30 Free Metal Shop Project Ideas

The following is a collection of metal shop project ideas to help inspire hobby metalworkers to get back in the shop and start creating.

1. Camp Saw

2. fireplace tool set, 3. pickup tongs, 4. stackable tables, 5. caddy tray, 6. fishing net, 7. decorative planter box, 8. bird feeder, 9. paper/pad holder, 10. colonial hanging lamp, 11. spice rack, 12. charcoal hod, 13. mailbox, 14. small waste basket, 15. small candy dish, 16. decorative metal box, 17, 18, 19, & 20. bracelet, armband, letter opener, and scriber, 21 & 22. tack hammer and plumb bob, 23. bookends, 24. hobby knife, 25. paperweight, 26 & 27. tack hammer and c-clamp, 28, 29, & 30. cold chisel, punches, and screwdriver, from videos, make your own ideas, bench metal and wrought metal project ideas.

These projects are made primarily with Bench/Wrought Metal:

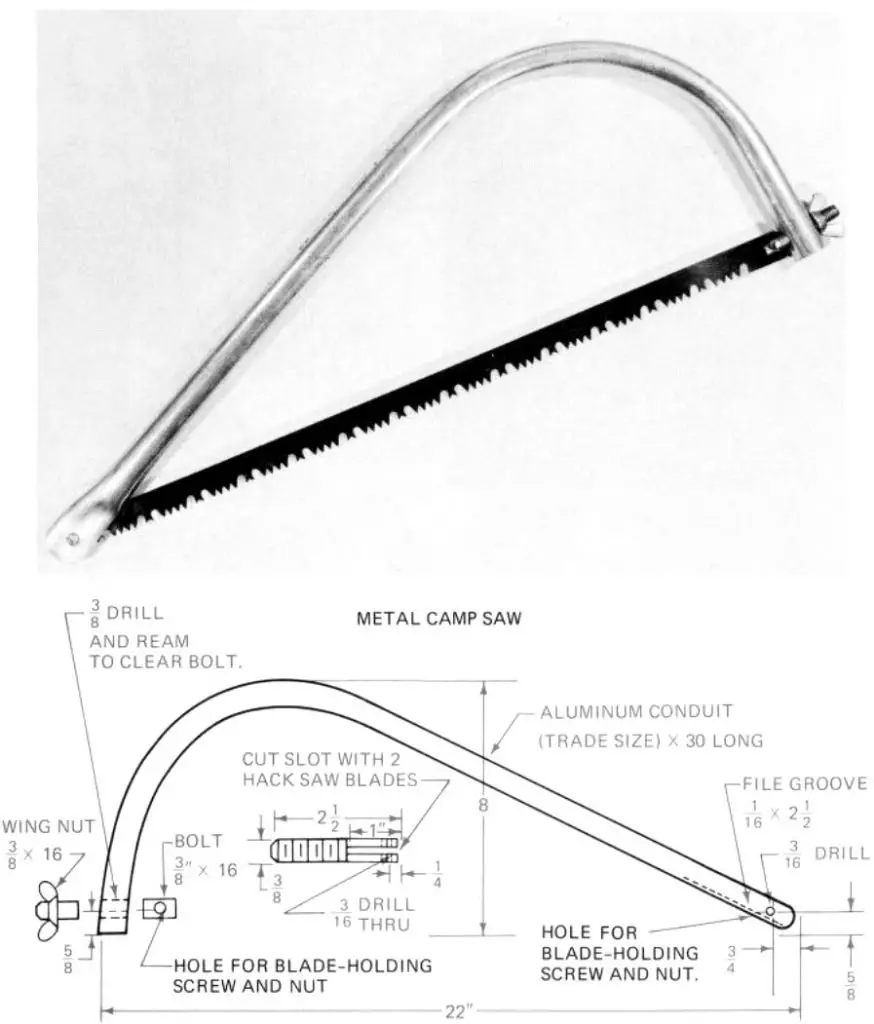

This lightweight yet sturdy camp saw is simple to make.

The aluminum tubing is strong but easy to bend.

You should be able to find saw blades which fit this size, but the length of the bow can be altered for other size blades.

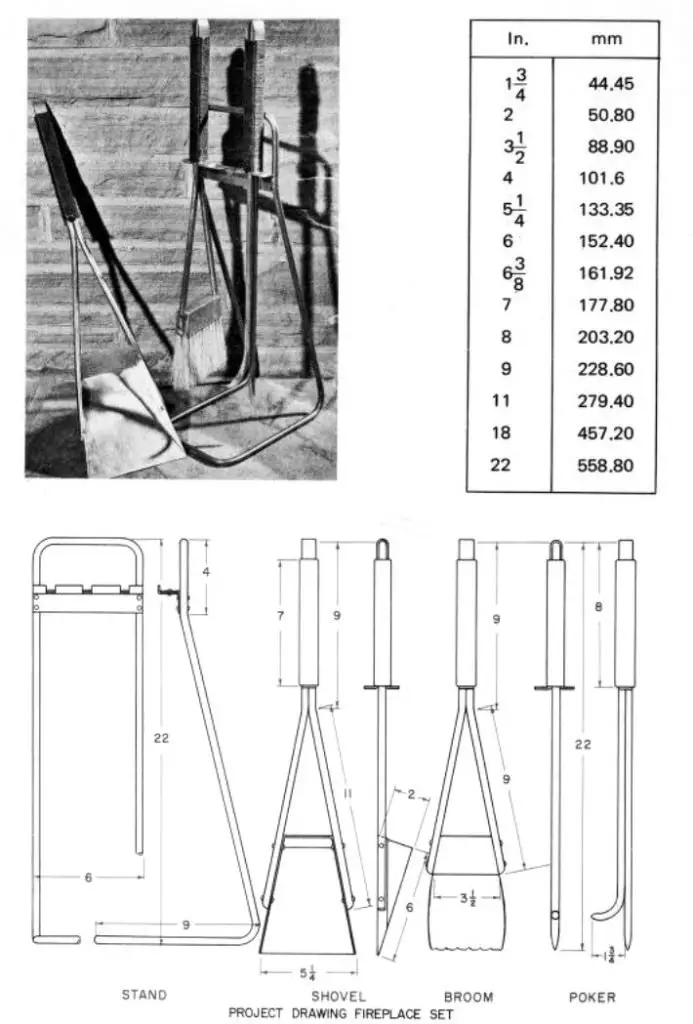

This fireplace set is made of aluminum.

The handles are wrapped with heavy cord or plastic material.

The shovel and broom sections can be assembled with rivets or machine screws.

A metric equivalent chart is added to use metric measuring tools.

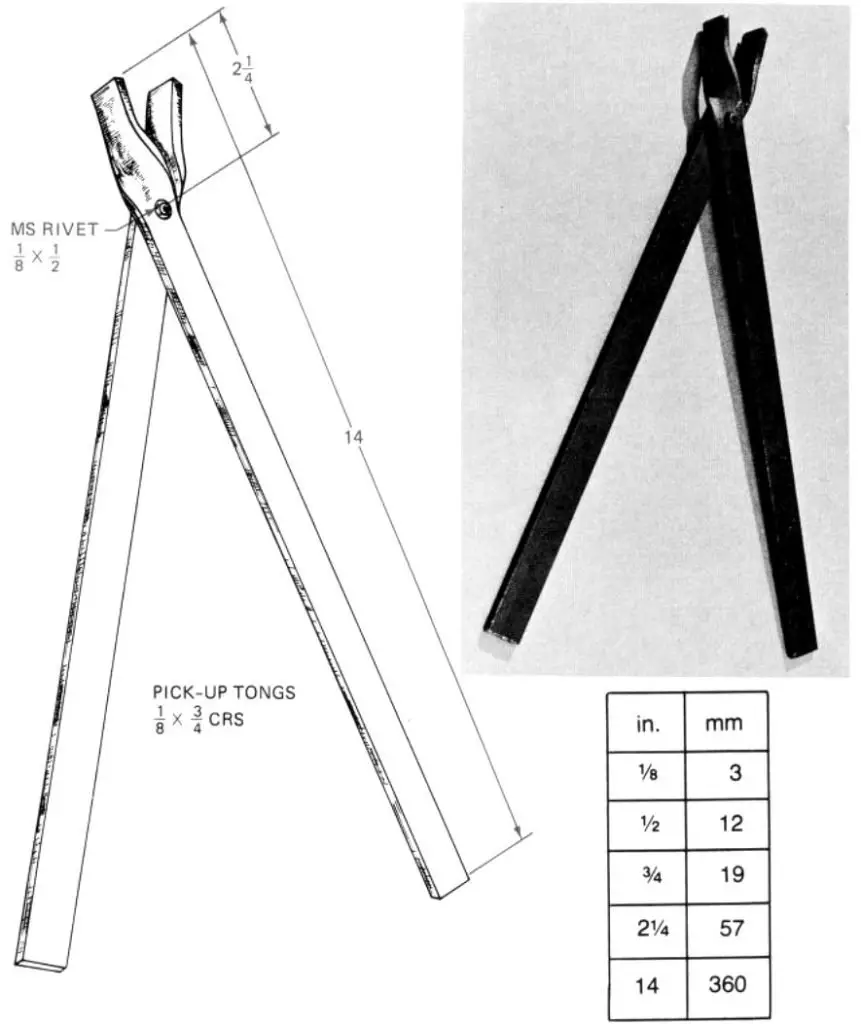

These tongs are a useful tool for the workshop.

They are handy for holding hot metal parts and containers.

The sizes and shapes of the jaws can be altered to meet special needs.

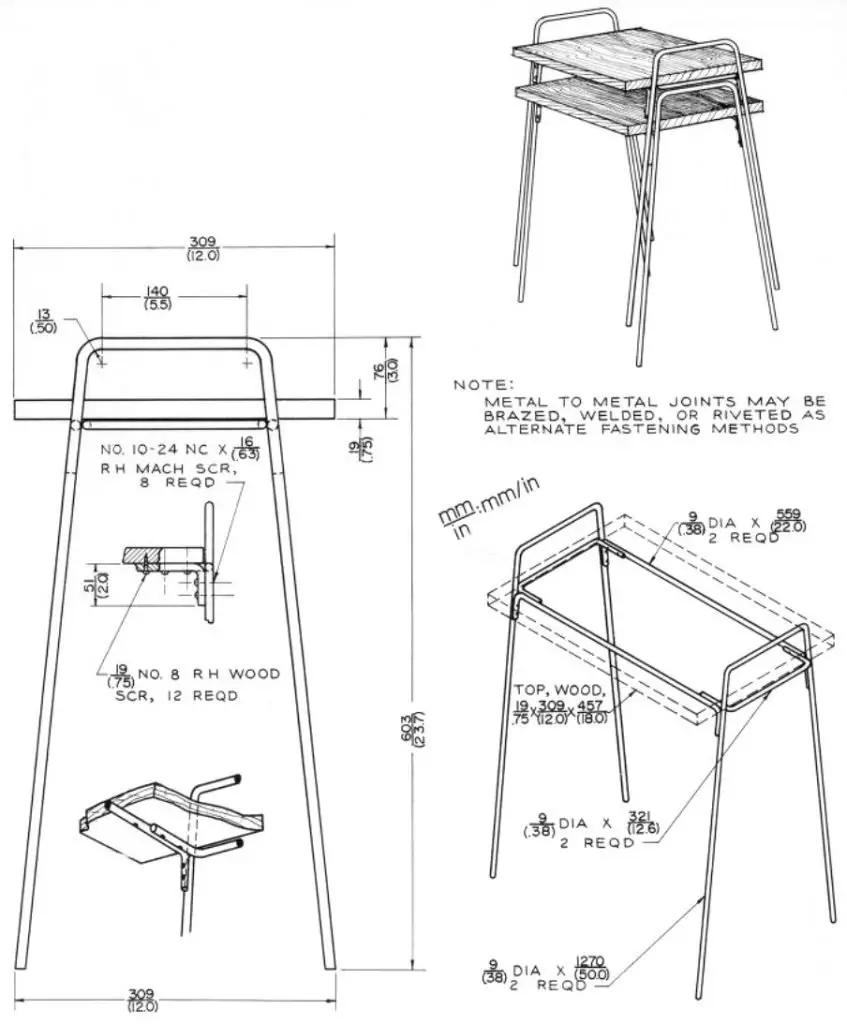

These tables combine metal with either wood or plastic.

The dimensions are given in both inches and millimeters.

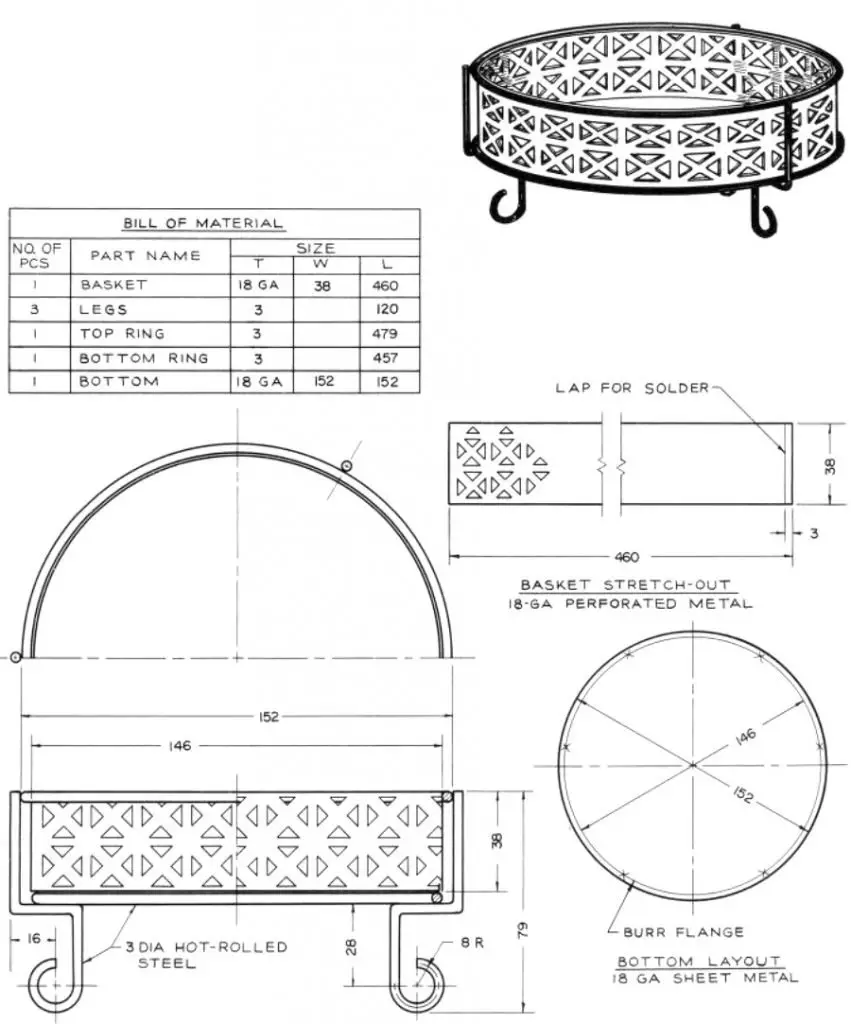

This tray can be used as a desk accessory or anywhere to hold small items.

The wire parts can be assembled by brazing.

All dimensions are given in millimeters.

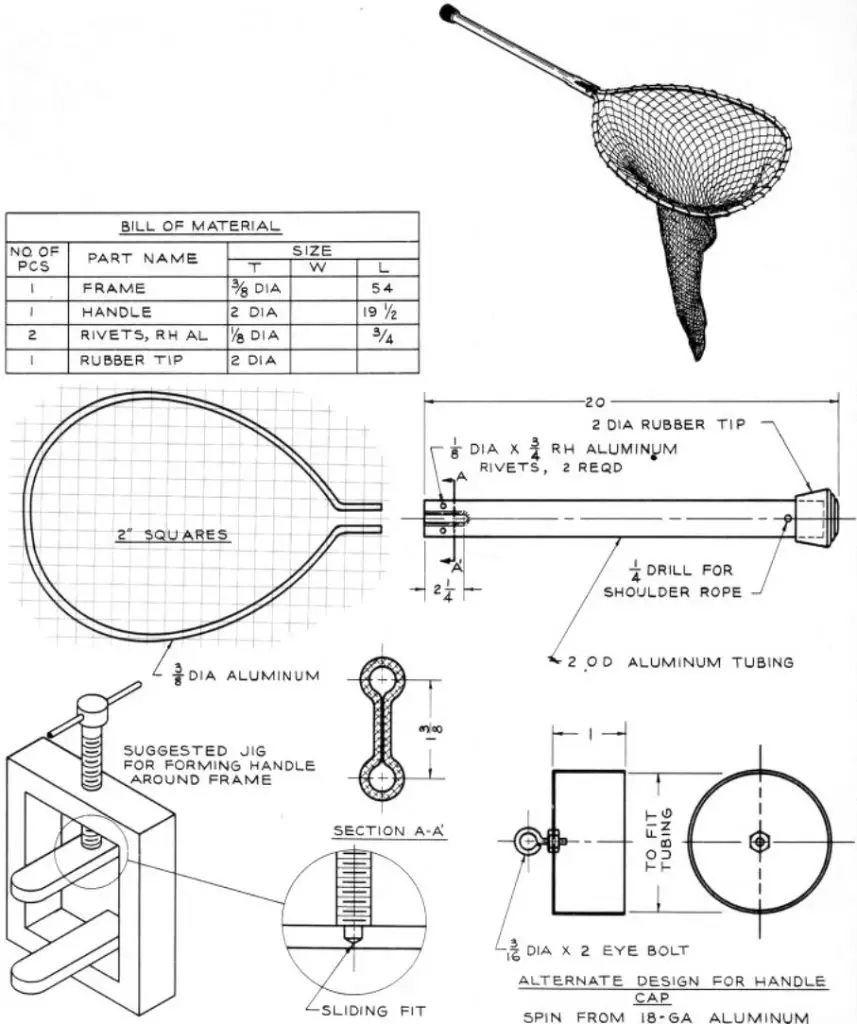

This fishing net is made from aluminum.

It would make a great gift for a fisherman or possibly a mass produced item to sell.

Measurements are in inches.

Sheet Metal Projects Ideas

These projects are made primarily with sheet metal:

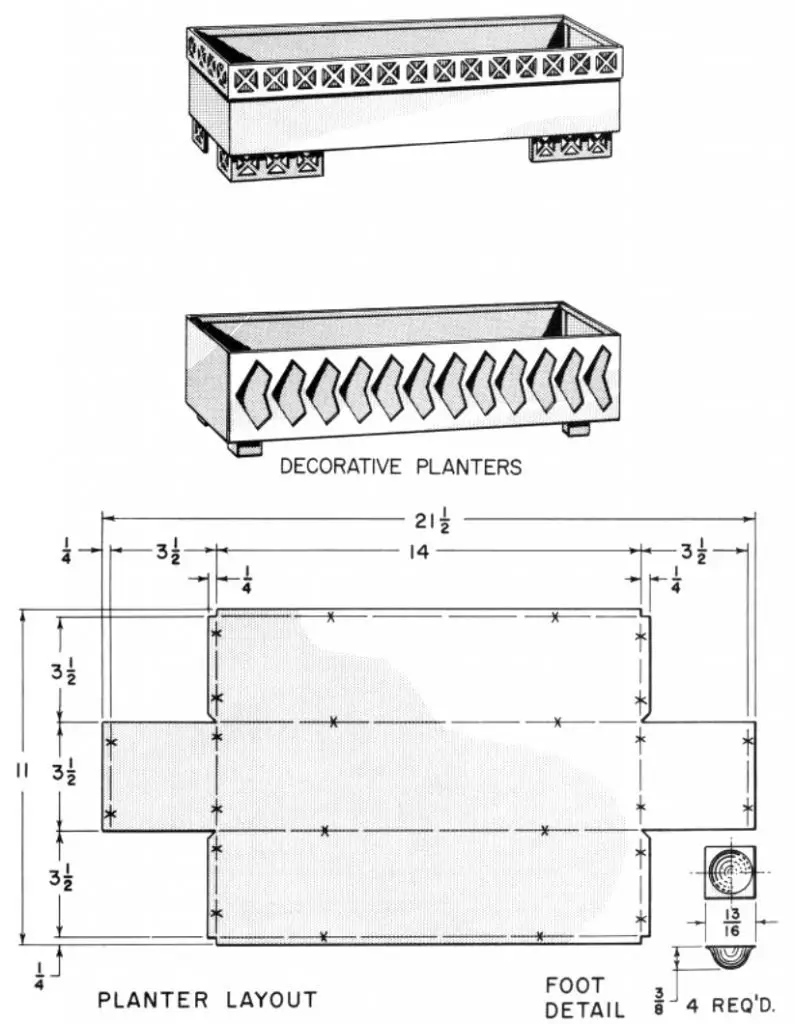

Many sizes and shapes of planter boxes can be made with sheet metal.

This front of the planter can be decorated with scraps from stampings or with perforated or expanded metal.

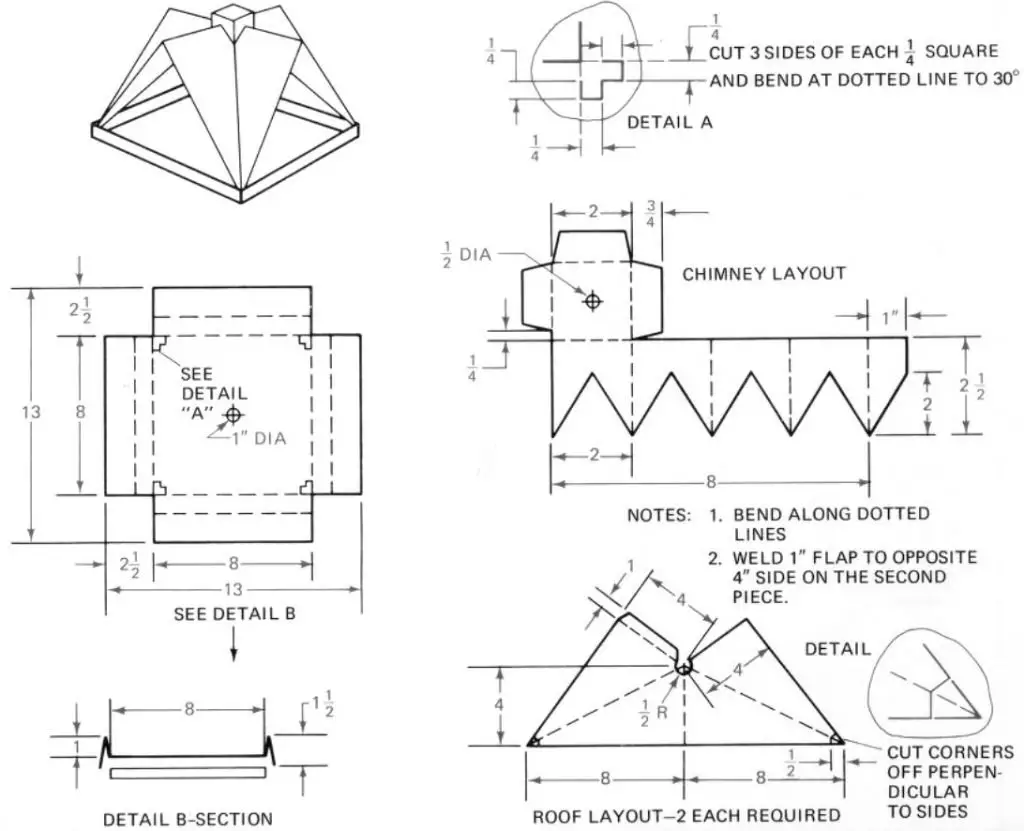

This useful feeder can be made in many shapes and sizes. Here is a suggested form.

One way to experiment with further ideas is to fold sheets of paper into interesting shapes.

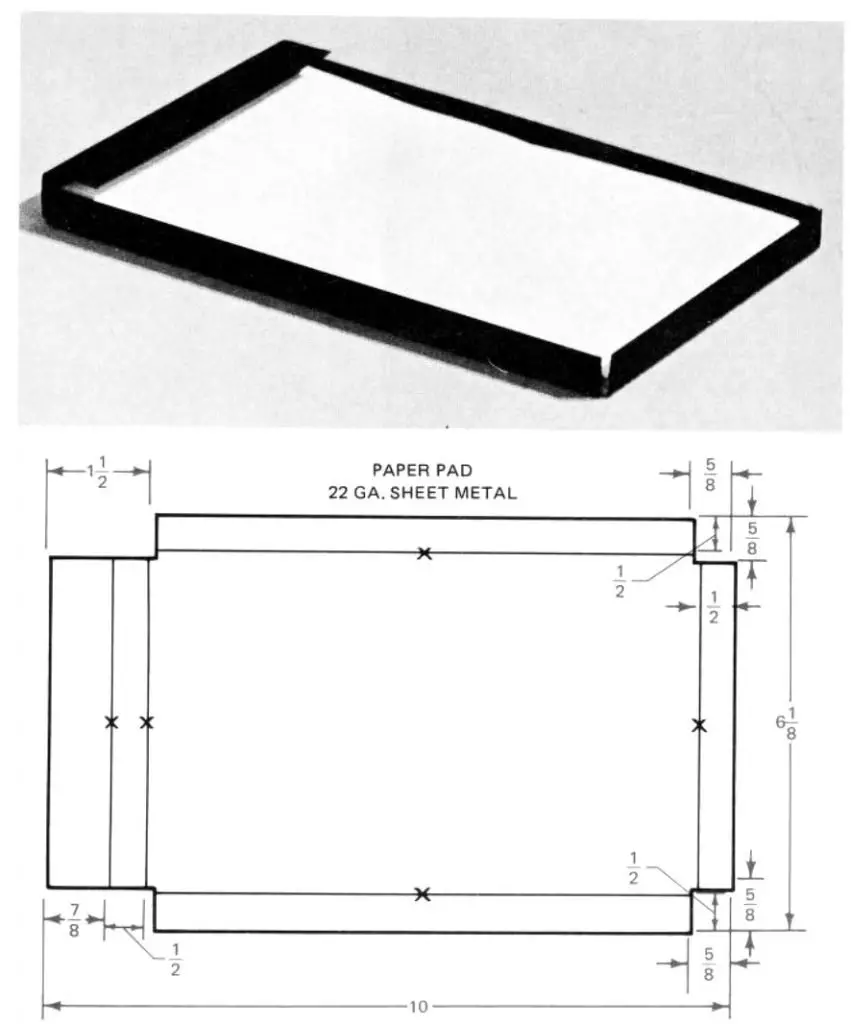

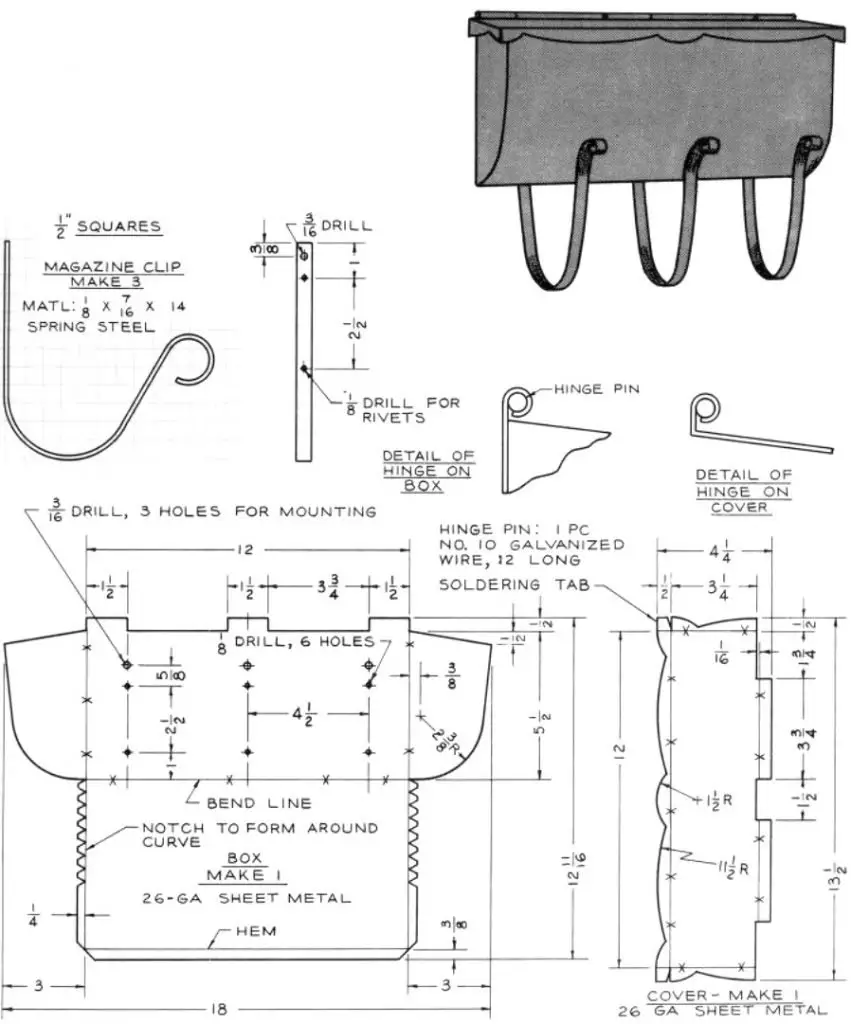

This simple metal container is a handy item for holding sheets of note paper on a desk.

It can be made in a variety of sizes to match standard paper sizes.

Finish it in the color of your choosing.

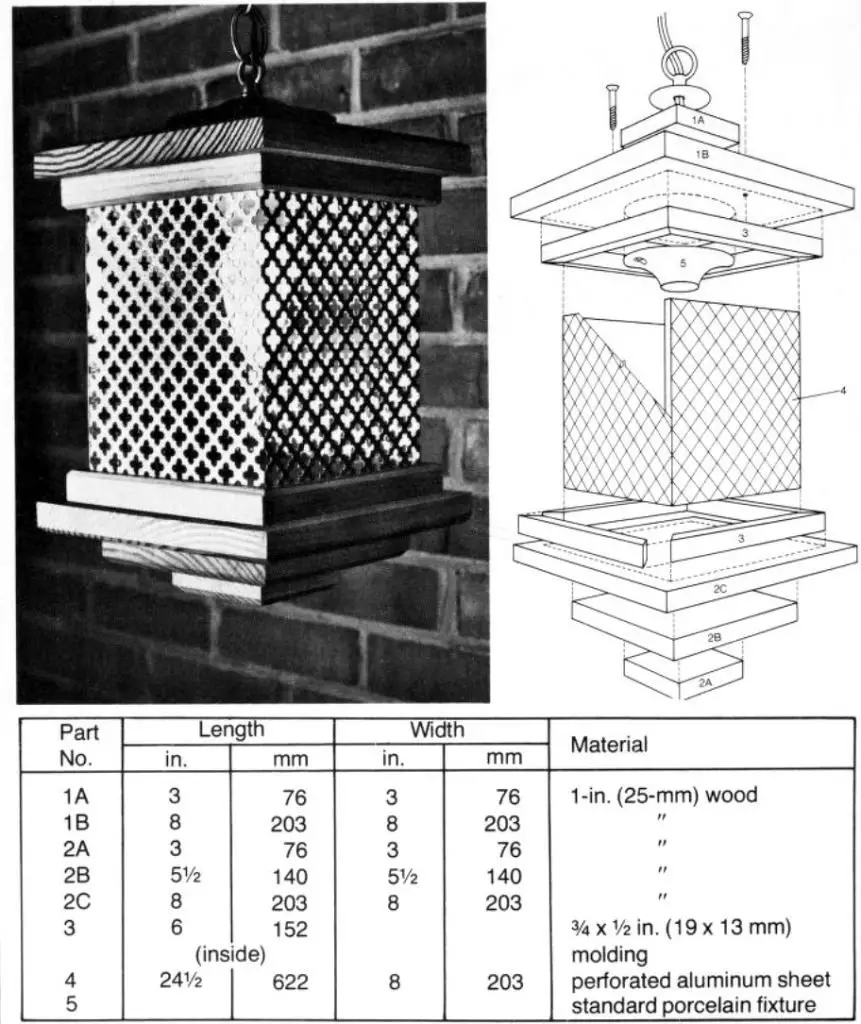

This beautiful lamp can be made from a few simple materials.

Assemble the perforated sheet with pop rivets.

Change the bulb by removing the two #8 by 1 1/4 inch flat head wood screws shown at the top of the assembly.

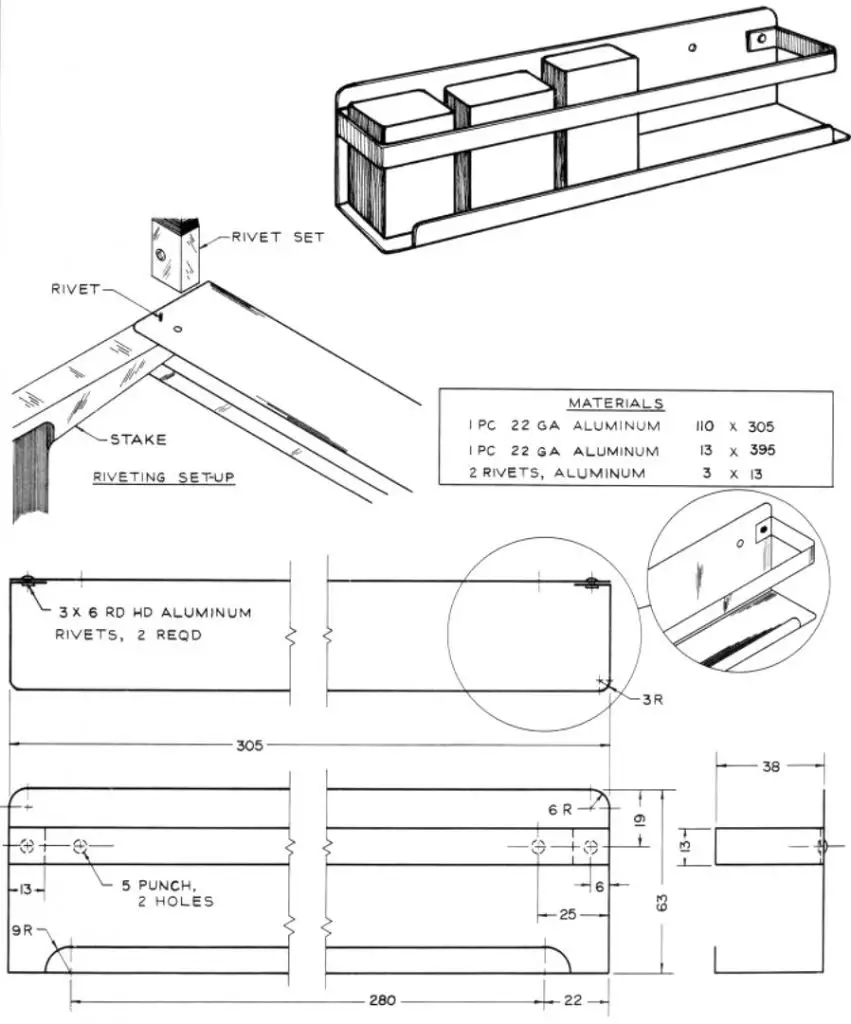

A handy kitchen accessory to hold all the small cans and jars of spices.

Several of these can be mounted on the inside of a kitchen/cabinet door.

All dimensions are in millimeters.

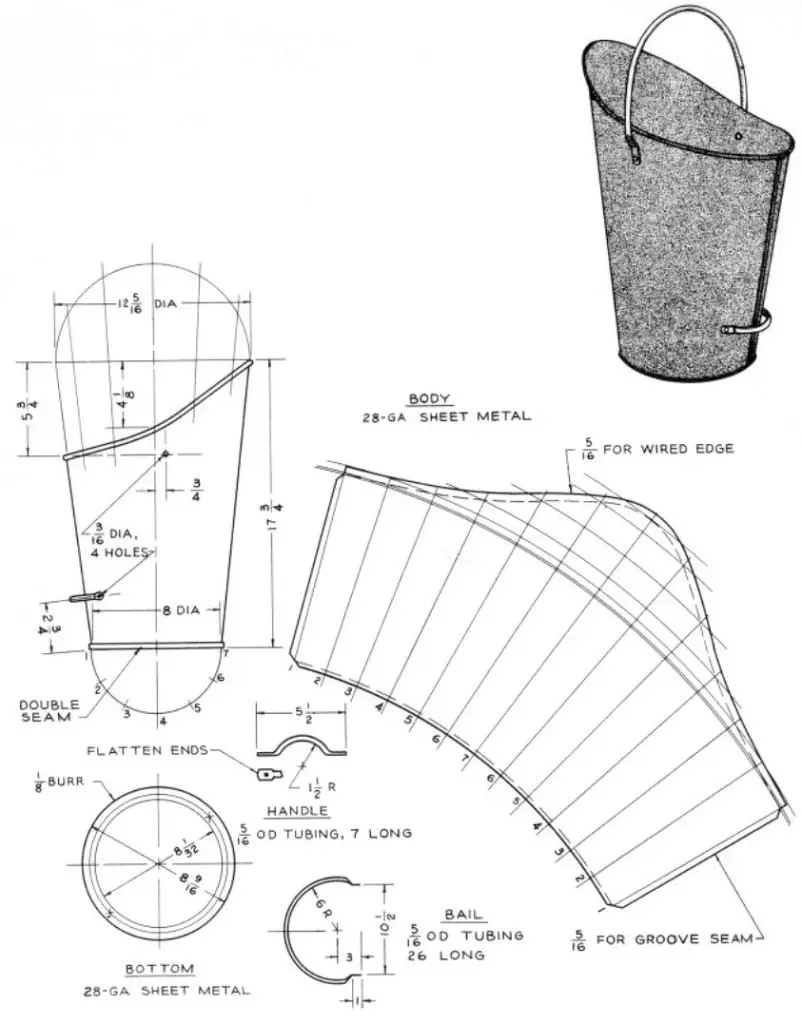

This is a very useful item for a patio or around a fireplace.

It is great for holding charcoal.

This useful mailbox will give you practice in laying out, cutting, forming, and assembling sheet metal.

The project can be finished with colored enamel.

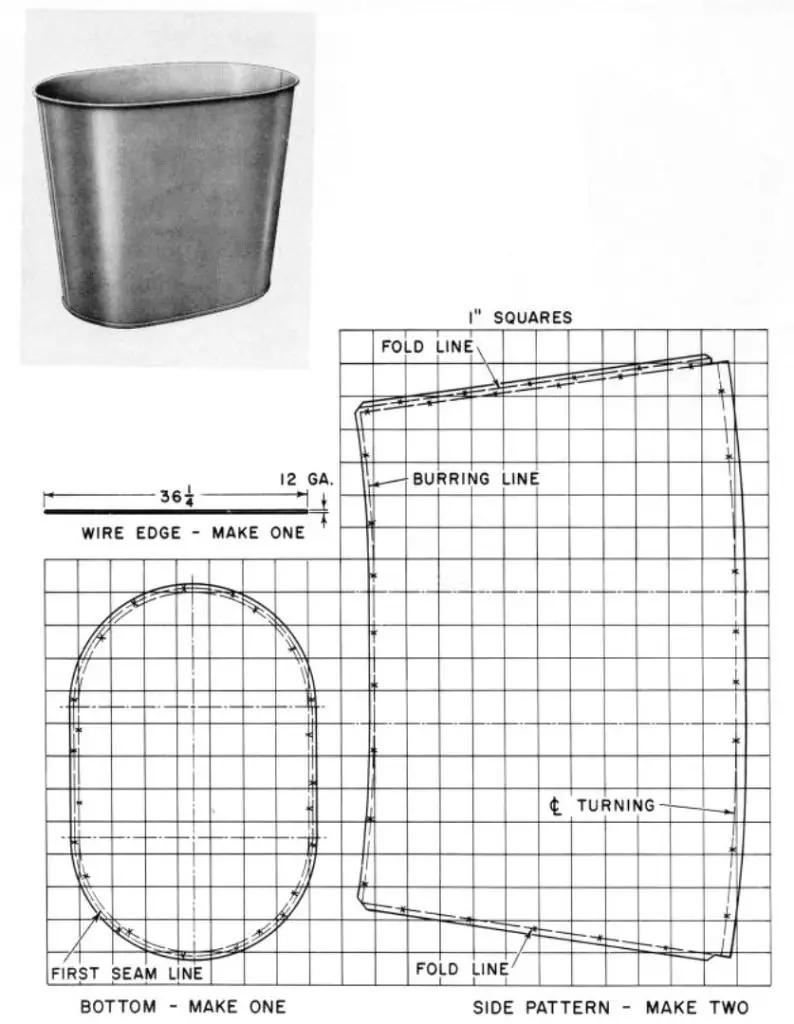

A practical waste basket container that you can finish by painting.

Art Metal and Jewelry Project Ideas

These are smaller/more artistic projects:

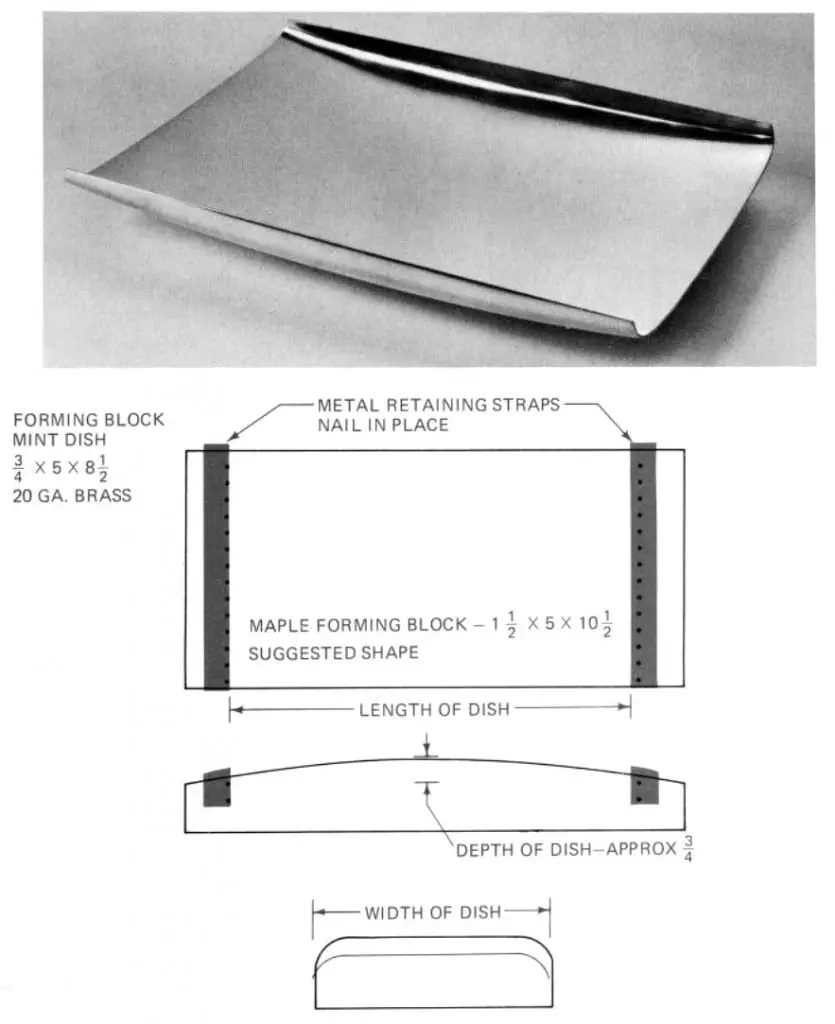

Here is a simple yet elegant metal candy dish.

The wooden form is shown in the drawing, but other forms can be made for other shapes.

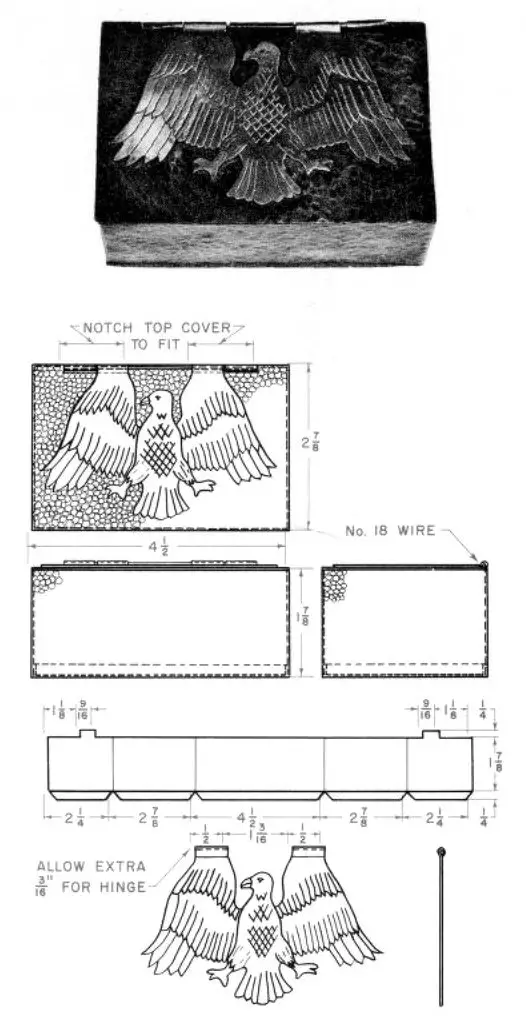

This decorative copper box has a chased design on the cover.

The inside of the box can be covered with flocking.

The bottom can be finished by gluing a piece of walnut to it.

The box can be used for storing jewelry or other small items.

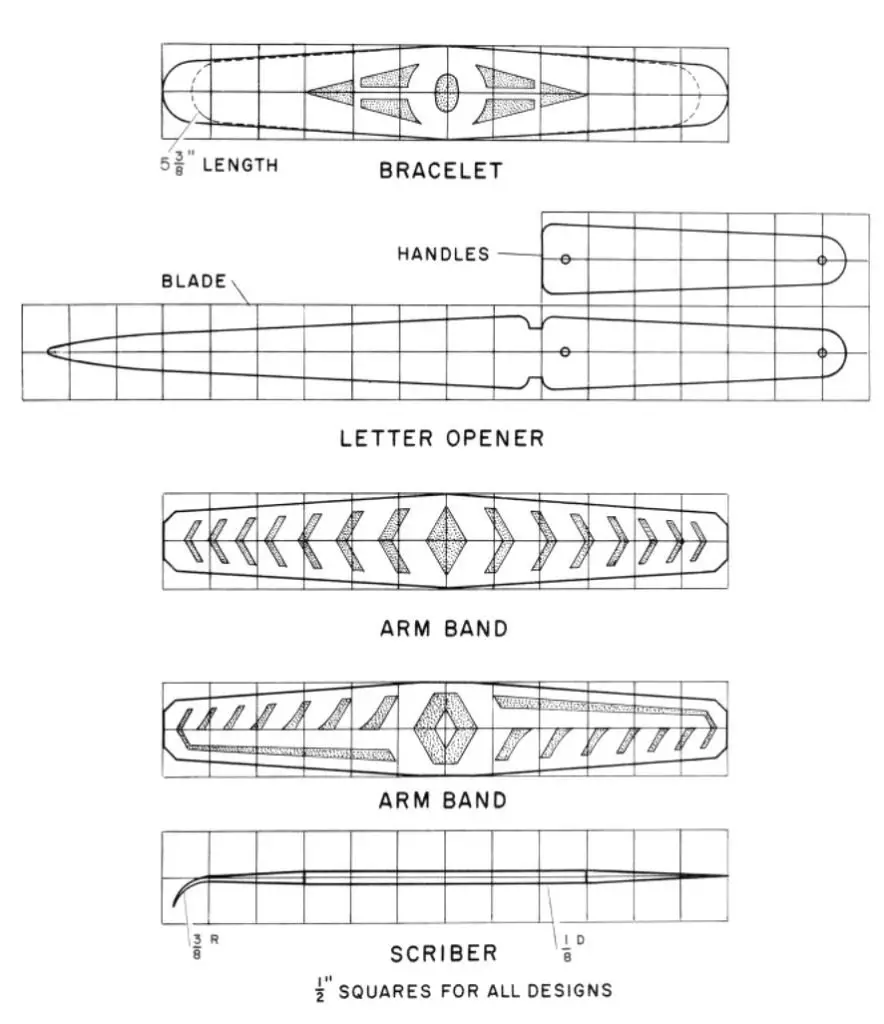

Three of these give practice in art metal.

The other gives practice in bench metal or beginning machine shop.

They include many steps in metalwork.

Machine Shop, Foundry, Forging and Heat Treating Project Ideas

These are projects which will require more advanced processing such as forging and heat treating:

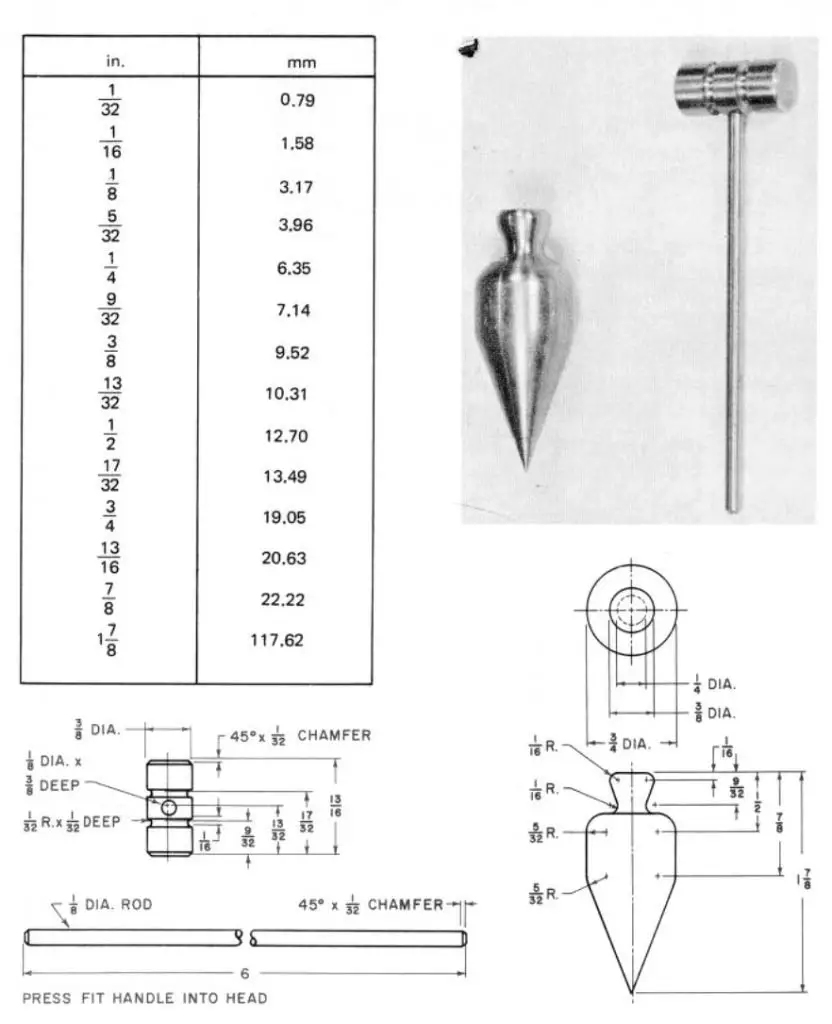

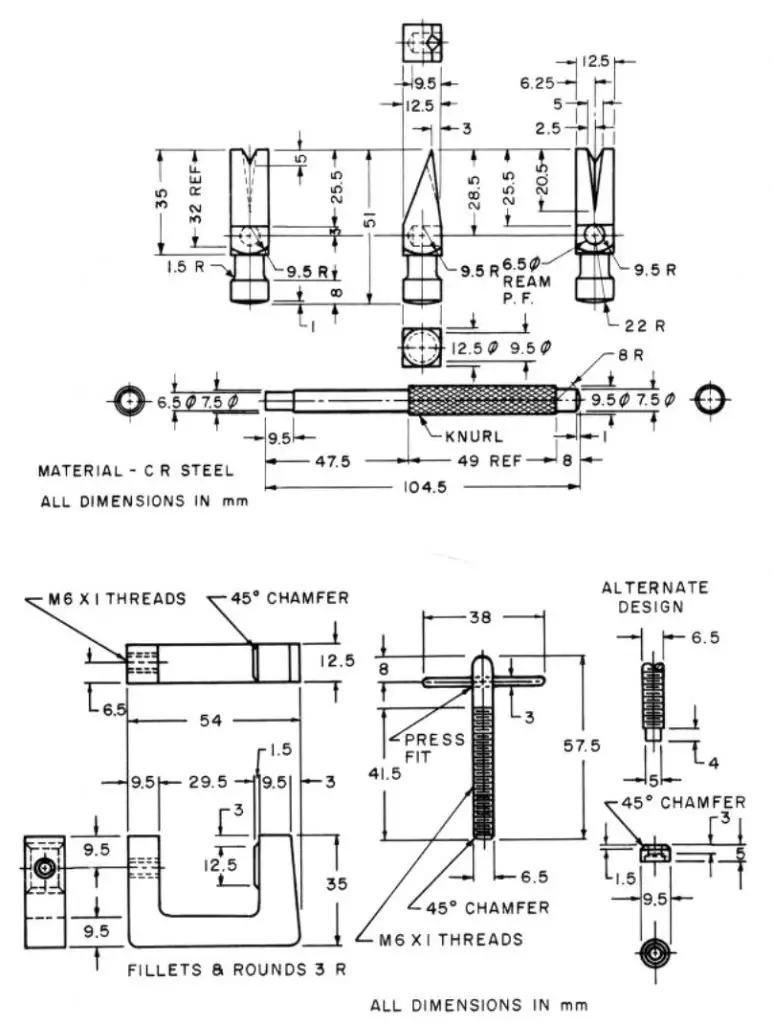

This brass tack hammer and plumb bob are two examples of the miniature tools that can be made in machine shop and used for hobby work or as souvenirs.

The hammer handle can be knurled to provide a better grip.

Any tool can be made to a smaller or larger scale.

A metric equivalent chart is given for reference.

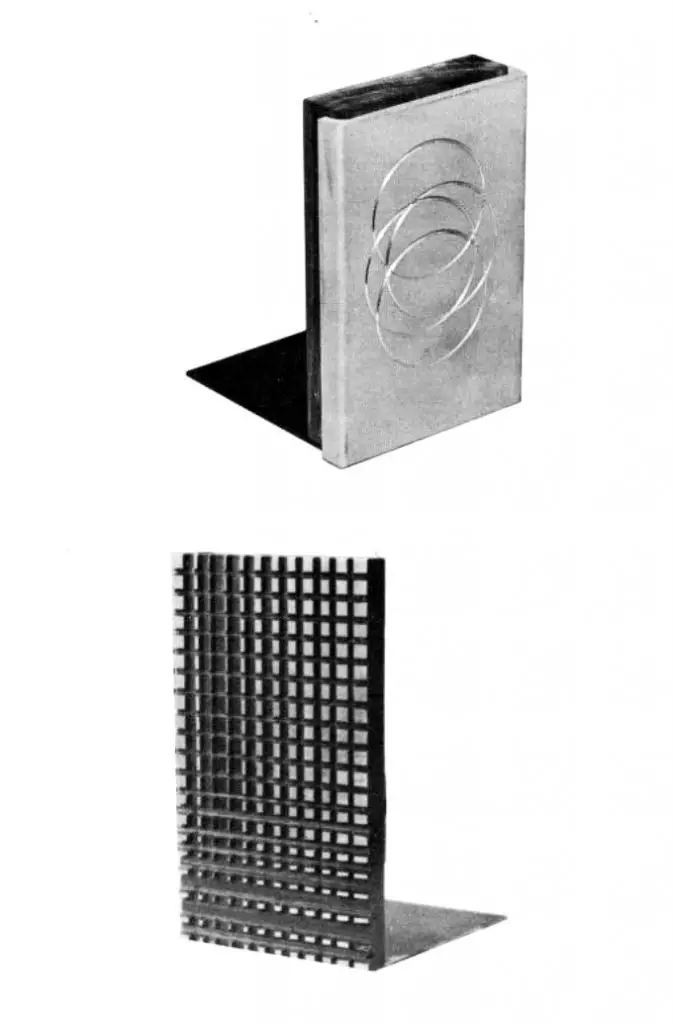

Here are two interesting machine-shop projects.

One bookend is made from shallow aluminum channel, backed with contrasting walnut.

The decorations are made with a circle cutter or fly cutter.

The other piece is made of mild steel.

A shaper was used to create the striking cross-textured effect.

Both pieces measure 3 by 3 1/2 inches (76 by 89 mm).

They are screwed in place.

Try your own ideas for decorative bookends.

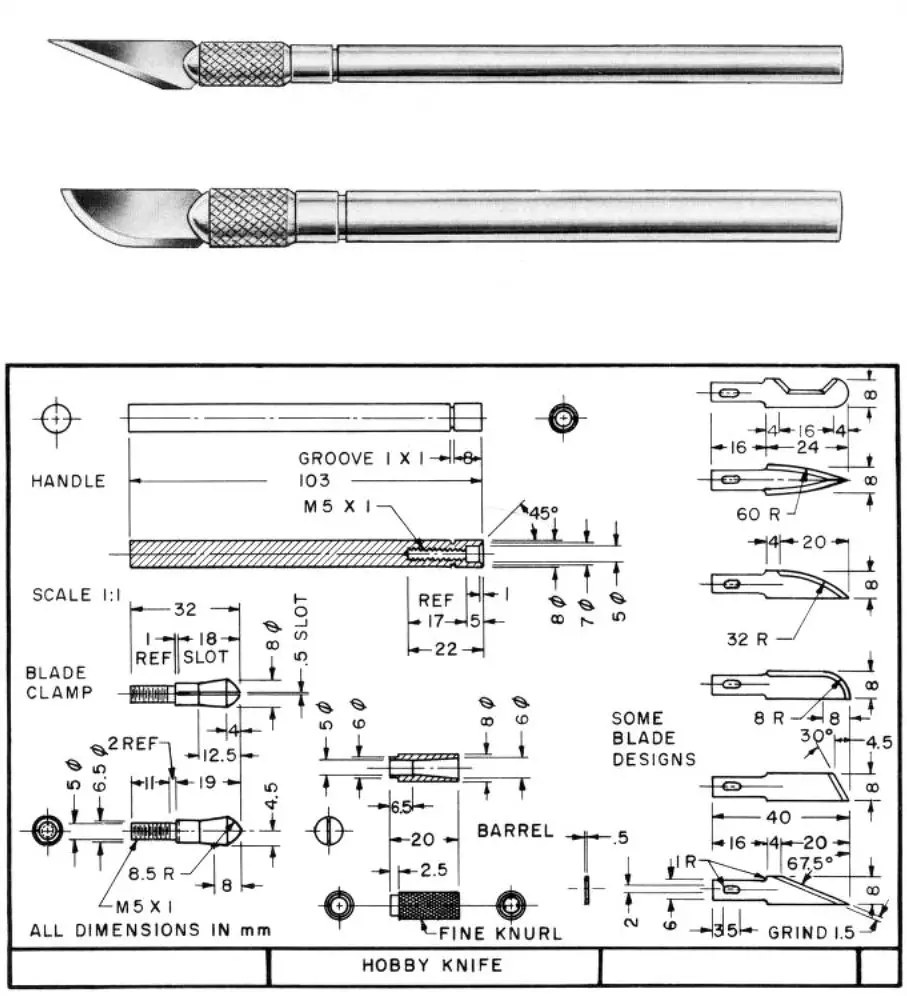

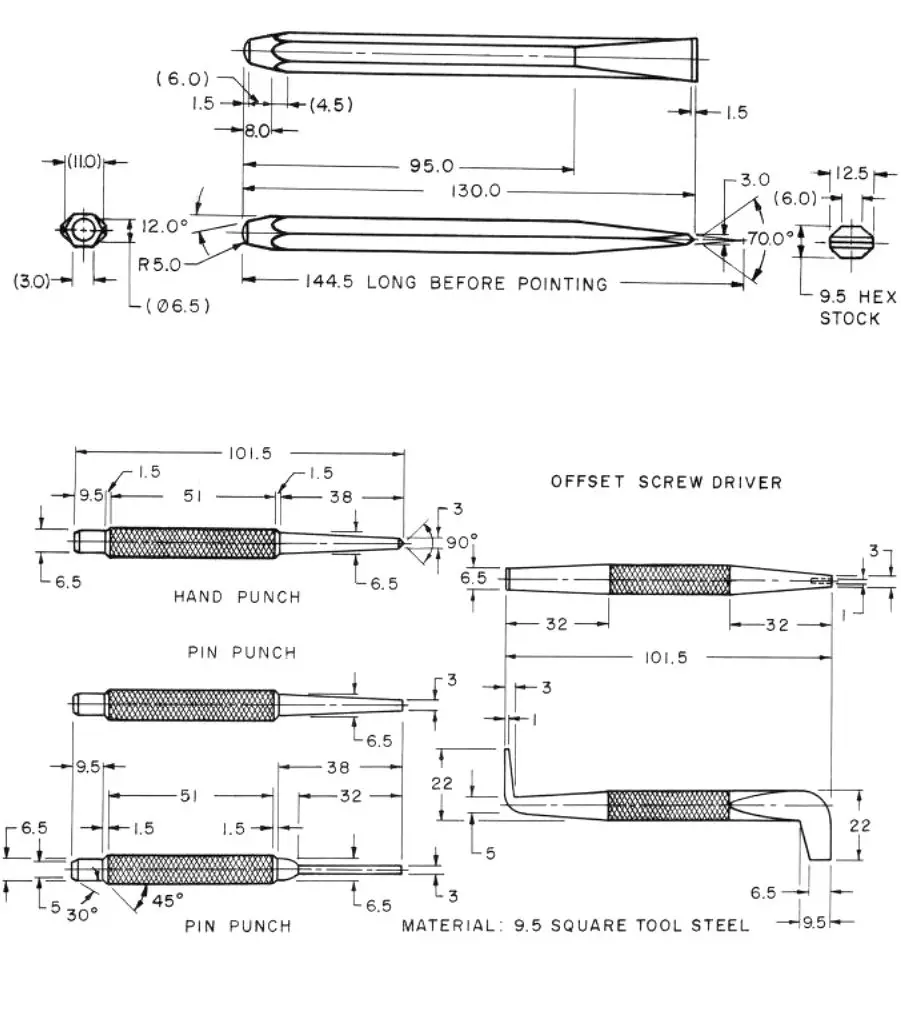

A good machine shop and heat-treating project.

The blades must be shaped, heat-treated, and ground.

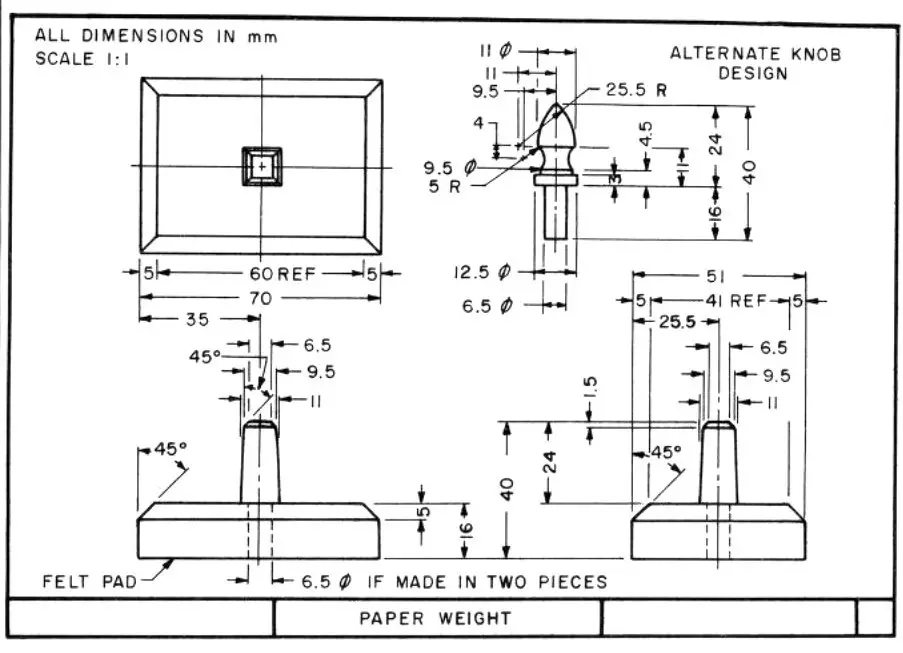

This project will give you experience in casting (foundry) and machine shop.

Here are two small machine shop projects. The heads of the tack hammer can made of cast aluminum.

These tools will be a good addition to your tool box.

Producing them will give you experience in forging and heat treating.

Other Ideas

None of these ideas are piquing your interest?

Here are some videos of metal project ideas which could also inspire your creativity.

100 DIY Project Ideas From Metal:

80 Metal Furniture Ideas:

Still nothing?

Come up with your own metal shop project idea by looking around your life for problems which need to be solved or tasks which need to be done.

Is there a metal object which could assist you?

Start planning and designing, maybe you’ll come up with a new invention!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Forstner Bit RPM Speed Guide

Forstner bits are high-quality cutting tools that are used for making precise, flat-bottomed holes in wood and other materials. The speed at which you should use a Forstner bit depends on several...

How Mechanical Pendulum Clocks Work

Here's a detailed explanation of how mechanical pendulum clocks work. The Basics Clockworks are made up of a collection of gears (called wheels in clock parlance) that convert the...

- Skip to main content

- Skip to primary sidebar

DIY Projects by Big DIY Ideas

DIY Ideas for Making Money

Hello, DIYers!

Crafting with metal can seem a bit intimidating at first, but there is SO MUCH that you can make! The upcycle projects are pretty much limitless with a little bit of creativity. Get artistic and crafty or make something practical for your home. Metal projects and art can also be incredibly profitable if you were considering selling your DIY projects on Etsy or somewhere similar! However you feel comfortable getting started is fine! And here are some ideas and inspiration to get you in the mood for metal crafting!

Happy creating!

Welding for Beginners

Is welding a part of your metal crafting journey? Check this out!

Found Welding Info Center

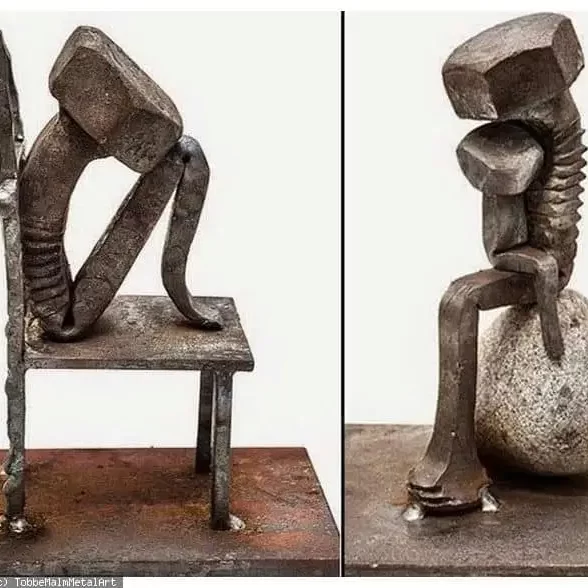

Metal Scorpion

How amazing is this?!

Found Tom Allmon

Simple Etched Metal

Found The Creative Cottage

Flower Art

How ridiculously adorable is this?! Water spickets make for the perfect flowers, barbed wire for the stem, and a scrap metal pocket!

Found Pinterest

Hand Crafted Metal Wall Hooks

Wall hooks can always come in handy!

Found Instructables

Silver Soldering

This silver soldering tutorial helps you to make a motorcycle and other creations!

Little Snail

Metal crafting doesn’t get any easier than these little snails!

Metal Firewood Rack

Hold your cut firewood in a rack made by you!

Metal Bumble Bee

How adorable are these?!

Found Reddit

Copper Rose

This is insanely gorgeous!

Metal Fidget Spinner

Make your own, custom fidget spinner!

Found YouTube

Metal Key Holder

Hold your keys with a metal crafting project you did yourself!

Dinosaur Metal Craft

How adorable is this!?

Found Permies

Metal Christmas Trees

Each tree is unique!

Metal Leaves

These are lovely to stand alone or use as a part of an art project!

Sheet Metal Bending

This is a great tutorial for bending sheet metal!

Found Minifaber

Metal Ring

Check this out!

Found Instructables

How cute is this owl?!

Found Dakr3n_metal_crea

Sheet Metal Fireplace

Perfect for a backyard fire!

Solder Brass and Copper

This is everything you need to know for the basics of soldering brass and copper!

Found Industrial Metal Supply

Metal Can Origami

Have a lot of aluminum laying around from canned beverages? This is a great way to upcycle them!

DIY Metal Lampshade

This is so neat! Give it a try!

Found MJ Designs

Metal Painted Bug

Made of nails and bolts, this metal bug is adorable! You may choose to paint it or not!

Found Pinterest

Metal Key Bowl

This is so cool! And easy to make! Give it a try!

Found DIY Home Décor Guide

Sheet Metal Front Man Mask

Were you all about Squid Game? Maybe consider this for Halloween!

Metal Table

This is SO COOL! This project uses an old auger, a large gear and a wrapped chain to make this awesome, metal table!

Found Lammy

Steel Table Legs

Make a table and add these lovely and trendy steel table legs!

Found YouTube

Rocking Dude

Found David McGrath

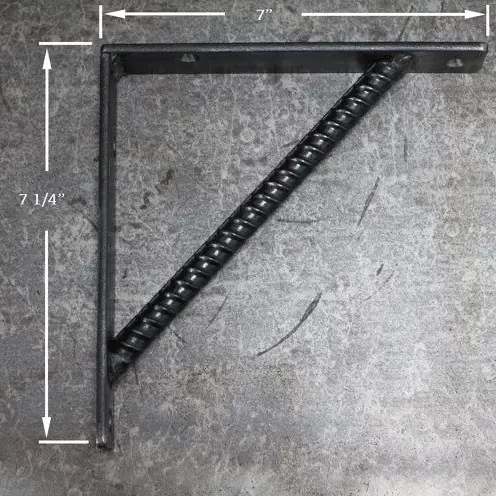

Faux Aged Metal Brackets

Want your metal aged fast? Try this!

Industrial Shelves on a Budget

Industrial shelves can get so pricey! Why not make your own?

Found Renovated Faith

You May Also Enjoy…

31 Awesome Punch Needle Embroidery Projects

33 Beautiful DIY Feature Mirrors for Your Home

30 Must Try Woodworking Projects For Beginners!

31 Fabulous and Unique Shelves That You Can Make Yourself

30 DIY Fire Pits for Your Outdoor Oasis

31 Outdoor Furniture Projects

13 Practical Machining Projects for Students and Beginners

When I went to school for machining, I worked on a bunch of different projects that taught me the basics of the trade. From keychains to hammers, I did all the typical stuff.

One thing that I found out after the program, though, is that the chess pieces and keychains were quickly lost, but the tools I made are still in my box and used daily 12 years later. When you’re able to use great tools that you made yourself, it adds a definite element of pride to your work.

I’ve compiled a list of practical projects for up-and-coming machinists to hone their skills. They’re not decorative pieces, like turner’s cubes or random widgets. All of them are tools that you’ll likely use every week, if not every day.

For each one, I’ll go over the BOM, the equipment needed, and give you the drawings. Most of them are ones that I’ve made myself, and some of them are the upgraded versions to make them more useful as tools.

Table of Contents

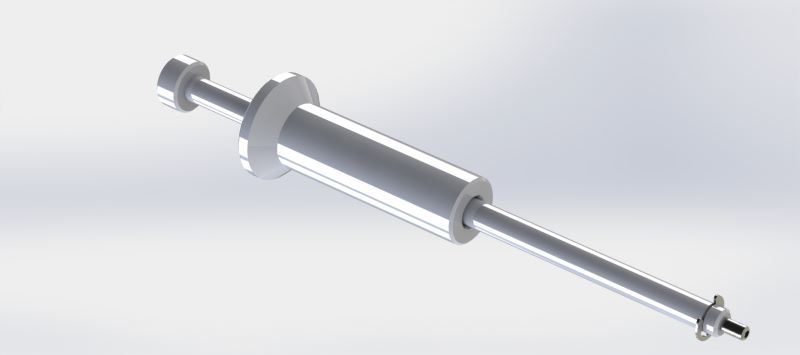

Slide Hammer

If you’re working with pull dowels, which are a common fixturing element in many shops, then you’ll need one of these in your toolbox.

This is a nice and simple project that is great for absolute beginners. It doesn’t take too long to do, but it will give an opportunity to learn the fundamentals of turning.

This tool is exactly what you’ll need to pull 1/2 dowels from tight holes. To make it last longer, there’s a replaceable 1/4-20 set screw that’s used to hold on to the dowel. Mine’s in perfect shape still, aside from a few scuffs and dings, and I use it daily.

Personally, I like making tools out of stainless where possible, since they’ll last longer than I will. If the budget is tight or selection is limited, though, you can just as easily use steel or aluminum.

Here’s the BOM:

- Ø 2.0″ x 4-5/8″ long stainless (1 pc)

- Ø 0.50″ x 12-1/8″ long stainless (1 pc)

- Ø 1.0″ x 5/8″ long stainless (1 pc)

- 1/2″ E-clip (1 pc)

- 1/2-13 x 1″ long socket head set screw (1 pc)

And here are the drawings:

Machinist’s Hammer

I don’t know a single machinist that hasn’t made one of these.

The actual design varies by school, but they all look essentially the same.

I modified the design of the one I made over a decade ago based on things I wasn’t crazy about. For example, this one has flats on the handle. I always found it annoying that with a fully round handle, you couldn’t keep the hammer straight by feel – you had to look at it. Now that’s fixed.

To mill the flats, I wait until the hammer is finished and assembled. Then I stick it in a milling vise, dial in the hammer head, and mill one side and add the chamfer. Then I flip it, using the underside as a register for the second flat and chamfer.

I also drilled a hole in the bottom of the handle. I use it to fit allen keys, so I can use the hammer as a small cheater bar. It’s saved my knuckles a few times. You can make it shallower or deeper to get a hammer balance that suits you.

I adjusted the balance between the head and the handle to something I find more comfortable for the light tapping that this type of hammer is more typically used for. Some people like to have one end brass and one end aluminum, although I prefer two brass inserts – that’s the end I always use anyway. And, since brass is significantly heavier than aluminum, I find that it feels better.

This is a good project to get familiar with taper cutting on the lathe. For cutting the self-holding tapers for the inserts, I usually lock the compound rest at the angle and use a single setup to cut both the male and female tapers. If you get a smooth surface, that taper will hold forever. Either the taper attachment or the offset tailstock method can be used for the handle.

- Ø 1.25″ x 10.125″ long steel (1 pc)

- Ø 1.25″ x 2.125″ long steel (1 pc)

- Ø 1.50″ x 1.25″ long steel (2 pcs)

Here are the drawings:

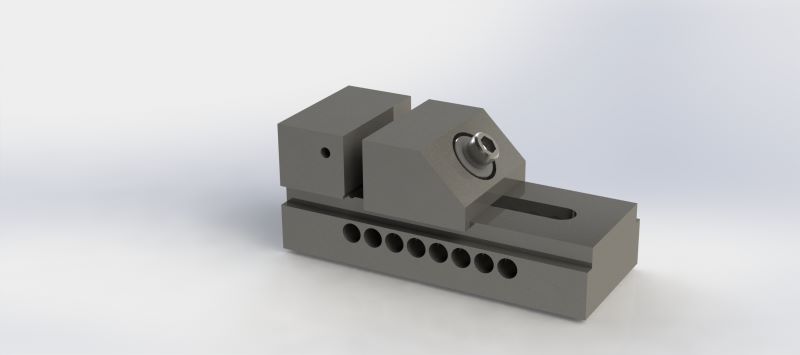

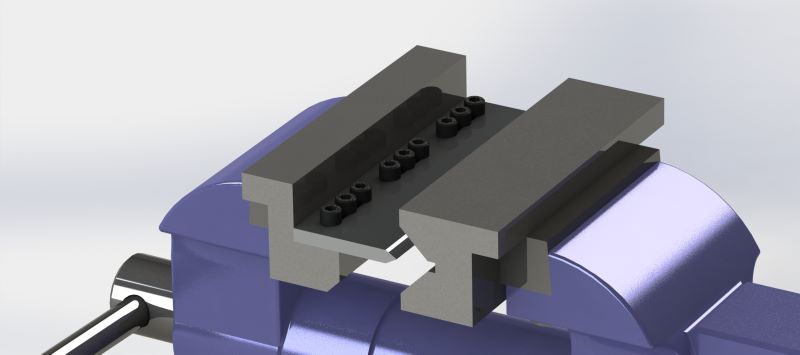

Toolmaker’s Vise

This one is good for more advanced students. Traditionally, this has been a project for tool and die makers. The skills that are targeted are job planning with grind allowance and order of operations. Machines used are mills, heat treating ovens, grinders, and lathes.

The vise is definitely an involved project, but one that’s well made is a work of art. For an extra challenge, try CNC engraving the name of the student in the vise body prior to heat treat and try to make the letters appear even after grinding.

I strongly prefer to make this out of A2, since it’s stable and air-quenched, which means that the vise will be nice and clean. Some schools choose to use 4140, but it can be pretty demotivating when a student rough machines the part, and then has to do it again because it cracked in the oil quench.

- 2.5″ x 2.5″ x 6.125″ A2 tool steel (1 pc)

- 2.5″ x 2.5″ x 1.4375″ A2 tool steel (1 pc)

- Ø 1″.0 x 1.0625″ long 4140 HTSR (1 pc)

- 3/8-16 x 2.25 SHCS (1 pc)

- CL-2-SW Spherical Washer (1 pc)

I went light on this drawing. Lots of schools have it slathered with GD&T. Personally, I love it, since it helps ensure a working part at the end of the day. If you want to add the GD&T requirements on this drawing, you’ll usually find this part covered in perpendicularity and parallelism callouts of 0.0003″everywhere. Use your discretion with what your students can reasonably measure.

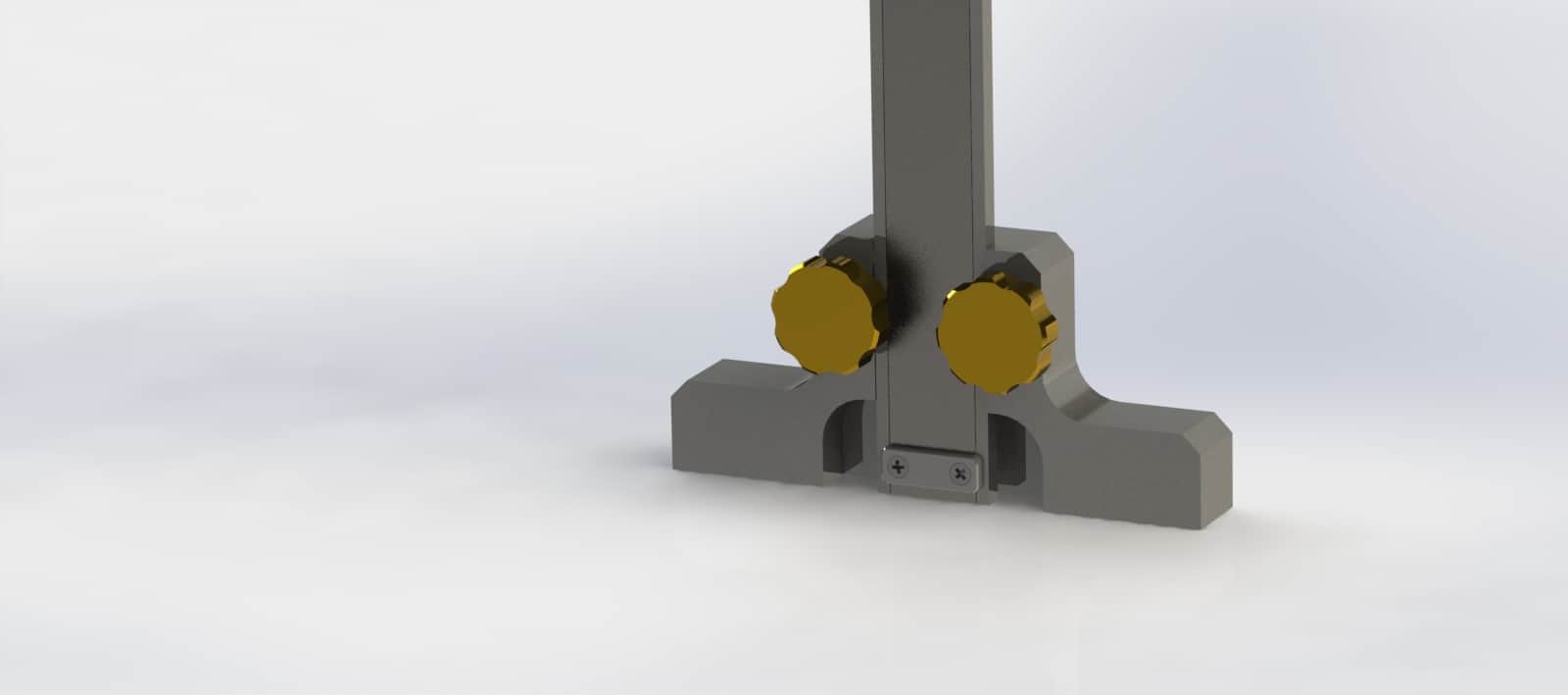

Micrometer Stand

This one is actually really uncommon to see as a school project, but it’s definitely a handy tool to have. Whether you’re checking against the standard or trying to measure an awkward little part to 0.0002″, a mic stand is worth having around.

What I like about this project is that it’s actually pretty forgiving, but it looks really nice if you can get good surface finish. Plus I always like how the combination of brass and steel look.

Overall this project will help the beginner learn basic things like slotting on a mill and threading on a lathe. There are lots of non-critical features that are purely cosmetic, but there are a handful that just need to be done right for this thing to work smoothly.

- 1.5″ x 2.5″ x 4.625″ steel (1 pc)

- 0.75″ x 0.75″ x 2.0″ brass (1 pc)

- Ø 0.625″ x 1.875″ long brass (1 pc)

- Ø 1.5″ x 0.75″ long brass (1 pc)

- 1/4-20 x 1″ long set screw (1 pc)

I use the 1/4″ set screw just to simplify the project to allow for tapping the holes. If you tighten up that set screw with a bit of threadlocker it’ll hold more than enough.

Dial Indicator Depth Attachment

A great attachment for making a simple dial indicator even more useful. This is a really good way of checking the depth of shallow steps or seeing how deep a damaged area on a part is.

This is the simpler of the two depth attachments. It’s a very basic project to get familiar with mills and lathes. You’ll get to do some threading on the lathe and learn how to make a clean undercut. You can also use it as an opportunity to grind some HSS cutting tools for threading and undercutting.

The milling portion is very simple. Even the perpendicularity of the hole to the bottom surface of the base isn’t critical enough to really affect the functionality of this tool.

- 1″ x 1″ x 2.125″ mild steel flat bar (1 pc)

- Ø 0.625″ x 0.625″ long brass bar stock (1 pc)

- Dial indicator (1 pc)

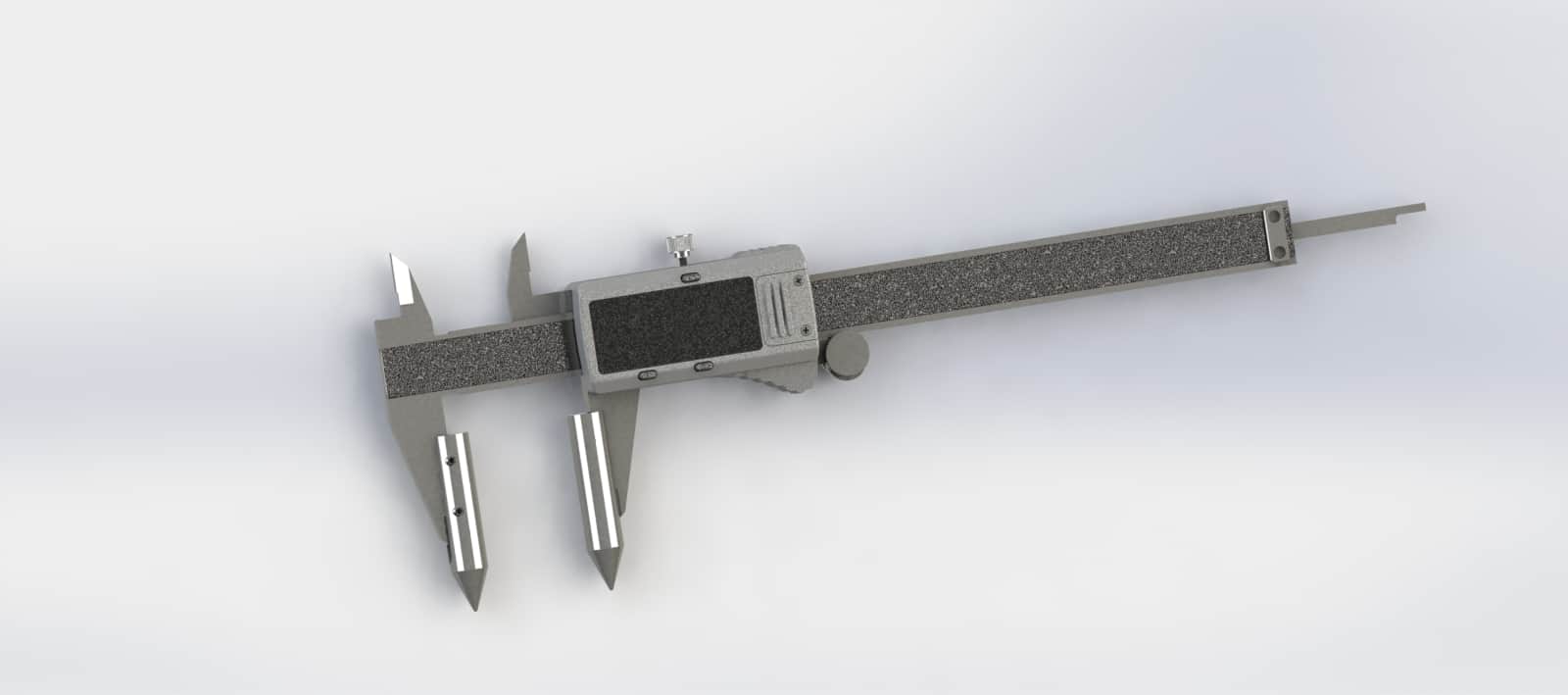

Caliper Depth Attachment

A simple, handly little attachment for your calipers, this will fit Mitutoyo 6 and 8 inch models. It’ll also fit most other brands, but I ain’t making any promises.

This project gives you a bit of experience on both a mill and a lathe. Specific skills to hone are how to maintain perpendicularity, turning and threading small parts, and how to do a bolt circle (although it’s just cosmetic).

What’s nice about this project is that it doesn’t use a lot of material, and it’s 100% home made – no hardware required.

The project could also be modified to allow for some practice with heat treating and grinding if you want a hardened steel body. You could also learn to polish the brass. Do whatever makes you happy.

Here’s the bill of materials:

- 1.5″ x 0.5″ x 3.125″ mild steel flat bar (1 pc)

- Ø 5/8″ x .625″ long brass round bar (2 pcs)

- Calipers (1 pc)

If you want to harden it and grind it, replace the mild steel with 4140 or A2.

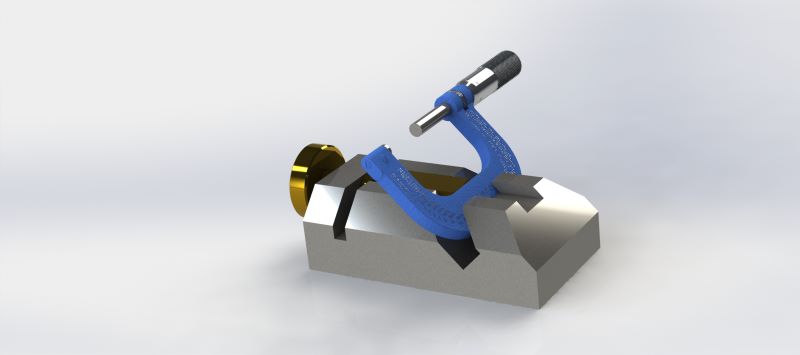

Caliper Center Distance Attachment

This is a really simple little job, but it does require precision. What’s kind of cool about this is that for marking student projects, you can just have a plate drilled with holes in known locations, then compare what you get on the calipers.

Since there’s so little material needed, this is a nice and cheap project for an entire classroom to work on. The bottom of the slot is aligned with the center of the taper, so the idea is that you should be able to keep your calipers set as they are instead of needing to rezero for basic measurements.

This is a really handy attachment for measuring things like bolt circles. The only downside is that the top of the hole needs to be in good condition.

Overall, you get to try out working with a collet on the lathe (ideally) and being able to very accurately aligning and cutting a slot on a shaft. You’ll also get to try tapping some really small 4-40 holes.

- Ø 0.375″ x 1.875″ long TGP stainless round stock (2 pcs)

- 4-40 x 0.125″ long UNC half-dog point set screws (4 pcs)

And here’s the drawing:

These are staple tools that you’ll seriously be using all the time.

This project will hone the skills of job planning, milling, heat treating, and grinding. If you choose to make the clamps using a band saw, there’s also the opportunity to practice layouts and some bench work.

If you’re teaching a course on machining, it might be cool to start on the clamps early on, and then later on make the vee blocks as a separate project. That way the students can be challenged at their skill level for both aspects of the project.

- 2″ x 2″ x 2″ 4140 steel (x2)

- 2.5″ x 2.5″ x 0.5″ mild steel (x2)

- 1/4-20 x 2″ long hex bolt (x2) – make sure to machine a half dog point on the tip so it doesn’t get stuck in the clamp

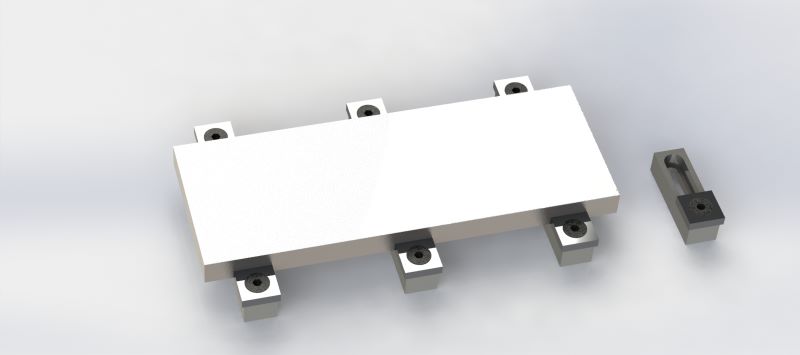

Edge Clamps

This is a handy little set of clamps to have, especially when you’re working with longer pieces of flat bar or plates.

If you can keep the 1″ thickness accurate then you can also use 123 blocks to support your workpiece.

Here’s how they work: When you loosen them and push them against the workpiece, the jaw is moved off the countersunk hole centerline. When you tighten them, the flat head screw tries to force the jaw back into alignment to it can properly seat. The result is clamping force.

I’d recommend making them in sets of 6. This can be a great little CNC job, since there are a couple of them to run.

This project is good for people wanting to learn things like slotting on a mill, drilling, tapping and countersinking. The jaws and body are heat treated and ground.

This also exposes you to more creative ways of workholding; not everything needs to be done in a milling vise. You can flip them around to accommodate different operations and parts.

If you want to have some clearance under the part for drilling through, try putting the clamps on a 45-degree angle so only a small part of the base is supporting the part. For thicker workpieces, they can be used very similarly to a standard toe clamp.

For more bite, you can tilt the jaws at an angle in a vise and use an endmill to machine teeth on one side.

Ultimately, aside from being good practice for a few milling and grinding operations, having these clamps can be a good way of teaching problem solving when it comes to workholding.

- 1.25″ x 1.25″ x 4.125″ 4140 steel (x1 per clamp)

- 1.5″ x 1.5″ x 0.5″ 4140 steel (x1 per clamp)

- 1/2″ UNC x 1″ long flat head socket cap screw (x1 per clamp)

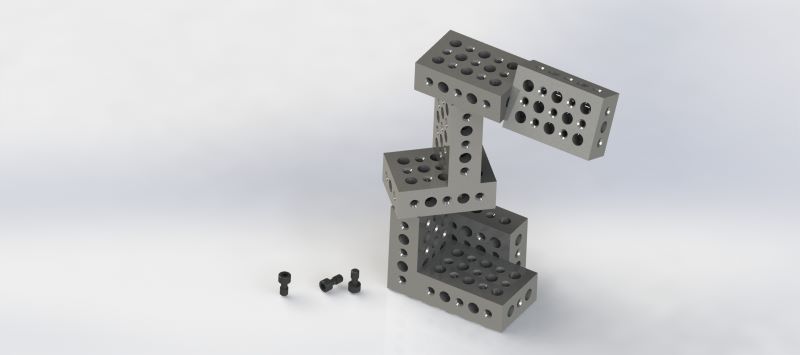

123 SuperBlocks

What kind of dark sorcery is this, you ask?

This isn’t the trick of CAD magic. You really can do this with 123 blocks.

By alternating a pattern of counterbored threaded holes, you can use a socket head cap screw with a large undercut to bolt these 123 blocks together. The best thing about it is that the bolt heads are competely inside the blocks, so there is zero interference as you’re making a creative setup.

Now, keep in mind that these bolts aren’t terribly strong. They won’t be competing with a hold-down clamp with a 1/2 stud and handling heavy machining. But they’re really handy when you want to use these block in a machine setup and don’t want them to move between cycles. Or if you need to stabilize a part in a way that gravity doesn’t agree with. Or if you need a creative inspection fixture. You get the idea.

Fair warning: these take a little longer to make than the more traditional (and less useful) 123 blocks. But it’s time well spent. They’ll be the envy of everyone in the shop and they’re just really cool. That’s why I call them 123 SuperBlocks.

Most people make the sets of 123 blocks match ground in pairs. I’d really recommend making at least a set of 4 of this kind. I’d even do 6 if possible. Since they’re so stackable, the more you have the better.

Personally I like to use A2 for jobs like this since it’s an air quench and very stable. I used O1 when I was in school and it worked OK but not great. It’s more prone to cracking, especially around sharp corners and threads, so a few guys had to start over. That said, it’ll work if that’s all you can afford.

- 1″ x 2″ x 3″ A2 steel, oversized 0.035″ (1 pc per block)

- 1/4-20 x 1/2″ socket head cap screw (2 pcs per block)

You might also want to make sure that you’re using an oversized tap (H11) instead of a more common H3 or H5, especially if you’re using O1. It tends to shrink and warp a little bit when heat treated, so you might not be able to use the threads otherwise.

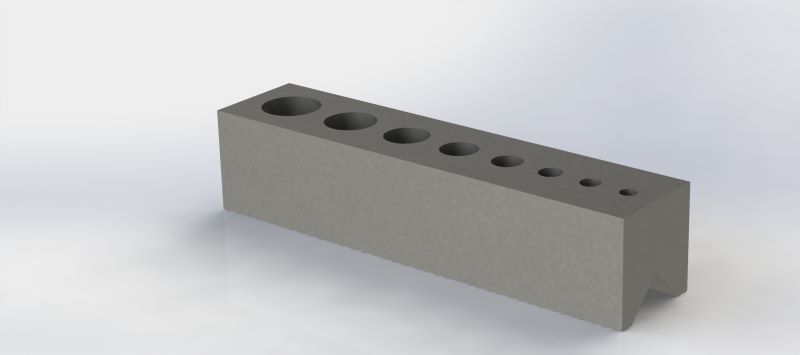

This is a dead easy project for something that’s actually pretty useful.

This is a tool that can help you keep your tap straight over a plate or a shaft. It has holes drilled to accommodate taps from #6 to 1/2″. The drawings specify mild steel, but you can use tool steel and heat treat it if you want it to last longer. If that’s the case, 4140 will work perfectly fine.

Even though this is a simple milling job, it’s a good opportunity to practice precision. The holes need to be aligned to the vee on the bottom. This can be an excellent exercise demonstrating how to precisely locate a vee using a pin and a depth mic to measure. You can use this to check both how it aligns to the outside edges as well as check the depth.

This is a good job for practicing how to align a vise. If you’re doing it on a CNC, there are also a bunch of drills to load up, so there’s some repetitive practice. The really nice thing about this is that it’s a handy tool and practical project that needs hardly any material.

- 1″ x 1″ x 4.125″ steel (1 pc)

Yep. Pretty basic.

Here’s the drawing:

Screw Jacks

This one is another classic. I made mine in a CNC course in college. One thing I didn’t like about the set I made, though, is that they were really limited on the amount of travel you could get out of them.

That’s why for this set, I included the drawings for the riser blocks. These should give you a really good amount of reach to make these worth keeping in your toolbox.

If you program them on the CNC, then you can get a really nice set. Technically the bare minimum that would be useful is 3 units, but I’d recommend making more than that. It seems that I’m always using about 6 at a time.

If you make a set of 6, make two riser blocks for each screw jack. If you run these on a CNC lathe, you should be able to do each piece in one operation. The only exception is that you might want to flip the screw, so it has a nice, smooth finish everywhere.

This is a good project for learning CNC lathes, and it also gives a great opportunity to wrap your head around clearances and unilateral tolerances. You can feel what the difference is between a slip fit of 0.005″ and 0.015″.

Here’s the BOM to make a set of 6 (2 risers, 1 body, 1 screw per unit):

- Ø 1.0″ x 8″ long 4140 HTSR (x1)

- Ø 2.0″ x 40″ long 4140 HTSR (x1)

I put those in as bar lengths with a little extra to grip on to near the end of the run. This is because usually this is a CNC job, so cutting them all up into individual pieces will just end up wasting material and taking longer.

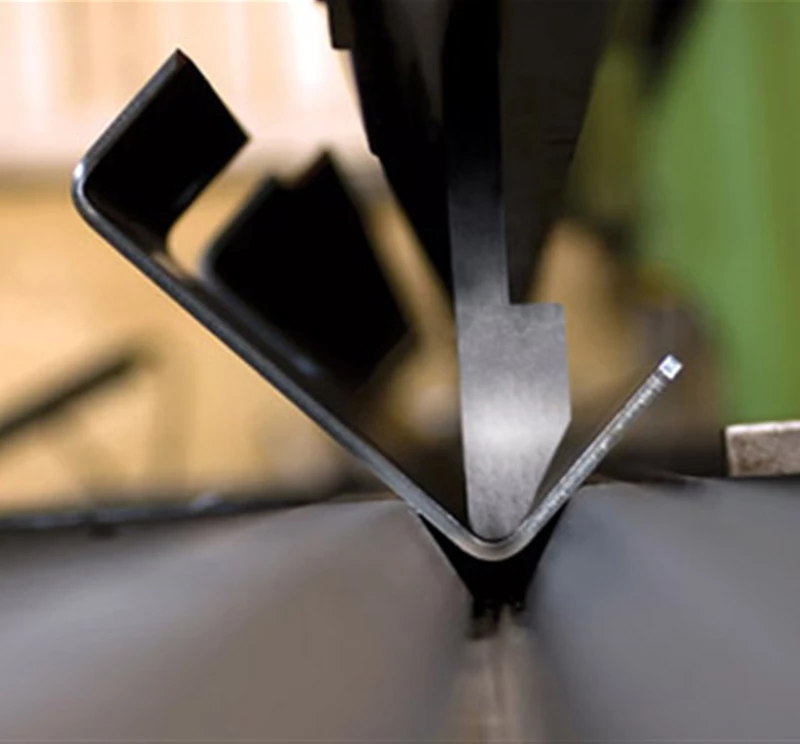

This is a cool project.

Realistically, the most common approach to bending a piece of metal when you don’t have easy access to a proper brake is to shove it in a vise and wail on it with a hammer. This just makes that happen a little more professionally.

It’s got magnets that help it to just snap on to any steel vise. This is a tool that can give you accurate and clean bends in a very basic shop. The die is in three sections, so you can remove and adjust as needed if you’re working on smaller pieces.

This is one that most of your machinist buddies have probably never even seen, so it’s got a pretty high “nifty factor”.

The tool itself is pretty easy to make and mostly just teaches you not to put a workpiece in the milling vise the wrong way. What’s interesting about it though is that it’s a nice, very basic introduction to tool and die. This can be a way of learning some of the fundamental terminology and principles of sheet metal forming.

Since this probably isn’t something that’s going to see a ton of daily use, most guys just make it out of mild steel. If you want something that will last a really long time, make it out of 4140 instead and heat treat it.

- 2″ x 2″ x 6.125″ mild steel (2 pcs)

- 2″ x .25″ x 2.125″ mild steel (3 pcs)

- 8mm x 3mm neodymium magnets (8 pcs)

- 1/4-20 x 1″ long socket head cap screws (9 pcs)

Well, there you have it. 13 machining projects for students and beginners.

There’s definitely nothing wrong with many of the more “trinket” style of projects that are common in many machining programs. You can get very focused in the operations to hone really specific skills.

The nice thing about making tools, though, is that there’s a lot of pride that goes into the workmanship, and the fact that you might very well still have them in your toolbox after ten or twenty years.

There are a whole slew of other tools that can be make by beginners. Here are a few other ideas:

- Dial indicator articulating arm

- Drill point gage

- Edge finder

- Magnetic chip shield

- Center finder

- Live tailstock center

- CNC tool height presetter

- Bushing installation tool set

Are there any projects that you’d add to this list? Add them in the comments below.

If you enjoyed this article and think others could benefit from it too, please consider giving it a share on social media.

Jonathan Maes

I've been working in manufacturing and repair for the past 14 years. My specialty is machining. I've managed a machine shop with multiaxis CNC machines for aerospace and medical prototyping and contract manufacturing. I also have done a lot of welding/fabrication, along with special processes. Now I run a consulting company to help others solve manufacturing problems.

Recent Posts

What is Forge Welding? A Comprehensive Beginner's Guide

Forge welding is essentially the oldest way of joining two pieces of metal together. Some say that it's been around for almost 4,000 years, starting from when people were learning to smelt iron from...

How to Cut Rebar with Simple Tools

I really like using rebar for making all kinds of industrial-looking welding projects. It's also useful for things like reinforcing concrete, surprisingly. There are also a lot of different tools...

Home Metal Shop Club

Here are things you can build, along with shop tips and wisdom from the club's members and other contributors.

Most of these projects are in web page html format. Just click on the picture or link to access the project. Some are in Acrobat pdf format, while others may be downloaded in zip format. Hover your mouse's cursor over a link to determine the file format before clicking.

Quick Change Toolpost for Small Lathes

3-Phase Converters

13 Welding Project Ideas to Build For Home or to Sell

Last Updated on Jul 17 2023

Whether you’re a hobby welder or a professional in the trade, DIY projects can be loads of fun. But it’s even better when you have plans to work from that have been tried and tested, so you know your labor will pay off.

We have a list of 55 projects, both small and large, from simple ones to more challenging ones designed for indoor and outdoor use. Each project has been made at least once, but usually a few times. They come with thorough instructions and photos, and some include videos displaying exactly how to complete them.

The lists are separated between beginner and advanced projects. Have a look through and choose your next item to fabricate.

Recommended: You can click to enlarge the table of contents below to get a complete overview.

13 Welding Project Ideas

Beginner welding projects, 1. corner desk by youtube.

Corner desks are a perfect option to utilize space. I like the stabilizing bars in between the end frames. This makes it super strong while giving it a classy look. Read these instructions to fabricate one for yourself.

Intermediate Welding Projects

2. firewood storage dolly by youtube.

No one likes lugging bucketloads of firewood to their fireplace. Follow the instructions for this project instead. It not only serves as a dolly ; it can double as your indoor wood shelf too.

Advanced Welding Projects

3. stainless steel fireplace screen project by youtube.

Take a look at the instructions for this fireplace screen if you want to make one for yourself. It’s simple, but it has an appealing look and is useful for helping keep your fireplace safe against those unwanted hands getting through.

See also: 20 High School Welding Projects To Try Today (With Videos)

Stools, Benches, and Chairs

4. height adjusting stool by youtube.

My local Pizza Hut has these throughout its store. They are great for adjusting quickly for people of different heights. This is another one of our quick beginner welding projects with clear instructions to follow that turns out exceptional.

5. Stylish Stool by Youtube

Usually, one less leg on a footstool ruins its intent. This time, its strength remains solid while it has a unique look that will stand out in the room. Read through the instructions to fabricate it for yourself.

Tables and Desks

6. coffee table by youtube.

Tables can cost a fortune to buy and can get a hammering if you have kids. This pallet coffee table is inexpensive and will withstand most things thrown at it. Even hot mug marks would only add to its rustic look. Check out the instructions here.

7. Modern Outdoor Table by Youtube

The design of this table is far easier than it looks. If you’re into modern-shaped furniture with a warm earthy look, this would be a perfect option for you to have a go at making.

8. Unique Square Coffee Table by Youtube

These coffee tables are incredibly simple in their design , but create a stunning look that gives the illusion of more space in your lounge while providing plenty of table space. Give this beginner welding project a try and let us know how they turned out.

9. Stunning Outdoor Light by Youtube

This is one of my favorite designs in the list we have made. It’s simple to make but creates a spectacular look you can hang on your own house. Give it a try for yourself.

10. Star Light by Youtube

Whether it’s Christmas time, or you’re after a lighting decoration for your house, this star light is a brilliant project. Bring some creativity to your home with a handmade project like this without the need to think up a design. Simply follow these instructions.

- What is Tack Welding?: Understanding it Thoroughly

Fire Pits and Stoves

11. triangular brazier project by youtube.

This brazier’s a bit smaller than the one above, but it has a smart-looking finish and doesn’t take up too much space. Check out the design to get building, and let us know how it went in the comment section below.

Related Read: 10 Scrap Metal Welding Projects to DIY Today (With Videos)

Furniture and Home

12. stainless steel handrail by youtube.

If you are after a brilliant handrail for your project, read these instructions for an easy guide to a fantastic outcome. I like the polished finish in this example, but you can leave it with whatever finish best suits your house.

13. Stainless Door by Youtube

This door is impressive for a stick welding job and is an advanced welding project. You can TIG , MIG, or stick weld it, but follow these instructions, and the result will parallel this example.

Other projects to try:

- 40 Rebar Welding Projects to DIY Today (With Videos)

- 10 Scrap Metal Welding Projects to DIY Today (With Videos)

- 60 Art Welding Projects to Try Today (With Videos)

Final Thoughts

Thank you for reading our list of 55 DIY welding projects. With a bit of online guidance like this, you can have the confidence to fabricate amazing creations in the confines of your own home.

Let us know your comments below, especially if you enjoyed creating some of these great projects. We’d love to hear from you.

If you’re interested in the business aspect of welding we recommend reading our “ Guide to starting a welding business ” article, and our “ 6 Side-Gig Ideas for Welders post “

More Welding Articles Like This:

9 Christmas Welding Projects to Try Today (With Pictures and Videos)

40 Welding Projects for Trucks to Try Today (With Pictures and Videos)

14 Aluminum Welding Projects to Try Today (With Pictures and Videos)

FCAW vs GMAW: Differences, & When to Use Them

How Much Are Welding Salaries in the UK? 2024 Statistics

What is a Typical Welding Salary in Ontario? (2024 Update)

How Much Is A Welding Technician Salary In Canada? (2024 Update)

How Much Are Welding Salaries in Canada? (2024 Update)

Cameron Dekker

Cameron grew up in Allentown, Pennsylvania, a once-proud steel town on the Lehigh River, where he got a taste of TIG welding in his high school shop class. He holds certificates for Certified WeldingEducator (CWE) and Certified Resistance Welding Technician (CRWT) from the American Welding Institute. His interests include scuba diving, sculpture, and kayaking.

61 Best Welding Projects to Build at Home – Excellent Ideas For Beginners and Professionals

There might be affiliate links in this post. Buying through them can earn us a small commission at no cost to you. This covers our wages and keeps our resources free to use.

Welding can be a great way to make money, and even beginners can go with it. Turning your hobby into a thing that pays extra money is one of the best things you can do.

Various welding projects are a great way to do it.

But, first, you need to consider your welding skills and the amount of money you are willing to invest. Beginners can always start with some simple projects made out of scrap metal. Then, once you get the hang of it, you can earn few bucks.

Experienced welders can opt for some serious welding project, where you have to invest a bit more into materials but earn a high profit.

That is why we made this list of best welding projects for beginners and professionals that can give you some great ideas on how to improve your workshop, yard, decorate home, or just sell.

Best Welding Projects for Your Workshop

Before doing any serious work, you should make sure your workplace is as comfortable as it can be. To do that, we brought you some ideas on how to improve your workshop and make your job easier

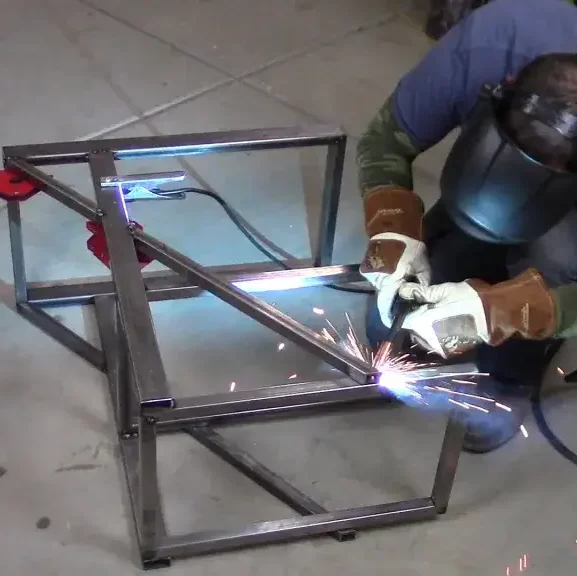

1. Simple Welding Table

The table is a crucial part of your workshop as it increases your productivity a lot. You can start by making a simple DIY welding table out of a handful of straight metal pieces. You need to make a basic box steel frame, then weld 12 straight metal slats along the top. Therefore you have a functional table that has enough space for clamping. Follow th ese instructions to find out how to make this project.

Subscribe: Get FREE 30 page PDF Welding Symbols Chart With Applied Examples for Each Symbol!

2. Simple Shop Stool

There is always some scrap metal around your workshop that gets in your way. To store it, you can always use some tubular steel to make a rectangular box frame and weld sheet steel on it. You can permanently attach a padlock, as you should only hinge the top. Therefore you got a simple box to store the metal you may find helpful in the future. Follow these instructions to find out how to make this project. Making it won’t take too much, and you’ll get quite useful box.

4. Tool Rack and Shelves to Store Your Welding Equipment

To organize your tools and equipment, you can always make a simple tool rack and shelves. However, the best thing about this welding project is that you can customize it the way you want it. If you have a small workshop, you should opt for a wall hanging rack as they don’t take too much space. Attach shelves to proper wall studs.

In addition, if you have a lot of equipment, you can always make a nice shelf. Just make sure it is big enough to fit all your stuff. A proper storage rack will grant you some extra storage space you are going to love.

5. Simple Welding Cart

Metal carts are a great way to move your welder and cylinders and organize cables. In addition, they are easy to make. You need a cold-rolled steel rod for handles, cartwheels caster and support, metal strips, and angle iron brackets.

Keep in mind that you need to draw a design before you start. Then, you should make it big enough to fit your welder and everything you need. Once you make it, you can easily move your heavy welder. Follow these instructions to make this simple welding cart.

6. MIG Gun Holder

If you use a MIG welder often, you don’t want to leave MIG welding tools around your workshop. You can always make a simple clamp attachment that will help you safely put your gun down. This is an easy project as it is efficient, and it may boost your productivity.

Leaving your MIG gun in the way can cause troubles, as you can have the automatic feed option on, or accidentally press the button. You can see an idea of a great holder on the picture below.

Easy and Simple Beginner Welding Projects

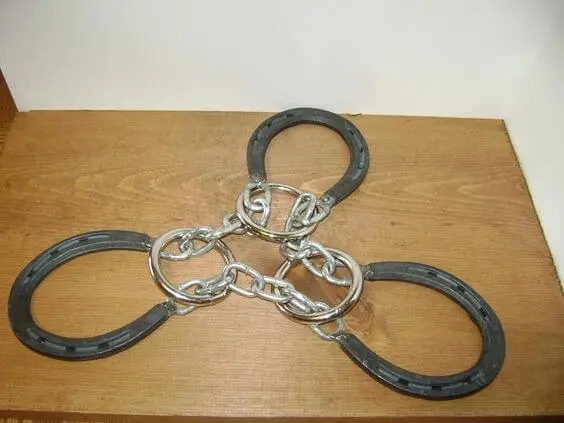

7. horseshoe coat rack.

Grab some horseshoes, clamp them down, and then weld them together. Then you just need to add the holders to what you’ve created so that it can hold coats. It can be put together in just minutes. The project is quite simple, and you can always watch the video below, to see how it is made. It is a great way to start your DIY career.

8. Metal Shoe Rack

If you have problems with all the shoes and boots around the house, you can always make a shoe rack. You can use cheap metal pieces you can even find around your house and weld them together, and your problem is solved.

9. DIY Pencil Holder

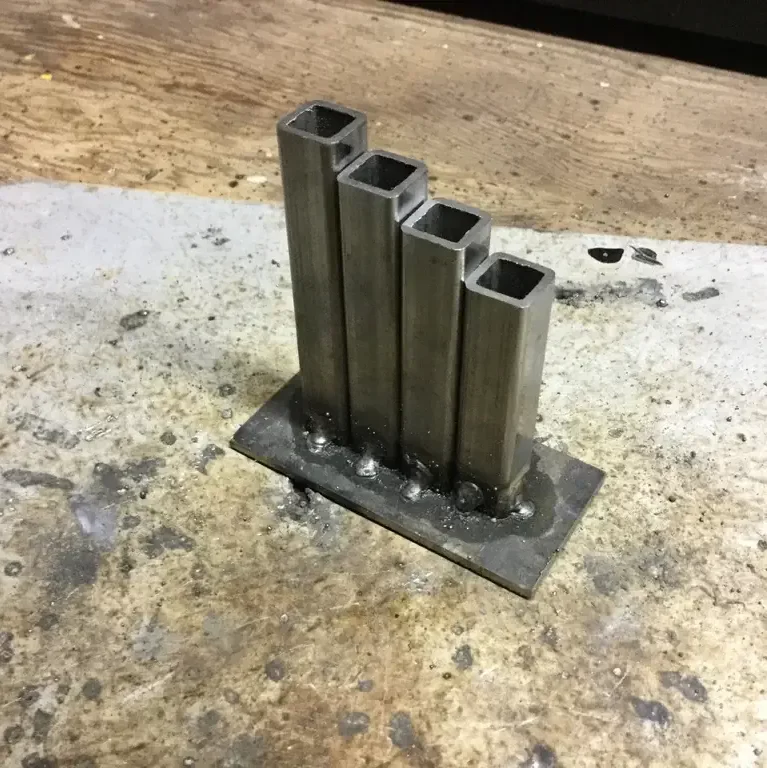

This is a cool welding project you can build very quickly. An industrial pencil holder is a great way to organize your markers end pencils around your workshop, and all you need is scrap metal. Simply weld the leftovers form other projects and you are good to go.

You can always paint it or use your unique design, and you also got a perfect handmade gift. You can find instructions on how to make it here , or just use it as an idea on your own unique project.

10. Jewelry Holder

This is a simple project that looks very awesome. First, you need to weld small, straight pieces and make the shape of a tree. Once you make a tree, weld it to a square piece of steel, and put it in your favorite place. You just made a great way to hold and exhibit your jewelry. Below, you can find an idea on how to make it. You can always improvise and use the picture just as guideline.

11. Miniature Sculptures

You can always make some miniature sculptures out of sheet metal or cuts of steel lying around your workshop. Just hand-hammer it into a shape you want and weld bits together. There are some fantastic sculptures out there, and you can always start by making something simple. Then, once you get the hang of it, you can create stunning sculptures that could fit the shelves of a modern gallery. In addition, you can decorate your workshop or even your house. Follow these instructions to learn more on how to make some awesome sculptures.

12. Atom And Snowflake Ornament

If you are a science lover, you can always make a simple atom ornament. First, you need ball bearings and steel rods to connect the elements into a cube shape. Leave the bearing on each point, one on the middle, and connect them with more steel rods. You can use ornament to decorate house, or as a gift to your scholar friend, as it is really simple to make. If they like it, you can always opt to sell it for a couple of bucks. Follow these instructions to find out how to make this awesome project.

Best Yard Welding Projects

Here are some excellent welding project ideas on how to make your yard look fabulous. Keep in mind that some of these require you to be an experienced welder. In addition, you can make some quite easily, so you should give it a try.

13. Outdoor Fire Pit

There’s nothing better than a cold night in a yard by the fire pit. As it provides heat, the fire pit looks fantastic when it is in full flame. You are going to need some steel sheets made of textured steel to make it. Just cut the side panels out of half sheet and the base, and weld them together.

Make the basic frame so the pit can sit nicely, and there you go. Keep in mind that you can always put a drain hole at the bottom of the fire pit to make sure it doesn’t hold the rain as it can rust. Follow these instructions to find out how to make this cool project.

14. Shepard’s Hooks

Shepard’s hooks are great decorative plant hangers that help your climbing plants grow. These are cool welding projects that require a bit more skill. You need a 0.25-inch space bare for the stem and a bending machine to create the scroll. You can make it a one or two-scroll hook with a few bends, as they both look fantastic.

15. Metal Trellis

If you like to grow your plants, you can always build a garden trellis to help the climbing plants grow. You can make it any size or shape, leave it stand-free or attach it to a fence. You need to make a basic frame and attach cross-sections and support bars. You can even connect the triangular roof section to make it look even better. You can always start by making a simple ones, as it will help your plants a lot. Follow these instructions to find out how to make this project.

16. BBQ Keg Pit

If you have an old steel keg, you can always use it to make a fantastic BBQ . However, keep in mind that this project might require some more skill. You need to cut the middle of the metal barrel and create a hinged lid. For the legs and the cross-sections, you can use square tubes. Keep in mind that you need some vents on the side and the top.

17. BBQ Pit

We all enjoy some excellent food cooked over an open fire in a yard. The BBQ pit is a wonderful and helpful project, and your friends will admire it. You can always weld a simple grill over the fire pit you already built. Even though you can always buy fancy store grills, making one can be satisfactory. Follow these instruction s to find out how to make this project.

If you love to grill in the yard, you should also get yourself a smoker. Of course, you can always buy a cheap one in the market, spend your money, and hope it will last more than a couple of seasons. Instead, you can build one on your own. This is a quick project, but you might need some experience. Follow these instructions to find out how to make this awesome smoker.

20. Wood Stove

If you like to cook some of your meals and make hot beverages outside, you can always build a wood stove. It is simple to use, and it will keep the smoke away from your yard. You just need to follow simple instructions, use steel drum, and cast iron door. You got yourself a cheap brand new wood stove that will serve you well. Follow these instructions to find out how to make this project.

21. Spoon Flower

To decorate your yard, you can always use some old spoons to make a spoon flower. You can make it easily by using the things you don’t need around your kitchen and weld them together. This simple project looks awesome and you don’t need much time to make. Still, it will give a unique look to your garden. Watch the video below to find out how to weld an awesome flower using spoons and old bike chain.

22. Wood-fired pizza oven

Having a couple of separate stoves, such as a fire pit, chimney, and pizza cooker, can take a lot of space in your yard. That’s why people got an idea of making pizza ovens on their own.

Use an old compressor tank to make a perfect DIY pizza cooker. Just add door, chimney, legs, and separate the cooking area. This project may require some skills, but the results are satisfying.

24. Triangular Brazier Project

This is just a fancier version of the simple fire pit mentioned above, and it might look more remarkable to some, but keep in mind that it is a bit harder to make. You will need to cut the triangular sides perfectly, weld the side sheets and rectangular frame to keep it all together, and make sure you can put it on the ground without falling. Watch the video below to find out how to make this amazing fire pit.

Make Your Tables, Desks, Stools, and Furniture

You can always refresh your old tables and coffee tables with brand new frames out of preferred material you can weld yourself. You don’t need to spend big bucks, but keep in mind that they might require some more welding skills.

25. Coffee Table

Coffee tables are usually expensive, and they can get worn out pretty quickly. However, you can make a simple table using cheap materials that can be much studier than shop ones. Of course, you can always use some old square tubing or opt for another preferred material. In addition, once they get damaged or burned by coffee mugs, they get an even better, rustic look. Find out how to make this amazing project by watching the video below.

26. Paired Block Table Set

If you like having friends over, this is an excellent welding project idea. This set will save your space but is capable of guesting more than a few friends. Innovative design helps you slip smaller ones in easily, providing more space in the room yet enough space to leave your drinks on. Follow these instructions to find out how to make this cool project.

27. Modern Outdoor Table

This project may look complicated the first time you see it. Yet, this modern-shaped unique square coffee table is actually easy to make. This is a great thing to have in your yard, as you can leave your food and drinks on it. This is one of many great unique square coffee table welding ideas. Find out how to make this awesome table by watching the video below.

28. Dining Table Set

You can make a functional dining table set without spending too much money. This might be a complicated project, but the money you’ve saved and the final result will be satisfying in the end. You can opt for making separate chairs or two sitting benches. Benches are easier to make, but someone dislikes the comfort. Table set might be a difficult to make, and you can also opt for selling ones in the future. Find out how to make this table by following these instructions .

29. Corner Couch

If you decide to buy a corner sofa in your retail store, you will spend quite a few bucks. Yet, you can easily make a simple frame using your welder and a few lengths of steel. It will be a lot cheaper if you only spend your money on cozy cushions. Restoring your old corner couch will be easy if you follow these instructions .

31. Serving Bar

To create an excellent serving bar, all you need power MIG welder to attach 1×1 inch steel tubing to a wrap-around sheet of corrugated metal. You can also make wooden shelves inside the bar. The top is made of a stainless steel sheet, and you just need to remove sharp pieces. You can also add lockable wheels to move it around the house and in the yard. This might be a bit complex project, but if you follow these instructions , you can make it easily.

32. Minimalist Steel Chair

People enjoy relaxing in a hammock, but it can be hard to move around. Some people even don’t have a place to hang them. This is a hammock-like rocking chair that can solve your problems. It might be a bit difficult to make, but all you need to do is follow instructions . Keep in mind that this project might be a bit difficult to make. Still, results are amazing as you will love your chair.

33. Simple Bar Stool

If you already made your other furniture, you can always make a simple bar stool. The unique design uses an angle section that can be pretty attractive. Yet, they distribute the weight perfectly. One of the most important things is keeping the angles perfect. You need to precisely mark and cut them. In addition, you need to weld brackets to ensure the stool is sturdy. In the end, they are welded easily. Watch the video below to find out how to make simple bar stool.

34. Corner Desk

Corner desks are a great way to utilize the limited space around the house. The design uses stabilizing bars, which makes it super sturdy. In addition, it has a classy look. The best thing about corner desks is that they save so much space. Watch the video below to find out how to build a cheap but functional corner desk.

House Decoration Welding Projects

These are some simple and small welding projects you can make easily to decorate your house. They won’t take too much of your time, and you don’t need to spend a fortune on materials. In addition, you can opt to sell them for few bucks and earn some money by doing what you love.

36. Hanging Sign

If you like having friends over, they will find the wrought iron hanging sign unique. You can use it to name their favorite place, but you can also put your address on it. The wrought iron sign is simple to make, and it will give a great look to your home. Follow these detailed instructions to find out how to build your sign and give your place a nice glow.

37. Metal House Numbers

If you live in a boring neighborhood, you can always make your home stand out from the crowd by using unique house numbers. You can make them as big and as bold as you want, use different welding technique to give them a unique design. They can even be 3D if you wish. Here are some ideas on what can you number design look like.

38. Stainless Steel Polygon Bowl

If you like art, you can always make yourself a unique stainless steel polygon fruit bowl. It might be hard to fain a stainless steel plate, but it is well worth it. All you need to do is follow simple instructions , read about all the necessary tools and materials, and that’s it. Then, you’ve got yourself a perfect minimalist fruit bowl.

40. Stainless Steel Vase

If you want to complete a stainless steel decorative collection, you can add a stainless steel vase to your fruit bowl. Vase also has a unique design that looks great as a set or a stand-alone piece. It might be a bit difficult to make it, but if you follow simple instructions , you’ll get a great vase, and you don’t need to worry about your pet breaking it.

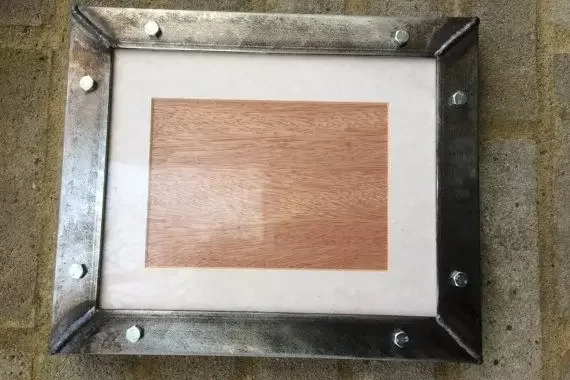

41. Steel Picture Frame

You can always make some awesome metal picture frames by cutting square tubing at a 45-degree angle. Then, connect them by using a clean TIG welding and clean the beads. This is one of the straightforward welding projects for beginners, and once you get the hang of it, you can sell them for few bucks. Find out how to make steel frames by watching the video below.

43. Flag Art

You can always use this fantastic wood/metal combination to make amazing flag art. You can hang this interesting welding project in front of your house or even sell it if your friends like it. You need some cutting skills to make it, but the final results are amazing. Here is an idea on how should it look with some additional information.

44. Wine Bottle Holder

Just follow simple instructions , and you can make it easier. For example, it might take you less than half an hour to do it. You can use an old chain that’s lying around your workshop to make a great wine bottle holder. This welding project looks incredible, and it will hold your bottle firmly.

45. Welded Portraits

You can use your welding skills to create a portrait of the characters or persons you love. But, first, you need to draw the picture on the metal and prove your TIG welding skill, following the directions. This is a great welding idea, and your friends will love it. Once you get the hang of it, you can even sell it. Here is a video to help you start welding your own pictures and portraits.

46. Christmas Tree Ornaments

If you lack ideas for the Christmas tree decoration, this beginner project might be a great idea to do it. You just need to weld simple shapes to make stars, angels, sleds, and everything that can fit your tree. If they impress the people, you can even sell them for few bucks. Yet, they are easy and cheap to make. Follow these instructions to find out how to make a simple ornament.

Fence, Door, and Gate Projects to Prove Your Welding Skills

Building a fence or gates is crucial to protect your garden from unwanted guests. You can also build a security door to make sure there are no intruders at your workshop. These are some serious welding projects that require slightly higher investment, and it may take some time to make them.

47. Garden Fence

You can always build a fence to protect your garden from the pets and wild animals that are straying. You are going to need steel rods and aluminum-magnesium wire mesh. Space your rods enough to make sure animals can’t get through. You can decide on a height on your own and make sure it is high enough to keep the unwanted guests. Here is a video with an idea on how to make metal garden fence.

48. Small Gates

Once you built your face, you are going to need a proper garden gate. They don’t need to be fancy, as small gates are usually used in your backyard. You can make them quickly as they are a simple welding project idea. You can use the video above to get an idea on how to make some nice gate.

49. Entry Gate Projects

If you want to stand out from the crowd, you can always build yourself a great and fancy entry gate. This cool welding project will take some time and money to make, but it is well worth it. To make a grand entry gate, you need aluminum bars or ornamental wrought iron and MIG welding tools. Even though they can be hard to make, it is way cheaper than buying one. In the end, you can opt to sell ones in the future. Here is a video on how to make an amazing entry gate.

50. Pet Gate

If you have pets, you are going to need to make a small door for them. They are simple to make and a great way to make sure your pets can go outside in an emergency. You need to make the gate big enough and weld the metal tubing borders. Here is just an idea on how should a pet gate look.

51. Security Door

This is a cool welding project if you want to increase the security of your home or workshop. You can use different materials, depending on how strong you want them to be. Keep in mind that you’ll need to think about the appearance. To make them look awesome and sturdy, just use some high-end finish and TIG welding tools. Here is a video that can help you build an awesome security door.

Other Interesting Welding Project Ideas

Here are some more exciting welding project ideas you can make at your home and maybe earn some money. They are easy to make, and you and your friends will love it.

52. Hanging Steel Pan Rack

This hanging shelf system gives your kitchen a modern industrial look. It is easy to make, as you need some cheap steel materials you can even find around the house. Follow simple instructions, and I’m sure you’ll be more than satisfied. In addition, you can find steel components cheap at any shop. Follow these instructions to find out how to build this project.

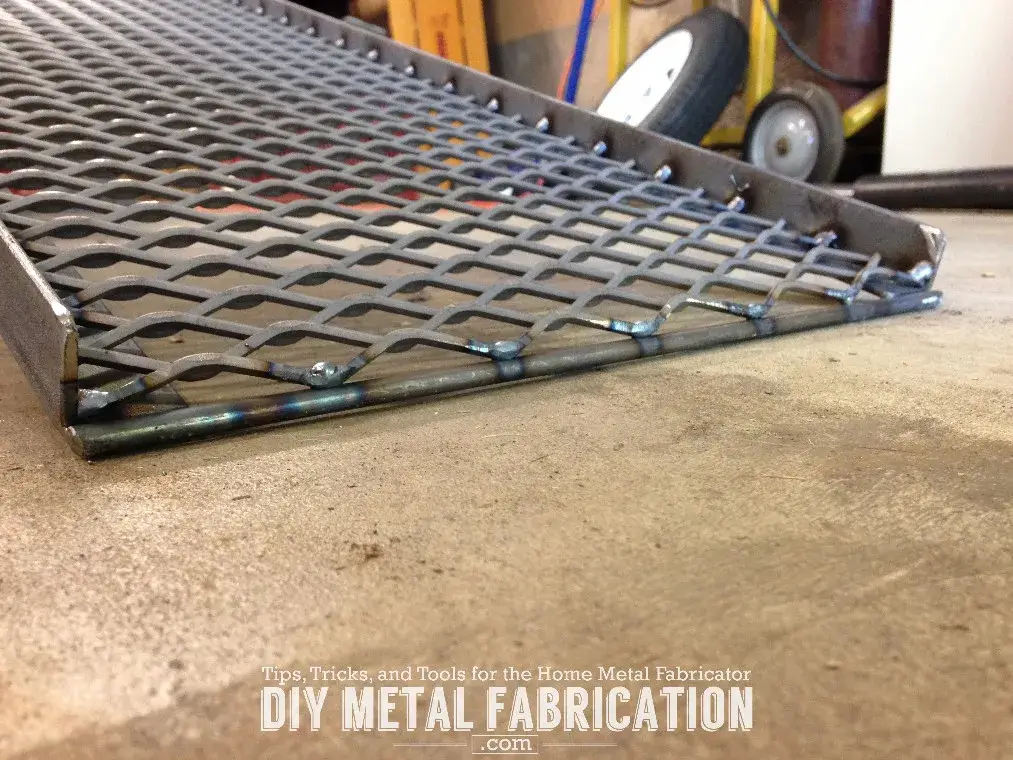

53. Car Ramp

Welding car ramps can be a great way to make some money as there is a high demand among car businesses and garage enthusiasts. They can be a bit expensive to make and quite heavy. Nevertheless, you can make money by selling them, as there are several dimensions and sizes customers may require. Here is a video that can help you build your own car ramps.

54. Garden Wagon

If you like working around the garden, you can always use this cool project, to help you carry around heavy tools and fertilizers. You need two sheets of metal for the sides, one thicker sheet metal for the base, and four brackets. Then, you just need to add a wagon handle, and you are good to go. Watch the video below to find out how to make garden wagon.

55. Wheelchair Ramp

Life is complicated enough for people in a wheelchair, and you can make it easier by building a wheelchair ramp. This is an excellent welding project idea you can create and use at home or even opt to sell. It might take some time to make them, but having one helps a lot. Follow these instructions to find out how to build a wheelchair ramp.

56. Horseshoe Puzzle

This is an excellent welding project idea for puzzle lovers, as it never gets old. Furthermore, it is a simple project to make, as you only need a couple of horseshoes, a ring, and a couple of pieces of chain. Follow these instructions to find out how t o make this amazing, yet simple puzzle.

57. Firewood Rack

If you love staying by the fireplace in the winter, you need dry wood by your hand. Building a nice firewood rack is a great way to keep your home clean, and always have some firewood by your hand. You need two U-shaped strips of metal and cross supports along with the frame. You can use the picture below to get an idea how to build it.

59. Metal Brackets

If you don’t like when your coffee gets cold, you can always make this simple but exciting project. You can enjoy pleasant and warm coffee any time of the day. It is easy to make, as you only need to follow simple instructions and give it a couple of welds.

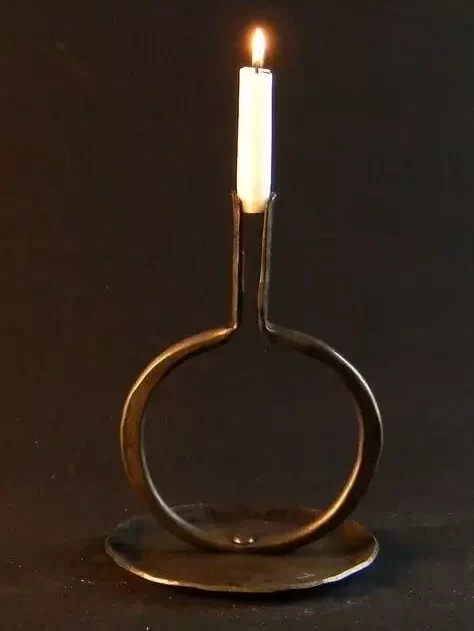

61. Candle Light Tree

You can always opt for making metal brackets out of scrap steel as they are an excellent way to make some extra money. In addition, they can be used in making shelves, frames, and furniture. You can always buy some to get an idea of what’s best at the moment, and you are set for success. Here is a video that can help you make industrial brackets.

This is one of the relatively simple welding ideas popular among teens and truck enthusiasts. You can make it easy as it doesn’t take too much time. They are usually not that useful, but they give vehicles that extraordinary and rugged appearance. Here is a video that can help you make an awesome off-road bumper kit.

If you are a welding professional, you can do some serious projects like fences, gates, car ramps, and furniture frames. A complex project can earn you serious money, and it won’t take too much of your time. It doesn’t matter if you are a beginner or an professional. You can use these 61 project ideas to improve your workshop, yard, decorate your house or sell some serious stuff. So, what are you waiting for? Grab your machine and start welding!

Leave a Comment Cancel reply

WeLDingpros.net

Mentioned On:

Welding Machines

TIG Welders

MIG Welders

SMAW Welders

Plasma Cutters

Flux Core Welders

Multi Process Welders

Welding Guides

Welding Symbols PDF

How to MIG Weld

TIG Welding (GTAW)

Welding Joints

Best Welding Schools

Welding Stainless

Welding Helmets

1/1/1/1 VS 1/1/1/2

Change The Battery

Underwater Welding Helmet

Welding Gloves

Lens Shade Guide

Disclaimer Weldingpros.net is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com.

Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.

As a YesWelder affiliate, I earn commissions for qualifying purchases.

Copyright © 2021 Weldingpros.net

6 Essential Metal Working Tools For Beginners

If you've taken a few metalworking classes or have a long-standing interest in the practice, you may be wondering what it takes to set up shop at home. While it may seem like a daunting task, assembling the things you need for an at-home metal shop is simple. We've narrowed it down to just six things you need to get together if you want to have a good go at tackling this hobby.

Below is a list of tools and equipment that should be enough to tackle pretty much any home metalwork project. These are all "essentials" if you want to get the most out of metalworking, so while you may be able to take on some limited projects without everything on our list, you may be somewhat restricted. Cost is obviously a major factor, and while there's nothing "industrial" in our roundup, some pieces of kit can set you back a few hundred dollars.

However, there are plenty of used tools available at knockdown prices if you know where to look. We'd suggest scouring auction sites, classifieds, and estate sales to snag some bargains. With that being said, tools can be dangerous. So, thoroughly inspect anything you buy used, and walk away if it has signs of obvious damage.

We used our own metalworking experience to assemble this list, including some time spent as a professional plater. This is also just a starting point — you can add plenty of other equipment to your shop as time goes on.

Personal protective equipment

Personal protective equipment (PPE) isn't the most exciting stuff in the world, but it's essential. This isn't one tool but a whole set of equipment that will help keep you safe from injury while you're working on metal. Metalwork is dangerous, but care and decent protective equipment can minimize the chances of you getting maimed or killed while pursuing your hobby.

As your tool collection grows, you'll likely need additional safety equipment to go with it. But getting a full range of basic safety equipment should be everyone's starting point. As a stray spark, piece of swarf, or hunk of metal can easily blind you, eye protection is vital. You should make sure it's properly graded. Look for goggles and glasses marked Grade F or EN166 to ensure you can grind, saw, and hammer in them. Goggles tend to be stronger and offer protection on the sides, too — but they are less comfortable than glasses. If you get both, you can have the glasses on for general use and switch to the goggles when performing riskier tasks.

Welding gauntlets offer some protection from cuts and will insulate your hands against hot metal. A proper pair of safety boots can mean the difference between a dropped piece of steel making a clang and breaking your foot. Sparks are a common side effect of metalwork and will set your clothing on fire. So, some flame-resistant coveralls will protect you from both dirt and immolation. Loud noise is also common when working on metal, so consider ear defenders or at least ear plugs. Finally, there's a lot of metal dust and vapors you shouldn't really be breathing in , so an N95 mask is recommended at the very least.

Marking and measuring tools

Metalwork can be very forgiving. If something is a little off, you may be able to correct it with a hammer, grinder, or welding set. But you're better off just not making mistakes in the first place. Property measuring and marking can help minimize mistakes and make building whatever you're building a lot easier in the long run. It can also save you a lot of money.

If you take time to plan and mark a piece of metal out properly, you'll get the most out of it. Metal will be one of your main expenses once your tools are in place. On the measuring side, a good quality tape measure, a set of engineer's squares, a divider caliper, a flat ruler, and a spirit level should really help you measure things. You shouldn't underestimate the usefulness of a ball of string, either.

As for marking, a scriber is a great way to scratch precise marks on a piece of metal. Cheaper scribers are made from steel, but one tipped with a hard material like tungsten carbide is recommended. It's only slightly more expensive, will last a lot longer, and is a lot easier to use. Engineers flat French chalk is another popular way to mark up steel. It can be sharpened so it has a fine, flat edge and will produce small, accurate markings if needed.

A larger square, such as a roofer's square, and a chalk line are handy if you want to bulk out your measuring and marking kit. Magnets and clamps are also handy to keep things together until you can get a few tack welds in place.

An anvil and forge

It may seem a touch medieval, but a good, old-fashioned hammer and anvil is one of the most useful pairs of metalworking tools you can get. An anvil is an ideal platform for hammering out and shaping steel. You can complete entire projects using just an anvil, hammer, and a heat source. You can even make most of your own metalworking tools on one.

Anvils also have a couple of parts you can use to cut, bend, or shape metal. They come in a variety of weights and sizes and can range from something small enough to fit on a workbench to huge examples that probably weigh more than you. Used anvils can be found online for as little as a few hundred dollars, but moving them may require some help.

Your anvil will require a couple of accessories. A two-pound hammer is a good, versatile choice. It's heavy enough to work the metal but still light enough to control. You may also want a way to heat your metal. The simplest way to do this is with a propane torch. Alternatively, a small forge isn't actually hard to build if you want to go that route. Some fire bricks, insulation, and a little time are all you need to construct a small propane or coal forge. Said construction could even be your first project. Small forges can also be purchased should you want to save some effort.

An angle grinder

A lot of cutting, smoothing, and polishing metal is involved in your new hobby. You can spend an eternity achieving this with a hacksaw and a set of files — or you can just buy a 4.5-inch angle grinder like Makita's X-Lock . Grinders around the four-inch mark are versatile and easy to handle. If you buy the correct disks, you can cut, grind, and polish with ease. They're relatively cheap, with that Makita example costing just $77 new, and will open up a lot of possibilities. The grinder is also a pre-requisite to some other tools like the welding set. Good welds should be prepped, and a small grinder is great for this prep work.

Larger grinders are likely overkill for at-home metalwork and take a little strength and experience to handle properly. With that being said, the four-inch grinder is still a serious tool and needs to be treated with respect. Make sure to use the correct disk for the correct purpose — grinding wheels won't cut very well, and if you grind with a cutting disk, it may shatter and embed itself in you. Be aware of the stream of sparks your grinder is shooting out, or you may set yourself on fire. Let the tool do the work; don't force it through something. And be aware of where you're cutting, so you don't go through the wire or yourself.

A welding set

If you're getting into metalworking, you're probably going to need a welding set. It's the best way to join a couple of bits of metal together permanently. And if you're moving beyond small forged objects made on an anvil, it's essential.

When buying a welding set, you have a couple of choices. You can opt for a "Manual Metal Arc" (MMA) style set, which uses welding rods, or a "Metal Inert Gas" (MIG) set, which uses a spool of metal wire. The MIG set is far easier to use. You set your parameters like voltage and wire speed, and then it's just a case of pointing at where you want to weld, pulling a trigger, and moving at the correct pace. MMA welding is a little more complex. You have to set similar parameters but also need to choose the correct rod for the job.

Different thicknesses have different purposes and require different voltages. Then there's the fact you have to "strike" your own arc. This involves touching the rod to the metal so the arc is formed, and you can actually see through your welding mask. Because of this, you can't line everything up beforehand like you can with an MMA set. Then, there's the fact you'll need to change rods constantly. The main benefit of an MMA set is cost. It's far cheaper to buy and run one. It may also be seen as a more skillful way to weld. But if you can afford it, a MIG set will likely yield better results with less stress.

A cutting torch

A propane torch is fairly inexpensive and can be one of the most useful tools in the metal shop. Cutting an elaborate shape from a large piece of steel can take a lot of time and effort with a grinder, but a cutting torch can get through it in a few minutes. The torch uses burning propane to melt metal, which is then hit with a blast of oxygen. This oxidizes the molten metal and blasts the slag out through the other side, leaving a somewhat clean cut. With that being said, you will probably have to clean up the edges of cuts you make this way, but it's still far easier than just using a grinder.

As an added benefit, a propane torch is an easy way to heat bits of metal up. This means it's a great accessory for the anvil we mentioned earlier. You can buy the cutting torch and tubing for under $200, which need to be connected to a propane tank. Make sure there are no leaks and a flashback arrestor is in place before you fire up the torch for the first time.

Welding with a cutting torch is also possible, but you'll need to move beyond propane for that. A hotter acetylene torch is required. Acetylene also cuts through metal a lot easier and will heat things faster. However, propane is cheaper and easier to find, so you should probably stick with that while you're getting started.

POPULAR SEARCHES:

- Raspberry Pi

- Woodworking

- 3D Printing

- Maker Faire

- All Stories

- Magazine Projects

- Board Guide

- Magazine Issues

A Dozen of Our Top Homemade Tool Projects

By Gareth Branwyn

Gareth branwyn.

Gareth Branwyn is a freelance writer and the former Editorial Director of Maker Media. He is the author or editor of over a dozen books on technology, DIY, and geek culture. He is currently a contributor to Boing Boing, Wink Books, and Wink Fun. His free weekly-ish maker tips newsletter can be found at garstipsandtools.com.

Have you ever made any of your own tools? It may be one of those things that you can’t fully appreciate until you do, but it really does deepen your relationship with the tool when it came from your own hand and not a big box store. Try it and see.

Here are twelve tools that we’ve featured on Make: that you can make yourself. Some of these projects, like the turned brass scriber for metalwork and the flatter hammer for blacksmithing, are the kind of tools that you would likely have by your side for the rest of your makery days. If you want to ease into homemade tool-making, try your hand at the flashlight from trash project (and then tell me that you don’t think to yourself, “I made this!,” every time you use it).

Make Your Own Shop Calipers

Making Your Own Block Plane

Turn Your Hammer Into a Multitool

Make a Flashlight Out of Kitchen Trash

Upcycle a Microwave into a Spot Welder

Turn a Metal Scriber from Brass

How to Make Your Own Rotary Tool Bits

The DiResta Ice Pick 2.0

Blacksmithing Basics: Forge Your Own Flatter

How to Make Spring Clamps Out of Plastic Pipe

How to 3D Print Your Own Leather Tooling Stamps

Build Your Own Router Trammel

ADVERTISEMENT

Related Articles from Make:

From the shed: new arrivals.

DIY Arcade Joystick Kit

Make: Arduino Electronics Starter Pack

Maker's Notebook - Hardcover 3rd Edition

Transistor Cat Kit

Our websites use cookies to improve your browsing experience. Some of these are essential for the basic functionalities of our websites. In addition, we use third-party cookies to help us analyze and understand usage. These will be stored in your browser only with your consent and you have the option to opt-out. Your choice here will be recorded for all Make.co Websites.

Ready to dive into the realm of hands-on innovation? This collection serves as your passport to an exhilarating journey of cutting-edge tinkering and technological marvels, encompassing 15 indispensable books tailored for budding creators.

Escape to an island of imagination + innovation as Maker Faire Bay Area returns for its 15th iteration!

Buy tickets today save 15% and lock-in your preferred date(s)..

15 Mill Projects That Are SUPER Easy for Beginners!

Last Updated on March 1, 2023 by Charles Wilson

Milling machines are one of the best tools to have around. It’s useful and powerful, and you will have mill projects to work on.

If you’re a beginner looking for ideas on what to do with your milling machine , you’ve come to the right place.

I’ve listed some of the best beginner-friendly mill projects you can do, which I’m sure you’ll enjoy!

Table of Contents

15 Milling Machine Projects That You Can Try

I have a few favorite milling projects I did as a beginner. The difficulty ranged from easy to fair, which included a few challenging tasks to sharpen my skills.

Here are some cool and useful CNC mill projects you should try out.

1) Coasters

Coasters are pretty easy to make, which makes it a great beginner-friendly idea! It doesn’t require a lot of tools, and you can even use leftover materials like acrylic and wood.

You don’t need any fancy tools for this project. You’re all set as long as you’ve got your CNC mill machine with you and a determination to learn.

What makes this project great for beginners is cutting your material into a perfect circle. Cylindrical shapes take some time to master, and it could be challenging for a beginner.

Nonetheless, it’s nothing several practices can’t cure. You’ll be able to practice carving well-defined curves and master the skill in no time.

You can create your original design and be as creative as you want! The project can take a day or two to complete, depending on your skill level.

Project Information

- Difficulty Level: Beginner

- Duration: 1 to 2 days

- Material Type: Acrylic or wood

2) Fashion Jewelry or Pendants

Jewelry and pendants are easy to make with the help of a CNC milling machine. What better way to accessorize than by using your very own jewelry collection?

You can create jewelry that matches your style. Plus, your accessory will always be unique to you! It’ll make a great conversation starter when you’re out with friends.

CNC machines have always been a handy tool for creating statement pieces like earrings, belts, rings, necklaces, and pendants!