking or breaking. The material used also should be non-corrosive. The finished appearance of the clip is also a design consideration. The clip can have various finishes, smooth or slightly serrated, shiny or dull, and it can be made in many different sizes. So even though the basic Gem design has survived primarily unchanged for about a hundred years, manufacturers still confront design and materials options when making new paper clips.

The Manufacturing Process

The manufacturing process for paper clips is fairly simple, using a specialized wire forming machine. Moreover, the process has not changed much since the 1930s.

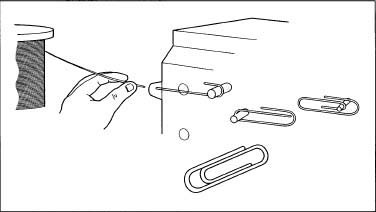

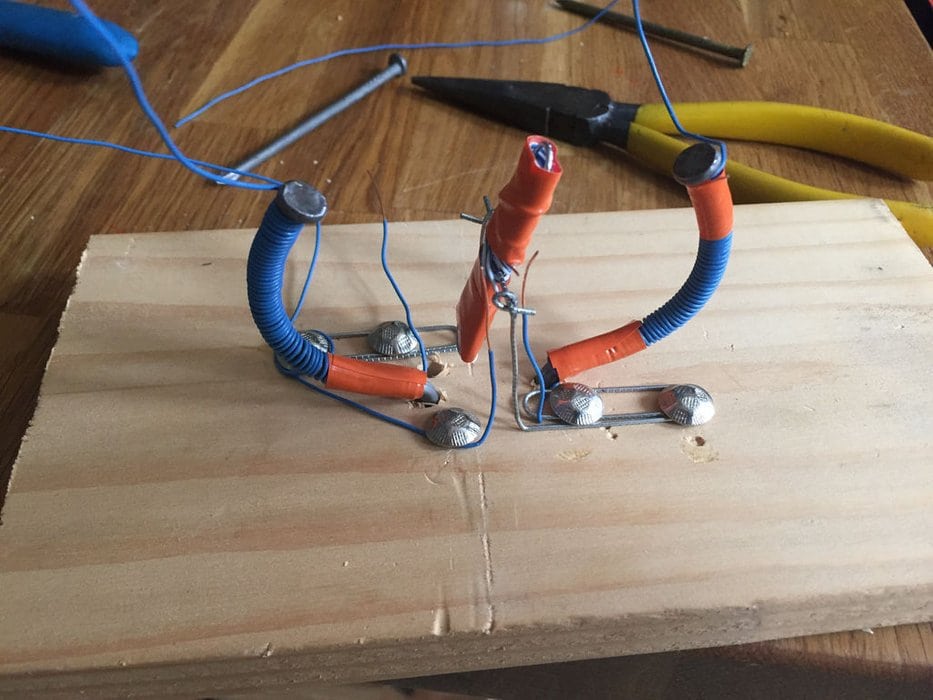

- The process begins with a huge spool of galvanized steel wire. A worker feeds the end of the wire into the paper clip machine. A finished paper clip has three bends. The machine forms the wire into these three bends by cutting it and passing it by three small wheels. The wheels are slightly roughened, and catch the length of wire as it passes.

- The first wheel turns the wire 180 degrees, making the first bend, the second makes the next bend, and the third wheel makes the final turn. The entire process is so quick, the machine can churn out hundreds of clips a minute.

Quality Control

Quality control is not a particularly important issue in paper clip manufacturing. Visual inspection of the product is enough to identify a problem with the process. No special tests are needed. The manufacturing equipment must be maintained in order to work properly. Some machines still in use today in the United States were built in the 1930s or even earlier. Trained workers check the equipment for wear and defects that might affect the quality of the finished clips.

By products/Waste

Though paper clips are re-usable, many are thrown away. Some office paper recyclers ask that paper clips be removed before paper is put in recycling bins. Some recyclers use metal detecting equipment that can separate out staples and paper clips, so this material can be recycled separately. One paper clip industry study estimated that the vast percentage of paper clips were never used as intended—to hold paper—but were bent and destroyed by people, used as cleaning or prying instruments, etc. Since paper clips are inexpensive, both to manufacture and to buy as a retail item, most are not re-used or recycled but simply thrown away.

The Gem clip has held sway against other contenders in paper clip design for a very long time. All-plastic paper clips came on the market in the 1950s, to some success, followed by plastic-coated clips. In the 1990s a Pennsylvania company began marketing what looks like essentially a giant Gem clip, which can hold more than one hundred sheets of paper at one time. None of these developments differs markedly from the turn-of-the-century design consumers are so familiar with. This leads to the question of whether the Gem clip is already a perfect design, thus leaving no room for improvement.

Where to Learn More

Kalpakjian, Serope. Manufacturing Engineering and Technology. Reading, MA: Addison-Wesley, 1992.

Petrovsky, Henry. The Evolution of Useful Things. New York: Alfred A. Knopf, 1992.

Periodicals

Allen, Frederick. "How Do You Make Paper Clips?" American Heritage Invention & Technology (Summer 98).

"Now This Is a Paper Clip!" Managing Office Technology (April 1997): 16.

Angela Woodward

User Contributions:

Comment about this article, ask questions, or add new information about this topic:.

The History and Invention of the Paperclip

B_Me/Pixabay

- Famous Inventions

- Famous Inventors

- Patents & Trademarks

- Invention Timelines

- Computers & The Internet

- American History

- African American History

- African History

- Ancient History and Culture

- Asian History

- European History

- Latin American History

- Medieval & Renaissance History

- Military History

- The 20th Century

- Women's History

Historical references describe fastening papers together as early as the 13th century. During this time, people put ribbon through parallel incisions in the upper left-hand corner of pages. Later, people started to wax the ribbons to make them stronger and easier to undo and redo. This was the way people clipped papers together for the next six hundred years.

In 1835, a New York physician named John Ireland Howe invented the machine for mass-producing straight pins, which then became a popular way to fasten papers together (although they were not originally designed for that purpose). Straight pins were designed to be used in sewing and tailoring, to temporally fasten cloth together.

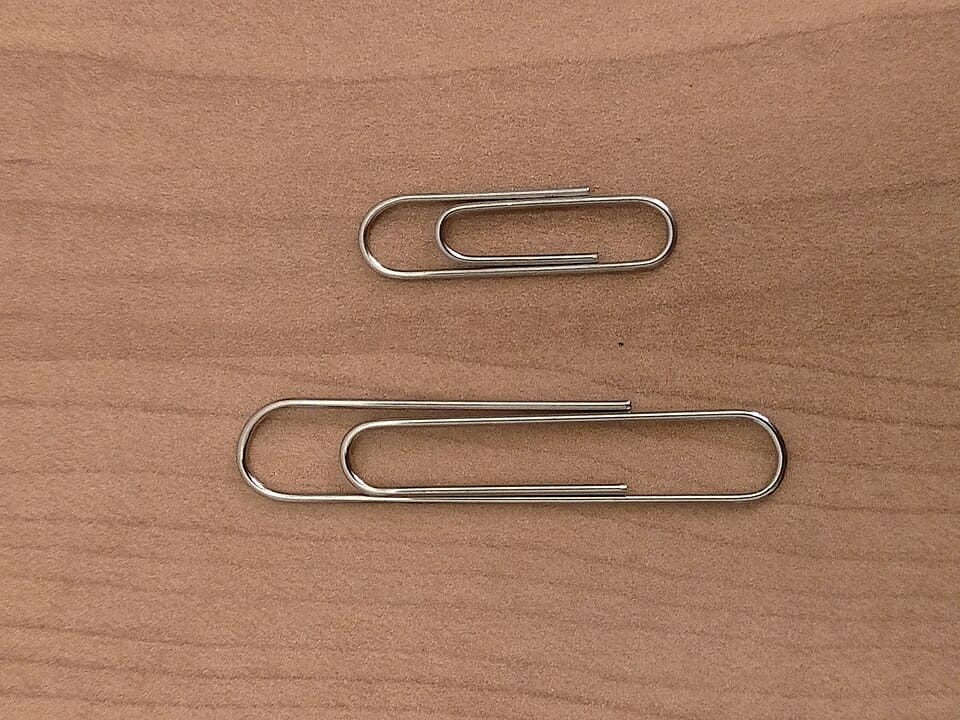

Johan Vaaler

Johan Vaaler, a Norwegian inventor with degrees in electronics, science, and mathematics, invented the paperclip in 1899. He received a patent for his design from Germany in 1899, as Norway had no patent laws at that time.

Vaaler was an employee at a local invention office when he created the paperclip. He received an American patent in 1901. The patent abstract says, "It consists of forming same of a spring material, such as a piece of wire, that is bent to a rectangular, triangular, or otherwise shaped hoop, the end parts of which wire piece form members or tongues lying side by side in contrary directions." Vaaler was the first person to patent a paperclip design, although other unpatented designs might have existed first.

American inventor Cornelius J. Brosnan filed for an American patent for a paperclip in 1900. He called his invention the "Konaclip."

A History of Paperclips

It was a company called the Gem Manufacturing Ltd. of England that first designed the double oval-shaped, standard paperclip. This familiar and famous paperclip was and still is referred to as the "Gem" clip. William Middlebrook of Waterbury, Connecticut, patented a machine for making paperclips of the Gem design in 1899. The Gem paperclip was never patented.

People have been re-inventing the paperclip over and over again. The designs that have been the most successful are the Gem with its double oval shape, the "non-skid" which held in place well, the "ideal" used for thick wads of paper , and the "owl" paperclip that does not get tangled up with other paperclips.

World War II Protest

During World War II, Norwegians were prohibited from wearing any buttons with the likeness or initials of their king on them. In protest, they started wearing paperclips, because paperclips were a Norwegian invention whose original function was to bind together. This was a protest against the Nazi occupation and wearing a paperclip could have gotten them arrested.

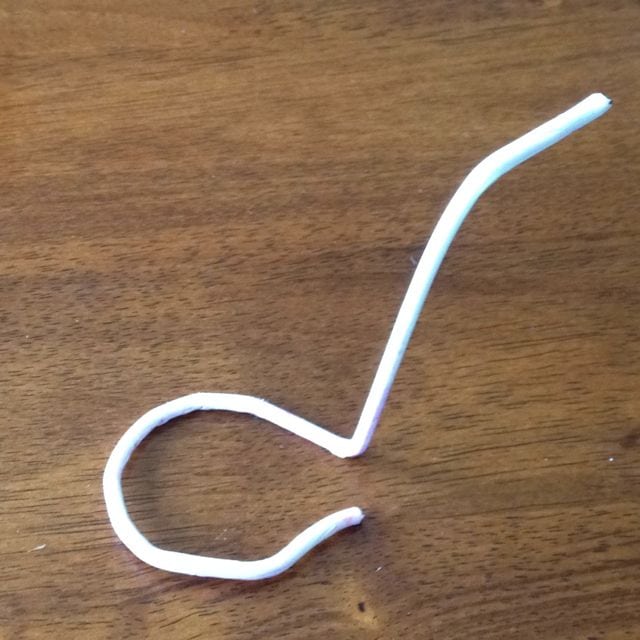

A paperclip's metal wire can be easily unfolded. Several devices call for a very thin rod to push a recessed button which the user might only rarely need. This is seen on most CD-ROM drives as an "emergency eject" should the power fail. Various smartphones require the use of a long, thin object such as a paperclip to eject the SIM card. Paperclips can also be bent into a sometimes effective lock-picking device. Some types of handcuffs can be unfastened using paper clips.

- Who Invented the Fountain Pen?

- History of the Sewing Machine

- The Invention of the Safety Pin

- The History of the Zipper

- The History of the Jet Engine

- Important Innovations and Inventions, Past and Present

- The Invention and History of the Vacuum Cleaner

- Who Invented the Snowmaking Machine?

- The History of Hardware Tools

- The History of Radio Technology

- The History of Candy Canes

- A History of the Automobile

- Famous July Inventions and Birthdays

- The Invention of the Flashlight

- Andrew Beard - Jenny Coupler

- Biography of Thomas Adams, American Inventor

Back to all articles

The History of Paper Clips

The first bent wire paper clip was patented by Samuel B. Fay in 1867. The Gem paper clip (named for the Gem Office Products Company) is what most of us think of as a paper clip today; it first appeared around 1892. Both the Gem paper clip and the machine that makes it can trace their origins to pin-making. In the early 19th century, office workers pinned their papers together with T-pins. Victorian-era pin-making machines had already made mass-producing wire pins possible. To make paper clips, the machines simply had to be reconfigured to make wire bending possible. Today, paper clips are available in a variety of materials, including molded plastic, wire clips coated with colored plastic, and even semicircular sheets of aluminum that can carry a logo or design. And of course, many other methods of paper binding are still available, including classic T-pins, owl clips, and binder clips. Still, Gem-style paper clips remain one of the most ubiquitous and popular paper-binding methods on the market today.

Share this article

Your go-to guide for weird history facts

Subscribe to the FREE daily email that makes learning about history fun.

- Newsletters

- Account Activating this button will toggle the display of additional content Account Sign out

The Discreet Charm of the Paperie

A quirky history of pens, notebooks, tape, paper clips, and highlighters..

Illustration by Fumio Obata

It takes a confident writer to begin a book with a long discussion of the evolution of paper clips, push pins, and binder fasteners before even touching on sexier subjects like glue, sticky tape, and pencil erasers. Fortunately, James Ward, the author of the quirky history of stationery The Perfection of the Paper Clip , has a gift for isolating the kind of odd detail that counteracts the human eye’s tendency to glaze over.

Did you know, for instance, that while Carter Hi-Liters are available in a wide range of colors, yellows and pinks account for around 85 percent of their sales? That highlighter pens owe their existence to the Day-Glo paints and dyes that allowed U.S. planes to fly night missions from aircraft carriers during World War II? That during the Nazi occupation Norwegians wore paper clips as a symbol of resistance, or that the British tape manufacturer Sellotape makes half its annual sales during the three-month run-up to Christmas?

The history of stationery is the story of human ingenuity, of oddball geniuses who looked at a product that served its purpose perfectly adequately and saw ways to improve upon it. Ward writes with great affection of the entrepreneurs who risked their fortunes on dreams that might seem prosaic: files stored laterally rather than vertically, or a pen that could write upside down. He clearly admires, and perhaps finds kinship with, these obsessive tinkerers.

Unfortunately, the book is terribly parochial, stuffed with references to brands and concepts that Americans are unlikely to recognize: Silvine Memo Books , the Oxford Set of Mathematical Instruments , Jack Duckworth’s spectacles , “ GCSE maths classrooms.” That would be fine—exotic even—if Ward, an Englishman, would provide some context to orient American readers. Since he occasionally notes some transatlantic differences, such as his repeated observation that unlike their British counterparts American schoolchildren don’t hold much truck with pencil cases, I can only conclude that he doesn’t realize his references aren’t universal. When he writes, “Like the Pritt Stick or Sellotape, the Post-it has become not only the generic term but the definitive term for its type,” you wonder if he has really thought about what the phrase “definitive term” means.

To be fair, stationery is shockingly parochial. It’s no surprise that different brands should dominate in different markets, but everything from paper sizes to the pencil grading system to the number of holes in a ring binder varies around the world. We can blame some of this on American exceptionalism when it comes to weights and measures: Ward notes that Burma, Liberia, and the United States are the only nations that still refuse to embrace the metric system. But the English-speaking world can’t even agree on stationery nomenclature: Brits call thumb tacks drawing pins and refer to erasers as rubbers . (I still remember the look of consternation on the face of the American friend visiting my childhood home in England when the little girl next door offered to show off her collection of rubbers.)

Still, if you’re a reader who can’t resist the charms of British patter, this book is like accompanying Ward on a relaxed ramble through an independent stationery store, one of those old family businesses where they can’t bear to take even the most outmoded items off the shelf. He’s prone to go off on tangents, as in his random disquisition on saucy seaside postcards, which will surely be quite mystifying to readers who have never seen these very un-PC PCs. And his interests are wildly idiosyncratic: He’s got more to say about erasers than pencils, can discuss fastening devices at extraordinary length, and doesn’t seem all that interested in pens. Odd enthusiasms can be delightful, if occasionally frustrating, but some sections—like his flabby, heart-not-in-it paragraphs on novelty souvenir stationery—read like filler designed to pump up the word count.

Photo courtesy Richard John

Even Ward’s cheeky chappy interjections can’t rescue some parts of the book from tedium. (Since his first writing success came from the blog I Like Boring Things , perhaps this is intentional.) During an excruciatingly detailed history of the company that popularized highlighters in the United States, I was tempted to Sellotape the pages together so that I would never again expose myself to paragraph after paragraph listing all the names the business traded under through the years. Ward relies rather too heavily on patent applications (rarely a source of bons mots ) and promotional materials put out by the companies he’s profiling. He occasionally mocks the claims made in these press releases, but he seldom questions them, at least not seriously: He enters into an extended correspondence with Blu-Tack (a replaceable adhesive popular in Britain) about the “thousands of uses” promised on its packaging, but he never questions claims like Uni-Ball’s assertion that its specially formulated ink makes the Uni-Ball 207 “the only pen in the world that cannot be altered by chemicals or solvents.”

My biggest frustration with The Perfection of the Paper Clip is that Ward treats office supplies like obsolete museum pieces rather than practical objects. He boasts about peculiar eBay scores (historical staplers!) and talks about the elation of finding ancient products on the dusty shelves of small-town stationers, but he rarely describes the tactile pleasure of actually using these items. Pens, notebooks, and paper clips are made for scribbling, writing in, and clipping—not collecting. If Ward and I found ourselves together in that old, dusty stationery store, we’d head in different directions—he to hunt for ancient boxes of binder clips whose history he could investigate, while I’d search for a brand new notebook containing paper so smooth it would draw the words right out of me. It’s good to learn about these familiar products’ storied pasts, but analog tools aren’t dead yet.

The Perfection of the Paper Clip: Curious Tales of Invention, Accidental Genius, and Stationery Obsession by James Ward. Touchstone.

See all the pieces in this month’s Slate Book Review . Sign up for the Slate Book Review monthly newsletter .

Important disclaimer information about this About site.

Advertisement

Most Popular

Optical Disk Famous Inventions - A - History of Inventions The History of the Atomic Bomb The History of Computers - Computer History Timeline Automobile History - The History of Cars and Engines

Gyroscopes - Elmer Sperry and Charles Stark Draper Gyroscope... Angel Alcala The History of the Bikini Rusi Taleyarkhan Jack Johnson

Related Topics

20th Century History Small Business Information Entrepreneurs

Mental Health

Depression Self-Test Vitamins for Depression? Bipolar Red Flags Coping With Disasters Celebrities With Bipolar

How Paper clips evolved throughout time!

The paper clip is a simple yet essential office supply that has been in use for over a century. The evolution of paper clip has been marked by various designs and materials, each with its own unique set of advantages and disadvantages.

The first paper clip was patented in 1867 by Samuel B. Fay, a U.S. inventor. Fay’s design was a simple “Gem” paperclip, which was a thin wire bent into a looped shape. However, this design had a major drawback: it was not very effective at holding papers together and often required frequent replacement.

In 1899, a Norwegian inventor named Johan Vaaler patented a new design for a paperclip. His design was a bent wire that had two opposing loops, which held papers together more securely. This design, known as the “Common-Clip,” quickly became popular in Europe and eventually made its way to the United States.

During World War II, the demand for paper clips increased as the government used them to bind together classified documents. As a result, manufacturers began to experiment with different materials, such as plastic and steel, to make paperclips that were stronger and more durable.

In the 1950s, the “Gem” paperclip design was reintroduced with a new, more efficient manufacturing process. This design, known as the “Gem Paperclip,” became the most popular paperclip in the United States.

Today, paperclips come in a variety of designs and materials, including plastic-coated wire, steel wire, and even colorful plastic paperclips. They are used in a wide range of settings, from homes and offices to schools and libraries.

In conclusion, the evolution of paper clip has been a constant process to improve its design and materials to make it more efficient and user friendly, it started with a simple bent wire to now colorful plastic paperclips. The paper clip may seem like a small and insignificant item, but its history is a testament to the ingenuity and determination of inventors to constantly improve upon everyday objects.

The evolution of paper clip has come a long way since its invention in 1867. From the early “Gem” paperclip design, to the more secure “Common-Clip,” to the modern plastic-coated and steel wire designs, the paper clip has undergone many changes to become the versatile and reliable office supply that it is today.

One of the major advancements in the evolution of paper clip was the introduction of plastic coating. This added a layer of durability and corrosion resistance to the wire, making it more suitable for long-term use. It also allowed for the creation of colorful paperclips, which not only made them more visually appealing but also made it easy for people to color code and categorize their documents.

Another important development was the introduction of steel wire. Steel wire paperclips are known for their strength and durability, making them perfect for holding large stacks of papers together. They are also resistant to rust and corrosion, making them suitable for use in humid and damp environments.

In addition to the advancements in design and materials, the manufacturing process of paperclips has also improved over time. With the use of new technologies, paperclips can now be produced in large quantities at a faster rate, making them more accessible and affordable for everyone.

The paper clip has also been used in various creative ways, such as jewellery and art, which is a testament to its versatility and design.

In conclusion, the evolution of the paper clip has been driven by the need for a more efficient and user-friendly office supply. With new materials and manufacturing processes, the paper clip has become more durable, reliable, and visually appealing. Its history serves as a reminder of how small, everyday objects can evolve and improve over time.

The evolution of the paper clip also includes advancements in the way it is packaged and sold. In the past, paperclips were typically sold in bulk, with buyers having to purchase large quantities in order to get a good price. However, with the advent of new packaging technologies, paperclips can now be packaged in smaller, more convenient quantities. This has made them more accessible to a wider range of consumers, including individuals and small businesses.

Another important aspect of the evolution of paper clip is its eco-friendliness. With the growing awareness of environmental issues, many manufacturers have started to produce paperclips made from recycled materials. This not only reduces the environmental impact of paperclip production but also helps to conserve resources.

The evolution of paper clip also oversees it being utilized in various industries beyond the office setting, such as in the medical field. They can be used to hold together X-rays or MRI scans, or even as a temporary device in certain surgical procedures.

In recent years, the paper clip has also seen a resurgence in popularity as a symbol of resistance and unity. This can be traced back to the Norwegian resistance movement during World War II, where paperclips were worn as a symbol of resistance against the Nazi occupation. Today, the paperclip is often used as a symbol of hope and resilience, reminding us that even the smallest and simplest of things can make a big impact.

In conclusion, the evolution of the paper clip is not just about the design and materials, but also about the way it is packaged, sold and the impact it has on the environment. The paper clip has evolved to be more eco-friendly, versatile and also has a cultural significance. The evolution of the paper clip is an ongoing process and it will continue to adapt and improve to meet the changing needs of its users.

Paper Clips Project For Fun

How paperclip necklaces conquered the year 2022, related posts.

5 Stories about Paper Clips that will…

Have you ever given thought to how frequently we take paper clips

Paperclips in History: The Norwegian Resistance Movement

During World War 2, Nazi Germany conquered Norway, and the country's populace

Partner Way, Easy Way

YUMMY SWEET

JUNGLE ANIMAL

RAINBOW SMILES

HALO SUNSHINE

GRAPHIC SPACE

CHERRY BABE

FLORAL LADY

BOOMING BEAUTY

PSYCHE & CUPID

ELEGANT LOVE

HI HALLOWEEN

HOME / ABOUT US

WHAT ARE PAPER CLIPS MADE OF? INTRODUCING 6 COMMON TYPES

Release time :

The paper clip, a simple yet indispensable tool, has been a staple in our offices and homes for decades. Beyond its primary function of holding papers together, its history, design variations, and materials reveal a deeper story of innovation and practicality. This guide explores the multifaceted world of paper clips, from their origins to their modern-day applications.

Quick Links

● Who invented a paper clip?

● What are paper clips made of?

● What are the thick paper clips called?

● How long is a paper clip?

● How much does a paper clip weigh?

● How to use paper clips?

● Are Paper Clips Magnetic?

● Where to buy paper clips?

● Explore the Intricacies of Paper Clips!

Who invented a paper clip?

The first U.S. patent for a paper clip was awarded to Samuel B. Fay in 1867, designed for attaching tickets to fabric. While several designs emerged, the modern paper clip we recognize today is the Gem paper clip. It likely started production in Britain in the early 1870s by "The Gem Manufacturing Company". By 1899, the Gem-type design was well-established, as evidenced by William Middlebrook's patent for a machine to produce such clips. Despite many variations over the years, the Gem remains the most iconic and widely-used design, even becoming a symbol for inventive design.

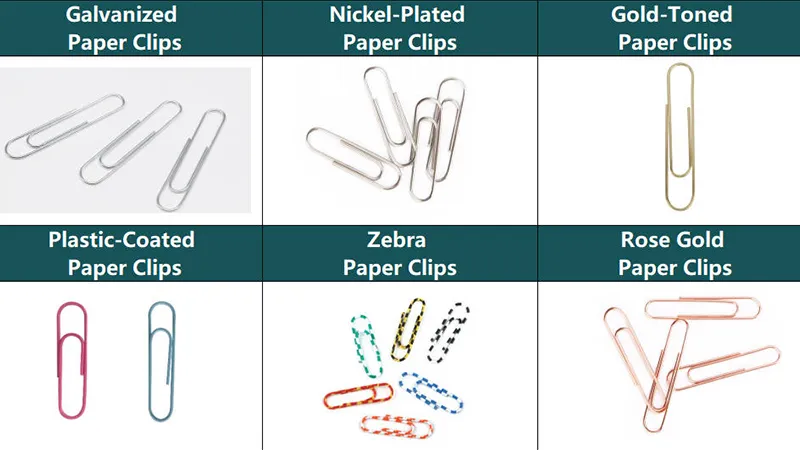

What are paper clips made of?

Paper clips, integral to our daily tasks, come in a diverse range of materials and finishes. Here's an overview of the common types based on their material and surface treatment:

1. Galvanized Paper Clips : Made by coating steel with zinc, this process ensures the clip is protected from rust, enhancing its durability.

2. Nickel-Plated Paper Clips : These clips, plated with nickel, boast a shiny finish. They're not only elegant but also resistant to corrosion.

3. Gold-Toned Paper Clips : While not genuine gold, these clips emulate the rich appearance of gold, often chosen for decorative or special occasions.

4. Plastic-Coated Paper Clips : Coated with plastic in various colors, these clips offer protection against rust while adding a vibrant touch to documents.

5. Zebra Paper Clips : Recognized for their striped design, these clips come in a myriad of color combinations, not just the traditional black and white, making them a playful choice for organizing papers.

6. Rose Gold Paper Clips : With their pinkish-gold hue, these clips are both modern and elegant, often preferred for their aesthetic appeal in contemporary office settings.

Each type of paper clip, while serving a primary functional role, also caters to aesthetic preferences, allowing users to select based on utility and style.

What are the thick paper clips called?

Thicker paper clips, designed to hold a larger number of sheets together, are commonly referred to as " jumbo " or " giant " paper clips. Their increased size and sturdiness make them ideal for heavy-duty tasks where standard paper clips might not suffice. These jumbo clips are often used in professional settings, such as legal or architectural firms, where large stacks of documents need to be securely fastened. While they serve a primarily functional role, their larger size also allows for more decorative and creative designs, making them both practical and aesthetically pleasing.

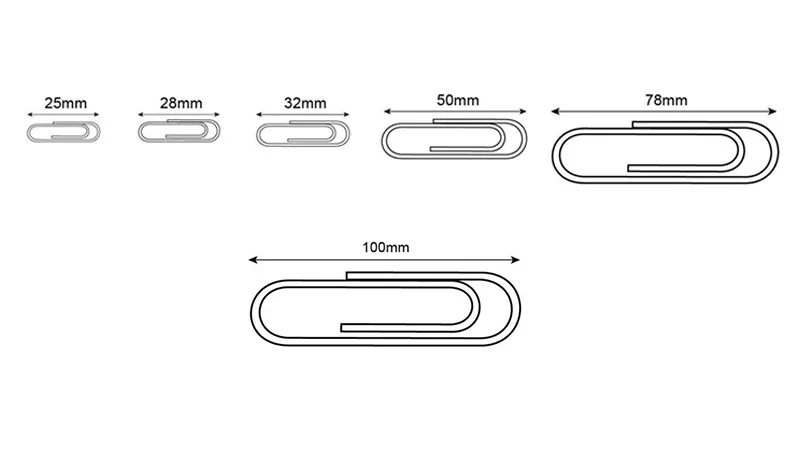

How long is a paper clip?

The length of a paper clip can vary based on its design and intended use. Typically, standard-sized paper clips, often used in everyday office tasks, measure about 1 inch (2.5 cm) in length. However, there are also larger sizes available:

1. Jumbo Paper Clips : These are usually around 2 inches (5 cm) in length, designed to hold together thicker stacks of paper.

2. Giant Paper Clips : Even larger than the jumbo size, these can measure up to 4 inches (10 cm) or more, ideal for heavy-duty tasks or for use as bookmarks.

It's essential to choose the right size based on the number of sheets you intend to fasten together. Using a clip that's too small for a thick stack can cause it to lose its shape, while using an overly large clip for a few sheets might not hold them securely.

How much does a paper clip weigh?

The weight of a paper clip varies based on its size, design, and the material from which it's made. Generally:

1. Standard Paper Clips : These are the most commonly used clips in everyday tasks. Their weight is minimal, making them easy to handle and distribute.

2. Jumbo Paper Clips : Given their larger size, they have a slightly more substantial feel compared to the standard clips.

3. Giant Paper Clips : These are the heaviest of the common types due to their increased size and thickness.

For a clearer understanding, the table below provides a detailed breakdown of the weights and wire diameters corresponding to common paper clip sizes.

How to use paper clips?

Paper clips, with their simple yet ingenious design, are primarily used to fasten together sheets of paper. Here's a basic guide on using them:

1. Holding Papers : Take your stack of papers and align them. Slide one end of the paper clip over the edge of the papers, ensuring it clasps multiple sheets. The double-loop design ensures the papers stay together.

2. Bookmarks : Due to their slim profile, paper clips can be used as temporary bookmarks. Simply slide them onto the edge of the page you wish to mark.

3. Organizing : For larger documents or projects, you can use colored or differently designed paper clips to categorize sections or topics.

4. Alternative Uses : Beyond paper, they can be used to reset electronic devices, mark tape ends, or even as makeshift hooks in some scenarios.

While these are the most common uses, the versatility of paper clips means they can be employed in numerous creative ways, limited only by one's imagination.

Are Paper Clips Magnetic?

A common query, especially relevant in office and academic settings, is whether paper clips are magnetic. Most traditional paper clips are made from metals like galvanized or nickel-plated steel, which are inherently magnetic. This means they can be attracted to magnets, a feature that can be quite useful in certain scenarios. For instance, using magnetic holders or magnets on whiteboards can conveniently secure papers clipped together. However, not all paper clips exhibit magnetic properties. Those coated in plastic or made from non-magnetic metals, like aluminum, will not be attracted to magnets. Considering whether paper clips are magnetic when choosing the right type can help ensure they meet your specific requirements.

Where to buy paper clips?

Paper clips, indispensable in both office and academic environments, can be sourced from various outlets:

1. Stationery Stores : Traditional outlets offering a diverse range of sizes and designs.

2. Supermarkets : Many feature an office supplies section stocked with basic paper clip options.

3. Online Retailers : Platforms like Amazon and eBay provide a vast selection, often complemented by user reviews.

4. Specialty Stores : For those in search of unique designs, specialty or craft stores might have exclusive collections.

5. Wholesale Suppliers : Ideal for businesses or institutions needing bulk quantities. Among them is SYLOON, a stationery manufacturer that, in 2006, distinguished itself with a focus on pin-type products , emphasizing creative and fashionable designs. While SYLOON has since broadened its product range, its dedication to innovation and style remains evident.

When shopping, it's essential to consider factors like material, design, and quantity to ensure you select the right paper clips for your needs.

Explore the Intricacies of Paper Clips!

The humble paper clip, with its rich history and diverse designs, is a testament to the beauty of functional innovation. As you delve deeper into understanding this everyday essential, consider SYLOON, a leader in fashionable stationery design. With a commitment to both form and function, SYLOON ensures that your paper clip needs are met with style and precision. Trust in a brand that understands the blend of history, design, and utility. Choose SYLOON for your next stationery adventure.

What is Stone Paper? A Key to Sustainability

STATIONERY DESIGN'S TOP 6 PRINCIPLES

Related News

SYLOON's Ultimate Guide to Stationery

Explore SYLOON's Ultimate Guide for an insightful journey into the world of stationery. Delve into comprehensive knowledge and tips.

Learn more >

Top 6 Stationery Manufacturers in China

Discover 2024's top stationery manufacturers in China, from Beifa to Syloon, and learn about their global influence and innovative products.

Chat with us,we’re online !

Leave your messages

Please message us and we will be sure to respond ASAP.

OUR HISTORY

FACTORY TOUR

MEET OUR TEAM

WHO TRUST US

JOBS & CAREER

LATEST NEWS

OFFICE SUPPLIMENT

CLIPS & PINS

OFFICE BASICS

STORAGE & ORGANIZATION

PLANNER ACCESSORIES

PLASTIC BALL PEN

METAL BALL PEN

ROLLERBALL PEN

GEL INK PEN

NOVELTY PEN

MULTICOLOR PEN

HIGHLIGHTER

INSULATED WATER BOTTLES

TUMBLERS & MUGS

INSULATED WATER JUGS

BPA FREE WATER BOTTLES

GLASS BOTTLES

CERAMIC MUGS

ECO & SUSTAINABLE

ACCESSORIES

PAPER & NOTEBOOKS

HARDCOVER NOTEBOOK

SPIRAL NOTEBOOK

NOVELTY NOTEBOOK

STITCHED NOTEBOOK

STICKY NOTE

ART & CRAFTS

KIDS CRAFTS

ADULTS CRAFTS

SEASONAL CRAFTS

ART SUPPLIES

ECO PRODUCT

ECO MATERIAL

CERTIFICATED DATA

BAGS & CASES

PENCIL CASE

COSMETIC BAG

FASHION BAG

JEWELLERY ORGANIZER BAG

KIDS COLLECTIONS

TEENAGER COLLECTIONS

GIFTING COLLECTIONS

EVENTS COLLECTIONS

NINGBO SYLOON IMP & EXP CO., LTD.

Add: Fl 13-15, No. 510 Heyuan Road, Yinzhou District, Ningbo, Zhejiang, China Tel: +86-574-86235533 E-mail: [email protected]

©2016 - 2024 Ningbo Syloon Imp & Exp Co., Ltd All rights reserved

Privacy Policy

Terms & Conditions

Terms & Conditions ("Terms")

Please read these Terms and Conditions ("Terms", "Terms and Conditions") carefully before using the https://www.syloon.com website (the "Service") operated by Ningbo Syloon Imp & Exp Co., Ltd ("us", "we", or "our").

Your access to and use of the Service is conditioned on your acceptance of and compliance with these Terms. These Terms apply to all visitors, users and others who access or use the Service.

By accessing or using the Service you agree to be bound by these Terms. If you disagree with any part of the terms then you may not access the Service.

PRIVACY POLICY

These Terms of Service incorporate our privacy policy which sets out how we hold and use your information and can be found at Privacy Policy. By using this Website, you consent to the processing described in the policy and that the information you provide is accurate. You are responsible for maintaining and updating account information.

PROHIBITIONS

You must will not misuse this Website in anyway, you will not: commit or encourage a criminal offence; transmit or distribute a virus, trojan, worm, logic bomb or post any other material which is malicious, technologically harmful, in breach of confidence or in any way offensive or obscene; hack into any aspect of the service; corrupt data; cause annoyance to other users; infringe upon the rights of any other person's proprietary rights; send any unsolicited advertising or promotional material, commonly referred to as "spam"; or attempt to affect the performance or functionality of any computer facilities of or accessed through this Website. We will not be liable for any loss or damage caused by a distributed denial-of-service attack, viruses or other technologically harmful material that may infect your computer equipment, computer programs, data or other proprietary material due to your use of this Website or to your downloading of any material posted on it, or on any Website linked to it. The use of automated systems or software to extract data from this Website for commercial purposes, (‘screen scraping’) is prohibited without license.

INTELLECTUAL PROPERTY, SOFTWARE AND CONTENT

The intellectual property rights in all software and content made available to you on or through this Website remains the property of Ningbo Syloon Imp & Exp Co., Ltd.

You may store, print and display the content for your own personal use. You are not permitted to publish, manipulate, distribute or otherwise reproduce, in any format, any of the content which appears on this Website nor may you use any such content in connection with any business or commercial enterprise. You shall not modify, translate, reverse engineer, decompile, disassemble or create derivative works based on any software or documentation supplied by Ningbo Syloon Imp & Exp Co., Ltd.

REGISTRATION

Where you register on this Website, the following terms and conditions apply.

• You must provide us with accurate registration information. • You must keep any user name and password allocated to you confidential, and we are entitled to assume that anyone using that user name and password is you. • We reserve the right to close accounts if you are attempting to hide the use of multiple accounts or disrupt any of our services in any way. • If you sign into any area of this Website that uses a single-sign on a public computer and do not sign out, someone else who uses that computer after you may be able to access your account(s). • Where you access the Website using a mobile device (e.g. a phone or tablet) through a web browser, depending on your settings you may stay signed on from that device. This means that someone else with access to your device may be able to access your account(s).

Our website is intended to provide general information about our products and services, including making the inquiries via our website. While we do our best to supply accurate information on this site, errors and omissions may occur. We do not accept any liability to you or any third parties for any loss or damage which may directly or indirectly result from your use of the website or your access to, or inability to access, the website.

We reserve the right, at our sole discretion, to modify or replace these Terms at any time. If a revision is material we will try to provide at least 30 (change this) days' notice prior to any new terms taking effect. What constitutes a material change will be determined at our sole discretion.

If you have any questions about these Terms, please contact us.

NINGBO SYLOON IMP & EXP CO., LTD ("us", "we", or "our") operates https://www.syloon.com (the "Site"). This page informs you of our policies regarding the collection, use and disclosure of Personal Information we receive from users of the Site.

We use your Personal Information only for providing and improving the Site. By using the Site, you agree to the collection and use of information in accordance with this policy.

Information Collection And Use

While using our Site, we may ask you to provide us with certain personally identifiable information that can be used to contact or identify you. Personally identifiable information may include, but is not limited to your name ("Personal Information").

Like many site operators, we collect information that your browser sends whenever you visit our Site ("Log Data").

This Log Data may include information such as your computer's Internet Protocol ("IP") address, browser type, browser version, and the pages of our Site that you visit, the time and date of your visit, the time spent on those pages and other statistics.

In addition, we may use third party services such as Google Analytics that collect, monitor and analyze this …

Communications

We may use your Personal Information to contact you with newsletters, marketing or promotional materials and other information.

Cookies are files with small amount of data, which may include an anonymous unique identifier. Cookies are sent to your browser from a web site and stored on your computer's hard drive.

Like many sites, we use "cookies" to collect information. You can instruct your browser to refuse all cookies or to indicate when a cookie is being sent. However, if you do not accept cookies, you may not be able to use some portions of our Site.

The security of your Personal Information is important to us, but remember that no method of transmission over the Internet, or method of electronic storage, is 100% secure. While we strive to use commercially acceptable means to protect your Personal Information, we cannot guarantee its absolute security.

Changes To This Privacy Policy

This Privacy Policy is effective as of July 15, 2020 and will remain in effect except with respect to any changes in its provisions in the future, which will be in effect immediately after being posted on this page.

We reserve the right to update or change our Privacy Policy at any time and you should check this Privacy Policy periodically. Your continued use of the Service after we post any modifications to the Privacy Policy on this page will constitute your acknowledgment of the modifications and your consent to abide and be bound by the modified Privacy Policy.

If we make any material changes to this Privacy Policy, we will notify you either through the email address you have provided us, or by placing a prominent notice on our website.

If you have any questions about this Privacy Policy, please contact us.

Paper Clip Strategy: Boosting Productivity and Organization

This guide will walk you through the essential elements of using paper clip strategy - the productivity method to keep your team productive and engaged.

The paper clip strategy is an innovative approach to enhancing productivity and organization by employing simple yet effective methods. In today's fast-paced work environment, where digital clutter and distractions abound, the paper clip strategy offers a refreshing solution to streamline tasks and optimize workflow.

What is the Paper Clip Strategy in the Context of Productivity?

The paper clip strategy is a methodology centered around the concept of visual and tactile organization. It involves using physical paper clips or digital equivalents to represent and manage tasks, projects, or information. By employing this strategy, individuals can visually categorize, prioritize, and track their activities, thereby boosting productivity and reducing mental clutter.

Understanding the Origin of the Paper Clip Strategy

The paper clip strategy originated from the idea of using a physical paper clip as a visual cue to remind individuals of specific tasks or projects. This simple yet effective approach gained traction as a practical organizational method that resonated with individuals seeking to simplify their workflow and improve their productivity.

Who Can Benefit from the Paper Clip Strategy?

The paper clip strategy is beneficial for a wide range of individuals across various professions and industries. It is particularly advantageous for:

Entrepreneurs : Entrepreneurs juggling multiple responsibilities can leverage the paper clip strategy to efficiently manage their ventures and prioritize tasks.

Students : Students can utilize this strategy to categorize and prioritize study materials, assignments, and projects, leading to better organization and enhanced academic performance.

Professionals : Professionals in diverse fields, such as project management, consulting, and creative arts, can employ the paper clip strategy to optimize their workflows and improve time management.

Use Lark to unleash your team productivity.

Exploring the Pros and Cons of the Paper Clip Strategy

Simplicity : The paper clip strategy's uncomplicated nature makes it accessible and easy to implement for individuals at any organizational skill level.

Visual Organization : By representing tasks or projects with paper clips, individuals benefit from a visual and tactile approach to organization, aiding in task prioritization and completion tracking.

Flexibility : Whether physical paper clips, kanban boards, or digital tools, the strategy allows for flexibility in adapting to various preferences and work environments.

Reduced Cognitive Load : The visual representation of tasks with paper clips can alleviate mental burden and decision fatigue, enabling individuals to focus on critical activities.

Physical Limitations : In digital work environments, the physicality of the paper clip strategy may pose challenges, necessitating the use of digital organizational tools.

Over-reliance on Visual Cues : Dependency on visual cues alone may lead to neglect of other essential organizational and productivity methods.

Maintenance Effort : Regular upkeep of the paper clip organization may require consistent effort and attention to ensure its effectiveness.

Getting Started with the Paper Clip Strategy

To embark on the paper clip strategy journey and unlock its productivity potential, consider the following steps:

Identify Areas for Application : Determine the tasks or projects within your workflow that would benefit from the visual and tactile organization provided by the paper clip strategy.

Select Your Medium : Choose between physical paper clips, digital tools, or software solutions to best implement the paper clip strategy based on your work environment and preferences.

Create a Categorization System : Establish a system for utilizing different colored paper clips or digital labels to represent categories, priorities, or status of tasks or projects.

Designate a Workspace : Dedicate a physical area or digital platform where you will arrange and display your paper clips to serve as a visual organizational framework.

Regular Review and Adjustments : Schedule routine reviews to reorganize, update, and reprioritize the representation of tasks or projects using the paper clip strategy.

Step-by-Step Guide for Implementing the Paper Clip Strategy

Organizing tasks with physical paper clips.

Gather Necessary Supplies : Collect an assortment of paper clips in various colors and sizes to differentiate between tasks or projects.

Define Categories : Designate specific categories or priorities to correspond with different colors of paper clips, such as urgent tasks, pending projects, or completed assignments.

Assign and Display : Attach the paper clips to a designated board or surface, arranging them according to the established categories and priorities.

Tracking Progress : Regularly update and move paper clips based on task status, providing a visual representation of progress and pending actions.

Implementing the Paper Clip Strategy Digitally

Select Digital Tools : Choose from an array of productivity and organizational software or applications that offer digital alternatives to the paper clip strategy.

Digital Representation : Utilize the software to visually represent tasks or projects with labels, colors, or status indicators, simulating the paper clip approach in a digital environment.

Dynamic Adaptation : Leverage the flexibility of digital solutions to easily modify and update task representations as priorities shift or projects evolve.

Integration with Workflows : Integrate the digital paper clip strategy seamlessly into your existing digital workflows, ensuring continuity and synergy with other productivity tools.

Actionable Tips for Embracing the Paper Clip Strategy

Leverage Color Coding : Assign specific meanings to different colors of paper clips or digital labels to convey priorities, deadlines, or task categories at a glance.

Regular Maintenance : Dedicate time for periodic reviews and adjustments to keep the paper clip organization system aligned with your evolving workload and objectives.

Visual Display : Ensure your paper clip display, whether physical or digital, is positioned in a prominent and accessible location to serve as a constant visual reminder and organizational aid.

3 Pro Tips to Uplift Employee Engagement & Productivity | Lark Blog

Learn more about Lark x Productivity

Do's and Dont's

The paper clip strategy offers a practical and tangible approach to optimizing productivity and organization in today's dynamic work landscape. By leveraging the visual and tactile representation of tasks or projects, individuals can effectively streamline their workflows, minimize mental clutter, and prioritize critical activities. Whether through the traditional use of physical paper clips or digital alternatives, the paper clip strategy presents a versatile and accessible solution for individuals striving to enhance their productivity and efficiency.

Frequently Asked Questions

How frequently should i update the representation of tasks with paper clips.

It is advisable to schedule regular reviews, ideally on a weekly basis, to ensure that the representation of tasks accurately reflects their current status and priority levels.

Can the paper clip strategy be applied in collaborative work environments?

Yes, the paper clip strategy is adaptable to collaborative settings. By establishing shared visual cues and categorization systems, teams can benefit from improved organization and task visibility.

What if I prefer digital tools over physical paper clips for organization?

Digital alternatives to the paper clip strategy offer the same principles of visual representation and categorization, allowing individuals to seamlessly adapt the strategy to their preferred digital platforms.

Is the paper clip strategy suitable for long-term project management?

The paper clip strategy can be effectively applied to long-term projects by providing a visual roadmap and progress tracker, enabling individuals to manage complex tasks with enhanced clarity and organization.

Can I combine the paper clip strategy with other productivity methodologies?

Absolutely, the paper clip strategy can complement and enhance existing productivity methodologies, providing an additional layer of visual organization and task management.

In conclusion, the paper clip strategy exudes simplicity and effectiveness as a productivity and organizational tool, offering individuals a tangible and practical approach to managing tasks and projects. Whether through the tactile use of physical paper clips or digital adaptations, this strategy empowers individuals to declutter their workflows, prioritize effectively, and achieve heightened productivity.

Lark, bringing it all together

All your team need is Lark

Explore More in Productivity Glossary

- PRO Courses Guides New Tech Help Pro Expert Videos About wikiHow Pro Upgrade Sign In

- EDIT Edit this Article

- EXPLORE Tech Help Pro About Us Random Article Quizzes Request a New Article Community Dashboard This Or That Game Popular Categories Arts and Entertainment Artwork Books Movies Computers and Electronics Computers Phone Skills Technology Hacks Health Men's Health Mental Health Women's Health Relationships Dating Love Relationship Issues Hobbies and Crafts Crafts Drawing Games Education & Communication Communication Skills Personal Development Studying Personal Care and Style Fashion Hair Care Personal Hygiene Youth Personal Care School Stuff Dating All Categories Arts and Entertainment Finance and Business Home and Garden Relationship Quizzes Cars & Other Vehicles Food and Entertaining Personal Care and Style Sports and Fitness Computers and Electronics Health Pets and Animals Travel Education & Communication Hobbies and Crafts Philosophy and Religion Work World Family Life Holidays and Traditions Relationships Youth

- Browse Articles

- Learn Something New

- Quizzes Hot

- This Or That Game

- Train Your Brain

- Explore More

- Support wikiHow

- About wikiHow

- Log in / Sign up

- Education and Communications

How to Use a Paper Clip in Many Ways

Last Updated: June 19, 2023 Fact Checked

This article was co-authored by Robert Vallelunga . Robert Vallelunga is a Locksmith and the Owner of ACME Locksmith in the Phoenix Metro Area. Robert has over 15 years of experience in the industry and specializes in working with automotive ignitions, locks, keys, and master key systems. Robert and the team at ACME are the #1 Rated Phoenix Locksmith Service and the Winner of the Better Business Bureau Ethics Award. Robert has his Residential & Commercial Contractor’s License and a Bachelor of Science in Electrical Engineering from Arizona State University. There are 7 references cited in this article, which can be found at the bottom of the page. This article has been fact-checked, ensuring the accuracy of any cited facts and confirming the authority of its sources. This article has been viewed 127,309 times.

Paper clips are traditionally used to, well, clip together paper. But, there are plenty more creative and practical ways to make use of this common (and wonderfully inexpensive) office supply. When you take advantage of its small size, strong metal wire, and convenient bending ability, a simple paper clip can become anything from a handy tool to a work of art.

Using Paper Clips as Tools

- If you’re feeling adventurous, reshape your paper clip into a heart-shaped holder. It’ll lend a little love and excitement to your bundles. [1] X Research source

- This is also a useful way to prepare a hem to resew it. Using paper clips around the edge will help ensure that your hem is even all the way around.

- This is an easy and cheap way to hang everything from ornaments to strings of lights to wall decor. Just be sure that whatever you’re hanging is light enough that it won’t break the paper clip with its weight.

- You can even reshape the paper clip into a miniature clothes hanger.

- You can either fold the open edge of a bag over and clip it closed or unbend your paper clip to use it like a twisty tie.

- To open a padlock, you’ll need two paper clips, one unbent to be completely straight and the other bent into an “L” shape.

- Insert the straight clip into the very top of the keyhole (where the jagged edge of your key would normally go), and the L-shaped clip into the bottom. Then, you need to swiftly and firmly pull the top clip out while firmly twisting the bottom clip in the same direction as you would your key. It’s tricky to get the action exactly right, so it may take a few tries.

Crafting with Paper Clips

- Be sure that you're using a paper clip made from a substantial wire that it can hold the weight of your key(s).

- You should also be sure that the two loops of wire are as tight or close together as possible so that your key will not slip off. If you are worried about losing your key, twist the two ends of your paper clip around the loops a few times to prevent them from opening up.

- You can also add colorful flare and help mark your spot by tying a tassel to the end made from knotting together a bundle of ribbon, string, or sewing floss.

- The easiest style is a chain necklace or bracelet made from linking together multiple clips to achieve the length you want. Either attach the open ends together or twist together your clips into interlocking spirals.

- Experiment by making long necklaces and bracelets with multiple loops of different colors.

- Try decorating your jewelry with beads, ribbons, colorful paper wrapped around each clip with glue, or whatever else strikes your fancy!

- Try using multicolored paper clips to introduce multiple hues into your sculpture. Doing so can make it more vibrant or help you better represent the object you’re portraying, like a flower with red petals and green leaves.

- Try out designs that take advantage of the typical shape of a paper clip. For instance, the shape of the paper clip works really well to form the body and wings of an angel with a bead for a head. It also lends itself perfectly to being the blades on a pair of ice skates cut out from paper or felt. [12] X Research source

- Paper clips are likewise ideal for attaching ornaments to ribbons so that they can be easily hung up for display.

Expert Q&A

- Be creative! Thanks Helpful 2 Not Helpful 0

- Keep paper clips of many different sizes and colors on hand to maximize your possibilities. Thanks Helpful 1 Not Helpful 0

- Since they’re made of metal and sometimes have sharp edges, paper clips can be dangerous for kids to use. If you’re doing any of these activities with young children, be sure to supervise them closely. Thanks Helpful 5 Not Helpful 2

You Might Also Like

Expert Interview

Thanks for reading our article! If you’d like to learn more about unlocking a safe, check out our in-depth interview with Robert Vallelunga .

- ↑ http://wonderfuldiy.com/paper-clips-crafts/

- ↑ http://www.countryliving.com/diy-crafts/g2928/paper-clip-tricks/

- ↑ https://www.youtube.com/watch?v=AxUI5WKDr7s

- ↑ http://www.marieclaire.com/beauty/a1883/how-to-pick-a-lock/

- ↑ http://www.pbs.org/parents/crafts-for-kids/paper-clip-bookmarks/

- ↑ https://www.youtube.com/watch?v=rRQYkiV6mZ4

- ↑ https://www.youtube.com/watch?v=XsNb7awWnTY

About This Article

- Send fan mail to authors

Did this article help you?

Featured Articles

Trending Articles

Watch Articles

- Terms of Use

- Privacy Policy

- Do Not Sell or Share My Info

- Not Selling Info

Get all the best how-tos!

Sign up for wikiHow's weekly email newsletter

Quill And Fox

Best Design Studio

Amber Robertson

Amber Robertson is the founder of Quill and Fox. A creative writing studio that helps people find their voice and share their stories. Amber is also a published author, with her first book slated for release in 2020. She loves spending time with her family and friends, reading, writing, and traveling. When Amber was younger, she loved to write short stories and plays. But somewhere along the way, she lost touch with her creativity. It wasn’t until she became a mom that she realized how important it was to share her stories—both the good and the bad—with the people she loves most. That’s when Quill and Fox was born. Amber is passionate about helping others find their voice and share their stories. She believes that every person has a story worth telling, and it’s her mission to help them tell it in a way that is authentic and true to themselves

What Are Paper Clips Made Of?

Table of Contents

Introduction

Paper clips are an essential part of our daily lives, used to hold papers together and keep them organised. However, have you ever wondered what paper clips are made of? In this article, we will explore the materials used to make paper clips and their properties.

Paper clips come in various shapes and sizes, but their primary function remains the same. They are used to keep papers together, preventing them from getting lost or mixed up. The invention of the paper clip dates back to the 19th century, where it was patented by Samuel B. Fay. Since then, paper clips have undergone various changes, but their importance remains unchanged.

Materials Used to Make Paper Clips

Paper clips are made from a variety of materials, depending on the intended use, durability, and cost. The most common materials used to make paper clips are steel, plastic, and wire.

Steel is the most common material used in making paper clips. It is strong, durable, and can be easily shaped into various shapes and sizes. Steel paper clips are available in many different grades, ranging from low-grade steel to high-grade stainless steel.

Low-grade steel is cheaper and may rust over time. High-grade stainless steel, on the other hand, is more expensive but is rust-resistant and lasts longer. Steel paper clips are also coated with different materials, such as nickel, to improve their appearance and durability.

Plastic paper clips are also available and are made from different types of plastic, such as PVC, nylon, and polypropylene. They are cheaper than steel paper clips and come in a variety of colours, making them ideal for colour-coding documents. However, plastic paper clips are not as strong as steel paper clips and can break easily. They are also not suitable for holding large stacks of paper.

Steel Paper Clips

Steel paper clips are the most commonly used type of paper clip. They come in various sizes, from small to large, and are available in different grades of steel.

Composition of Steel Paper Clips

Steel paper clips are made from a combination of iron and carbon. The amount of carbon added to the steel determines the steel’s strength and durability. Low-grade steel paper clips contain less carbon and are less durable than high-grade steel paper clips, which have a higher carbon content.

Advantages and Disadvantages of Steel Paper Clips

One of the advantages of steel paper clips is their strength and durability. They can hold large stacks of paper without bending or breaking. Steel paper clips are also rust-resistant, making them ideal for long-term use.

However, steel paper clips are more expensive than plastic paper clips and can be heavier, making them unsuitable for some applications. Steel paper clips can also leave marks on paper if left on for an extended period, leading to damage.

Plastic Paper Clips

Plastic paper clips are an alternative to steel paper clips and are becoming increasingly popular. They are made from different types of plastic, such as PVC, nylon, and polypropylene.

Types of Plastic Used in Making Paper Clips

PVC is the most commonly used plastic in making paper clips. It is a cheap and flexible material that can be easily moulded into various shapes and sizes. Nylon is another type of plastic used in making paper clips. It is stronger and more durable than PVC, making it ideal for holding large stacks of paper. Polypropylene is a more environmentally friendly option, as it is recyclable and does not contain harmful chemicals.

Advantages and Disadvantages of Plastic Paper Clips

One of the advantages of plastic paper clips is their cost. They are much cheaper than steel paper clips, making them ideal for bulk purchases. Plastic paper clips are also available in a variety of colours, making them ideal for colour-coding documents.

However, plastic paper clips are not as strong as steel paper clips and can break easily. They are also not suitable for holding large stacks of paper, as they do not have the same grip strength as steel paper clips. Plastic paper clips can also leave marks on paper if left on for an extended period, leading to damage.

Alternative Materials

Innovations in paper clip materials have led to the development of new materials that are more sustainable, eco-friendly, and cost-effective. One of these materials is bamboo. Bamboo paper clips are made from bamboo fibres, making them biodegradable and eco-friendly.

Another alternative material used in making paper clips is recycled materials. These paper clips are made from recycled plastic or metal, reducing waste and promoting sustainability.

In conclusion, paper clips are an essential part of our daily lives, and their importance cannot be overstated. The materials used to make paper clips determine their strength, durability, and cost. Steel paper clips are the most common type of paper clip and are available in different grades of steel. Plastic paper clips are also available but are not as strong as steel paper clips.

Innovations in paper clip materials have led to the development of new materials that are more sustainable, eco-friendly, and cost-effective. Bamboo paper clips and recycled paper clips are examples of these alternative materials.

When selecting paper clips, it is crucial to consider the intended use, durability, and cost of the materials used. With this knowledge, you can choose the best paper clips for your needs and promote sustainability in your daily life.

Early Office Museum History of the Paper Clip Advertisement for the Common-Sense Paper Clip

What counts as a paper clip? For purposes of the discussion and timeline presented here, a paper clip is a flat or nearly flat piece of metal that slides over an edge of a set of papers and holds the papers together without being bent or pinched by the user and without piercing the papers. A large majority of different paper clip models were made by bending single pieces of resilient spring steel wire. Three others were stamped from sheet metal (Eureka, Sheet Brass Gothic, Proco) and another four (Angell, Utility, Vise, Acme Correspondence) were made by folding small pieces of resilient sheet steel. One (Nifty) was made by bending a wire into a spiral and then flattening it. Recently some paper clips have been made of plastic, but these are not covered here.

When were paper clips introduced? The first paper clip was patented by Samuel B. Fay in 1867. This clip was originally intended primarily for attaching tickets to fabric, but the patent recognized that it could be used to attach papers together. We have found no advertisement for, or other mention of, the Fay design until 1896. In 1896, the American Stationer announced that D. S. Gorman was the New York, NY, distributor for a "new paperclip," named "Clinch;" this clip used the Fay design. Also in 1896, the Cinch Clip Co., Buffalo, NY, was identified as the manufacturer of a paper clip named "Cinch," which also used the Fay design. It therefore appears unlikely that paper clips with the Fay design had significant, if any, sales prior to 1896. However, beginning in the late 1890s and for decades thereafter, the Fay design was widely advertised under many brand names for use in fastening papers. In 1918, the brand name "Fay" was used by the American Clip. Co. for a paper clip with the Fay patent design. A second paper clip design was patented by Erlman J. Wright in 1877. This clip was advertised at that time for use in fastening newspapers. A third paper clip was patented by Frank Angell in 1889.

When did paper clips come into widespread use in offices? A patent application filed at the end of 1896 indicated that a number of different paper clips were in use. A flood of paper clip patents were issued beginning in 1897. A 1900 trade publication stated that "The wire clip for holding office papers together has entirely superseded the use of the pin in all up-to-date offices." ( Business , March 1900, p. 173) This evidence indicates that paper clips came into widespread use in U.S. offices in the late 1890s.

With what products did paper clips compete most closely? The two earliest patents indicate that bent-wire paper clips could be used in lieu of pins, sewing, "pointed bent-over paper fasteners," and eyelets. In 1904, Clinch Clips were advertised as "Cheaper than Pins." Around 1910 advertisements compare paper clips to straight pins for temporary attachment of papers. By contrast, early paper clip advertisements do not refer to staples.

What is included in the paper clip time-line below? The Early Paper Clip Gallery below identifies every paper clip that we are aware of that has a patent date before the end of 1902 plus every one for which we have found an advertisement, box, or example (but excluding modern plastic and decorative paper clips, e.g., ones in the shape of a bone or star). Many additional designs that are not shown here were patented. Presumably most of these were not advertised widely or for long, if at all. In the case of paper clips patented before the end of 1902, if we do not have an advertisement or box that tells us the brand name of the clip, we have identified the clip using the patent holder's last name in italics .

We did not include paper clips that were patented after 1902 unless we could find evidence that they were produced. We used that cutoff date because 13 paper clip patents were awarded in 1903, 10 of them to one inventor, George W. McGill. Of the latter 10, only three appear to have been produced (Banjo, Ring, Improved Gem).

Would you like to swap, sell, donate, or purchase early paper clips? If the Early Office Museum has an example of a particular paper clip, we put an "X" at the end of the text in the box in the right-hand column in the pertinent row of the table below. We have duplicates of most of those, but not all. We would be happy to swap our duplicate early paper clips for ones we do not have. We will also sell duplicates, and we will purchase or accept donations of ones we do not have. We are also interested in photos/scans of paper clips, boxes, and advertisements (if possible dated) that we do not have to post on the Museum web site with a credit to you. Please email the Curator: eomcurator, followed by @, followed by hotmail.com with the subject line "paper clips".

Early Paper Clip Gallery

Additional paper clips are listed by name but not illustrated in Who Makes It and Where: The Stationers' Book of Knowledge, 1918-19 , Andrew Geyer, Inc., New York, copyright 1916. Also, "You are Cordially Invited to a Preview of the Emanuel Fritz Paper Clip Collection at the Smithsonian Institution, Washington, D.C.," American Collector , July 1973, contains photographs of portions of several paper clips that are not included above. Because the complete clips are not visible, we are unable to match them to patent diagrams.