Abattoir Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Agriculture Industry » Agro Processing & Allied Industry » Meat Shop and Abattoir

Do you want to start an abattoir and need to write a plan? If YES, here is a sample abattoir business plan template & FREE feasibility report. It can be truly challenging starting any business , but one business that you can start with little challenges and wide market coverage is an abattoir.

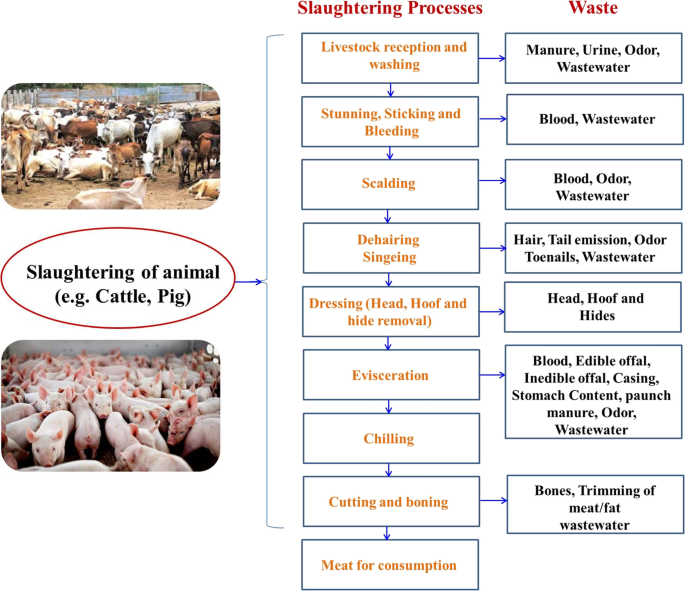

An abattoir is a business that slaughters animals to produce meat. Abattoirs also produce fresh or frozen meat as carcasses and cuts, in addition to by-products like rendered lard, tallow and pulled wool and they also bone, preserve and pack meat.

Starting an abattoir comes with its own fair share of challenges, but that does not rule out the fact that it is indeed a profitable business. An aspiring entrepreneur can either choose to start an abattoir business on a small scale or on a large scale depending on their financial status.

So, if you have decided to start your own abattoir, then you should ensure that you carry out thorough feasibility studies, market survey and secure the needed public health and hygiene certificates and permits. Below is a sample abattoir business plan template that can help you to successfully write your own with little or no difficulty.

A Sample Abattoir Business Plan Template

1. industry overview.

Abattoir business falls under the Meat, Beef & Poultry Processing industry and players in this industry basically slaughter poultry birds and animals, process the meat and package them into products and by-products. The industry is also known to be involved in purifying and refining animal fat, bones and meat scraps.

Products are sold to other food manufacturers , renderers, grocers, meat wholesalers and retail traders. It is important to state businesses that primarily cut and pack meats from purchased carcasses are also part of this industry.

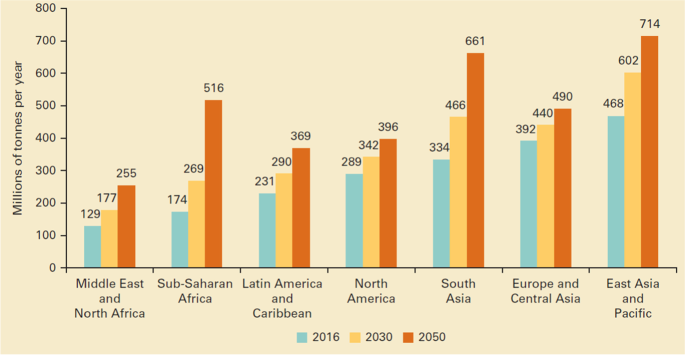

Even though meat consumption based on per capita income is expected to remain stagnant in the next half a decade, economic woes before this period aggravated consumption drops. Because of recovering consumer sentiment, population growth and strong export demand, meat-processing revenue is projected to increase going forward.

In spite of the stability of consumer demand for meat-based products, unpredictable weather conditions and disease outbreaks can cause instability in the revenue generated by industry players.

The Meat, Beef & Poultry Processing Industry is indeed a very large industry and pretty much thriving in all parts of the world. Statistics have it that in the united states of America alone, there are about 5,664 licensed and registered Meat, Beef & Poultry Processing companies directly responsible for employing about 480,178 employees.

The industry rakes in a whooping sum of $225 billion annually with an annual growth rate projected at 1.4 percent. It is important to state that the establishments with lion shares of the available market in this industry are Cargill Inc., JBS SA, Inc., Tyson Foods and Smithfield Foods.

Several researches conducted linked red meat consumption with increased risks of several diseases, hence the need for nutritional awareness among consumers. As a result of this, consumers have started choosing white meat (chicken) instead of beef and pork.

Nonetheless, the prices of these products have risen faster than those of poultry products, leading this segment’s share of revenue to also increase.

Statistics also have it that an estimate of about 35 companies are involved in the business of raising, processing and marketing chicken on a commercial level. It is on record that Americans consume more chicken than anyone else in the world – more than 90 pounds per capita in 2015.

So also, in 2015, almost 9 billion broiler chickens, weighing 53 billion pounds, live – weight, were produced. More than 40 billion pounds of chicken product was marketed, measured on a ready-to-cook basis.

The abattoir or slaughterhouse business will continue to blossom because people will always want to purchase fresh meat. Despite the fact that the industry seems over – saturated, there is still room big enough to accommodate aspiring entrepreneurs who intend opening their own abattoir in any part of the United States of America.

Some of the factors that encourage entrepreneurs to start their own abattoir business despite the required licensing and permits could be that the business is a thriving business. Lastly, if you are looking towards leveraging on the beef, meat and poultry processing industry to generate huge income, then one of your best bet is to start an abattoir.

One thing is certain about starting this business, if you are able to conduct your market research and feasibility studies , you are more likely not going to struggle to sell your products because there are loads of distributors and consumers out there who are ready to buy from you.

2. Executive Summary

East – Coast Abattoir®, LLC is a registered slaughterhouse that will be involved in the slaughtering and retailing of fresh meat. Our slaughterhouse facility will be located close to one of the largest farming community in Trenton – New Jersey.

We have been able to lease a storage facility that is big enough for the kind of abattoir that we intend launching and the facility is centrally located in the heart of town. East – Coast Abattoir®, LLC will be involved in slaughtering animals, producing cuts of beef, lamb and mutton, pork, other red meats and selling by-products from the slaughtering process to a wide range of customers.

We are aware that there are several abattoirs and even well – established farm markets and meat processing companies all around Trenton – New Jersey that are also into meat and beef retailing, which is why we spent time and resources to conduct our feasibility studies and market survey so as to offer much more than our competitors will be offering.

We have robust collection and distribution network, strong online presence and modern storage facilities and we are armed with the various payments options available in the United States. Beyond selling slaughtered animals, our customer care is going to be second to none in the whole of Trenton – New Jersey and our deliveries will be timely and highly reliable.

We know that our customers are the reason why we are in business which is why we will go the extra mile to get them satisfied when they patronize our products. East – Coast Abattoir®, LLC will ensure that all our customers are given first class treatment whenever they visit our abattoir.

We have a CRM software that will enable us manage a one on one relationship with our customers no matter how large they may grow to. We will ensure that we get our customers involved in the selection of the types of animal to be slaughtered and also when making some business decisions that directly affects them.

East-Coast Abattoir®, LLC will at all times demonstrate her commitment to sustainability, both individually and as a firm, by actively participating in our communities and integrating sustainable business practices wherever possible. We will ensure that we hold ourselves accountable to the highest standards by meeting our client’s needs precisely and completely.

East-Coast Abattoir®, LLC is a family business that is owned by Silas Joshua and his immediate family members. Silas Joshua has a B.Sc. in Animal Science, with over 8 years of hands on experience in the agribusiness industry, working for some of the leading brands in the United States.

Although the business is launching out by focusing on Trenton – New Jersey, but there is a plan to expand our distribution network all across the state of New Jersey.

3. Our Products and Services

We are in the agribusiness industry to make profits and we will ensure that we do all that is permitted by the law in the United States to achieve our business aim and objectives. Our products and services offerings are listed below;

- Slaughtering animals

- Producing cuts of beef

- Producing cuts of lamb and mutton

- Producing cuts of pork

- Producing cuts of other red meats

- Selling by-products from the slaughtering process

4. Our Mission and Vision Statement

Our vision is to become one of the leading brands in the abattoir line of business in the whole of Trenton – New Jersey. Our mission is to establish an abattoir business that will slaughter and sell a wide range of animals at affordable prices to wholesalers and retailers in Trenton and other cities in New Jersey where we intend marketing our produce.

Our Business Structure

East-Coast Abattoir®, LLC do not intend to start a slaughterhouse business like the usual mom and pop business around the street corner; our intention of starting our business is to build a standard slaughterhouse in Trenton – New Jersey.

We will ensure that we put the right structures in place that will support the kind of growth that we have in mind while setting up the business.

We will make sure that we hire people that are qualified, honest, customer centric and are ready to work to help us build a prosperous business that will benefit all our stakeholders. As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of ten years or more.

In view of that, we have decided to hire qualified and competent hands to occupy the following positions that will be made available at East – Coast Abattoir®, LLC;

- Manager (Owner)

- Warehouse / Storage Facility Manager

- Merchandize Manager

Sales and Marketing Manager

- Abattoir Workers

- Drivers/Distributors

5. Job Roles and Responsibilities

Manager / Owner:

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions.

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Creates, communicates, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Defines job positions for recruitment and managing interviewing process

Warehouse cum Storage Facility Manager:

- Responsible for organizing the safe and efficient receipt, storage and dispatch of slaughtered animals and byproducts

- Responsible for liaising with customers, suppliers and transport companies

- Responsible for using space and mechanical handling equipment efficiently and making sure quality, budgetary targets and environmental objectives are met

- In charge of coordinating the use of automated and computerized systems where necessary

- Ensures that proper records of goods are kept and warehouse does not run out of products

- Ensures that the slaughterhouse facility is in tip top shape and goods are properly arranged and easy to locate

- Controls meat, beef and poultry meat distribution and supply inventory

- Supervises the workforce in the abattoir floor.

Merchandise Manager

- Manages vendor relations, farm cum market visits, and the ongoing education and development of the organizations’ buying teams

- Responsible for the purchase of cows, goats, pigs, turkeys and chickens et al directly from farmers for the organizations

- Responsible for planning sales, monitoring inventory, selecting the merchandise, and writing and pricing orders to vendors

- Ensures that the organization operates within stipulated budget.

- Responsible for slaughtering animals, producing cuts of beef, producing cuts of lamb and mutton, producing cuts of pork, producing cuts of other red meats and selling by-products from the slaughtering process.

- Responsible for cleaning the abattoir before and after slaughtering of animals

- Handles any other duty as assigned by the manager (owner)

- Manages external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Models demographic information and analyze the volumes of transactional data generated by customer purchases

- Identifies, prioritizes, and reaches out to new partners, and business opportunities et al

- Identifies development opportunities; follows up on development leads and contacts; participates in the structuring and financing of projects; assures the completion of development projects.

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develops, executes and evaluates new plans for increasing sales

- Represents the company in strategic meetings

- Helps to increase sales and growth for the company

Accountant/Cashier:

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyzes financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization

Distribution Truck Drivers

- Assists in loading and unloading live and slaughtered animals

- Maintains a logbook of their driving activities to ensure compliance with federal regulations governing the rest and work periods for operators.

- Keeps a record of vehicle inspections and make sure the truck is equipped with safety equipment

- Assists the transport and logistics manager in planning their route according to a distribution schedule.

- Local-delivery drivers may be required to sell meat, beef and poultry et al to stores on their route, obtain signatures from recipients and collect cash.

- Inspect vehicles for mechanical and safety issues and perform preventative maintenance

- Complies with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures

- Collects and verifies delivery instructions

- Reports defects, accidents or violations

6. SWOT Analysis

Our intention of starting our abattoir in Trenton and work with cattle farmers only within Trenton – New Jersey is to test run the business for a period of 2 to 5 years to know if we will invest more money, expand the business and then open our abattoir in major cities throughout the United States of America.

We are quite aware that there are several slaughterhouses all over Trenton and even in the same location where we intend locating ours, which is why we are following the due process of establishing a business. We know that if a proper SWOT analysis is conducted for our business, we will be able to position our business to maximize our strength, leverage on the opportunities that will be available to us, mitigate our risks and be equipped to confront our threats.

East – Coast Abattoir®, LLC employed the services of an expert Business Analyst with bias in the meat, beef, and poultry processing industry to help us conduct a thorough SWOT analysis and to help us create a Business model that will help us achieve our business goals and objectives. This is the summary of the SWOT analysis that was conducted for East – Coast Abattoir®, LLC;

Our location, the business model we will be operating on, varieties of payment options, healthy environment and our excellent customer service culture will definitely count as a strong strength for East – Coast Abattoir®, LLC. So, also our management team members have what it takes to grow a business from startup to profitability with record time.

A major weakness that may count against us is the fact that we are a new abattoir business and we don’t have the financial capacity to compete with leaders in the industry for now.

- Opportunities:

The fact that we are going to be operating our abattoir business in Trenton – New Jersey which happens to be among the top 5 food producing states in the US provides us with unlimited opportunities to sell our fresh meats to a large number of wholesale distributors and retailers.

We have been able to conduct thorough feasibility studies and market survey and we know what our potential clients will be looking for when they visit our abattoir. We are also aware that free-trade agreements and interest in biofuels benefit industry performance, and continued vertical integration of the farm process will open more opportunities for us.

Some of the threats and challenges that we are likely going to face when we start our own slaughterhouse business are global economic downturn that can impact negatively on household spending, bad weather cum natural disasters, unfavorable government policies and the arrival of a competitor (a new abattoir or even a well-organized farm market) within same location where we have our abattoir.

There is hardly anything you can do as regards these threats and challenges other than to be optimistic that things will continue to work for your good.

7. MARKET ANALYSIS

- Market Trends

In recent time, consumers are becoming conscious or what they eat especially as it relates to meat. Those advocating for healthy eating are against the consumption of meat especially red meat, and it takes extra effort for those in the abattoir business to canvass to such people to patronize them.

The truth is that slaughtering animals for food has been in existence for as long as humans started trading goods, but one thing is certain, the meat, beef and poultry processing industry is still evolving. The introduction of technology has indeed helped in reshaping the industry.

Lastly, it is now a common phenomenon for abattoirs to leverage on technology to effectively predict consumer demand patterns and to strategically position their business to meet their needs; in essence, the use of technology helps slaughterhouses to maximize supply chain efficiencies.

8. Our Target Market

The meat, beef and poultry processing industry has a wide range of customers; a large chunk of people on planet earth consume different types of meat or poultry products and it is difficult to find people around who don’t.

In view of that, we have positioned our abattoir business to service consumers in and around Trenton – New Jersey and every other location we will cover all over the state of New Jersey. We have conducted our market research and we have ideas of what our target market would be expecting from us.

We are in business to engage in the slaughtering and selling of freshly butchered meats to the following businesses;

- Restaurants

- Retailers of meat

- Grocery stores

- Supermarkets

- Wholesale Distributors of meats

Our Competitive Advantage

A close study of the meat, beef and poultry processing industry reveals that the market has become much more intensely competitive over the last decade. As a matter of fact, you have to be highly creative, customer centric and proactive if you must survive in this industry.

We are aware of the stiff competition and we are prepared to compete favorably with other leading abattoirs in and around Trenton – New Jersey.

One thing is certain; we will ensure that we have a wide range of meats in our warehouse/storage facility at all times. One of our business goals is to make East – Coast Abattoir®, LLC a one stop abattoir. The fact that our output is sold under contract – incorporate long-term sales contracts, and that we enjoy upstream vertical integration (ownership links) and economies of scale gives us edge over our competitors.

So also, our excellent customer service culture, neat and healthy environment, timely and reliable delivery services, online presence, and various payment options will serve as a competitive advantage for us.

Lastly, our employees will be well taken care of, and their welfare package will be among the best within our category in the industry meaning that they will be more than willing to build the business with us and help deliver our set goals and achieve all our aims and objectives.

We will also give good working conditions and commissions to freelance sales agents that we will recruit from time to time.

9. SALES AND MARKETING STRATEGY

- Sources of Income

East – Coast Abattoir®, LLC is in business to engage in slaughtering animals and retailing fresh meats and byproducts. We are in this industry to maximize profits and we are going to go all the way to ensure that we achieve our business goals and objectives.

Our source of income will be;

- Selling by-products from the slaughtering process.

10. Sales Forecast

One thing is certain when it comes to abattoir business, if your business is centrally positioned coupled with reliable supply of healthy meats and effective distribution network, you will always attract customers cum sales and that will sure translate to increase in revenue generation for the business.

We are well positioned to take on the available market in Trenton – New Jersey and we are quite optimistic that we will meet our set target of generating enough income from the first six months of operation and grow the business and our clientele base.

We have been able to critically examine the meat, beef and poultry processing industry, we have analyzed our chances in the industry and we have been able to come up with the following sales forecast. The sales projections are based on information gathered on the field and some assumptions that are peculiar to startups in Trenton – New Jersey.

- First Fiscal Year: $340,000

- Second Fiscal Year: $650,000

- Third Fiscal Year: $1 million

N.B : This projection was done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same products and services as we do within the same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

Before choosing a location for East – Coast Abattoir®, LLC, we conducted a thorough market survey and feasibility studies in order for us to penetrate the available market and become the preferred choice for households, meat wholesale distributors, retailers, grocery stores and supermarkets in and around Trenton – New Jersey.

We have detailed information and data that we were able to utilize to structure our business to attract the number of customers we want to attract per time.

We hired experts who have good understanding of the meat, beef and poultry processing industry to help us develop marketing strategies that will help us achieve our business goal of winning a larger percentage of the available market in and around Trenton – New Jersey.

In summary, East – Coast Abattoir®, LLC will adopt the following sales and marketing approach to win customers over;

- Open our business in a grand style with a party for all.

- Introduce our business by sending introductory letters alongside our brochure to households, restaurants, hotels, caterers, BBQ joints, wholesale distributors, retailers, grocery stores , supermarkets and other key stake holders in and around Trenton – New Jersey

- Ensure that we have a wide range of meat in our abattoir at all times

- Make use of attractive hand bills to create awareness of our business

- Position our signage / flexi banners at strategic places around Trenton – New Jersey

- Create a loyalty plan that will enable us reward our regular customers

- Engage on roadshows within our neighborhood to create awareness for our abattoir cum slaughterhouse business.

11. Publicity and Advertising Strategy

Despite the fact that our abattoir business is well structured and well located, we will still go ahead to intensify publicity for the business. We are going to explore all available means to promote the business.

East – Coast Abattoir®, LLC has a long-term plan of opening distribution channels all around the state of New Jersey and key cities throughout the United States which is why we will deliberately build our brand to be well accepted in Trenton before venturing out.

As a matter of fact, our publicity and advertising strategy is not solely for winning customers over but to effectively communicate our brand. Here are the platforms we intend leveraging on to promote and advertise East – Coast Abattoir®, LLC;

- Place adverts on community based newspapers, radio and TV stations

- Encourage the use of word of mouth publicity from our loyal customers

- Leverage on the internet and social media platforms like YouTube, Instagram, Facebook, Twitter, LinkedIn, Google+ and other platforms to promote our business.

- Ensure that our we position our banners and billboards in strategic positions all around Trenton – New Jersey

- Distribute our fliers and handbills in target areas in and around our neighborhood

- Advertise our abattoir business in our official website and employ strategies that will help us pull traffic to the site

- Brand all our official cars and distribution vans/trucks and ensure that all our staff members and management staff wears our branded shirt or cap at regular intervals.

12. Our Pricing Strategy

Pricing is one of the key factors that gives leverage to wholesale distributors and retailers and abattoirs are not left out, it is normal for retailers to purchase products from distribution companies that they can goods at cheaper price.

We will work towards ensuring that our meat is retailed at highly competitive prices compare to what is obtainable in the United States of America. We also have plans in place to discount our meat once in a while and also to reward our loyal customers from time to time.

- Payment Options

The payment policy adopted by East – Coast Abattoir®, LLC is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that East – Coast Abattoir®, LLC will make available to her clients;

- Payment via bank transfer

- Payment with cash

- Payment via credit cards / Point of Sale Machines (POS Machines)

- Payment via POS machines

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our client make payment for meat, beef and poultry purchase without any stress on their part. Our bank account numbers will be made available on our website and promotional materials.

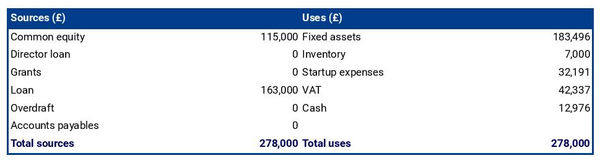

13. Startup Expenditure (Budget)

In setting up any business, the amount or cost will depend on the approach and scale you want to undertake. If you intend to go big by renting a place, then you would need a good amount of capital as you would need to ensure that your employees are well taken care of, and that your facility is conducive enough for workers to be creative and productive.

This means that the startup can either be low or high depending on your goals, vision and aspirations for your business. The tools and equipment that will be used are nearly the same cost everywhere, and any difference in prices would be minimal and can be overlooked.

As for the detailed cost analysis for starting an abattoir business; it might differ in other countries due to the value of their money. These are the key areas where we will spend our startup capital on;

- The total fee for registering the business in the United States of America – $750.

- Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – $3,300.

- Marketing promotion expenses for the grand opening of East – Coast Abattoir®, LLC in the amount of $3,500 and as well as flyer printing (2,000 flyers at $0.04 per copy) for the total amount of $3,580.

- The cost for hiring business consultant – $2,500.

- The cost for insurance (general liability, workers’ compensation and property casualty) coverage at a total premium – $2,400.

- The cost for payment of rent for 12 months at $1.76 per square feet warehouse facility in the total amount of $105,600.

- The total cost for abattoir facility remodeling (construction of drainages et al) – $20,000.

- Other start-up expenses including stationery ( $500 ) and phone and utility deposits ( $2,500 ).

- Operational cost for the first 3 months (salaries of employees, payments of bills et al) – $60,000

- The cost for Start-up inventory (purchase of livestock and slaughtering tools) – $200,000

- Storage hardware (bins, rack, shelves, food case) – $3,720

- The cost for counter area equipment (counter top, sink, etc.) – $9,500

- The cost for store equipment (cash register, security, ventilation, signage) – $13,750

- The cost of purchase and installation of CCTVs – $5,000

- The cost for the purchase of furniture and gadgets (Computers, Printers, Telephone, TVs, Sound System, tables and chairs et al) – $4,000.

- The cost for the purchase of distribution vans / trucks – $25,000

- The cost of launching a website – $600

- The cost for our opening party – $7,000

- Miscellaneous – $10,000

We would need an estimate of five hundred and fifty thousand dollars ( $500,000 ) to successfully set up our abattoir business in Trenton – New Jersey.

Generating Startup Capital for East – Coast Abattoir®, LLC

East – Coast Abattoir®, LLC is a private business that is solely owned and financed by Silas Joshua and his immediate family members. They do not intend to welcome any external business partners which is why he has decided to restrict the sourcing of the startup capital to 3 major sources. These are the areas we intend generating our startup capital from;

- Generate part of the startup capital from personal savings

- Source for soft loans from family members and friends

- Apply for loan from the Bank

N.B: We have been able to generate about $200,000 ( Personal savings $150,000 and soft loan from family members $50,000 ) and we are at the final stages of obtaining a loan facility of $300,000 from our bank. All the papers and documents have been signed and submitted, the loan has been approved and any moment from now our account will be credited with the amount.

14. Sustainability and Expansion Strategy

The future of a business lies in the number of loyal customers that they have, the capacity and competence of their employees, their investment strategy and business structure. If all of these factors are missing from a business, then it won’t be too long before the business closes shop.

One of our major goals of starting East – Coast Abattoir®, LLC is to build a business that will survive off its own cash flow without the need for injecting finance from external sources once the business is officially running.

We know that one of the ways of gaining approval and winning customers over is to retail / distribute our meat, beef and poultry a little bit cheaper than what is obtainable in the market and we are well prepared to survive on lower profit margin for a while.

East – Coast Abattoir®, LLC will make sure that the right foundation, structures and processes are put in place to ensure that our staff welfare are well taken of. Our company’s corporate culture is designed to drive our business to greater heights and training and retraining of our workforce is at the top burner.

We know that if that is put in place, we will be able to successfully hire and retain the best hands we can get in the industry; they will be more committed to help us build the business of our dreams.

Check List/Milestone

- Business Name Availability Check: Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Leasing of abattoir facility and remodeling the facility: In Progress

- Conducting Feasibility Studies: Completed

- Generating capital from family members: Completed

- Applications for Loan from the bank: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of The Company’s Logo: Completed

- Printing of Packaging/Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Purchase of butcher tools: In progress

- Purchase of distribution vans: Completed

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community: In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Opening party/launching party planning: In Progress

- Compilation of our list of products that will be distribute: Completed

- Establishing business relationship with farmers within and outside of Trenton – New Jersey: In Progress

Related Posts:

- Butchery and Meat Shop Business Plan [Sample Template]

- Energy Drink Production Business Plan [Sample Template]

- Potato Chips Business Plan [Sample Template]

- Evaporated Milk Production Business Plan [Sample Template]

- Food Processing Business Plan [Sample Template]

Poultry Farm Business Plan Template

Written by Dave Lavinsky

Poultry Farm Business Plan

Over the past 20+ years, we have helped over 1,000 entrepreneurs and business owners create business plans to start and grow their poultry farms. On this page, we will first give you some background information with regards to the importance of business planning. We will then go through a poultry farm business plan template step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Poultry Farm Business Plan?

A business plan provides a snapshot of your poultry farm as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategy for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Poultry Farm

If you’re looking to start a poultry farm, or grow your existing poultry farm, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your poultry farm in order to improve your chances of success. Your poultry farming business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Poultry Farms

With regards to funding, the main sources of funding for a poultry farm are personal savings, credit cards, USDA Farm Service Agency (FSA) loans, bank loans, and angel investors. With regards to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to confirm that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business. Personal savings and USDA FSA loans are the most common funding paths for poultry farm.

Finish Your Business Plan Today!

How to write a business plan for a chicken farm.

If you want to start a poultry farm or expand your current one, you need a business plan. We detail each section of a traditional business plan for a poultry farming business.

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of poultry farm you are operating and its status. For example, are you a startup, do you have a poultry farm business that you would like to grow, or are you operating poultry farm businesses in multiple locations?

Next, provide an overview of each of the subsequent sections of your plan. For example, give a brief overview of the poultry farm industry. Discuss the type of poultry farm you are operating. Detail your direct competitors. Give an overview of your target customers. Provide a snapshot of your marketing plan. Identify the key members of your team. And offer an overview of your financial plan.

Company Analysis

In your company analysis, you will detail the type of poultry farm you are operating.

For example, you might operate one of the following types of poultry farms:

- Breeder Farms : this type of poultry farm produces hatching eggs for delivery to the hatchery. After the 21 day incubation period, the hatchery then delivers the baby chicks to the broiler houses.

- Broiler Farms: this type of farm produces a 2.5 lb. to 8 lb. bird in 4 to 8 weeks which is processed for various types of retail sale to consumers, grocery stores or fast food chains as whole birds, cut-up breast, wings, thigh, drumsticks, deboned breast meat, or further processed pieces.

- Pullet Farms: this type of poultry farm produces pullets and roosters to be delivered to a breeder hen house at 20-22 weeks old when they are sexually mature to breed and lay eggs.

In addition to explaining the type of poultry farming business you will operate, the Company Analysis section of your business plan needs to provide background on the business.

Include answers to question such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of chickens and/or turkeys produced, number of production contracts, etc.

- Your legal structure. Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry analysis, you need to provide an overview of the poultry farm industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the poultry farm industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your strategy, particularly if your research identifies market trends.

The third reason for market research is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section of your poultry farming business plan:

- How big is the poultry farm industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential market for your poultry farm business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your target market.

Customer Analysis

The customer analysis section of your poultry farming business plan must detail the customers you serve and/or expect to serve.

The following are examples of customer segments: processors, grocery stores, and restaurants.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of poultry farm business you operate. Clearly, processors would respond to different marketing promotions than restaurants, for example.

Try to break out your target customers in terms of their demographic and psychographic profiles. With regards to demographics, include a discussion of the ages, genders, locations and income levels of the customers you seek to serve. Because most poultry farm businesses primarily serve customers living in their same region, such demographic information is easy to find on government websites.

Psychographic profiles explain the wants and needs of your target customers. The more you can understand and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Poultry Farm Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other poultry farm businesses.

Indirect competitors are other options that customers have to purchase from that aren’t direct competitors. This includes producers of other meat such as beef, pork, or fish, as well as producers of meat alternatives. You need to mention such competition as well.

With regards to direct competition, you want to describe the other poultry farms with which you compete. Most likely, your direct competitors will be poultry farms located very close to your location.

For each such competitor, provide an overview of their businesses and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as:

- What types of customers do they serve?

- What kinds of poultry do they produce (breeders, broilers, pullets)?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you use superior production methods?

- Will you provide services that your competitors don’t offer?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a poultry farm business plan, your marketing plan should include the following:

Product : In the product section, you should reiterate the type of poultry farm company that you documented in your Company Analysis. Then, detail the specific products you will be offering. For example, in addition to traditional poultry, will you provide organic or cage-free poultry?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your marketing plan, you are presenting the products and services you offer and their prices.

Place : Place refers to the location of your poultry farm company. Document your location and mention how the location will impact your success. For example, is your poultry farm located near a processing facility, near a transportation hub, etc. Discuss how your location might be the ideal location for your customers.

Promotions : The final part of your poultry farm marketing plan is the promotions section. Here you will document how you will drive customers to your location(s). The following are some promotional methods you might consider:

- Advertising in trade papers and magazines

- Reaching out to local agriculture extension offices

- Social media marketing

- Local radio advertising

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your poultry farm, including animal care / feeding, flock supervision, animal transportation, sourcing feed, etc.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to sign your 20th production contract, or when you hope to reach $X in revenue. It could also be when you expect to expand your poultry farm to a new location.

Management Team

To demonstrate your poultry farm’s ability to succeed, a strong management team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally you and/or your team members have direct experience in managing poultry farms. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act like mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in managing farms or successfully running small businesses.

Financial Plan

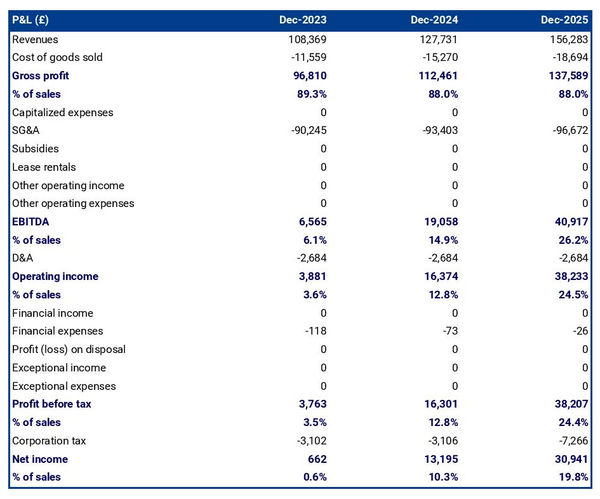

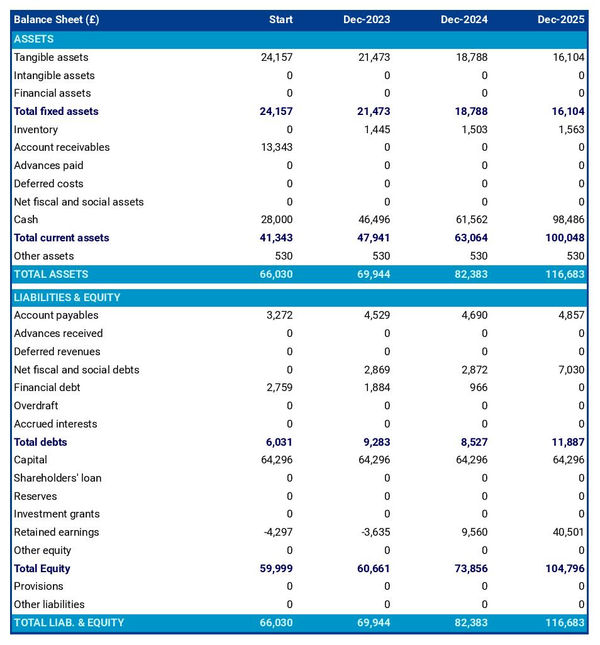

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet and cash flow statements.

Income Statement

An income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenues and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you supply 50 restaurants, or produce 2,000 birds for processing each month? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets

Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your poultry farming business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a bank writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement

Your cash flow statement will help determine how much money you need to start or grow your business, and make sure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

In developing your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a poultry farm business:

- Location build-out including design fees, construction, etc.

- Cost of equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Taxes and permits

- Legal expenses

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your farm title or lease, or blueprints of the production facility.

Putting together a business plan for your poultry farm is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will really understand the poultry farm industry, your competition, and your customers. You will have developed a marketing plan and will really understand what it takes to launch and grow a successful poultry farming business.

Poultry Farm Business Plan FAQs

What is the easiest way to complete my poultry farm business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily complete your Poultry Farm Business Plan.

What is the Goal of a Business Plan's Executive Summary?

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of poultry farm business you are operating and the status; for example, are you a startup, do you have a poultry farm business that you would like to grow, or are you operating a chain of poultry farm businesses?

Don’t you wish there was a faster, easier way to finish your Poultry Farm business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how Growthink’s professional business plan consulting services can create your business plan for you.

Other Helpful Business Plan Articles & Templates

Sample Slaughterhouse Business Plan

Slaughterhouse business plan sample.

Thinking about setting up a slaughterhouse business? Are you having difficulty putting together good poultry, chicken, or cattle abattoir plan? Well if you do, we’re here to help.

Our slaughterhouse business plan targets people within this category. We offer reliable insights into how your plan should look like and some important areas you shouldn’t overlook.

Before we go further, we’d like you to know that simplicity should be the watchword. In other words, you should try as much as possible not to complicate the process.

Hence, this sample should provide enough guidance on how it should look.

EXAMPLE OF AN ABATTOIR BUSINESS PLAN FOR CATTLE, POULTRY, AND CHICKEN

– Executive Summary

Clean-cut Slaughterhouse Inc. is a business that handles the meat needs of our City. Located in the outskirts of Madison, Wisconsin, we are poised to offer top of the range slaughterhouse services.

Founded by the duo of Carlos Henderson and Louis Douglas, Clean-cut Slaughterhouse Inc. will compete favorably with the big players. To achieve this, we are putting in place the right structures necessary.

The founders have worked with major slaughterhouse brands in America. This has given them critical experience and expertise. As a result, we will not be starting from a position of disadvantage. We are deploying all our experience into making sure we succeed.

Our Services

At Clean-cut Slaughterhouse, our services are varied and include the slaughter of 7 types of animals which include cattle , pigs , sheep, horses, goats , poultry , and chicken.

Our other services include deboning and cutting of carcasses as well as the supply of butcher shops with our products. We have 2 main slaughter lines. But before animals are loaded onto the line, they undergo a healthy inspection.

This is done to ensure our products are safe for consumption. Hence the need for an inspection unit headed by qualified veterinarians .

We have seen the need to enhance the quality of services provided by slaughterhouses. As a result, we are coming with 3 decades of experience. By bringing our expertise and experience to bear, we are on course to establish one of the best slaughterhouses in Wisconsin and beyond.

Hence within 8 years of our operations, we expect to listed among the top 20 slaughterhouses in Wisconsin.

Our Mission

Quality of products and services are held dear at Clean-cut Slaughterhouse Inc. To achieve this, we have put our efforts at ensuring that only healthy animals are accepted.

Also, our state-of-the-art facility enhances hygiene as well as humane treatment slaughter of animals. As a result, only the best products are supplied to butcher shops .

Adequate financing is the lifeline of our operations. As such, we seek to source for a capital amounting to $1,500,000.00. This amount will be used for the purchase of equipment, building a slaughterhouse as well as for running costs. We have identified a bank through which the loan will be sourced.

However, only loans with considerably low-interest rates will be applied for.

SWOT Analysis

We have been careful to identify potentials as well as likely pitfalls for our business. This has led us to call for an assessment of our operations. As expected, important findings were made. This has enabled us to adjust and redouble our efforts where necessary.

i. Strength

We have the advantage of expertise and experience. In addition to these, our extensive network within the industry gives us a unique opportunity to boost our business operations significantly.

ii. Weakness

By objectively assessing our areas of weakness, we have identified them to include our immediate financial limitations. This is seen concerning major/established slaughterhouses who have bigger budgets.

This is key because the budget determines output or capacity. Luckily, this will only be short-lived as we will pursue an aggressive expansion drive.

iii. Opportunities

Opportunities are boundless. Hence our passion to float a business. Apart from the domestic market, the international market beckons. Markets within developing countries offer the biggest potential. Thus, while supplying the domestic market, we have plans to grow international.

iv. Threats

Our business can be disrupted by animal diseases. As a result, there is a huge drop in demand. Most importantly, having this knowledge helps us prepare beforehand. But in Inspite of preparations, we can only lessen the effects of such misfortunes.

Competitive Advantage

This is the language of business and we have structured our operations around it. Our areas of advantage include our use of the latest technology. We have discovered that most slaughterhouses used older equipment.

Although this is true, they carry out an overhaul after some years. This places us at an advantage. We have decided to always update our operations with the latest technology.

What more? Our personnel is our pride. In other words, they bring experience to the job. In addition to this, our wide network allows us to operate seamlessly.

Marketing Strategy

There’s little a business can achieve without marketing. Thus having an effective marketing strategy is necessary. At Clean-cut Slaughterhouse, we have decided to work closely with meat shops. These and more will be targeted.

All such activities will be headed by our marketing department. A lot of work was put into choosing our team.

Hence we’ve chosen people with a deep understanding of how our business works. Our result-oriented approach will spur us to achieve our target.

Sales Projection

We are in business for profits and growth. This is in addition to providing quality slaughter services. Hence we’ve seen the need for profitability assessment. Consequently, using available data, we’ve done a three-year projection.

This has considered several aspects of our operations. Results obtained show the following;

- First Financial Year. $500,000.00

- Second Financial Year. $1,100,000.00

- Third Financial Year. $3,500,000.00

Have you found the information provided here useful? We hope you have.

We’ve been able to simplify the process. We also advise that you strip your plan of ambiguity. But why? Because it gives greater clarity.

So what’s better than having a highly implementable slaughterhouse business plan ? Writing your plan isn’t enough. Implementation is equally important.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

How To Start An Abattoir Business

An abattoir is a facility where livestock is slaughtered for the processes of meat preparation along with the production of other meat products. The meat and meat products produced are predominantly meant for the human food consumption market though other products and by-products are earmarked for other uses. With the incessant rise in the number of people starting livestock businesses it comes as no surprise why starting an abattoir is a strategic venture. Most livestock farmers still heavily rely on commercial abattoirs most of which are usually run poorly or are distant from them. Some of these abattoirs are in a deplorable state of filth thus posing health hazards for the subsequent consumers of products produced. This article shall take you along explaining how you can start an abattoir business and some abattoir business plan tips.

There is a deliberate reason as to why we mentioned how some abattoirs are not hygienic. This is meant to show you a loop hole or gap that you as an aspiring entrepreneur can capitalize on. The most prudent approach will be to establish a small scale abattoir that offers service to a particular geographical location (i.e. communities or localities). This is akin to opening private abattoirs which is a strategy that neutralizes the effect of a somewhat saturated commercial market (referring to the big players here). The small scale aspect will help ease financial burden and also makes it easier to uphold high quality control standards.

Another benefit will be that you would have created convenience to most livestock farmers who cannot easily access abattoir services usually far from them. This is not to say that you cannot start on a large scale – if you have the funds then you can do it. Some of the most commonly slaughtered livestock are cattle, pigs, goats and sheep . Thus your core focus can be on any of these or all of them and even more. Some abattoirs also incorporate the slaughtering of birds which is a broad domain that includes birds like poultry. Though meat is the major focus for most abattoirs you can diversify into making meat products or by-products.

There is a whole load of by-products that can be produced by an abattoir. We believe that if aspiring abattoir business owners seriously look into this they can make a whole lot more money. One common by-product is offal which is a hit amongst many customers in several parts of the world. Not forgetting leather which is a high-value by-product made from cattle hides. Bones and rendered meat can be used in stock feeds and fertilizers. By-products such as gelatin ( mainly from pigs ) can be used in making medications. Animal fat can be used in the making of detergents whilst other by-products such as lanolin can be used in the making of beauty products . By-products must be taken very seriously in an abattoir business – do not just dispose certain things as waste. Your abattoir business plan should clearly specify which products your abattoir will deal with.

Market Research

This is a precursor to commencing business operations because there are things you must ascertain beforehand. You have to find out the availability of a market, its segmentation, its needs and its characteristic demographics such as location, scale of operations and the like. You must also study current players on how they are conducting business. We are looking at things like services offered, business processes, strategies, marketing approaches, pricing and so on. In your market research you must take time to find out about pertinent regulations that you are required to adhere to when operating an abattoir business. There are certain health and environmental certifications that one must acquire from relevant authorities. So you must research on that or better still you can find out from established players. This will help you come up with a well detailed abattoir business plan.

Make Sure You Have A Comprehensive Abattoir Business Plan

The failure to plan is the beginning of business failure. The abattoir business plan must be clear and succinct enough to give your potential partners, clients and investors an overview of what your objectives are. At the same time, it must be detailed enough to explain the operations of the business that you propose. At the very minimum you need to have the following included in your abattoir business plan:

- The mission, vision and operational strategy

- Market Analysis And Customer Segmentation

- A business case showing that the business is financial viable and sustainable

- A marketing and customer care plan

- An organizational chart and human resource policy

- A three-year expansion outlook

- A risk and rewards Analysis

Location And Premises

It is wise to establish the business close to livestock farming locations. This can actually give you a competitive edge over other abattoirs that might be situated quite far from livestock farmers. Be somewhere where there is an excellent road network for ease of accessibility. The actual place where the abattoir will be must have a reliable water source. For smooth disposal of effluent or other waste the terrain must be a gentle slope to avoid water logging or settling of waste in one place. The premises must be sufficiently large, well-lit, well-aerated and easily cleanable. The costs of purchasing or leasing the premises should be included in your abattoir business plan.

There is a range of equipment required for the smooth running of this business. An abattoir business is technical and that is why specialized equipment is needed. Slaughtering machines and slaughtering tools are required – manual and automatic. Other handling equipment such as bins, knives, sinks; counter tops, trays, tables, weighing scales and so on are needed. Some of the specialized equipment necessary is scalding and de-hairing machines, conveyor belts, hoists, splitting saw, shears and scalding tanks. Trolleys, stunners, de-hiders, de-horners, rail systems, stunners, gambrels and protective clothing are also needed. As you can see there is a broad range of equipment needed which will depend on your funds, scale of operations or types of services you will be offering. The abattoir business plan should include the costs of acquiring the equipment.

Staff And Management

It is highly advised that you hire or outsource people with qualified expertise who know what they are supposed to do. As usual the management needs can be effectively run by you and family members where applicable. Generally the staff and management requirements are informed by your scale of operations. When looking for people to work with look out for people with qualifications in abattoir processes, abattoir supervision, slaughtering processes, meat examination and classification amongst other related skill sets. The salaries and wages of all your staff should be included in the abattoir business plan.

This must be enough information to equip you with the necessary traction to kick-start your abattoir business. Ensure you stick to high standards of hygiene and adhere to all regulatory requirements. The abattoirs industry is growing and as long as you keep in mind the details discussed herein you will definitely make it.

Related Posts

7 Top Manufacturing Business Ideas

9 Business Ideas For The Future (2020 – 2030)

Top 9 Business Ideas For Kids

Starting Potato Farming Business Plan (PDF)

Join our mailing list to receive the latest posts and updates from our website.

You have Successfully Subscribed!

Poultry Farm Business Plan Template

Written by Dave Lavinsky

Poultry Farm Business Plan

You’ve come to the right place to create your Poultry Farm business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Poultry Farms.

Below is a template to help you create each section of your Poultry Farming business plan.

Executive Summary

Business overview.

Smith Poultry Farm is a new farm business located in Mason City, Iowa. The business is a newly established farm founded by John and Sue Smith. As native Iowans, the couple has spent their life in the farming industry as their families have established farms throughout Iowa. Currently, there is a poultry shortage throughout the midwestern United States as some farms have been forced to shut down their business due to rising costs, labor shortage, and higher technology standards. John and Sue have decided to take this opportunity to alleviate the poultry shortage as well as finally establish the farm they have been planning to do for the past six years.

As native Iowans, John and Sue have already recruited a team of farmhands that have extensive experience working in poultry farms. Most of them have been recently laid off from other poultry farms that have shut down their operations.

John and Sue plan on starting with 5,000 chickens, 500 turkeys, and 100 ducks on 10 acres of land. Their business operations will be centered around daily processes and procedures to tend to the chickens and prepare them for packaging for resale and distribution.

Product Offering

The following are the products that Smith Poultry Farm will provide:

- Chicken for consumption

- Turkey for consumption

- Ducks for consumption

Customer Focus

Smith Poultry Farm will target all residents residing in northern Iowa and throughout the state. They will target families, individuals, supermarkets, large retail chains, and restaurants.

Management Team

Smith Poultry Farm will be owned and operated by John and Sue Smith. They will recruit a very experienced and knowledgeable operator to manage the day-to-day operations of the poultry farm.

John Smith was born and raised on a local farm and has been working in farms most of his life. He left to pursue his agriculture degree from Iowa State and returned to work full-time at his father’s large farm. That farm produces beef, poultry, pork, and vegetables. Once he married Sue, the couple decided that they would begin to save up to pursue a farm of their own.

Sue Smith was raised on a farm as well. Once she graduated from high school, she attended Iowa State to pursue a degree in Business Administration. It was there where she met John and planned for their future farm where he would manage the farm operations and she would be in charge of the financial management and administration of the poultry farm operations.

Success Factors

Smith Poultry Farm will be able to achieve success by offering the following competitive advantages:

- Ownership has extensive experience and knowledge in the poultry farming industry.

- Owners will invest in the latest technology and equipment to make their poultry farm the most superior in the Midwest.

- Smith Poultry Farm will breed high quality chickens, turkeys, and ducks in order to produce the freshest and quality poultry.

Financial Highlights

Smith Poultry Farm is seeking $500,000 in debt financing to launch its property management business. The funding will be dedicated towards securing the farm land and purchasing the necessary equipment and supplies. Funding will also be dedicated towards three months of overhead costs to include payroll of the staff, mortgage, and marketing costs for the poultry farm. The breakout of the funding is below:

- Purchase 10 acres of farmland: $100,000

- Farm equipment, supplies, and materials: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $150,000

- Marketing costs: $50,000

- Working capital: $100,000

The following graph below outlines the pro forma financial projections for Smith Poultry Farm.

Company Overview

Who is Smith Poultry Farm?

Smith Poultry Farm is a new poultry farm business located in Mason City, Iowa. The business is a newly established poultry farm founded by John and Sue Smith. As native Iowans, the couple has spent their life in the farming industry as their families have established farms throughout Iowa. Currently, there is a poultry shortage throughout the midwestern United States as some farms have been forced to shut down their business due to rising costs, labor shortage, and higher technology standards. Growing up in the farming industry, John and Sue have decided to take this opportunity to alleviate the poultry shortage as well as finally establish the farm they have been planning to do for the past six years. The couple plans to raise chickens, turkeys, and ducks to produce poultry for food consumption as well as eggs. Once the business is established, the couple will add more birds to the farm and purchase additional land.

As native Iowans, John and Sue have already recruited a team of farmhands that have extensive experience working in poultry farms. Most of them have been recently laid off from other poultry farms that have shut down their operations. John and Sue have already identified the lead farmhand who will assist John in the day to day farm operations oversight.

Smith Poultry Farm History Smith Poultry Farm is owned and operated by John and Sue Smith, Iowa natives who have extensive experience in farm operations and business administration. John has worked for his father’s large farm for most of his life and wants to finally pursue his own poultry farm since a number of poultry farms have ceased operations due to increased labor and distribution costs. John has already pursued a number of local grocery stores, large retail stores, and restaurants to have contracts to be their sole poultry distributor.

Since incorporation, Smith Poultry Farm has achieved the following milestones:

- Registered Smith Poultry Farm, LLC to transact business in the state of Iowa.

- Has 6 contracts in place to provide poultry for local restaurants, grocery stores, and large retail chains.

- Reached out to numerous individuals and households to purchase their household’s poultry directly from Smith Poultry Farm.

- Began recruiting a staff of farmhands to assist in the day to day operations of the poultry farm.

Smith Poultry Farm Products

The following will be the products Smith Poultry Farm will provide:

Industry Analysis

Customer analysis, demographic profile of target market.

Smith Poultry Farm will target all residents of Mason City and the surrounding states. The target market will consist of households, grocery stores, restaurants, and large retail chains.

The precise demographics for Mason City, Iowa are:

- 503,642 residents

- 310,000 households

- 1,000 restaurants

- 500 grocery stores

- 6 large retail grocery stores

Customer Segmentation

Smith Poultry Farm will primarily target the following customer profiles:

- Individuals and households

- Grocery Stores

- Restaurants

- Large Grocery Chains

Competitive Analysis

Direct and indirect competitors.

Smith Poultry Farm will face competition from other companies with similar business profiles. A description of each competitor company is below.

Myson Poultry Farm

Myson Poultry Farm is a modern, multi-national, protein-focused food company that produces approximately 20% of the beef, pork, and chicken in the United States. Along with its subsidiaries, the company operates a food company worldwide. The company began during the Great Depression when the eldest Myson began selling chickens. A few decades later, Myson’s son grew it into the large company it is today and is one of the largest poultry producers and distributors in the world.

By investing in technology, Myson was able to grow the brand. Through the development of better feeds and better disease control methods, chickens were maturing more quickly. These improvements, combined with increased competition, meant lower prices for consumers and households were able to purchase their poultry products in larger quantities.

Iowa Poultry Farm

Iowa Poultry Farms started in the 1920s when Liam Nelson sold and traded eggs by the dozen as a means to put food on the table for his family. Four generations later, the Nelson family has grown the business year-over-year to continue to meet the changing needs of the egg and pullet industry. More than 90 years of experience has established Iowa Poultry Farm as a well-respected pullet and hatching business as well as a reliant commercial egg producer under the current leadership.

The strength of Iowa Poultry Farm began when master plans for growth from the late 1980s to present day have produced new and improved pullet production facilities that have the capacity to accommodate the growth of the majority of the pullets in NPF’s proprietary facilities. Recent capital development has been invested in hatchery and breeder facilities that have the capacity to produce up to 9 million female chicks per year as well as supplementary aviary growing facilities for both cage-free and floor-grown conventional pullets.

Iowa Poultry Farm continues to innovate as a pullet and hatching business under the leadership of Frank and his son, Brett.

Good Cluck Poultry Farm

Good Cluck Poultry Farm maintains more than 50,000 breeders on its company owned farms. The company currently hatches and sells 79 standard chicken breeds/varieties, 58 breeds/varieties of bantams, 9 breeds of ducks, 3 breeds of geese, and 4 breeds/varieties of guineas. In addition, Good Cluck has available, as a service to its customers, 9 heritage breeds of turkeys, pheasants, and chukar.

Good Cluck certainly has good luck. While many hatcheries have been forced to close, Good Cluck Poultry Farm has become a leader in producing non-commercial poultry annually, selling more than six million items of baby poultry.

Good Cluck’s full list of products are white egg layers, brown egg layers, colored egg layers, standard assortments, broilers, crested chickens, feather legged bantams, bantam assortments, clean leg bantams, ducks, geese, guineas, turkeys, pheasants, chukar, and supplies.

Competitive Advantage

Smith Poultry Farm will be able to offer the following advantages over their competition:

- Ownership has extensive experience and knowledge in the poultry farming industry and has over 20 years of experience managing poultry farm operations

- Smith Poultry Farm will breed high quality chickens, ducks, and turkeys in order to produce the freshest and quality poultry.

Marketing Plan

Brand & value proposition.

Smith Poultry Farm will offer the unique value proposition to its clientele:

- All farming practices will utilize the latest technology and equipment for safe breeding practices, production, and distribution of all farm animals.

- The farm will only breed the highest quality poultry.

- Unbeatable pricing to its clients and customers – Smith Poultry Farm does not mark up its poultry products at a large percentage. All poultry will be on par with competition.

Promotions Strategy

The promotions strategy for Smith Poultry Farm is as follows:

Word of Mouth/Referrals

John Smith has built up an extensive list of contacts over the years by living and working in the midwestern farming industry. Since a number of local poultry farms have ceased operations, they have committed to John that Smith Poultry Farm will be their poultry supplier. They trust his work ethic and commitment to the local community.

Professional Associations and Networking

Smith Poultry Farm will become a member of American Farmland Trust, Farming NGO, National Farmers Union, and the Iowa Chamber of Commerce. They will focus their networking efforts on expanding their client network and marketing their new brand.

Print Advertising

Smith Poultry Farm will invest in professionally designed print ads to display in programs or flyers at industry networking events.

Website/SEO Marketing

Smith Poultry Farm will hire a third-party marketing company to design their print ads and design their website. The website will be well organized, informative, and list all the poultry products they plan to offer. The website will also list their contact information and directions to the poultry farm. The marketing company will also include SEO tactics so that anytime someone types in the Google or Bing search engine “Iowa poultry farm” or “poultry farm near me”, Smith Poultry Farm will be listed at the top of the search results.

Zero po, hindi rin po kami mahilig malabas ng mga panood.

The pricing of Smith Poultry Farm will be moderate and on par with competitors so customers feel they receive value when purchasing their poultry products.

Operations Plan

The following will be the operations plan for Smith Poultry Farm.

Operation Functions:

- John Smith will be the Owner and President of the company. He will oversee all staff and manage client relations. John, along with Sue, has spent the past year recruiting the following staff: