Welding Business Plan Template

Written by Dave Lavinsky

Welding Business Plan

Over the past 20+ years, we have helped over 500 entrepreneurs and business owners create business plans to start and grow their welding companies.

If you’re unfamiliar with creating a welding business plan, you may think creating one will be a time-consuming and frustrating process. For most entrepreneurs it is, but for you, it won’t be since we’re here to help. We have the experience, resources, and knowledge to help you create a great business plan.

In this article, you will learn some background information on why business planning is important. Then, you will learn how to write a welding business plan step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Welding Business Plan?

A business plan provides a snapshot of your welding business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategies for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Welding Business

If you’re looking to start a welding business or grow your existing welding company, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your welding business to improve your chances of success. Your welding business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Welding Businesses

With regards to funding, the main sources of funding for a welding business are personal savings, credit cards, bank loans, and angel investors. When it comes to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to ensure that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business. Personal savings and bank loans are the most common funding paths for welding companies.

Finish Your Business Plan Today!

How to write a business plan for a welding business.

If you want to start a welding business or expand your current one, you need a business plan. The guide below details the necessary information for how to write each essential component of your welding business plan.

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your executive summary is to quickly engage the reader. Explain to them the kind of welding business you are running and the status. For example, are you a startup, do you have a welding business that you would like to grow, or are you operating an established welding business that you would like to sell?

Next, provide an overview of each of the subsequent sections of your plan.

- Give a brief overview of the welding industry.

- Discuss the type of welding business you are operating.

- Detail your direct competitors. Give an overview of your target customers.

- Provide a snapshot of your marketing strategy. Identify the key members of your team.

- Offer an overview of your financial plan.

Company Overview

In your company overview, you will detail the type of welding business you are operating.

For example, you might specialize in one of the following types of welding businesses:

- Aluminum welding: Aluminum welders can produce a variety of aluminum products such as baseball bats, bicycle frames, and golf clubs.

- Heavy steel fabricating: This type of welding business specializes in large projects using thick metals to manufacture products such as industrial tanks and agriculture machines.

- Mobile welding: This type of business specializes in small welding projects in residential homes or commercial businesses.

- Truck trailer manufacturing: This type of welding business specializes in manufacturing tuck trailers, trailer decks, and trailer bodies.

- Underwater welding: This type of business specializes in welding services that require the welder to be submerged in water such as working on dams, pipelines, and nuclear power facilities.

In addition to explaining the type of welding business you will operate, the company overview needs to provide background on the business.

Include answers to questions such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, the number of projects completed, and reaching $X amount in revenue, etc.

- Your legal business Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the welding industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the welding industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your marketing strategy, particularly if your analysis identifies market trends.

The third reason is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section of your welding business plan:

- How big is the welding industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential target market for your welding business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section of your welding business plan must detail the customers you serve and/or expect to serve.

The following are examples of customer segments: individuals, schools, families, and corporations.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of welding business you operate. Clearly, individuals would respond to different marketing promotions than corporations, for example.

Try to break out your target customers in terms of their demographic and psychographic profiles. With regards to demographics, including a discussion of the ages, genders, locations, and income levels of the potential customers you seek to serve.

Psychographic profiles explain the wants and needs of your target customers. The more you can recognize and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Welding Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other welding businesses.

Indirect competitors are other options that customers have to purchase from that aren’t directly competing with your product or service. This includes businesses that provide other forms of manufacturing methods, welders who use other types of techniques or materials, and companies that use their own in-house welders. You need to mention such competition as well.

For each such competitor, provide an overview of their business and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as

- What types of customers do they serve?

- What type of welding business are they?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you make it easier for customers to acquire your product or service?

- Will you offer products or services that your competition doesn’t?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a welding business plan, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of welding company that you documented in your company overview. Then, detail the specific products or services you will be offering. For example, will you provide heavy welding, underwater welding, trailer manufacturing, or aluminum fabrication services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your plan, you are presenting the products and/or services you offer and their prices.

Place : Place refers to the site of your welding company. Document where your company is situated and mention how the site will impact your success. For example, is your welding business located in a busy retail district, a business district, a standalone facility, or is it a mobile operation? Discuss how your site might be the ideal location for your customers.

Promotions : The final part of your welding marketing plan is where you will document how you will drive potential customers to your location(s). The following are some promotional methods you might consider:

- Advertise in local papers, radio stations and/or magazines

- Reach out to websites

- Distribute flyers

- Engage in email marketing

- Advertise on social media platforms

- Improve the SEO (search engine optimization) on your website for targeted keywords

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your welding business, including answering calls, meeting with clients, sending invoices and collecting payments, etc.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to acquire your Xth customer, or when you hope to reach $X in revenue. It could also be when you expect to expand your welding business to a new city.

Management Team

To demonstrate your welding business’ potential to succeed, a strong management team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally, you and/or your team members have direct experience in managing welding businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act as mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in managing a welding business or successfully running a small welding operation.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet, and cash flow statements.

Income Statement

An income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenue and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you employ 3 welders, and will each welder work for 8 hours per day at an hourly wage of $50 per hour? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets

Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your welding business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a lender writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement

Your cash flow statement will help determine how much money you need to start or grow your business, and ensure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

When creating your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a welding business:

- Cost of welding equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Other start-up expenses (if you’re a new business) like legal expenses, permits, computer software, and equipment

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your facility location lease, or a list of successful welding projects completed.

Writing a business plan for your welding business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will understand the welding industry, your competition, and your customers. You will develop a marketing strategy and will understand what it takes to launch and grow a successful welding business.

Welding Business Plan Template FAQs

What is the easiest way to complete my welding business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily write your welding business plan.

How Do You Start a Welding Business?

Starting a welding business is easy with these 14 steps:

- Choose the Name for Your Welding Business

- Create Your Welding Business Plan

- Choose the Legal Structure for Your Welding Business

- Secure Startup Funding for Welding Business (If Needed)

- Secure a Location for Your Business

- Register Your Welding Business with the IRS

- Open a Business Bank Account

- Get a Business Credit Card

- Get the Required Business Licenses and Permits

- Get Business Insurance for Your Welding Business

- Buy or Lease the Right Welding Business Equipment

- Develop Your Welding Business Marketing Materials

- Purchase and Setup the Software Needed to Run Your Welding Business

- Open for Business

Learn more about how to start your own welding business .

Don’t you wish there was a faster, easier way to finish your Welding business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how a Growthink business plan writer can create your business plan for you.

Other Helpful Business Plan Articles & Templates

Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai Pitch Deck Generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customer Success Stories

Business Plan Course

Small Business Tools

Strategic Planning Templates

E-books, Guides & More

- Sample Business Plans

- Construction, Architecture & Engineering

Welding Business Plan

Demand is increasing for welding services. Many different businesses, including manufacturing, transportation, and construction, use welding. Because of this, there is a constant need for welders who can deliver excellent services.

Anyone can start a new business, but you need a detailed business plan when it comes to raising funding, applying for loans, and scaling it like a pro!

Need help writing a business plan for your welding business? You’re at the right place. Our welding business plan template will help you get started.

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Welding Business Plan?

Writing a welding business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

Start your executive summary by briefly introducing your business to your readers.

Market Opportunity:

Welding services:.

Highlight the welding services you offer your clients. The USPs and differentiators you offer are always a plus.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

Describe your business in this section by providing all the basic information:

Describe what kind of welding company you run and the name of it. You may specialize in one of the following welding businesses:

- General welding services

- Aluminum welding

- Mobile welding

- Specialty welding services

- Heavy steel fabricating

- Describe the legal structure of your welding company, whether it is a sole proprietorship, LLC, partnership, or others.Explain where your business is located and why you selected the place.

Mission Statement:

Business history:.

If you’re an established welding service provider, briefly describe your business history, like—when it was founded, how it evolved over time, etc.

Future Goals

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

Start this section by describing your target market. Define your ideal customer and explain what types of services they prefer. Creating a buyer persona will help you easily define your target market to your readers.

Market size and growth potential:

Describe your market size and growth potential and whether you will target a niche or a much broader market.

Competitive Analysis:

Market trends:.

Analyze emerging trends in the industry, such as technology disruptions, changes in customer behavior or preferences, etc. Explain how your business will cope with all the trends.

Regulatory Environment:

Here are a few tips for writing the market analysis section of your welding business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Welding Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Welding services:

Mention the welding services your business will offer. This list may include services like,

- Metal fabrication

- Welding & repair services

- On-site welding services

- Structural steel & pipe welding

- Custom artistic welding

Describe each service

: Provide a detailed description of each service you provide, including the process involved;

Quality measures

: This section should explain how you maintain quality standards and consistently provide the highest quality service.

Additional Services

In short, this section of your welding plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

Define your business’s USPs depending on the market you serve, the equipment you use, and the unique services you provide. Identifying USPs will help you plan your marketing strategies.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your welding company business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your welding business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Operational process:, equipment & machinery:.

Include the list of equipment and machinery required for welding, such as welding machines, welding tools & accessories, welding consumables & accessories, cutting equipment, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your welding business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

Introduce your management and key members of your team, and explain their roles and responsibilities.

Organizational structure:

Compensation plan:, advisors/consultants:.

Mentioning advisors or consultants in your business plans adds credibility to your business idea.

This section should describe the key personnel for your welding business, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

Cash flow statement:, balance sheet:, break-even point:.

Determine and mention your business’s break-even point—the point at which your business costs and revenue will be equal.

Financing Needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your welding business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample welding business plan will provide an idea for writing a successful welding plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our welding business plan pdf .

Related Posts

Woodworking Business Plan

Painting Business Plan

10 Best Business Plan Software

Important Key Elements of Business Plan

Key Business Problem Statement Examples

Steps for Creating Business Plan

Frequently asked questions, why do you need a welding business plan.

A business plan is an essential tool for anyone looking to start or run a successful welding business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your welding company.

How to get funding for your welding business?

There are several ways to get funding for your welding business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your welding business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your welding business plan and outline your vision as you have in your mind.

What is the easiest way to write your welding business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any welding business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

Can a good welding business plan help me secure funding?

Indeed. A well-crafted welding business plan will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can certainly help you secure your business funding.

What's the importance of a marketing strategy in a welding business plan?

Marketing strategy is a key component of your welding business plan. Whether it is about achieving certain business goals or helping your investors understand your plan to maximize their return on investment—an impactful marketing strategy is the way to do it!

Here are a few pointers to help you understand the importance of having an impactful marketing strategy:

- It provides your business an edge over your competitors.

- It helps investors better understand your business and growth potential.

- It helps you develop products with the best profit potential.

- It helps you set accurate pricing for your products or services.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

- Industrial Materials

Welding Electrode Manufacturing Plant Project Report

Welding electrode manufacturing plant project report 2024: industry trends, plant setup, machinery, raw materials, investment opportunities, cost and revenue.

- Report Description

- Table of Contents

- Methodology

- Request Sample

Report Overview:

IMARC Group’s report titled “Welding Electrode Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a welding electrode manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Welding electrodes are essential tools used in the welding process to join two metals together. These electrodes come in various shapes, sizes, and types and are used for different purposes, depending on the type of metal being welded, the thickness of the metal, and the welding technique used. It is made up of two parts, namely, the core wire and the coating. The core wire provides the electrical current needed to create the arc. At the same time, the coating protects the weld from contamination, stabilizes the arc, and influences the final properties of the weld. They offer numerous advantages, including their ability to produce strong, durable, and high-quality welds. They also offer high versatility, allowing them to be used for different welding techniques, including shielded metal, gas tungsten, and gas metal arc welding. In terms of comparison, welding electrodes are more cost-effective than other welding methods, such as gas welding. They are also more effective at welding thicker materials and can be used in outdoor or remote locations where other methods may not be practical. Currently, there are several types of product variants available, including coated, uncoated, and consumable electrodes.

The growing demand for welding electrodes across various end-use industries, such as automotive, construction, and manufacturing, and the increasing product adoption in emerging economies due to rapid industrialization and urbanization are some of the factors fueling the market growth. Moreover, the development of innovative and high-performance welding electrodes by key players and the rising need for maintenance and repair activities in the aging infrastructure are boosting the market growth. This is further supported by the stringent regulations and standards related to safety and quality in welding operations. Besides this, the escalating trend of automation and mechanization in welding processes and the expansion of the oil and gas industry are propelling the market growth. Furthermore, the surging construction of pipelines and offshore structures and the growing focus on renewable energy sources, such as wind and solar power, are accelerating the market growth. Apart from this, the increasing adoption of welding electrodes in the aerospace and defense sectors for manufacturing and repair purposes is contributing to the market growth. Other factors, such as the availability of various product variants for different materials and applications, along with the increasing popularity of online sales channels, are positively impacting the market growth.

The following aspects have been covered in the report on setting up a welding electrode manufacturing plant:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Forecast

The report provides insights into the landscape of the welding electrode industry at the global level. The report also provides a segment-wise and region-wise breakup of the global welding electrode industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of welding electrode, along with the industry profit margins.

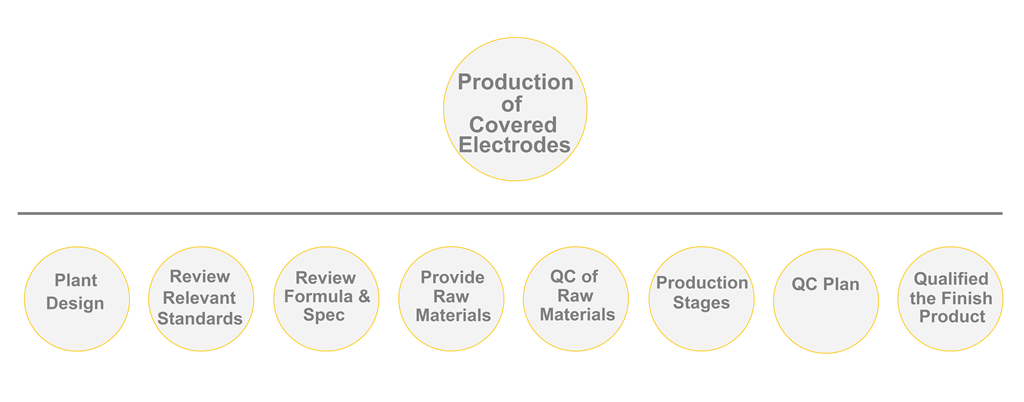

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the process flow and various unit operations involved in a welding electrode manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, and expenditure for setting up a welding electrode manufacturing plant. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a welding electrode manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a welding electrode manufacturing plant.

Report Coverage:

Key questions answered in this report.

- How has the welding electrode market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global welding electrode market?

- What is the regional breakup of the global welding electrode market?

- What are the price trends of various feedstocks in the welding electrode industry?

- What is the structure of the welding electrode industry and who are the key players?

- What are the various unit operations involved in a welding electrode manufacturing plant?

- What is the total size of land required for setting up a welding electrode manufacturing plant?

- What is the layout of a welding electrode manufacturing plant?

- What are the machinery requirements for setting up a welding electrode manufacturing plant?

- What are the raw material requirements for setting up a welding electrode manufacturing plant?

- What are the packaging requirements for setting up a welding electrode manufacturing plant?

- What are the transportation requirements for setting up a welding electrode manufacturing plant?

- What are the utility requirements for setting up a welding electrode manufacturing plant?

- What are the human resource requirements for setting up a welding electrode manufacturing plant?

- What are the infrastructure costs for setting up a welding electrode manufacturing plant?

- What are the capital costs for setting up a welding electrode manufacturing plant?

- What are the operating costs for setting up a welding electrode manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for a welding electrode manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up a welding electrode manufacturing plant?

- What are the key success and risk factors in the welding electrode industry?

- What are the key regulatory procedures and requirements for setting up a welding electrode manufacturing plant?

- What are the key certifications required for setting up a welding electrode manufacturing plant?

Report Customization

While we have aimed to create an all-encompassing report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. have played a crucial role in constructing, expanding, and optimizing sustainable manufacturing plants worldwide.

India Dairy Market Report Snapshots Source:

Statistics for the 2022 India Dairy market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports.

- India Dairy Market Size Source

- --> India Dairy Market Share Source

- India Dairy Market Trends Source

- India Dairy Companies Source

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Purchase options

Benefits of Customization

Personalize this research

Triangulate with your data

Get data as per your format and definition

Gain a deeper dive into a specific application, geography, customer, or competitor

Any level of personalization

Get in Touch With Us

UNITED STATES

Phone: +1-631-791-1145

Phone: +91-120-433-0800

UNITED KINGDOM

Phone: +44-753-713-2163

Email: [email protected]

Client Testimonials

IMARC made the whole process easy. Everyone I spoke with via email was polite, easy to deal with, kept their promises regarding delivery timelines and were solutions focused. From my first contact, I was grateful for the professionalism shown by the whole IMARC team. I recommend IMARC to all that need timely, affordable information and advice. My experience with IMARC was excellent and I can not fault it.

The IMARC team was very reactive and flexible with regard to our requests. A very good overall experience. We are happy with the work that IMARC has provided, very complete and detailed. It has contributed to our business needs and provided the market visibility that we required

We were very happy with the collaboration between IMARC and Colruyt. Not only were your prices competitive, IMARC was also pretty fast in understanding the scope and our needs for this project. Even though it was not an easy task, performing a market research during the COVID-19 pandemic, you were able to get us the necessary information we needed. The IMARC team was very easy to work with and they showed us that it would go the extra mile if we needed anything extra

Last project executed by your team was as per our expectations. We also would like to associate for more assignments this year. Kudos to your team.

.webp)

We would be happy to reach out to IMARC again, if we need Market Research/Consulting/Consumer Research or any associated service. Overall experience was good, and the data points were quite helpful.

The figures of market study were very close to our assumed figures. The presentation of the study was neat and easy to analyse. The requested details of the study were fulfilled. My overall experience with the IMARC Team was satisfactory.

The overall cost of the services were within our expectations. I was happy to have good communications in a timely manner. It was a great and quick way to have the information I needed.

My questions and concerns were answered in a satisfied way. The costs of the services were within our expectations. My overall experience with the IMARC Team was very good.

I agree the report was timely delivered, meeting the key objectives of the engagement. We had some discussion on the contents, adjustments were made fast and accurate. The response time was minimum in each case. Very good. You have a satisfied customer.

.webp)

We would be happy to reach out to IMARC for more market reports in the future. The response from the account sales manager was very good. I appreciate the timely follow ups and post purchase support from the team. My overall experience with IMARC was good.

IMARC was a good solution for the data points that we really needed and couldn't find elsewhere. The team was easy to work, quick to respond, and flexible to our customization requests.

- Competitive Intelligence and Benchmarking

- Consumer Surveys and Feedback Reports

- Market Entry and Opportunity Assessment

- Pricing and Cost Research

- Procurement Research

- Report Store

- Aerospace and Defense

- Agriculture

- Chemicals and Materials

- Construction and Manufacturing

- Electronics and Semiconductors

- Energy and Mining

- Food and Beverages

- Technology and Media

- Transportation and Logistics

Quick Links

- Press Releases

- Case Studies

- Our Customers

- Become a Publisher

United States

134 N 4th St. Brooklyn, NY 11249, USA

+1-631-791-1145

Level II & III, B-70, Sector 2, Noida, Uttar Pradesh 201301, India

+91-120-433-0800

United Kingdom

30 Churchill Place London E14 5EU, UK

+44-753-713-2163

Level II & III, B-70 , Sector 2, Noida, Uttar Pradesh 201301, India

We use cookies, including third-party, for better services. See our Privacy Policy for more. I ACCEPT X

Welding Electrode Manufacturing Plant Project Report 2024: Comprehensive Business Plan

Syndicated Analytics' latest report titled “ Welding Electrode Manufacturing Plant Project Report 2024 Edition: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities” covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a Welding electrode manufacturing plant. The study, which is based both on desk research and multiple waves of qualitative primary research, is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who are planning to foray into the Welding electrode industry in any manner.

What is a Welding electrode?

A welding electrode is a crucial component in the welding process, serving as a conductor that enables the current to pass through the welding arc. This electrode is used in arc welding to fuse two metal pieces by generating intense heat. Electrodes can be made of various materials, including steel, aluminum, or other alloys, and are coated with flux to stabilize the arc and shield the weld area from oxygen and other atmospheric gases. The choice of electrode depends on the type of welding being performed and the materials involved. They come in different sizes and types, each tailored to specific welding needs, offering controlled deposition rates, penetration, and weld bead shapes. The electrode not only conducts current but also melts into the weld, adding a filler material to the joint, thus forming a strong, durable bond upon cooling. Proper selection and handling of welding electrodes are fundamental for achieving high-quality, structurally sound, and reliable welds in various industrial, construction, and fabrication applications.

Request for a Sample Report: https://bit.ly/4c5Xu4p

What are the growth prospects and trends in the welding electrode market?

The global welding electrode market is primarily driven by global industrialization and infrastructure development. The escalating demand for welding consumables is directly tied to the growth in the construction, automotive, fabrication, and shipbuilding industries, where welding is indispensable. As these sectors expand, the need for durable, high-quality welds increases, driving the demand for specialized welding electrodes that can meet the stringent requirements of modern engineering and construction projects. In line with this, the development of advanced electrodes that offer improved welding characteristics, such as better arc stability, reduced spatter, and enhanced mechanical properties, is in high demand hence driving the market growth. Moreover, the trend towards automation and the use of robotics in welding operations has necessitated the development of electrodes that are compatible with automated welding systems, thereby creating a positive outlook for the market across the world.

Which aspects are covered in our report on setting up a Welding electrode manufacturing plant?

Market Overview:

- Market Performance

- Regional Insights

- Key Market Segmentation

- Price Trend Analysis

- COVID-19 Impact

- Market Outlook

- Market Key Players Analysis

Manufacturing Operations:

- Product Description and Insights

- Detailed Process Flow

- Identification of Unit Operations Involved

- Mass Balance Analysis and Raw Material Requirements

- Quality Control

Project Requirements, Details, and Costs:

- Site Development, Location, and Land Requirements

- Plant Layout

- Machinery Requirements and Associated Costs

- Raw Material Requirements and Associated Costs

- Packaging Requirements and Associated Costs

- Transportation Requirements and Associated Costs

- Utility Requirements and Associated Costs

- Manpower Requirements and Associated Costs

Project Financial Analysis:

- Capital Investments Analysis

- Operating Costs Analysis

- Expenditure Projections Analysis

- Revenue Projections Analysis

- Taxation and Depreciation Analysis

- Profit Projections Analysis

- Comprehensive Financial Analysis

Browse the Full Report with TOC & List of Figures: https://www.syndicatedanalytics.com/welding-electrode-manufacturing-plant-project-report

Need Customized Project Report?

You can share any particular business requirements that you have, and we will adjust the scope of the report to your needs. The following are some typical customizations that our clients ask for:

- The report may be customized based on the region/country in which you intend to locate your business.

- The production capacity of the facility can be customized in accordance with your needs.

- Suppliers of machinery and prices can be tailored to your requirements.

- Depending on your needs, we may also modify the current scope.

Key Questions Addressed in the Report on Welding Electrode Manufacturing Project:

- How has the performance of the Welding electrode market been thus far, and what can be expected in the upcoming years?

- What is the market segmentation of the global Welding electrode market?

- What is the regional distribution of the global Welding electrode market?

- What are the price trends of various feedstocks in the Welding electrode industry?

- What is the structure of the Welding electrode industry, and who are the major players?

- What are the different unit operations involved in the manufacturing of Welding electrodes?

- What is the total land area required for the establishment of a Welding electrode manufacturing plant?

- What is the layout of a Welding electrode manufacturing plant?

- What are the machinery requirements for establishing a Welding electrode manufacturing plant?

- What are the raw material requirements for setting up a Welding electrode manufacturing plant?

- What are the packaging requirements for establishing a Welding electrode manufacturing plant?

- What are the transportation requirements for establishing a Welding electrode manufacturing plant?

- What are the utility requirements for establishing a Welding electrode manufacturing plant?

- What are the human resource requirements for establishing a Welding electrode manufacturing plant?

- What are the infrastructure costs associated with establishing a Welding electrode manufacturing plant?

- What are the capital costs involved in setting up a Welding electrode manufacturing plant?

- What are the operating costs associated with establishing a Welding electrode manufacturing plant?

- What should be the pricing mechanism for the final product?

- What will be the income and expenditures for a Welding electrode manufacturing plant?

- What is the timeframe required to achieve the break-even point?

- What are the profit projections for establishing a Welding electrode manufacturing plant?

- What are the key factors for success and risks in the Welding electrode industry?

- What are the essential regulatory procedures and requirements for establishing a Welding electrode manufacturing plant?

- What are the necessary certifications required for establishing a Welding electrode manufacturing plant?

Why Choose Syndicated Analytics Reports:

- Our reports offer valuable insights for stakeholders to make informed business decisions and determine the feasibility of a business venture.

- With a vast network of consultants and domain experts in over 100 countries spanning North America, Europe, Asia Pacific, South America, Africa, and the Middle East, we provide in-depth market analysis and competitive intelligence.

- Our extensive database of equipment and raw material suppliers across major continents, combined with our ongoing tracking and updates of costs of land, construction, utilities, and labor across 100+ countries, provide valuable information for decision-making.

- As a trusted business partner to leading corporations, governments, and institutions worldwide, our client list ranges from small and start-up businesses to Fortune 500 companies.

- Our dedicated in-house team of experts, including engineers, statisticians, modeling experts, charted accountants, architects, and more, have a proven track record of building, expanding, and optimizing sustainable manufacturing plants globally.

Browse Other Reports:

Ginger Manufacturing Plant Project Report

Electric Vehicle Charging Station Manufacturing Plant Project Report

Anti-Pollution Mask Manufacturing Plant Project Report

Toothpaste Manufacturing Plant Project Report

Aluminium Foil Manufacturing Plant Project Report

Soybean Oil Manufacturing Plant Project Report

About Us: Syndicated Analytics, a subsidiary of IMARC Group, offers consulting services and provides comprehensive market intelligence in the form of research reports, production cost reports, and feasibility studies. Our team, consisting of experienced researchers and analysts from diverse industries, is deeply committed to the quality of the information and insights delivered to the clients, which range from small and medium enterprises to Fortune 1000 companies. These firms are able to achieve this by studying the qualitative and quantitative aspects of the market as well as staying up to date with the current and evolving trends of the industry.

Contact Info:

Katherine Shields

Senior Sales & Marketing Manager

134 N 4th St. Brooklyn

NY 11249, USA

Phone No.: +1-213-316-7435

Website: https://www.syndicatedanalytics.com/

Email Address: [email protected]

This article was written by jamie cooke for on .

Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for 'lorem ipsum' will uncover many web sites still default model text.

@jamiecooke Articles

Enter Channel details below

Or select existing Channel

How To Write a Business Plan for Welding Company in 9 Steps: Checklist

By alex ryzhkov, resources on welding company.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

Welcome to our blog post on how to write a business plan for a welding company! If you're considering starting your own welding business or looking to refine your existing one, you're in the right place. With the demand for welding services on the rise, it's a great time to enter this thriving industry. In fact, according to the American Welding Society, the welding industry is expected to grow by 6% between 2020 and 2028 , creating numerous opportunities for success.

Now, let's dive into the 9 essential steps to create a comprehensive business plan for your welding company.

- Conduct market research

- Define your target market

- Identify your competitors

- Determine your unique selling proposition

- Develop a pricing strategy

- Outline your business goals and objectives

- Analyze your financial capabilities and requirements

- Assess legal and regulatory requirements

- Identify potential risks and develop a risk management plan

By following these steps, you'll be well-equipped to set a solid foundation for your welding company and increase your chances of long-term success in the industry. So, let's get started!

Conduct Market Research

Conducting thorough market research is an essential step in creating a successful business plan for your welding company. Market research enables you to gather crucial information about your industry, target market, and competitors, allowing you to make informed decisions and develop effective strategies. Here are some key aspects to consider while conducting market research:

- Industry Analysis: Gain a comprehensive understanding of the welding industry in the US. Identify current trends, growth potential, and any challenges that may impact your business.

- Target Market Identification: Define your target market by considering factors such as location, demographics, industries, and specific welding needs. This will help you tailor your services and marketing efforts accordingly.

- Competitor Assessment: Research and analyze your competitors to determine their strengths, weaknesses, and market position. This information will help you identify areas where you can differentiate your welding company and gain a competitive advantage.

- Customer Needs and Preferences: Understand your potential clients' requirements, preferences, and expectations when it comes to welding services. This will help you tailor your offerings and provide superior customer satisfaction.

- Utilize online resources, industry reports, and trade publications to gather reliable market data.

- Engage in discussions with industry experts, potential clients, and other professionals in the welding field to gain valuable insights and feedback.

- Consider conducting surveys or interviews to gather firsthand information from your target market.

- Stay updated with industry trends and technological advancements that may impact the welding sector.

Define Your Target Market

Before starting a welding company, it is essential to define your target market. This will help you focus your efforts on the right audience and tailor your services and marketing strategies accordingly.

To define your target market, consider the following:

- Industry: Identify the industries that commonly require welding services. This could include construction, manufacturing, automotive, or even artistic industries.

- Geographic location: Determine the geographical areas you plan to serve. This could be a specific city, region, or even nationwide.

- Customer demographics: Understand the characteristics of your potential customers, such as age, gender, income level, and education. This will help you tailor your messaging to effectively reach and attract your target audience.

- Customer needs: Analyze the specific welding needs of your target market. Are they looking for precision welding for intricate designs, structural welding for large-scale projects, or a combination of both?

Tips for defining your target market:

- Conduct surveys or interviews with potential customers to gather insights on their preferences and needs.

- Utilize market research reports and industry publications to identify trends and opportunities within your target market.

- Keep a close eye on your competitors' target markets and see if there are any untapped niches you can target.

- Regularly update and refine your target market as your business grows and evolves.

Defining your target market is a crucial step in developing a successful business plan for your welding company. It will help you understand your customers' needs, determine your competitive advantage, and position your company as the go-to provider of welding services in your chosen market.

Identify Your Competitors

In order to successfully establish and grow your welding company, it is important to identify and analyze your competitors. Knowing who your competitors are and understanding their strengths and weaknesses can give you valuable insights into the market landscape and help you position your business strategically.

Here are some steps to help you identify your competitors:

- Research the market: Conduct thorough research to identify other welding companies operating in your target market. Look for both direct competitors who offer similar services and indirect competitors who may provide alternative solutions for your potential clients.

- Consider location: Take into account the geographic proximity of your competitors. Local competitors may pose a more direct threat, as they may have established relationships with clients in the area. On the other hand, regional or national competitors may have a broader reach and offer more diverse services.

- Examine their offerings: Analyze the services and capabilities of your competitors. Look for areas in which they excel or have unique expertise. This will help you identify gaps in the market that you can potentially fill or areas where you can differentiate your business.

- Assess their reputation: Research your competitors' online presence, customer reviews, and reputation within the industry. This will give you an idea of how they are perceived by clients and whether there are any areas where you can offer a better customer experience.

- Analyze their pricing: Study your competitors' pricing strategies to understand how they position themselves in the market in terms of cost. This will help you determine a competitive pricing strategy that aligns with the value you offer.

- Identify market trends: Keep an eye on industry trends and changes in customer preferences. Identify any emerging competitors or technological advancements that may disrupt the market. Anticipating and adapting to these trends will help you stay competitive.

Tips for identifying competitors:

- Join industry trade associations and attend networking events to meet and learn from industry professionals.

- Utilize online business directories, industry-specific websites, and online forums to find information about competitors.

- Stay up-to-date with industry publications, blogs, and newsletters to stay informed about new market entrants.

- Consider conducting mystery shopping or reaching out to potential clients to gather information about competitor offerings and customer experiences.

Determine Your Unique Selling Proposition

Identifying your unique selling proposition (USP) is crucial for the success of your welding company. Your USP sets you apart from your competitors and defines what makes your business special and valuable to your customers. It gives potential clients a compelling reason to choose your welding services over others.

When determining your USP, consider your strengths, experience, and expertise in the welding industry. Reflect on what makes your company different and how it can benefit your target market. Here are some steps to help you define your USP:

- Evaluate your competitors: Research your competitors to understand their strengths and weaknesses. This will help you identify gaps in the market that you can fill with your unique offering.

- Understand your target market: Gain insights into the needs, preferences, and pain points of your target market. This will enable you to tailor your USP to meet their specific requirements.

- Showcase your expertise: Highlight your experience, certifications, and qualifications that set you apart as a trusted and skilled welding company.

- Focus on specialization or diversification: Determine whether specializing in a specific type of welding or offering a broad range of welding services will be your USP. Choose the option that aligns with your strengths and the demands of your target market.

- Promote quality and timely project delivery: Emphasize your commitment to delivering high-quality welding projects on time and within budget. Reliability and customer satisfaction can be powerful differentiators.

- Be specific and clear: Ensure your USP clearly communicates the unique value your welding company brings to clients. Avoid generic statements that may not resonate with potential customers.

- Stay consistent: Ensure your USP aligns with your overall brand messaging and is consistently communicated across your marketing materials, website, and interactions with clients.

- Continuously reassess your USP: As the market evolves and customer preferences change, periodically review and update your USP to remain relevant and competitive.

Defining a compelling unique selling proposition will help your welding company stand out in a crowded marketplace and attract clients who recognize the value you offer. Take the time to carefully evaluate your strengths and target market needs to create a USP that resonates with your ideal customers.

Develop A Pricing Strategy:

Developing a strong pricing strategy is crucial for the success of your welding company. It allows you to determine the value you provide to your clients and ensure that your prices are competitive in the market. Here are some key steps to consider:

- 1. Analyze your costs: Determine all the costs involved in running your welding business, including materials, labor, and overhead expenses. This will help you understand the minimum amount you need to charge to cover your costs and make a profit.

- 2. Evaluate market prices: Research the market to understand what other welding companies charge for similar services. This will give you an idea of the price range you should consider.

- 3. Consider your unique selling proposition: Take into account your specializations or unique capabilities that set you apart from competitors. This could justify a higher price point for your services.

- 4. Value-based pricing: Instead of solely basing your prices on your costs, consider the value you provide to your clients. If your welding services save them time, provide superior quality, or offer unique benefits, you can price accordingly.

- 5. Segment pricing: If your welding company caters to different types of clients or industries, you may need to adopt a segmented pricing strategy . This means offering different pricing tiers or packages tailored to each segment's specific needs.

- 6. Monitor and adjust: Regularly evaluate your pricing strategy and keep an eye on market trends, changes in costs, and customer feedback. Be prepared to adjust your prices if necessary to remain competitive and profitable.

- Consider offering package deals or bundled services to attract customers.

- Offer special promotions or discounts to incentivize clients and gain an edge over competitors.

- Communicate the value of your services to customers to justify your pricing.

- Regularly evaluate your cost structure to ensure your pricing remains profitable.

By carefully considering these factors and implementing a well-thought-out pricing strategy, you can position your welding company for success and ensure you are providing excellent value to your clients while maintaining profitability.

Outline Your Business Goals And Objectives

When starting a welding company, it is essential to have clear business goals and objectives in place. These goals will serve as a roadmap for the company's growth and success. Here are some key considerations to keep in mind as you outline your business goals and objectives:

- Define your long-term vision: Start by envisioning where you want your welding company to be in the next five to ten years. Think about the scale of your operations, the industries you want to cater to, and the reputation you want to establish in the market.

- Set measurable objectives: To ensure that your goals are achievable, it is crucial to define them in specific and measurable terms. For example, instead of saying 'increase revenue,' set a target like 'increase annual revenue by 20% within the next two years.'

- Focus on customer satisfaction: Make customer satisfaction a primary objective of your welding company. Aim to deliver high-quality workmanship, meet project deadlines consistently, and exceed client expectations. Satisfied customers will not only provide repeat business but also serve as brand advocates.

- Invest in employee development: Your goals should prioritize the growth and development of your employees. Consider implementing training programs, workshops, and certifications to enhance their expertise in welding techniques and safety practices. This will not only improve the overall quality of your work but also foster employee loyalty.

- Regularly review and revise your goals and objectives to align them with market trends and changes in your business environment.

- Break down your long-term goals into short-term milestones and track your progress regularly to stay focused and motivated.

- Consider both financial and non-financial objectives, such as building strong industry partnerships or implementing sustainable practices, to create a well-rounded business strategy.

By outlining your business goals and objectives, you create a clear direction for your welding company and provide a framework for decision-making and resource allocation. Keep in mind that goals and objectives can evolve over time, so be ready to adapt and refine them as your business grows.

Analyze Your Financial Capabilities and Requirements

When starting a welding company, it is crucial to carefully analyze your financial capabilities and requirements to ensure the success and sustainability of your business. Understanding your financial position will help you make informed decisions, allocate resources effectively, and plan for potential challenges. Here are a few key steps to consider:

- Evaluate your current financial resources: Assess your savings, investments, and available capital to determine the funding you have available to start your welding company. Additionally, take into account any loans or financing options you may consider to support your business.

- Estimate startup costs: Determine the expenses associated with starting your welding company, such as equipment purchases, facility rentals, permits, licenses, insurance, marketing, and initial staff salaries. Create a detailed budget to forecast your expenses accurately.

- Project revenue streams: Identify the potential sources of revenue for your welding company. Consider the types of projects you plan to undertake, the prices you can charge for your services, and the volume of work you anticipate. This analysis will help you estimate your income and cash flow projections.

- Allocate funds for marketing and branding: Set aside a portion of your budget to develop a strong marketing strategy and create brand awareness. This may include website development, advertising, business cards, online presence, and promotional activities.

- Establish financial goals: Clearly define your short-term and long-term financial goals. These goals will serve as benchmarks to measure your company's growth and success. Creating targets will help you stay focused and motivated.

Here are a few tips:

- Consider consulting with a financial advisor or accountant familiar with the specific needs of a welding company.

- Keep track of your expenses and regularly review your financial statements to assess your company's financial health.

- Explore different funding options, such as small business loans or grants, to secure additional capital if needed.

Assess Legal And Regulatory Requirements

When starting a welding company, it is crucial to assess the legal and regulatory requirements that apply to your business. Compliance with the law and regulations not only ensures smooth operations but also builds credibility and trust with clients and stakeholders. Here are some important considerations:

- Licensing and permits: Research and acquire the necessary licenses and permits required to operate a welding business in your state or locality. This may include a general business license, contractor's license, or a specialized welding license.

- Environmental regulations: As a welding company, you must be mindful of your environmental impact. Ensure compliance with environmental regulations related to hazardous materials, waste disposal, and air and water pollution.

- Workplace health and safety: Protect the health and safety of your employees and clients by complying with workplace health and safety regulations. This includes providing appropriate personal protective equipment, training employees on safety protocols, and maintaining a safe working environment.

- Insurance: Evaluate the types of insurance coverage needed for your welding business. Consider liability insurance, worker's compensation insurance, and property insurance to mitigate risks.

- Contracting laws: Familiarize yourself with the laws governing contracts and agreements in your jurisdiction. Develop a clear understanding of important terms such as payment terms, warranties, and dispute resolution mechanisms.

- Tax obligations: Consult with a tax professional to understand your tax obligations as a welding company. Be aware of income tax, sales tax, and payroll tax requirements.

- Consult with a legal professional or business advisor to ensure you fully understand and comply with all legal and regulatory requirements.

- Stay updated on any changes in laws and regulations that may affect your welding business.

- Maintain accurate and organized records to demonstrate compliance with legal and regulatory obligations.

- Join industry associations or organizations that provide resources and guidance on legal and regulatory matters specific to the welding industry.

Identify Potential Risks And Develop A Risk Management Plan

Identifying potential risks is an essential aspect of running any business, including a welding company. By identifying risks early on, you can develop a comprehensive risk management plan to minimize their impact and ensure the smooth operation of your business. Here are some key steps to help you identify potential risks and develop an effective risk management plan:

- Conduct a comprehensive risk assessment: Begin by identifying and assessing all potential risks that could affect your welding company. This may include operational risks, such as equipment failure or supply chain disruptions, as well as financial risks, such as fluctuations in material costs.

- Determine the likelihood and impact of each risk: Once you have identified the potential risks, evaluate their likelihood of occurring and the impact they would have on your business if they were to happen. This will help you prioritize your risk management efforts and allocate resources accordingly.

- Develop risk mitigation strategies: After assessing the risks, it's important to develop strategies to mitigate their impact. This may involve implementing preventive measures, investing in backup equipment or resources, or developing contingency plans to address potential disruptions.