how to start used cooking oil recycling business

Introduction.

Welcome to the world of used cooking oil recycling! If you are passionate about environmental sustainability, seeking a profitable business opportunity, and looking to make a positive impact on the planet, then starting a used cooking oil recycling business may be the perfect venture for you. In this comprehensive guide, we will walk you through all the essential steps and considerations involved in launching and running a successful used cooking oil recycling enterprise.

Overview of the Used Cooking Oil Recycling Business

The used cooking oil recycling industry plays a critical role in reducing waste, protecting the environment, and promoting renewable energy sources. It involves the collection, processing, and repurposing of used cooking oil into valuable products such as biodiesel, animal feed, and other industrial applications. By diverting used cooking oil from landfills or improper disposal methods, this business helps prevent environmental pollution and supports the circular economy.

Benefits of Starting a Used Cooking Oil Recycling Business

Starting a used cooking oil recycling business offers numerous benefits, both from an environmental and economic standpoint. Firstly, it contributes to a cleaner and greener world by reducing the harmful environmental impact of improperly discarded cooking oil. By recycling this waste product, you are helping to conserve resources and minimize pollution.

Secondly, the profitability potential of this business is significant. Used cooking oil has value as a raw material in various industries, such as biofuel production, animal feed manufacturing, and even soap making. By establishing a network of collection points and processing facilities, you can generate revenue by selling the recycled oil or its by-products to interested buyers.

Market Potential and Demand for Used Cooking Oil Recycling

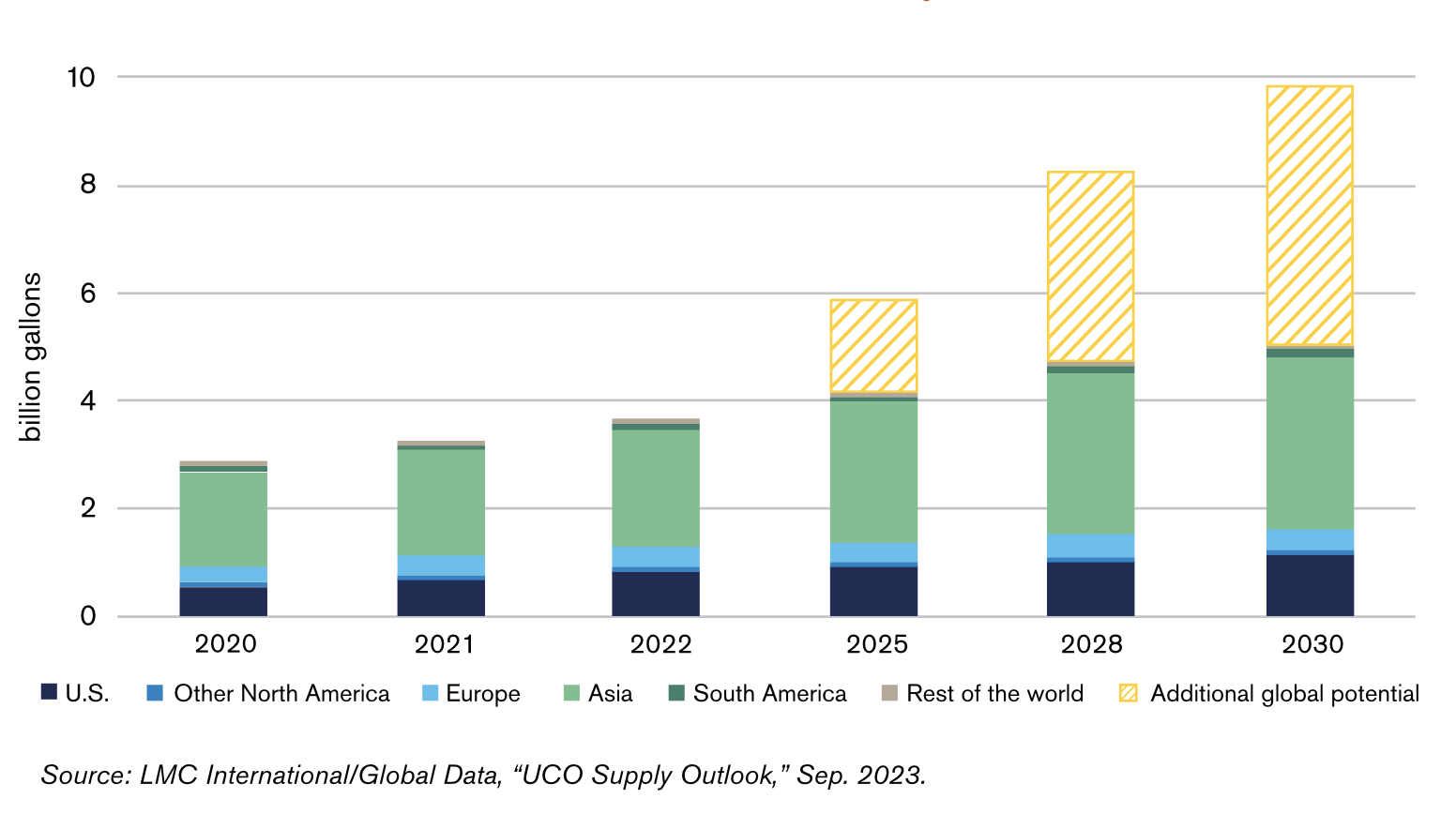

The market for used cooking oil recycling is experiencing steady growth, driven by increasing awareness of environmental issues and the growing demand for sustainable alternatives. Governments, businesses, and individuals are recognizing the importance of responsibly managing used cooking oil, creating a substantial market for recycling services.

Restaurants, hotels, food manufacturers, and other food service establishments are the primary sources of used cooking oil. As the hospitality and food industries continue to expand worldwide, the volume of used cooking oil generated also increases. This creates a significant opportunity for entrepreneurs to enter the used cooking oil recycling market and cater to the rising demand.

Moreover, governments and regulatory bodies are implementing stricter regulations and guidelines for the disposal of used cooking oil. This further emphasizes the need for recycling services, as businesses must comply with these regulations or face penalties. By positioning your business as a reliable and compliant recycling solution, you can tap into this growing market and establish a strong customer base.

In the next section, we will delve deeper into the concept of used cooking oil recycling, exploring what it entails, its environmental impact, and the regulations surrounding this industry. So let’s dive in and uncover the fascinating world of used cooking oil recycling!

Understanding Used Cooking Oil Recycling

Recycling used cooking oil is not only a responsible and eco-friendly practice but also a valuable resource for various industries. In this section, we will explore the concept of used cooking oil recycling, its different types, the environmental impact of improper disposal, and the reasons why recycling is a crucial step in waste management.

What is Used Cooking Oil?

Used cooking oil refers to oil that has been previously used for frying or cooking food. It is typically generated in large quantities by restaurants, fast-food chains, hotels, and other food service establishments. Used cooking oil can come from various sources, including vegetable oils like soybean, canola, or corn oil, as well as animal fats such as lard or tallow.

Different Types of Used Cooking Oil: 1. Vegetable Oil: This type of used cooking oil is derived from plant sources, such as soybeans, sunflowers, or palm fruits. It is commonly used in commercial food establishments due to its affordability and availability. 2. Animal Fat: Animal-based used cooking oil is obtained from rendering processes that extract fats from meat or poultry. It is often used in deep-frying applications due to its high smoke point and flavor-enhancing properties.

Environmental Impact of Improper Disposal

Improper disposal of used cooking oil can have severe consequences for the environment. When poured down the drain or discarded in landfills, it can cause clogs in pipes and sewage systems. The oil forms fatty deposits that can lead to blockages, resulting in costly repairs and potential sewage overflows. These blockages can also harm aquatic ecosystems if the oil makes its way into rivers, lakes, or oceans.

Moreover, used cooking oil can contain harmful substances such as food particles, grease, and contaminants. These impurities, if not properly disposed of or recycled, can contribute to water pollution and harm both marine life and terrestrial ecosystems. The accumulation of used cooking oil in landfills can also release harmful greenhouse gases, contributing to climate change.

Why Recycle Used Cooking Oil?

Recycling used cooking oil offers numerous advantages and benefits, making it a sustainable and economically viable practice.

Environmental Benefits: By recycling used cooking oil, you are diverting it from improper disposal methods and reducing environmental pollution. Recycling allows the oil to be transformed into valuable products such as biodiesel, which can replace fossil fuels and contribute to cleaner air quality. Additionally, recycling helps conserve resources by repurposing waste into useful materials.

Renewable Energy Source: Used cooking oil can be converted into biodiesel, a renewable and clean-burning alternative to petroleum diesel. Biodiesel is produced through a process called transesterification, which removes impurities and converts the oil into a usable fuel. Biodiesel can be used in vehicles, generators, and even heating systems, reducing reliance on fossil fuels and decreasing greenhouse gas emissions.

Economic Opportunities: The used cooking oil recycling industry presents significant economic potential. As the demand for sustainable alternatives grows, there is a market for recycled cooking oil and its by-products. Biodiesel production, for example, can generate revenue through sales to transportation companies, power plants, or individual consumers. Additionally, recycled cooking oil can be used in the production of animal feed, soap, and other industrial applications, creating additional revenue streams.

In the next section, we will delve into the regulations and permits required for starting a used cooking oil recycling business. Understanding the legal aspects of this industry is essential to ensure compliance and mitigate any potential risks. So let’s continue our journey and explore the regulatory landscape of used cooking oil recycling.

Starting a Used Cooking Oil Recycling Business

Starting a used cooking oil recycling business requires careful planning, market research, and a solid business plan. In this section, we will guide you through the essential steps involved in launching your own venture in the used cooking oil recycling industry.

Market Research and Analysis

Before diving into the used cooking oil recycling business, it is crucial to conduct thorough market research and analysis. This step will help you understand the market dynamics, identify potential customers, and assess the competition. Here are some key considerations for your market research:

Identifying Target Customers and Industries: Determine the primary sources of used cooking oil in your target area. Restaurants, hotels, catering services, and food manufacturers are common generators of used cooking oil. Analyze their current practices, disposal methods, and receptiveness to recycling initiatives. Understanding your potential customers’ needs will help you tailor your services accordingly.

Analyzing Competition and Market Trends: Research existing used cooking oil recycling companies in your region. Identify their strengths, weaknesses, and market positioning. Look for gaps or underserved areas where you can differentiate yourself. Additionally, stay updated on industry trends, technological advancements, and government regulations related to recycling and renewable energy. This knowledge will help you stay ahead of the curve and adapt your business strategy accordingly.

Business Plan Development

A well-crafted business plan is essential for the success of any venture, including a used cooking oil recycling business. It serves as a roadmap, outlining your mission, vision, goals, and strategies. Here are key components to include in your business plan:

Defining Your Mission, Vision, and Goals: Clearly articulate the purpose of your business and the values it stands for. Outline your long-term vision and set achievable goals that align with your mission. For example, your mission might be to provide sustainable and reliable used cooking oil recycling services to businesses in your community, while your vision might be to expand your operations and become a leading player in the industry.

Conducting a SWOT Analysis: Assess your business’s strengths, weaknesses, opportunities, and threats (SWOT analysis). Identify what sets you apart from competitors, such as unique collection methods, advanced processing techniques, or exceptional customer service. Address any weaknesses and develop strategies to overcome them. Capitalize on opportunities in the market, and anticipate and mitigate potential threats.

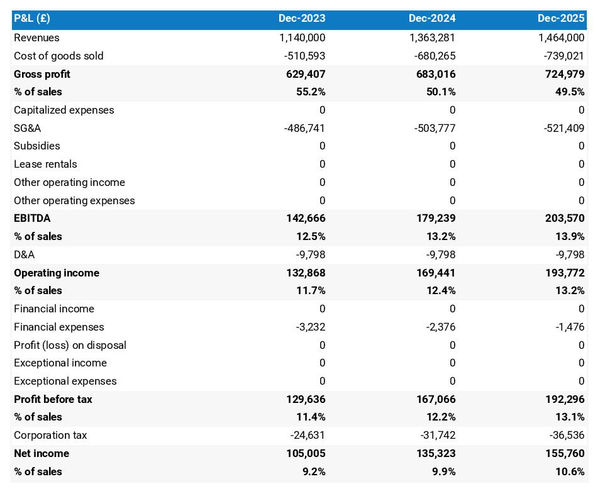

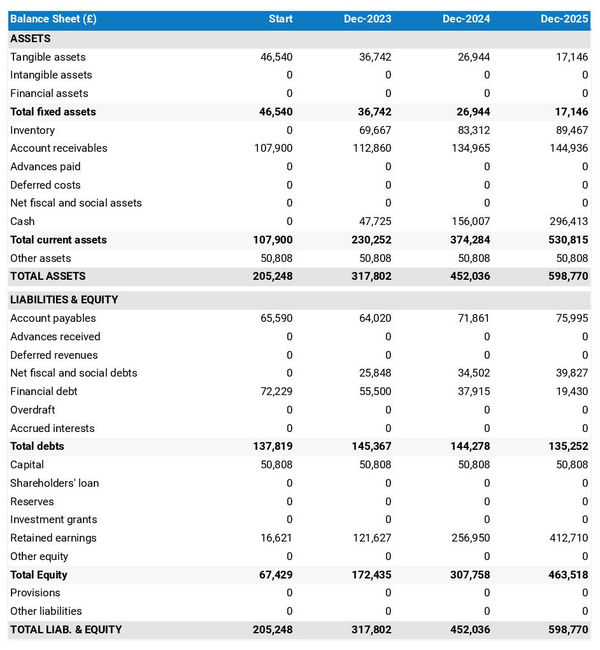

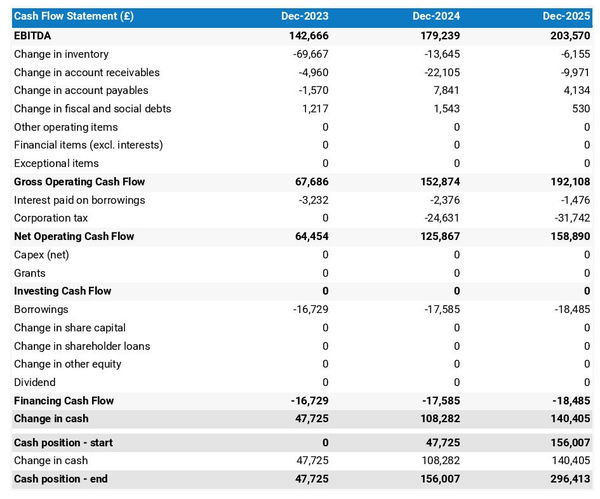

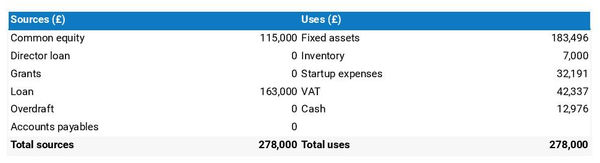

Financial Projections and Budgeting: Create a detailed financial plan that includes revenue projections, operating costs, and profit margins. Consider the initial investment required for equipment, infrastructure, permits, and licenses. Determine your pricing structure and estimate the volume of used cooking oil you expect to collect and process. A comprehensive financial plan will help you secure funding, attract investors, and monitor the financial health of your business.

Equipment and Infrastructure

To start a used cooking oil recycling business, you will need essential equipment and infrastructure to collect, store, and process the oil effectively. Here are key considerations in this regard:

Essential Equipment for Used Cooking Oil Collection and Processing: Invest in suitable containers, barrels, or tanks for the collection and storage of used cooking oil. Consider whether you will collect the oil directly from businesses or set up collection points. Additionally, research and invest in equipment for processing and refining the oil, such as filtration systems, centrifuges, and storage tanks.

Setting Up Storage Facilities and Transportation Logistics: Ensure you have adequate storage facilities to safely store the collected used cooking oil. Establish a system for regular pickups from your customers to maintain a consistent supply. Consider the logistics of transportation, including the type of vehicles needed, routes, and scheduling. Adhere to safety guidelines for handling and transporting used cooking oil to minimize any potential risks.

In the next section, we will explore the operations and logistics involved in a used cooking oil recycling business. From collection and transportation to processing and quality control, we will cover all the critical aspects of running your daily operations. So let’s continue our journey and discover the inner workings of a used cooking oil recycling enterprise.

Operations and Logistics

The operations and logistics of a used cooking oil recycling business are crucial for the efficient collection, transportation, processing, and quality control of the oil. In this section, we will delve into the various aspects involved in running the day-to-day operations of your recycling enterprise.

Collection and Transportation of Used Cooking Oil

Establishing an effective collection and transportation system is essential to ensure a steady supply of used cooking oil. Here are key considerations for this aspect of your business:

Establishing Collection Points and Routes: Identify suitable collection points where businesses can deposit their used cooking oil. This can be done through partnerships with restaurants, hotels, or food service establishments. Determine the frequency of pickups based on the volume of oil generated and the availability of collection vehicles. Optimize collection routes to minimize travel time and costs.

Ensuring Safe Handling and Storage Procedures: Provide clear instructions to your customers on how to handle and store the used cooking oil before pickup. Emphasize the importance of using leak-proof containers and securing lids to prevent spills and contamination. Educate your customers on the benefits of proper oil storage and the negative consequences of improper disposal.

Processing and Recycling Methods

Once the used cooking oil is collected, it needs to undergo processing and recycling to transform it into valuable products. Here are key considerations for this stage:

Filtering and Refining Techniques: The collected oil should undergo filtration to remove impurities, food particles, and solid debris. Filtration methods can include using filter bags, mesh screens, or centrifuges. Additionally, refining techniques may be necessary to further purify the oil, depending on the desired end product. Refining processes can involve chemical treatments or additional filtration steps.

Converting Used Cooking Oil into Biodiesel or Other Products: One of the primary recycling methods for used cooking oil is the production of biodiesel. Biodiesel is a renewable fuel that can be used in diesel engines with little to no modifications. The transesterification process involves combining the used cooking oil with an alcohol (usually methanol) and a catalyst to produce biodiesel and glycerin as a by-product. Research the specific production methods and quality standards for biodiesel in your region.

Quality Control and Testing

Maintaining high-quality standards is crucial to ensure the safety and reliability of your recycled cooking oil. Here are key considerations for implementing quality control measures:

Importance of Testing for Contaminants and Impurities: Regularly test samples of your recycled cooking oil for contaminants and impurities. Common tests include measuring acidity levels, moisture content, and the presence of contaminants such as heavy metals or residual chemicals. Implement a robust quality control framework to ensure compliance with local regulations and the satisfaction of your customers.

Ensuring Compliance with Quality Standards: Familiarize yourself with the quality standards and regulations relevant to recycled cooking oil in your region. These may include specifications for biodiesel production, labeling requirements, or documentation for traceability purposes. Adhering to these standards will not only ensure the safety and legality of your products but also enhance your reputation in the market.

In the next section, we will explore the marketing and expansion strategies for your used cooking oil recycling business. Building a strong brand, developing customer relationships, and scaling your operations are essential for long-term success. So let’s continue our journey and uncover the secrets to effectively promoting and growing your recycling enterprise.

- Smart Service

- 1-888-518-0818

How to Start a Cooking Oil Recycling or Waste Oil Collection Business

Follow these simple steps to launch your own cooking oil recycling business..

Cooking oil recycling and waste oil collection are ongoing needs you can build a business around, providing a very useful and valuable service for restaurants, automotive mechanics, and other businesses. If you have access to a small amount of startup funds, understand the regulations of your area, and can make connections with local businesses, you may just have everything it takes to start your very own waste oil business.

One way or another, businesses that use oil consistently have to properly dispose of it later on. By dependably doing this as a service, you can reduce the costs other companies incur and take care of something they may consider an annoying problem.

Whether you want to handle all types of waste oil or have specific waste products you plan to collect, you’ll need to know how to keep your business compliant with all applicable regulations, how to organize your new company, and how to find customers.

What is the waste oil industry?

Businesses that collect waste oil for future recycling allow restaurants, manufacturing plants, automotive facilities, and other operations that regularly use oil to properly dispose of it, giving the oil a renewed life elsewhere. Since companies repeatedly use oil for their processes, they have a constant need for someone to collect it.

What can you do with used oil? That depends on the type of oil:

- Cooking oil: Vegetable and animal oils are used to cook food in restaurants, cafeterias, and other institutions. Although they can’t be reused directly to cook food again, these oils can be converted to biodiesel to fuel vehicles. Biodiesel is a clean, nontoxic, reduced-pollution alternative fuel. Specialized vehicles can use it instead of traditional fuel types.

- Automotive oil: Vehicles use oil, and a lot of it. Mechanics and dealerships represent ideal customers for a business collecting automotive oil.

The Environmental Protection Agency (EPA) considers waste oil a contaminated, used oil containing other substances. These oils can be recycled through a specific process. Oil recycling minimizes dumping, making it good for the environment. A single gallon of used motor oil produces just as much refined, high-quality oil as 42 gallons of crude oil. The efficiency of oil recycling saves energy and reduces the overall price of oil.

Getting Started in the Waste Oil Industry

Processing waste oil as a business requires the right plan. To get started, you’ll need to research local requirements, obtain the right equipment, and do other feasibility research. From there, carefully craft your business plan and determine how you’ll find clients. If you need more guidance, follow these steps:

- Gain experience: Get the right experience and knowledge by taking classes, working in someone else’s business for a while, or learning about local requirements. Find out more about the industry if you’re new to it. If you already have the experience, you can start sooner.

- Research your market: Look at the competition and determine the accessibility of current waste oil options to potential customers. Make sure your area can support another waste collector. If you’re the first in your sector, that’s even better!

- Create your business: When you’re confident in your business plan, start registering and opening your business. Choose a legal structure, a name , and a marketing identity. Decide how you’ll spread the word about your new company. Find out what licenses you’ll need and regulations you’ll have to follow.

- Purchasing and renting equipment: The type of oil collection you do may dictate what equipment you need, but generally you’ll want to have barrels or other containers for the oil, a commercial transportation truck to haul barrels away from customer businesses, and a location for storing oil. Your barrels and equipment will probably cost at least a few thousand dollars. Once you add in the costs of a decent truck , the total price tag will likely hit ~$20k. Be sure to factor in how much money you’ll need to obtain the right equipment.

- Advertising and getting your first customers: Begin by letting others know about your new business. You could send an ad in the mail to all local companies that use oil, for instance. You can also start a website and rely on SEO and word of mouth advertising to let everyone know about it.

- Refine your plan: Once your business starts getting its first customers, revise your plan to make sure your back office processes keep up with your needs. You should make more accurate revenue projections with the added information you have from your first contracts and making your first deals.

Your Cooking Oil Recycling or Waste Oil Collection Startup

Continuously market your services and work on refining your plans, and you will find yourself in a better position to take advantage of market opportunities.

This article was written by the field service industry experts at Smart Service . Smart Service is a mobile scheduling, work order, and customer management software system for QuickBooks. Thousands of field service businesses rely on Smart Service to streamline their workflow, eliminate waste and boost revenue

Request a free, online demo of Smart Service to discover how you can supercharge your business.

Did you enjoy reading this article? Share it with your friends and co-workers!

Check out our products.

HVAC Service Technician Tool List

The most talented technician in the world can't do anything for your company unless they have the tools required to meet your customers' needs.

Best Phones for Construction Workers

Working in the construction industry means tough physical demands, for both you and your smartphone. Find one up to the task.

HVAC Formulas – A Quick and Handy Guide for Common HVAC Calculation

HVAC technicians often run into situations that require specific formulas and calculations. Check out this list of some of the most commonly used formulas in the HVAC industry.

The Best Hand Creams For Working Hands

When your hands take a beating from hard work and bad weather, use one of these amazing hand creams for working hands!

6 HVAC Interview Questions You Should Know How to Answer

Whether you're the interviewer or the interviewee, you need to come prepared to your next HVAC job interview. Take a look at these key HVAC interview questions.

Ready to grow your business?

Get organized, eliminate waste and boost revenue with Smart Service.

- News and Events

- Worldwide Installations

- Company Brochure

Call Now +91 99157 43183

Write to us [email protected]

- Company Profile

- About Founder

- About Chairman

- Chairman’s Message

- Production Head

- Executive Director

- Vision & Mission

- CSR & Child Labour

- Our Presence

- Certifications & Memberships

- Awards & Achievements

- Testimonials

- Fabrication Shop

- Machine Shop

- Assembly Shop

- Packaging and despatch

- Oil Expeller / Oil Press – G 10

- Oil Expeller / Oil Press – G 20

- Oil Expeller / Oil Press – G VC-I

- Oil Expeller / Oil Press – G 60

- Oil Expeller / Oil Press – G MK-III

- Oil Expeller / Oil Press – G 150

- Oil Expeller / Oil Press – G MK-IV

- Oil Expeller / Oil Press – G MK-V-C

- Oil Expeller / Oil Press – G 240

- Oil Expeller / Oil Press – G 600

- Oil Expeller / Oil Press – G 1500

- Oil Expeller / Oil Press – G 2400

- Oil Expeller / Oil Press – Palm Kernel

- Seed Decorticator

- Seed Cleaner

- Hammer Mill

- Copra Cutter

- Seed / Nut Cracker

- Copra Dryer

- Filter Press with Pump

- Pressure Leaf Filter

- Polishing Filters

- Vibro Separator

- Boiler – Horizontal (IBR)

- Boiler – Vertical (Non IBR)

- Thermic Fluid Heater

- Water Softening Plant

- Solvent Extraction Plant

- Edible Oil Refinery Plant

- Fish, Poultry & Animal Feed Mill Plant

- EFB, MSW, Plastic & Industrial Shredder

- Material Handling Equipments

- Palm Kernel & other Oil Expeller / Oil Press Spare Parts

- Enquire Now

- News & Events

8 Steps To Start a Small Edible Oil Manufacturing Business

- Oil Extraction Machine / Oil Press

- Oil Mill Plants

- Solvent Extraction Plants

- Cooking Oil Refinery Plants

- Sunflower Oil : Everything we need to know

- Shea Butter: Origins, Production, Uses and Benefits

- Canola Oil Extraction Machines

- Coconut Oil Machine

- Palm Kernel Solvent Extraction Plant

- Oil Expeller – Goyum 10

- Oil Expeller – Goyum 20

- Oil Expeller – Goyum VC-I

- Oil Expeller – Goyum 60

- Oil Expeller – Goyum MK-III

- Oil Expeller – Goyum 150

- Oil Expeller – Goyum MK-IV

- Oil Expeller – Goyum MK-V-C

- Oil Expeller – Goyum 240

- Oil Expeller – Goyum 600

- Oil Expeller – Goyum 1500

- Oil Expeller – Goyum 2400

- Oil Expeller – Palm Kernel

- Decorticator

- Seed Cracker

- Filterpress with Pump

- Boiler – Vertical (Non IBR)

- Palm Kernel & Other Oil Expeller Spare Parts

Vegetable edible oil refers to oil obtained from oilseeds and nuts through an extraction process. Since their is an improvement in people’s living standards, the consumption of edible oils is also increasing day by day. Therefore, the extraction of vegetable oil is a profitable venture that in most cases rewards manufacturers with good profitable returns.

Vegetable oil is extracted from various oil seeds & nuts such as mustard / canola / rapeseed, copra / coconut, soya bean / soybean, peanut / groundnut, sunflower, cottonseed, sesame, neem, palm fruit & palm kernel, niger, sheanuts, flaxseed / linseed, etc through a mechanical pressing process. Non-edible oil is extracted from jatrpoha seed, castor seed, etc. People use cooking oils for various purposes including Cooking / Household, Animal feed, Furniture polish and conditioner, Leather preservative / Soap making, Hair moisturizer, etc. Nowadays, vegetable oil is also used as biodiesel fuel.

So if you want to start a small business or self-employment business, a cooking oil production business may be the best option to consider.

The following steps you need to set up an edible oil manufacturing business:

Step 1. learn more about the business.

Learn more about the business is the first step to start an oil mill company. Study the requirements of cooking oil manufacturing business in terms of technology, capital, market and competition. Please visit the website page https://www.oilexpeller.com/various-activity-of-oil-mill/ to gain more knowledge of the edible oil manufacturing industry.

Step 2. Craft your business plan

Either you should have an oil mill project report or adequate knowledge to start an edible oil production plant which includes the proposed land for oil production plant, sources of funds / capital, right oil mill machinery & equipment provider , return on investment (ROI), etc.

Before choosing a place for your edible oil processing plant, you have to consider the availability of raw materials, workforce, transport & road infrastructure, electricity availability, target market, etc. Oil Manufacturing plant location should be close to the target market and raw material sources which will reduce supply and transportation costs.

Having a good business plan is like to have a compass before going on an ocean trip. This gives you insights into everything you will need to establish and run a business successfully.

Step 3. Select your source of raw materials

You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts.

Step 4. Find a good plant location

The location of your business is another very important factor that can make your business more successful. It’s best to find the location which is close to your source of raw materials. For example, if you will be going into mustard oil production, you should locate your extraction plant nearby mustard oil plantation or suppliers. This will reduce transportation costs which will add to your profits.

Step 5. Get the funds

You will need money for buying land, machinery, plant construction, raw materials, working capital, etc. You will easily attract investors or get loans from banks or other lending institutions if you have a detailed oil mill project report which reflects that your business is profitable, sustainable and you have good knowledge about it.

Step 6. Choose suitable manufacturer and machines

We – GOYUM are leading manufacturer and exporter of cooking oil processing line and already have experience and expertise of more than 50 years in edible oil industry. We have exported to more than 63 Countries worldwide.

We provide a complete oil extraction plant on turnkey basis with excellent after sales support. Our advanced technology plants are reliable, robust, excellent in quality, reasonably priced, works continuously with efficiency.

Step 7. Hire employees

By using different hiring mediums, you can hire employees as per your requirements for your oil production plant.

You can also use your personal contacts to hire employees / workforce for effective running of your edible oil processing plant.

Step 8. Plan the packaging and distribution

The oil is collected in the filtered oil storage tank and then it is tested, if it’s found up to the mark and has passed all the parameters set by your country government, the oil is taken to the packing stage for packing and distribution.

When the oilseeds are pressed, we get oil & oilcake. Oil Cakes have some quantity of oil in them and they are used to make animal feeds which are normally packed in bags.

Goyum Screw Press is engaged in designing, manufacturing, exporting, installation & commissioning and after-sales support for edible & non-edible oil mill industry.

We offer oil mill machinery for various oilseeds & nuts such as oil expeller / screw oil press machines , seed cleaner, decorticator, flaker, cracker, extruder, meal cooler, hammer mill, copra dryer, palm nutcrackers, boiler, oil filtration equipment, elevator, conveyor, control panel and many more.

Need guidance to start a vegetable oil manufacturing business?

Please contact us so that our sales team will communicate with you to provide you professional guidance and quotation as per your requirements. They will also share some videos, pictures, layouts, etc. for you better understanding.

Related Posts

Enquiry Now

(Please fill the below form)

- Troubleshooting

The Guide to Selling Your Used Cooking Oil

If your business has a commercial kitchen, did you know you can contribute to the renewable fuel industry? It might sound a bit backward but used cooking oil and fryer grease can actually be transformed into a local eco-friendly fuel that serves as a viable alternative to petroleum diesel. With so many establishments across the country with kitchens, used cooking oil can be found virtually anywhere, and business owners are now learning about ways to put their used fryer oil up for sale.

Along the West Coast, SeQuential has a long history of collecting used cooking oil from commercial kitchens and refining it into our clean-burning renewable fuel. Here, we explain how businesses can tap into the earning potential that their otherwise discarded cooking oil might provide.

Your Used Cooking Oil’s Worth

Many businesses understand the importance of properly disposing of their used cooking oil. Failing to do so can have dire consequences on their bottom line from costly fines and repairs due to clogged plumbing, harmful backwash flooding into local ecosystems, and more. However, businesses are now realizing used cooking oil is not only recyclable but potentially profitable as well. The global used cooking oil market is growing at a rapid rate, with an Allied Market Research report projecting the market’s size to grow to a whopping $8.89 billion by 2026.

Because the market is showing no signs of slowing down, businesses with high amounts of used cooking oil are being sought out by companies like SeQuential. High quality used cooking oil provides an essential feedstock to produce renewable fuel, which causes less air pollution than standard diesel due to fewer particulates and pollutants escaping into the atmosphere and reduces the need for diesel made from fossil fuels.

How to Cash In

When companies choose to recycle their cooking oil with SeQuential, they can immediately benefit financially, as we offer used cooking oil collection services for free. And you won’t have to pay for your own storage container, either. We’ll also provide you with a complimentary container and lock to store your used cooking oil in, which we’ll empty into our trucks on a predetermined collection schedule that fits your establishment’s volume of oil.

By recycling used cooking oil, eligible companies may also be able to receive compensation for what is collected. At each stop, our trucks record the exact amount of oil each establishment recycles so we know how much each client has contributed. We offer our collection services in the majority of the West Coast’s metropolitan areas, including Seattle, Portland, Sacramento, San Francisco, and Los Angeles.

Even after your used cooking oil has been hauled away, your business still has other opportunities to take advantage of additional operational savings. For instance, scheduling regular grease trap cleaning services will ensure that fats, oils, and grease stay out of your wastewater system, which can reduce the cost of maintenance in the long run. SeQuential is also part of the Pacific Northwest’s Preferred Pumper Program , which means we work directly with local grease inspectors to ensure your compliance with all grease regulations and save you the headache of paying hefty fines.

Start Recycling with SeQuential

If your business is on the West Coast and has used fryer oil for sale, sign up for used cooking oil recycling services today. We’ll schedule a free consultation with one of our knowledgeable account managers, who will learn about your company’s unique used cooking oil output and help you form a collection schedule that won’t disrupt your day-to-day operations.

- Best Practices

- Grease Traps

- Health risks of FOG

- Recycle Home Cooking Oil

- Recycle Used Cooking Oil

- Renewable Fuel

- Restaurant Maintenance

- Restaurant Used Oil

- SeQuential Services

- Sustainability

- Used Cooking Oil

- Used Oil Collection

" * " indicates required fields

How to Start a Profitable Olive Oil Business [11 Steps]

By Nick Cotter Updated Feb 02, 2024

Business Steps:

1. perform market analysis., 2. draft a olive oil business plan., 3. develop a olive oil brand., 4. formalize your business registration., 5. acquire necessary licenses and permits for olive oil., 6. open a business bank account and secure funding as needed., 7. set pricing for olive oil services., 8. acquire olive oil equipment and supplies., 9. obtain business insurance for olive oil, if required., 10. begin marketing your olive oil services., 11. expand your olive oil business..

When starting an olive oil business, a thorough market analysis is crucial to understand the current landscape, customer preferences, and competitive environment. This step lays the groundwork for making informed decisions about product offerings, pricing, and marketing strategies. Here's how you can perform an effective market analysis:

- Research the size of the olive oil market, including current demand and projected growth to assess the potential for your business.

- Analyze trends in olive oil consumption, such as the rising popularity of healthy and organic products, to tailor your offerings.

- Identify your target market by demographics, such as age, income level, or geography, and understand their purchasing behaviors.

- Study your competitors, noting their product range, pricing, marketing tactics, and market share to find a competitive edge.

- Examine the supply chain, from olive growers to distributors, to ensure you can source quality olives and deliver a superior product.

- Consider regulatory factors, including food safety standards and labeling requirements, that could impact your business operations.

- Seek out potential partnerships with local businesses or international distributors to expand your market reach and distribution channels.

Are olive oil businesses profitable?

Olive oil businesses can be profitable depending on the scale of operations and other factors. Factors that can affect profitability include market conditions, pricing, quality of product and cost of production.

Embarking on an olive oil venture requires a well-structured business plan to navigate the market and ensure profitability. This crucial document will serve as your roadmap, detailing essential components such as your business model, market analysis, and financial projections. Here's a concise guide to drafting your olive oil business plan:

- Executive Summary: Summarize your business objectives, mission statement, and the unique selling proposition of your olive oil.

- Company Description: Provide an overview of your company, including structure, ownership, and the types of olive oil products you will offer.

- Market Analysis: Research and document your target market, industry trends, competitor analysis, and customer demographics.

- Organization and Management: Outline your business's organizational structure, detailing the roles and responsibilities of your management team.

- Products Line: Describe the varieties of olive oil you plan to produce and sell, emphasizing any unique features or production methods.

- Marketing and Sales Strategy: Develop a strategy for branding, marketing, sales channels, and customer engagement.

- Financial Projections: Present realistic financial forecasts including profit and loss projections, cash flow statements, and a break-even analysis.

- Funding Request: If you're seeking financing, specify the amount needed and how it will be used, along with any proposed repayment terms.

How does a olive oil business make money?

An olive oil business can make money by selling its products to both consumers and businesses. Consumers may purchase olive oil for everyday use, while businesses may purchase it in bulk quantities for incorporation into their own products. Further, an olive oil business can increase revenue by targeting niche markets, such as health-focused clients, or international markets. An example target audience for an air duct cleaning business would be residential homeowners looking to increase the air quality in their homes. These customers are likely to appreciate a business that promotes efficiency, safety, and affordability with its services.

Creating a distinctive olive oil brand is crucial for standing out in a competitive market. It conveys your unique story, quality, and values to consumers. Here's how you can develop a compelling olive oil brand:

- Identify your unique selling proposition (USP) that distinguishes your olive oil from competitors. This could be your sourcing, production process, or a specific flavor profile.

- Design an eye-catching logo and label that embodies the essence of your brand and appeals to your target audience. Consider hiring a professional designer to ensure high-quality visuals.

- Choose a brand name that is memorable, easy to pronounce, and reflects the characteristics of your olive oil. It should resonate with your target market and support your brand's image.

- Develop a compelling brand story that connects with customers on an emotional level. Share the origin, the tradition, and the passion behind your olive oil production.

- Create consistent branding materials, including packaging, business cards, and a website, to establish a professional image and make your brand easily recognizable.

- Ensure the quality of your product matches your brand's promise to build trust and loyalty among your customers.

How to come up with a name for your olive oil business?

Naming your olive oil business can be both exciting and daunting. The key is to choose something unique, memorable and representative of the quality of your product. Consider combining words that relate to olive oil with words or phrases that best capture your brand’s identity. Additionally, be sure to consider how it will read on labels and marketing materials. Develop a few ideas, do some research and narrow down your choices to the one that best fits your vision for the business. With careful thought and consideration, you’ll find the perfect name for your olive oil business.

Formalizing your business registration is a pivotal step in legitimizing your olive oil venture and ensuring compliance with local and federal regulations. This process lays the foundation for your business's legal structure, taxation, and credibility in the marketplace. Here are the essential steps to consider:

- Choose a business structure (e.g., sole proprietorship, partnership, LLC, corporation) that aligns with your needs for liability protection, tax preferences, and future expansion.

- Register your business name with the appropriate state authority, ensuring it's unique and not already in use. If you plan to operate under a trade name or "Doing Business As" (DBA), file for it accordingly.

- Obtain an Employer Identification Number (EIN) from the IRS for tax purposes, especially if you plan to hire employees or open a business bank account.

- Apply for any required local and state business licenses and permits. This may include a food processor license, a sales tax permit, or health department permits, depending on your location and the nature of your olive oil business.

- Understand and comply with labeling and safety regulations specific to food products, as governed by the FDA and other regulatory bodies.

- Consider the need for trademark protection for your brand and product names to secure your intellectual property rights.

Resources to help get you started:

Explore vital resources designed for olive oil entrepreneurs, featuring industry insights, operational strategies, and growth advice:

- International Olive Council (IOC): Offers comprehensive market reports, quality standards, and promotional strategies for olive oil. http://www.internationaloliveoil.org/

- Olive Oil Times: A leading source for the latest news, trends, and advice in the global olive oil industry. https://www.oliveoiltimes.com/

- North American Olive Oil Association (NAOOA): Provides resources on olive oil benefits, quality assurance, and market analysis for North American businesses. https://www.aboutoliveoil.org/

- Olive Oil Market: An online portal for olive oil news, analysis, and reports, focusing on market trends and industry insights. http://www.oliveoilmarket.eu/

- The Olive Oil Source: Offers information on olive oil production, marketing, and sales, along with a marketplace for equipment and services. https://www.oliveoilsource.com/

Starting an olive oil business requires careful consideration of the legal landscape to ensure compliance with local, state, and federal regulations. Acquiring the necessary licenses and permits is a crucial step in legitimizing your business and avoiding any legal issues. Below is a guide to help you navigate this process:

- Research local business licenses – Check with your city or county government to find out what business licenses you need to operate an olive oil business in your area.

- Food processor license – If you're involved in the production of olive oil, you may need a food processor license from your state's Department of Health or Agriculture.

- FDA registration – If you plan to sell olive oil across state lines, you need to register your facility with the U.S. Food and Drug Administration (FDA).

- Weighing and measuring permits – If you are selling olive oil by weight, you may need a permit from your state's department of weights and measures.

- Organic certification – If you're selling organic olive oil, you'll need to get certified by an accredited organic certifying agent.

- Alcohol and Tobacco Tax and Trade Bureau (TTB) permit – If you plan to infuse olive oils with flavors derived from wine or spirits, you may need a permit from the TTB.

What licenses and permits are needed to run a olive oil business?

To run an olive oil business, you will need various licenses and permits depending on your location. Generally, you will need to obtain a business license from your city or county’s clerk office, a seller’s permit from the Department of Revenue, and any other necessary licenses for food sales (such as a Food Service Establishment permit). You may also need to obtain permits for things like food handling, food labeling, labeling for different types of products (organic, etc.), and more.

Opening a business bank account is a critical step in establishing financial organization and credibility for your olive oil business. It separates your personal finances from your business transactions, simplifying accounting and tax reporting. If your business requires additional capital, securing funding will enable you to cover startup costs, inventory, and other expenses. Below are the key points to consider.

- Choose a bank that offers business banking services with favorable fees, easy access, and good customer support.

- Gather required documents such as your business registration, EIN (Employer Identification Number), and ownership agreements before applying for an account.

- Consider different types of funding options such as small business loans, investors, crowdfunding, or grants specifically for food and agricultural businesses.

- Prepare a detailed business plan to present to potential lenders or investors, showcasing market analysis, financial projections, and a clear path to profitability.

- Explore local and regional initiatives that may offer financial support to new businesses in the food industry.

- Keep your business plan flexible to adapt to lenders' feedback and be prepared to revise your funding strategy as needed.

Setting the right price for your olive oil services is critical for business success. It involves a balance between covering your costs, offering value to customers, and staying competitive in the market. Here are some tips to guide you through the pricing process:

- Analyze your costs: Calculate the total cost of production, including raw materials, labor, packaging, and overhead expenses.

- Understand your market: Research your competitors' pricing and position your product accordingly, whether as a premium or value offering.

- Consider your target audience: Determine the price sensitivity of your customers and set a price that reflects their expectations and willingness to pay.

- Factor in distribution costs: If you're selling through retailers or distributors, ensure your pricing allows for their margins as well.

- Adopt a pricing strategy: Whether it's cost-plus, value-based, or penetration pricing, choose a strategy that aligns with your business objectives.

- Be adaptable: Be ready to adjust your prices based on market feedback, fluctuations in costs, or changes in consumer demand.

- Communicate value: Ensure that your pricing reflects the quality and uniqueness of your olive oil, and effectively convey this to your customers.

What does it cost to start a olive oil business?

Initiating a olive oil business can involve substantial financial commitment, the scale of which is significantly influenced by factors such as geographical location, market dynamics, and operational expenses, among others. Nonetheless, our extensive research and hands-on experience have revealed an estimated starting cost of approximately $90000 for launching such an business. Please note, not all of these costs may be necessary to start up your olive oil business.

Starting an olive oil business requires careful selection of equipment and supplies to ensure quality production and efficiency. From harvesting tools to oil extraction and bottling machinery, each piece plays a crucial role in the process. Here's a guide to help you acquire the necessary equipment and supplies for your olive oil venture:

- Harvesting Tools: Obtain rakes, shakers, and nets for efficient olive collection.

- Olive Press: Choose between a traditional stone mill, a hydraulic press, or a modern centrifugal decanter, depending on your production scale and budget.

- Storage Tanks: Invest in stainless steel tanks for storing the oil post-extraction to prevent oxidation.

- Filtration Systems: Acquire filters to remove impurities and improve oil clarity and shelf life.

- Bottling Equipment: Get reliable filling machines, cappers, and labeling machines for a professional packaging process.

- Quality Control Tools: Purchase testing kits and equipment to monitor acidity levels and other quality parameters.

- Packaging Supplies: Stock up on bottles, caps, labels, and boxes for product presentation and shipping.

- Safety Gear: Ensure you have gloves, goggles, and aprons to protect workers during production.

List of software, tools and supplies needed to start a olive oil business:

- Computer Software: $0-300

- Accounting Software: $20-100/month

- Word Processing Software: $0-100

- Olive Oil Labeling and Packaging Materials: $50-200

- Shipping Supplies (Boxes, Tape, etc.): $50-150

- Web Hosting and Domain Name: $15-30/month

- Legal Services: $500-1000

- Marketing Materials (Flyers, Ads, etc.): $50-500

- Business Cards and Stationery: $30-100

- Printing Services for Labels: $200-500

Starting an olive oil business involves various risks, from potential liability issues to property damage. Obtaining the right business insurance is a crucial step to protect your investment and ensure the smooth operation of your enterprise. Below is a guide to help you understand and acquire the necessary insurance for your olive oil business:

- General Liability Insurance: This is fundamental for any business. It covers legal fees, settlements, and medical costs if your company is sued for property damage or personal injury caused by your products or operations.

- Product Liability Insurance: As an olive oil producer or distributor, you need this insurance to protect against claims of bodily harm or property damage caused by your olive oil.

- Property Insurance: Whether you own or lease your facility, property insurance will protect your equipment, inventory, and buildings from fire, theft, or other damages.

- Business Interruption Insurance: This helps you cover lost income and expenses if your business is temporarily unable to operate due to a covered event.

- Commercial Auto Insurance: If you have vehicles for delivery or transportation of goods, this insurance is necessary to cover the associated risks on the road.

- Workers' Compensation Insurance: Required in most states if you have employees, it covers medical costs and lost wages for work-related injuries or illnesses.

Embarking on the marketing journey for your olive oil business is an exhilarating step that ensures your products reach the right audience. A strategic marketing plan can increase brand awareness, attract customers, and ultimately boost your sales. Consider the following tactics to effectively market your olive oil services:

- Website and SEO: Launch a professional website showcasing your products, and optimize it for search engines to increase visibility.

- Social Media: Create engaging content on platforms like Instagram, Facebook, and Twitter to connect with food enthusiasts and potential customers.

- Sampling Events: Host tasting events at local markets, food festivals, or in-store to let potential customers experience the quality of your olive oil firsthand.

- Partnerships: Collaborate with local chefs, restaurants, and gourmet food stores to feature your olive oil in their offerings.

- Content Marketing: Share recipes, cooking tips, and the health benefits of olive oil through a blog or newsletters to educate and engage your audience.

- Advertising: Invest in online ads, such as Google AdWords or Facebook ads, targeting those who have shown interest in gourmet cooking or healthy living.

- Public Relations: Get featured in local media, food blogs, or culinary magazines to gain credibility and attract attention to your brand.

Once your olive oil business has found its footing, expanding your reach and market share is the next step to success. Whether you're thinking about introducing new products, entering new markets, or optimizing your production process, careful planning and strategy are key. Here are some tips to help guide your expansion:

- Explore new markets by researching demand in different regions or countries, considering both online and brick-and-mortar opportunities.

- Develop new products or varieties of olive oil, such as organic, infused, or premium blends, to attract a wider customer base.

- Invest in marketing and branding efforts to build a stronger presence and recognition for your olive oil.

- Enhance your online presence with an improved e-commerce platform, SEO strategies, and social media engagement to reach a global audience.

- Form strategic partnerships with local chefs, restaurants, and food influencers to promote your olive oil through their networks.

- Streamline your supply chain and production processes to increase efficiency and reduce costs as you scale up.

- Consider attending trade shows and food expos to network with industry professionals and showcase your products.

- Regularly review customer feedback and market trends to adapt your business strategy and product offerings accordingly.

How to Start a Wholesale Cooking Oil Business

Cooking oil stands out as an important wholesale restaurant supply in any restaurant business , bakery business , and foodservice business in the food and beverage industry . The demand for cooking oil is very high, as a result investing in the wholesale cooking oil business is a great opportunity for success.

Key Takeaway: Starting a cooking oil wholesale business requires you to understand the basics and complexities as it isn’t a stroll in the park. If you are on this page, you are in for a ride because the rudiments and intricate elements that will guide you to a successful cooking oil business will be unraveled.

Wholesale cooking oil business goes beyond the profit, it is a fusion of passion, driven by eCommerce business skills, branding, and proper management. So, read on to get enlightened on how you can get your wholesale cooking oil business started.

7 Cooking Oil Business Ideas

If you have the dream of starting a wholesale cooking oil business, it is important that you are focused. The cooking oil industry is vast, as a result, you need to be strategic in your approach when starting your business.

There are several cooking oil business ideas you can venture into, depending on your preferences and available resources. To help you in your cooking oil wholesale distribution business niche selection, top seven cooking oil business ideas are discussed below.

- Specialty Cooking Oil Store

Special oils from rare sources are high demand products and are always needed for luxury cuisines. So, you can open a store that specializes in selling premium cooking oils.

Such oils include nut oils, cold-pressed olive oils, carrot oils and more. All you need to do is to keep educating your customers about the health and nutritional value of adopting the oils in your digital catalog for their respective cooking endeavors.

- Health and Organic-focused Oils

As a wholesale business owner , you can opt to focus more on health-conscious consumers and businesses. The fact here is that customers in this bracket are growing on a daily basis, so you can be sure to have a booming wholesale cooking oil business.

Health-focused oils include avocado oils, grapeseed oils and coconut oil. They are known for having rare nutritional benefits.

- Farm-to-Table Cooking oils

Selling farm-to-table cooking oils gives you an edge over everyone else. The reason being that, most consumers will drift more towards cooking oil products with a known raw material source.

All you need to do is to gain true access to local farmers that can make raw materials available to you, that is if you can’t farm your raw materials yourself.

- Online Cooking Oil Subscription

You can explore the potential of selling a cooking oil subscription box that allows weekly, biweekly and monthly oil deliveries. This will help you make recurring revenue and grow your customer base.

The beauty of the subscription box is that it is boundless. You stand the chance of getting orders far away from your locale.

- Ethnic Cuisine Cooking Oils

Choosing to make cooking oils for specialized meals is always lucrative. Here, you can sell oils that are used to make continental recipes.

You’ll have to make your oils to have flavors that appeal to these regions. Mixing wholesale spices and organic herbs during the cooking oil production process is a great idea to create exotic or ethnic flavors.

- Private Label and Repackaging

If you don’t have the time or resources to set up your own cooking oil manufacturing plant, you can resell and repackage cooking oil as a private label brand. To make the process easy, try partnering with established wholesale oil manufacturing companies and wholesale food distributors .

Ensure that your repackaging material is eco-friendly. You can even offer customized packages to your customers. This can serve as souvenirs and gift items.

- B2B Bulk Supply

Supplying cooking oils to catering businesses, restaurants and food manufacturers in bulk is another great cooking oil business idea. You have to ensure that you maintain consistent high cooking oil quality, competitive wholesale prices , and prompt delivery.

How to Start Cooking Oil Business

Launching a wholesale cooking oil business requires adequate planning to be successful. A prompt and professional execution of your plans is a great way to put your wholesale business out there.

To make it easier, here are the steps you need to follow for you to successfully start your wholesale cooking oil business anywhere in the world.

- Market Research and Product Selection

Knowing your target market is the first step in any business endeavor. Your research about customer preferences, needs and their respective consumer behaviors in the cooking oil industry will help you create your unique selling proposition and stand out from the competition.

With the information about consumer behavior at your disposal, you are already equipped with viable information that will scale your business as soon as possible. One of the main decisions you make after market research is deciding the kind of cooking oil you’d sell.

Your decision may depend on the choice of the oil that is in demand at the time of launch. This may be current health trends, your consumers’ location, or the purchasing behavior of your prospective customers .

One thing you might want to try out is selling a blend of regular cooking oils and specialty oils. This may be the option that will blow up your brand.

- Business Plan and Registration

Outlining your business goals, preferred target market and other key elements determines your brand’s success. Your business plan is a practical and workable roadmap that helps you channel your efforts.

In this document you have to write your wholesale marketing plan as well as your wholesale food pricing strategy. Also, do well to factor in your financial projections and expansion plans. It is important you have this written down because you will find it handy when your business begins to attract other investors.

Additionally, you need to have the necessary wholesale licenses that allow you to run your wholesale cooking oil business. Such licenses and food safety certificates are always location specific. Always ensure that you stick to all the licensing guidelines in order to forestall any occurrence of sanctioning that may hamper your business.

- Sourcing Suppliers and Quality Assurance

You need to get a dependable wholesale cooking oil supplier for your selected type of cooking oil. Search and reach sustainable agreements with suppliers of quality cooking oils.

When selecting your supplier, make sure you carry out all necessary and important quality checks. This shouldn’t stop at the beginning of your business, you should check for quality at every instance the supplier is making any supply to your depot. Maintaining a top quality cooking oil stock will keep your business growing.

Vendor negotiation is important. Talk about pricing, delivery timelines, online ordering schedules, minimum order quantities ( MOQ ), and the types of cooking oil you want at the initial stage.

You can then proceed to sign wholesale purchase agreements and contracts. It is important to implement vendor management best practices to maintain vendor relationships. You can also implement vendor management system to track vendors, vendor billing , invoice processing , and vendor payments .

- Branding and Wholesale Food Packaging

Having a strong brand identity will go a long way to influence your B2B vs B2C sales . Develop a branding strategy that speaks well to your target market. You can use the customer data from your market research to create a strategy that will suit your brand and target audience.

A catchy and compelling packaging design conveys the depth of quality and uniqueness of your cooking oil brand. It is a must that you get your packaging designs right.

- Marketing and B2B Sales Management

The next thing after packaging is marketing your brand to other businesses that will need your supply. There are several wholesale marketing strategies you can use to promote your wholesale cooking oil business

One effective strategy is digital marketing. It will give you a wider reach at a relatively low cost because your digital footprint will be everywhere it needs to be.

In the quest to market your business, do well to engage your customers. Listen to their feedback, attend to their questions and always create a positive customer experience . If you put in more energy and resources into marketing, then your eCommerce sales will definitely grow over time.

After all of these, you have to make a choice of your food distribution channels . Distribution channels will definitely vary depending on the location of the customer, and quantity being purchased. Just ensure that you don’t take options that will stress your customer.

Having done all these, make sure you keep records of all your financial engagements. Set up a reliable eCommerce accounting management system that can help you calculate your expenditures, taxes, salaries and profits. Monitor your accounts to ensure the sustainability of your brand.

Cost of Starting a Wholesale Cooking Oil Business

Now that you know how to start your wholesale cooking oil business, let’s look at the possible cost of setting the business up.

- Business Registration

Licensing and registration - $700 - $2500, legal fees - $800 - $1700

- Product Sourcing

$5000 - $25000

- Branding and Packaging

Label and eCommerce packaging design - $500 -$1200, printing labels and wholesale food packaging - $900 - $3000

- eCommerce website design and Development

$1500 - $6000

- eCommerce marketing and Advertising

Social commerce marketing - $2000 - $4000, influencer marketing - $2500 (Per Influencer)

- Wholesale Distribution Channel

Brick-and-mortar store - $3000 - $5000, online shipping will be determined by the distance and oil volume

- Operational cost

Utilities, packaging materials, office supplies, wholesale software tools - $1500 - $3500

- Emergency funds

$2000 - $3000

Note that all the figures written above are extrapolations and it may vary with respect to location and type of cooking oil you’ve selected to sell.

Frequently Asked Questions About How to Start Wholesale Cooking Oil Business

Setting up a cooking oil wholesale business comes with some headaches. It is important you clear your confusion. Here are some frequently asked questions about how to start a wholesale cooking oil business.

Is Vegetable Oil Business Profitable?

Yes, the vegetable oil business is profitable. Though the profitability depends on some factors like location, type of oil that you sell. The profit range in cooking oil business can be between 17% - 38%

Which Oil Business is Best?

Deciding the best oil business may be difficult as it depends on how you can manage your oil business. That notwithstanding, Castor oil, palm kernel oil, olive oil among others have been said to be among the best oils you can choose to deal with.

What are the 3 Best Oils For Cooking?

The three best oils for cooking are:

- Groundnut oil

An official website of the United States government

Here’s how you know

Official websites use .gov A .gov website belongs to an official government organization in the United States.

Secure .gov websites use HTTPS A lock ( Lock A locked padlock ) or https:// means you’ve safely connected to the .gov website. Share sensitive information only on official, secure websites.

JavaScript appears to be disabled on this computer. Please click here to see any active alerts .

Managing Used Oil: Answers to Frequent Questions for Businesses

- Guidance and Summary of Information Regarding the RCRA Used Oil Rebuttable Presumption

- e-CFR: 40 CFR Part 279 Requirements - Used Oil Management Standards

- Table Summarizing the Part 279 Used Oil Management Standards (pdf) (82 KB)

- “What is Used Oil?” Reference Table

- Compliance Assistance Center for Auto Repair

- Environmental Compliance for Auto Recyclers

A wide variety of businesses such as service stations, fleet maintenance facilities, and "quick lube" shops generate and handle used oil. EPA's used oil management standards--a set of "good housekeeping" requirements for used oil handlers—are detailed in Title 40 of the Code of Federal Regulations (CFR) part 279 . This Web page highlights essential information that businesses can use to manage their used oil while protecting human health and the environment.

Your state regulations governing the management of used oil might be stricter than EPA's. Contact your state or local environmental agency to determine your best course of action.

On this page:

General Questions

Regulatory questions, what is used oil, how is used oil recycled, what businesses handle used oil, how should my business manage used oil filters, how can my service station avoid costly cleanups, what are the recommended clean-up practices for used-oil handlers who have a spill on-site, what can my business do to conserve oil, does my business have to accept used oil from others.

EPA defines used oil as any oil that has been refined from crude oil or any synthetic oil that has been used and as a result of such use is contaminated by physical or chemical impurities. Simply put, used oil is exactly what its name implies—any petroleum-based or synthetic oil that has been used. During normal use, impurities such as dirt, metal scrapings, water, or chemicals can get mixed in with the oil, so that in time the oil no longer performs well. Eventually, this used oil must be replaced with virgin or re-refined oil to do the job at hand. EPA's used oil management standards include a three-pronged approach to determine if a substance meets the definition of used oil. To meet EPA's definition of used oil, a substance must meet each of the following three criteria:

- Origin - Used oil must have been refined from crude oil or made from synthetic materials.

- Use - Oils that are used as lubricants, hydraulic fluids, heat transfer fluids, buoyants, and for other similar purposes are considered used oil. Unused oils such as bottom clean-out waste from virgin fuel oil storage tanks or virgin fuel oil recovered from a spill, do not meet EPA's definition of used oil because these oils have never been "used." EPA's definition also excludes products used as cleaning agents or used solely for their solvent properties, as well as certain petroleum-derived products like antifreeze and kerosene.

- Contaminants - In other words, to meet EPA's definition, used oil must become contaminated as a result of being used. This aspect of EPA's definition includes residues and contaminants generated from handling, storing, and processing used oil. Physical contaminants could include metal shavings, sawdust, or dirt. Chemical contaminants could include solvents, halogens, or saltwater.

For more information on specific oils that can fall under RCRA’s definition of used oil, view our “What is Used Oil?” reference table .

Once oil has been used, it can be collected, recycled, and used over and over again. An estimated 380 million gallons of used oil are recycled each year. Recycled used oil can sometimes be used again for the same job or can take on a completely different task. For example, used motor oil can be re-refined and sold at the store as motor oil or processed for furnace fuel oil. Aluminum rolling oils also can be filtered on site and used over again.

Recycling Used Oil Is Good for the Environment and the Economy!

- Re-refining used oil takes only about one-third the energy of refining crude oil to lubricant quality.

- It takes 42 gallons of crude oil, but only one gallon of used oil, to produce 2 ½ quarts of new, high-quality lubricating oil.

- One gallon of used oil processed for fuel contains about 140,000 British Thermal Units (Btus) of energy.

Used oil can be:

- Reconditioned on site—Impurities are removed from the used oil, which is then reused. While this form of recycling might not restore the oil to its original condition, it does prolong its life.

- Inserted into a petroleum refinery—Used Oil is introduced as a feedstock into refinery production processes.

- Re-refined, which involves treating used oil to remove impurities so that it can be used as a base stock for new lubricating oil. Re-refining prolongs the life of the oil resource indefinitely. This form of recycling is the preferred option because it closes the recycling loop by reusing the oil to make the same product that it was when it started out, and therefore uses less energy and less virgin oil.

- Processed and burned for energy recovery, which involves removing water and particulates so that used oil can be burned as fuel to generate heat or to power industrial operations. This form of recycling is not as preferable as methods that reuse the material because it only enables the oil to be reused once. Nonetheless, valuable energy is provided (about the same as provided by normal heating oil).

Many types of businesses that handle used oil, including:

- Generators are businesses that handle used oil through commercial or industrial operations or from the maintenance of vehicles and equipment. Generators are the largest segment of the used oil industry. Examples of common generators are car repair shops, service stations, quick lube shops, government motor pools, grocery stores, metal working industries, and boat marinas. Farmers who produce less than an average of 25 gallons of used oil per month are excluded from generator status. Individuals who generate used oil through the maintenance of their personal vehicles and equipment are not subject to regulation under the used oil management standards.

- Collection centers and aggregation points are facilities that accept small amounts of used oil and store it until enough is collected to ship it elsewhere for recycling. Collection centers typically accept used oil from multiple sources that include both businesses and individuals. Aggregation points collect oil only from places run by the same owner or operator and from individuals.

- Transporters are companies that pick up used oil from all sources and deliver it to re-refiners, processors, or burners. Transfer facilities include any structure or area where used oil is held for longer than 24 hours, but not longer than 35 days. Examples of transfer facilities are loading docks and parking areas.

- Re-refiners and processors are facilities that blend or remove impurities from used oil so that it can be burned for energy recovery or reused. Included in this category are re-refiners who process used oil so that it can be reused in a new product such as a lubricant and recycled again and again. EPA's management standards primarily focus on this group of used oil handlers.

- Burners burn used oil for energy recovery in boilers, industrial furnaces, or in hazardous waste incinerators.

- Marketers are handlers who either (a) direct shipments of used oil to be burned as fuel in regulated devices or, (b) claim that certain EPA specifications are met for used oil to be burned for energy recovery in devices that are not regulated. They also sometimes help move shipments of used oil to burners. By definition, marketers must also fall into at least one of the above categories.

Generally, a common practice is to puncture the filters, drain the used oil into an appropriate container and then recycle the filters as scrap metal. The drained used oil should be recycled along with the used oil from the oil changes. Chapter 7 of Environmental Regulations and Technology: Managing Used Motor Oil (PDF) (84 pp, 6.09 MB, About PDF ) provides a summary of the federal regulations and recommendations for used oil filters.

As with all federal regulations, states may have more stringent regulations than the federal government for the management and disposal of used oil filters so it’s important for you to contact your state’s environmental agency to determine whether they have additional requirements or recommendations regarding filters. EPA maintains a list of state environmental agency websites so you can locate yours.

When service station dealers meet the following conditions, they are relieved from responsibility for costly cleanups and liabilities associated with off-site handling of used oil. To meet these conditions, service stations must:

- Comply with the management standards described above;

- Do not mix used oil with any hazardous substance; and

- Accept used oil from Do-it-yourselfers (DIYs) and send it for recycling.

EPA recommends, but does not require, the following cleanup practices for used oil handlers:

- maximize the recovery of used oil;

- minimize the generation of used oil sorbent waste by choosing reusable sorbent materials;

- use the spent sorbent materials to produce recycled sorbent materials; and

- buy sorbent materials with recycled content.

Extraction devices (e.g., centrifuges, wringers, and compactors) can be used to recover used oil from reusable sorbent materials. Sorbent pads can be reused between two and eight times depending on the viscosity of the used oil. These technologies, while not required, can be used to reduce the number of sorbent pads ultimately sent for remanufacture, energy recovery, or disposal. The potential to reduce waste and save money (i.e., lower disposal costs for spent pads and lower per use cost of sorbent pads) by reusing and recycling sorbent pads can be substantial.

Managing Cleanup Materials

If you have used oil on rags or other sorbent materials from cleaning up a leak or spill, you should remove as much of the free-flowing oil as possible and manage the oil as you would have before it spilled. Once the free-flowing used oil has been removed from these materials, they are not considered used oil and may be managed as solid waste as long as they do not exhibit a hazardous waste characteristic. Note, however, that materials from which used oil has been removed continue to be regulated as used oil if they are to be burned for energy recovery (regardless of the degree of removal).

- Minimize the amount of used oil you produce. The less used oil that is produced in the first place, the less that ultimately has to be handled. Businesses can filter, separate, and recondition used oil to prolong its usable life.

- Purchase re-refined used oil products instead of virgin oil products. Re-refined oil works just as well as virgin oil. Products that display the American Petroleum Institute (API) "starburst" meet the same high-quality specifications as virgin oil.

- Practice safe management of used oil. Don't mix used oil with anything. Always store used oil in leak-proof containers that are in secure areas safely away from workers and the environment. Send used oil to a re-refiner whenever possible.

While there are companies that sell motor oil and also accept used oil for recycling, there is no federal requirement that motor oil vendors must also accept used oil for recycling. Your state might have more stringent regulations than federal EPA so be sure to reach out to them to find out. Check out our Links to Hazardous Waste Programs and U.S. State Environmental Agencies web page for their contact information.

What Regulations Should My Business Follow?